Symptoms of air leaks

Symptoms of engine air leaks are most often unambiguous:

- Uncertain start in the morning.

- Rough idle – idle speed fluctuates constantly and is below 1000 rpm. the engine may stall. On a car with a carburetor engine, the quality and quantity screw becomes insignificant for setting the XX mode since the air bypasses the XX channel.

- Power drop - in the intake tract on systems with MAF (mass air flow sensor) - low idle speed; on systems with a MAP sensor (absolute pressure sensor), on the contrary - increased idle speed, lambda errors, lean mixture, misfires.

- Increased fuel consumption - in order to start and continue driving, you need to constantly maintain high revs, while staying in a lower gear longer.

Air leak points

The main places through which suction can occur include:

- intake manifold gasket;

- throttle body gasket;

- section of the pipe from the air filter to the throttle assembly;

- injector O-rings;

- vacuum brake booster;

- vacuum hoses;

- adsorber valve;

- idle air control (if equipped).

Separately, it is worth considering the places where air is sucked in on carburetor engines - there are no electronics there, and air can only be sucked in at the vacuum booster or somewhere in the carburetor.

Choke points (carburetor)

- The screw has the quality of the fuel mixture.

- For the gasket under the carburetor - areas with soot are a sure sign.

- Through a loose throttle valve.

- Through the throttle axes.

- Violation of the integrity of the throttle damper, economizer or starting diaphragms.

Air leaks in the diesel fuel system

In the fuel system of a diesel engine, airing occurs, as a rule, due to a leaky joint of the low-pressure fuel system pipes (from the tank to the filter and from the filter to the injection pump).

Cause of suction on a diesel car

Air leaks in a leaking fuel system occur because the atmospheric pressure is higher than that created when the pump sucks diesel fuel from the tank. It is almost impossible to detect such depressurization by leakage.

On modern diesel engines, the problem of air leaking into the fuel system is much more common than on older diesel engines. All through changes in the design of the fuel hoses, since previously they were made of brass, but now they make plastic quick releases , which have their own service life.

Plastic, as a result of vibrations, tends to wear out, and rubber sealing rings tend to wear out. This problem is especially pronounced in winter on cars with a mileage of more than 150 thousand km.

The main reasons for suction are often as follows::

- old hoses and loose clamps;

- damaged fuel pipes;

- loss of seal at the fuel filter connection;

- the tightness in the return line is broken;

- The seal of the drive shaft, the axis of the fuel control lever or in the fuel injection pump cover is broken.

In most cases, there is a banal aging of rubber seals , and the fuel system can become airborne if any of the branches, both forward and reverse, are damaged.

Signs of air leaks

The most common and common problem is that in the morning or after a long period of inactivity, the car stops starting quickly and you have to crank the starter for a long time (at the same time there is a little smoke coming from the exhaust - this will indicate that fuel is entering the cylinders). A sign of a large suction is not only a difficult start, but also when driving it begins to stall and stall.

This behavior of the car is due to the fact that the fuel injection pump does not have time to pass foam through itself only at high speeds, and at idle it cannot cope with the large amount of air in the fuel chamber. To determine that the problem in the operation of a diesel engine is related precisely to air leaks, replacing the standard tubes with transparent ones will help .

How to find a leak in a diesel fuel system

Air may be leaking in a connection, in a damaged tube, or even in the tank. And you can find it by elimination, or by applying pressure to the system to release it.

The best and most reliable way is to find leaks by elimination: to each section of the fuel system, connect the diesel supply not from the tank, but from the canister. And check one by one - immediately connect to the injection pump, then connect before the sump, etc.

A faster and easier option to determine the location of the leak would be to apply pressure to the tank. Then, in the place where the air is sucked in, either hissing will appear, or the connection will begin to get wet.

Was there an automatic choke?

Of course he was. As for domestic cars, he first used it on the Solex 21083 carburetor, but it was installed only on export VAZ 2110. The essence of its work was as follows - a special spring controlling the damper was connected to the coolant. The bimetal changed its properties as it warmed up, and, accordingly, opened or closed the damper depending on the temperature of the antifreeze.

There have also been developments for our country - this is an electronic suction control system. Instead of a cable, an electric drive was installed, and there was a programming button and a control unit in the cabin. First, the operation of the choke was programmed, and then it closed the damper based on the program. But each season had to be reprogrammed anew, because what worked in the summer, in the winter already required a different open time.

Photos taken from the Internet!

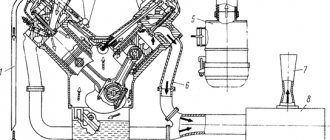

Air leak in the intake manifold

The essence of air leaks in the intake tract is that excess air that is not taken into account by the mass air flow sensor or DBP sensor enters the engine along with the fuel, which leads to a lean air-fuel mixture in the cylinders. And this, in turn, contributes to improper engine operation.

Cause of air leaks

- Mechanical impact.

- Overheating (affects the elasticity of gaskets and sealant).

- Excessive abuse of carburetor cleaning products (severely softens sealant and gaskets).

The most problematic place to find the air leak is in the area of the gasket between the cylinder head and the intake manifold.

Signs and causes of suction

When an engine develops a leak that allows extra air to pass through, the following symptoms are observed:

- The first sign is “floating” idle speed. The engine draws in excess air, and the control unit, which analyzes the composition of the exhaust gases using a lambda probe, tries to properly prepare the fuel mixture. But the mass air flow sensor (or DBP) does not take into account part of the inflow, so the speed is unstable (signs of a sensor malfunction).

- The proportion of fuel in the combustible mixture decreases, hence the difficulty of starting the power unit “cold” when enrichment is necessary.

