What is the mass air flow sensor, a valuable structural part of the car. This indicator is necessary for the electronic device that controls the motor. To monitor the correct amount of air being supplied. In this case, it is the air that is combustible for the fuel mixture. The sensors come in different designs, but their failure will lead to a malfunction of the main operating process of the car.

DMRV what is it

In modern cars, engines are equipped with gasoline injection devices. Therefore, it is necessary to use special measuring sensors - mass air flow sensors. Modern air flow indicators are installed on diesel and gasoline engines.

Functions and purpose of the sensor

Nowadays, cars use two types of fuel supply: with distributed injection, fuel is supplied to the inlet pipe, and with direct injection, fuel is supplied directly into the chamber. In both situations, the operation of the vehicle depends on the correct functionality of the mass air flow sensor. Several years ago it worked on a mechanical basis, but now there are no moving elements and the sensor is manufactured on a hot-wire type.

The mass air flow sensor is suitable for any type of engine, and the functionality of the valve of the exhaust gas removal and neutralization complex is concentrated on it.

As experienced drivers like to say, the engine does not function in only two ways - there is nothing to burn or nothing to ignite.

Using an air flow sensor, the control unit receives information about the volume of gases entering through the intake channel, which regulates the required amount of fuel to produce the mixture.

Carrying out maintenance

The sensor does not require any maintenance as such. Measures to clean the system are taken by the electronic control unit. And if the air flow sensor, the signs of malfunction of which will be discussed below, is broken, then a lot of dirt and dust will accumulate in it. The air entering the tube cannot be completely cleaned by any filter. Therefore, a method is provided by which all the dirt that accumulates on the platinum wire literally evaporates. There is a small peculiarity in the operating algorithm of the electronic control unit.

When you turn off the engine, a voltage is applied to the platinum wire that can heat it up to 1000 degrees. The heating occurs within a second, this time is enough to get rid of all the accumulated dirt on the surface of the wire. If you decide to restore the sensor yourself, you will need to thoroughly clean the wire and mesh. When carrying out work, it is forbidden to touch these objects, otherwise you will only have to change the entire device; it will not be able to work normally.

DMRV - what is it

The air flow indicator is designed to inform the owner that air is moving into the engine, because oxygen is a combustion catalyst for a flammable composition. Having received data from the air flow sensor, the fuel system prepares a correctly formed combustible mixture and ensures complete combustion of the fuel. The device located in the fuel inlet path includes two resistors. Which are performed in all sorts of variations.

In one embodiment, the element is exposed to a passing air mass. With a change in its intensity, the temperature of the thread decreases, as does the immanent resistance. In another embodiment, the resistor is not affected by the air mass. Based on the difference in resistance of the two elements, the volume of oxygen required by the motor for operation is calculated.

The principle of operation of the mass air flow sensor

At its core, mass air flow sensors are equipped with two sensitive thermistors in the form of a very thin heating metal wire. A direct current is supplied to them to heat them to the required number of degrees. One wire is in the air mass, due to the influence of air it is cooled. The second is provided with protection in the form of a screen. Thanks to this, the air cools the second thread less. Based on the difference between these two resistors, the air volume required for the smooth functioning of the engine is determined.

air supply sensor

Some MAF indicators have a built-in thermometer that shows the temperature order of the incoming air mass. This allows for more accurate calculations. Also, instead of metal threads, ceramic heating elements and thin films can be used. One way or another, they work according to the same system - the temperature difference between two components is taken into account - open and protected.

Principle of operation

The piston stroke occurs when fuel is burned with air in a ratio of 1:14, maintaining which ensures optimal operation of the power plant. When the proportion decreases or increases, the engine does not stop working, but there is excessive fuel consumption or a decrease in engine operating power. We need a mass air flow sensor so that air flows in portions. The operation of the unit proceeds as follows: the VAZ 2110 air flow sensor calculates the portion of fresh air, and then sends the data to the main computer, which, based on this information, calculates the portion of fuel.

The harder you push the gas, the more filtered air the powerplant requires. The mass flow sensor detects the increase and commands the electronics to increase the amount of fuel. When moving at the same speed, each portion should be equal to the previous one. The mass air flow sensor receives data on the load of the power unit, and then calculates the required portion of air. When the driver presses the pedal, the throttle valve opens, thereby increasing the volume of intake air - the load increases. When the pedal is released, the load drops.

Advertisements

Damaged sensor due to dust

Information about the operation and design of the mass air flow sensor

Again, we will not consider the historically outdated mechanical options with a weather vane and the General Motors frequency flow meter, which was used in conjunction with the January 4-series ECU. Modern flow meters for the VAZ 10 series operate on the principle of a hot-wire anemometer.

It is based on the properties of some metals to significantly change resistance depending on heat (the MAF sensor uses an alloy of iridium with platinum, which causes the high cost of the device). There are two resistors in the air flow: one is precision, the second can change the resistance using heat. Voltage is applied to it, the thread is heated until it matches the standard. Depending on the strength of the air flow, the thread cools and the resistance changes. By increasing the voltage across the resistor, the temperature and, accordingly, the resistance are restored. This happens in real time, that is, the control of the air mass is constant. At the output, the mass air flow sensor displays the signal voltage with an accuracy of hundredths of a volt. The received information is processed by the ECU to accurately dose gasoline into the fuel-air mixture.

What happens if the flow meter breaks down? The engine will continue to operate, but in emergency mode. At idle speed without load, the speed will be set to 1500, power will be lost, and fuel consumption will increase. In some modes the motor may stall.

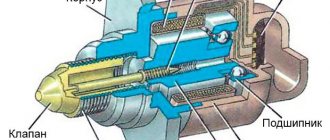

All elements are arranged into a single electronic model, which is placed in the measuring channel (air duct).

Sensor device

The sensor itself is a combination of two sensors - control and working, as well as a heating resistor.

View of the flow meter from the grid side.

The sensor is disassembled.

The platinum thread is visible in this photo.

As a result, air flow and temperature are converted into electrical impulses understandable to the ECU. This is a very gentle and accurate device; it allows you to calculate the cyclic filling of the cylinders with air and updates the parameters every 0.1 s.

Mass air flow sensor diagram.

The working body of the sensor is a heated platinum thread. It heats up to operating temperature (from 100 to 1000 degrees), and when air enters, it cools down. The amount by which the filament temperature drops is converted into an electrical signal and, based on this value, the ECU calculates the mass and temperature of the air entering the combustion chamber. And based on this data, it prepares the required portion of fuel. In short - yes.

Visual inspection

As for visual diagnostics, first of all it is necessary to check the condition of the corrugation in which the flow meter is installed, as well as the device itself. If, as a result of the check, you see traces of motor fluid or condensation, then it is possible that the device does not work for this reason. In some cases, cleaning the device from contaminants allows the flowmeter to resume operation and prevent possible replacement. It should be taken into account that contaminants usually accumulate as a result of infrequent replacement of the air filter element (the author of the video about the regulator malfunction is the channel In Sandro’s Garage).

If you notice traces of engine fluid, then there is a possibility that the reason lies in a clogged oil seal, or the problem may lie in exceeding the permissible level of lubricant in the crankcase. When cleaning is complete, you will need to make a visual inspection of the regulator - on the front of it you can see the rubber seal that is used for sealing. The seal is necessary to prevent uncleaned air flow and it may be that the rubber band moves a little - this will lead to the accumulation of dust on the flowmeter grid.

Types of mass air flow sensors, features of their design and operation

The earliest prototypes of the air flow sensor were based on the principles of changing the resistance of a resistive component. A plate in the mechanism body bent under the force of the air mass. The more the plate was bent, the more the resistance changed. The control system received measurements of the amount of fuel mass that the engine could burn.

At the moment, a pair of metal threads is used, heated to the same temperature. The operating principle of this sensor is described above. The most recent models use platinum-coated silicon wafers. It is this plate that measures the intensity of the air flow.

Currently, only two subtypes of the Sensor are used:

- resistor threads,

- sensitive film component.

They work according to fundamentally the same scheme - they measure the amount of air mass going into the engine. Both types of indicators have their positive and negative sides.

Advantages and disadvantages of fuel mass flow sensors

| Mass air flow sensor with thread | Mass air flow sensor with film element | ||

| pros | minuses | pros | minuses |

| Simplicity of design | Inaccurate readings | Accuracy | Impossibility of repair |

| Unpretentiousness | Does not meet Euro 3 and 4 standards | Environmental friendliness | Lack of self-cleaning |

| Not afraid of pollution | Meets Euro-3 requirements | Excessive sensitivity | |

| Self-cleaning capability |

Why does the air flow sensor become unusable?

The control system receives information from the fuel mass consumption indicator that air is reaching the injection devices. Then the control unit identifies the volume of fuel mass that is supplied according to these data. The most common proportion of fuel and air mass is 1 to 14. When the indicator breaks, the formation of this composite mass is disrupted and this affects the dynamic characteristics.

Adverse consequences of incorrect operation of the Fuel Flow Sensor

If the DMVR breaks down, you may notice changes in the behavior of the car. The main features are:

- Reduced car dynamics: the car accelerates poorly, its movement becomes jerky.

- The engine may stall spontaneously or fail to start. In the event of a false operation or an incorrect impulse being sent to the control unit, an excess or incomplete amount of fuel may be supplied at the start. It is clear that in this case the motor does not have enough power or there is too much of it, as a result of which it runs the risk of being flooded or simply stalling.

- The “Check Engine” error light on the dashboard starts to light up. By paying attention to this signal in time, you can avoid serious problems.

- Fuel consumption increases. If a car initially spends 10-12 liters per 100 km, and then suddenly starts to “eat” 15-20 liters of gasoline/diesel fuel, this is a reason to check the mass air flow sensor. Some cars with such a malfunction can empty the tank in a short time, and then return to normal consumption.

- Power unit vibrations. This happens when the car engine is idling or when the pedal is pressed. The threat to the car lies in a sudden increase in speed without the influence of the driver.