- Due to a lean mixture, engine power is lost - the car starts and accelerates more difficult.

- As the driver begins to press the gas pedal harder and forcefully increase the speed, fuel consumption increases.

There are several reasons why the tightness of the connections is broken and the engine sucks in air:

- deformation of adjacent planes (for example, the suction manifold to the cylinder head) as a result of overheating;

- too frequent use of car cleaning chemicals, which can soften gaskets and sealants;

- leaky hoses or clamps on the vacuum intake pipes in the engine.

On diesel engines, air is sometimes drawn in by the fuel pump through leaks in the line running from the tank. In carburetors, the path for air flow opens through worn axles and worn out valves.

How to find air leaks in the manifold

On gasoline engines, air not taken into account by the sensors enters the intake manifold through leaks or damage to the air ducts, leaky injector seals, and also through the hoses of the vacuum brake system.

We've sorted out the standard suction points, now it's also worth figuring out how to look for air leaks. There are several basic search methods for this.

A simple cigarette smoke generator

DIY oil smoke generator

The easiest way to check whether there is air leakage in the intake tract after the flow meter is to unscrew the air supply pipe together with the sensor from the air filter housing and start the engine. Then cover the assembly with the sensor with your hand and watch the reaction - if everything is normal, then the engine should stall, strongly squeezing the pipe after the air sensor. Otherwise, this will not happen and you will most likely hear hissing. If you cannot find an air leak using this method, then you need to continue your search using other available methods.

They often look for suction either by pinching the hoses or by spraying likely places with flammable mixtures, such as gasoline, carb cleaner or VD-40. But the most effective method of finding where unaccounted air passes through is to use a smoke generator.

Search for air leaks

As a rule, problems with XX, as well as the appearance of a lean mixture error, occur only with strong suction. A slight leak can be determined by observing the fuel trim at idle and high speeds.

Checking air leaks by pinching the hoses

To find the place where excess air is leaking, we start the engine and let it run for a while, and at this time we keep our ears open and try to hear the hissing, and if we can’t detect it, then we pinch the hoses that go to the intake manifold (from the fuel pressure regulator, vacuum amplifier, etc.). When, after pinching and releasing, changes are observed in the operation of the engine, it means there is a malfunction in this area.

Also, sometimes they use the compressed air search method . To do this, you need to close the filter pipe with the engine off and pump air through any tube, having previously treated the entire intake tract with a soap solution.

Finding air leaks by pouring gasoline

How to detect leaks by spraying

The method of spraying the joints with some flammable mixture while the engine is running effectively helps to determine the place where air is leaking into the engine. This can be either regular gasoline or a cleaner. The fact that you have found a place where it is leaking will be indicated by a change in engine speed (whether it will fall or increase). You need to draw the hot mixture into a small syringe and spray in a thin stream all the places where there may be leaks. After all, when gasoline or other flammable liquid gets into the place of a leak, it immediately seeps into the combustion chamber in the form of vapor, which leads to a jump or drop in speed.

When looking for suction, you should spray on:

- Rubber pipe from the flow meter to the idle air control and from the IAC to the valve cover.

- Connections of the intake manifold to the cylinder head (in the place where the gasket is located).

- Connection between the receiver and the throttle pipe.

- Injector gaskets.

- All rubber hoses are connected with clamps (inlet corrugation, etc.).

Checking the presence of suction with a smoke generator

Few people have a smoke generator lying around in the garage, so this method of searching for leaks in the system is used mainly at service stations. Although, if in a garage conditions the suction could not be found using the methods discussed above, then you can make a primitive smoke generator, although the usual one also has a simple design. Smoke is forced into any hole in the intake tract, and then begins to seep through the holes.

How to find a problem area

Sometimes this may only take a few minutes, in other cases quite a long period. In addition to the manifestation of the indicated symptoms, the on-board computer may indicate the occurrence of a malfunction with a “lean mixture” signal. Detecting air leaks in the power unit of a VAZ 2112, 2114 is not as easy as it might seem at first glance. There are several different ways to perform this operation. In this article we will look at them in more detail.

The entry of “extra” mixture is possible at the joints and seals in the engine intake tract. This fully applies to all hoses, gaskets, injectors, throttle valves, sensors, and other components of the intake manifold. There have been cases where the culprit for this phenomenon was the gasket between the head and the cylinder block. First of all, you should disconnect the MPB sensor. After this, start the engine and close the entrance with a flat object. The motor must stop, otherwise there is a “gap”.

Try spraying plain water on problem areas. It can close the hole that appears for a short time, which will lead to a slight decrease in speed. Instead of water, you can do the same procedure with ether. In this case, the speed should increase. It is not always possible to find the passage of excess mixture in a VAZ power unit using these methods, so mechanics use other methods. Reputable automotive centers in such cases simply measure the vacuum of the intake manifold. For this they have special measuring instruments. They are available for free sale, but purchasing them for single use is not economically feasible.

What should the driver do? Steam generators and smoke generators provide effective assistance in finding places for air leaks in VAZ 2112, 2114. They have a simple design and are easy to assemble at home. The process of describing their manufacture can be easily found on the Internet, so we will not dwell on this. Let us consider in more detail the issue of their use. Any, even the slightest violation of tightness, can be detected by the streams of smoke that form in the smoke generator.

To quickly find the “gap” you need to correctly connect the outlet of the smoke source to the intake tract. Many mechanics consider the most suitable place to connect the hose from the vacuum brake booster. They feed the smoke mixture and try to find leaks in the connections. In most cases this turns out to be the most effective method.