If any of the above described signs are detected, you should immediately contact the service for preventive maintenance of the car. In addition, the machine can only operate at low or only high speeds, which will negatively affect the condition of the engine.

Symptoms of a problem

The first sign that will immediately catch your eye is the illuminated CHECK ENGINE light on the instrument panel. Unfortunately, it talks about all engine breakdowns, so there are two options for determining an accurate diagnosis - visit a service station or monitor the condition of the engine in different operating modes. The second one turns out to be cheaper, but there is not much chance of determining which component in the engine is acting up. The symptoms of many breakdowns are the same. So, the engine can “triple” both due to malfunctions in the ignition system and when there is a breakdown in the fuel mechanism. Therefore, it is better to spend money, but send the car to a diagnostician who will tell you exactly which element has failed.

An increase or decrease in idle speed clearly indicates that there is a malfunction in the fuel supply system. In particular, such symptoms are also characteristic of defects in the air flow sensor. When accelerating, the car “thinks” for a long time, the speed is gained extremely slowly. The idle speed not only changes, but also becomes unstable. And this is only if the engine was able to start at all. Often it does not respond at all when the starter rotates. Here's how to check your air flow sensor by looking at the external signs only. But an accurate diagnosis can be made only after complete disassembly of the device.

How to replace the mass air flow sensor - general provisions

The engine type and car make have an impact on the sequence of service, including changing the air flow indicator. For the most part, the mechanism involves a separate part under the hood of the car that is attached to the air purification filter. There are also indicators included in the complex module. In such a situation, replacement is only possible for the entire block.

The procedure for changing the mass air flow sensor is as follows:

- Place the car on anti-roll bars or on the handbrake.

- Raise the hood and disconnect the negative terminal of the battery.

- Unscrew the indicator or loosen its fasteners.

- Disconnect the sensor terminal from the connector.

- Install a new sensor, performing all steps in reverse order.

During operation, it is necessary to carefully maintain cleanliness so as not to disrupt the fine settings of the device. If dust or moisture gets in, they can get lost, and therefore even a new indicator will not work correctly.

Prevention and testing of mass air flow sensor on VAZ 2110

As a preventive measure, we can recommend timely replacement of the air filter. The use of sports zeros shortens the life of the flow meter. In any case, regular cleaning of the air flow sensor will not hurt.

- We disconnect the sensor connector, having first removed the ground from the battery.

- Carefully unscrew the flow meter housing from the intake manifold flange.

- If dust deposits are detected, blow out the cavities with compressed air.

- Of course, you also need to clean the air duct and air filter box at the same time.

Tip: It is recommended to repeat this operation every time you replace the air filter.

If the contamination is severe (with oil and moisture), you can use a special Liqui Moly Luftmassensensor-Reiniger cleaner, which was created specifically for cleaning the mass air flow sensor. To do this, it is necessary to direct the jet not only to visible sensors, but also to hidden cavities where the platinum resistor (thread) is located.

After this, the flow meter is installed in its regular place and the functionality of the electronic part is checked.

Cleaning

Quite often you can avoid replacing the mass air flow sensor by simply cleaning this engine element.

You should do the cleaning yourself in this way:

- Remove the pipe from the mass air flow sensor;

- Now remove the sensor from the pipe. Otherwise, high-quality washing will not work;

- To remove the sensor, arm yourself with sprocket keys in advance. Finding such kits is not a problem;

- Unscrew all the fasteners, remove the sensor from the pipe and assess its external condition;

- Often there are traces of oil deposits on the sensor. The purpose of cleaning is to make the device as good as new;

- Carburetor cleaner is often used to clean the air flow sensor;

- Inside the film there are sensors, which are small wires attached to a special resin. These elements must be carefully sprayed with cleaner so as not to damage the devices;

- Wait a while for the surfaces to dry. To speed up the process, use a can of compressed air;

- It is not uncommon to use alcohol instead of carburetor cleaner, which also works quite effectively;

- Proper cleaning of the mass air flow sensor involves treating the pipes from accumulated debris, dirt and dust;

- Having carefully processed all the components of the removed mass air flow sensor, wait until it dries, and then reassemble it. Cleaning is complete.

Spray cleaning

Statistics show that in about 80% of cases, simple cleaning can return the mass air flow sensor to its previous functionality.

Additional manipulations

It is now clear how to clean the mass air flow sensor, but this procedure alone does not end everything; it is necessary to perform a number of additional and necessary manipulations. And you need to do this before installing a clean device. And while the cleaning agent is drying, it’s time to work on the air pipe. It is worth carefully inspecting it for integrity. And if the condition is unsatisfactory - there are cracks and other damage, then it should be replaced.

As experts note, before installing the mass air flow sensor, it is advisable to replace the filter element. You should also check the condition of the rubber seal. Here it is important to pay attention to how tightly it fits, otherwise it will not be possible to avoid the suction of outside air, which is flooded with various contaminants. As a result, cleaning will be required again, and in a fairly short time. Or it will lead to its failure altogether.