Installing a turbine on an engine with a carburetor

The vast majority of car owners strive to maximize the power of their car in various available ways. One of the questions that owners of carburetor cars often ask is how to install a turbine on a carburetor engine. If the owner of a carburetor internal combustion engine decides to engage in such improvement and tuning, then it is necessary to separately take into account a number of features.

A little theory

The most effective way to make such improvements is for those who have a clear understanding of their actions. To do this, you need to understand the theoretical part.

So, a car’s power and fuel consumption depend on the quality and degree of enrichment of the fuel-air mixture entering the cylinders, as well as on its volume.

The fact is that a conventional engine, when operating, pumps air into itself due to the vacuum created by the piston. In a turbocharged power unit, this work is performed by a turbocharger. In this case, the air is pre-compressed, which allows you to pump in a larger volume. That is, it is possible to burn a larger volume of fuel. The result is an increase in engine power in relation to engine volume and fuel consumed.

One important point: air, as you know, heats up when strongly compressed. It will heat up again when compressed in the combustion chamber. In this case, detonation may occur. And, in addition, due to heating, the air density in the cylinder will decrease, which will naturally reduce the efficiency of the entire system. To remove these negative phenomena, intercoolers are used - air coolers from the turbine. They are a radiator.

As already mentioned, there are two types of compressors:

The entire system, in addition to the turbine itself, includes several more important components that must be remembered during installation:

Is it possible to install a turbine on a carburetor engine? Personal experience

Alexander Rastorguev [razborkazapzap]

05.07.2019,

In order to install a turbine on a carburetor engine, you need to have some understanding of the theoretical part of the internal combustion engine and some laws of physics.

It is known that maximum power and efficiency generally depend on how much the fuel-air mixture is absorbed and how efficiently it ignites. If the combustion chamber is larger, then there will be more space for expansion of the working gases, as a result, greater pressure on the piston at the outlet gives more power.

Why is a turbine needed?

A conventional naturally aspirated engine takes in air due to vacuum when the piston, moving to BDC, sucks air into the cylinders.

A turbocharged engine works in such a way that a large amount of air is forced into the cylinder under high pressure. The more oxygen, the more efficiently and more fuel will burn. With an equal cylinder volume, an engine equipped with a turbocharger will have more power, at least 1.5 times. Since compressed air heats up to a critical temperature, provided that the pressure is above 0.5 Bar, you will have to install a cooler - an intercooler.

Related parts when installing a turbine on a carburetor:

- turbine pressure control valve

- bypass, or valve for returning compressed air to the pipes

- blow off, or excess pressure relief valve when the throttle is closed

- set of pipes (piping)

- oil pipes for supplying oil to the turbine and draining it into the oil pan.

What difficulties awaited us when installing a turbine on a VAZ 2106 carburetor engine?

In general terms, installing a turbine on such an engine resembles the same process on an injector. A labor-intensive process will involve installing the turbine itself on the carburetor. Since the fuel dispenser in the carburetor is played by jets, the standard throughput of standard jets will not be enough, otherwise the mixture will be too lean, leading to drying out of the cylinder and destruction of the piston. Selecting jets of larger diameter is also not easy; it will take a lot of time. You will have to install a “sandwich” of two cylinder head gaskets to prevent detonation. In this way, we lowered the compression ratio to 7:1 according to theoretical calculations. A large amount of time is spent manually adjusting the turbine so that the pressure is stable and suitable for each operating mode.

What benefits did we get as a result?

After a long and painful adjustment, it was possible to reduce fuel consumption, if you do not go beyond 3000 crankshaft revolutions per minute. In the city, fuel consumption measurements showed 8 liters, before previously the consumption was no less than 10 liters of 92 gasoline

no need to constantly turn the engine to quickly accelerate, which means there will be less noise; confident traction throughout the entire speed range, which means you can quickly pick up speed at any time.

Installation process

This process will be general indicative, and some points may differ depending on the design features of the power unit. There are ready-made installation kits for VAZ cars, but all of them are only for injection engines. We had to weld the intake and exhaust manifold ourselves. It is necessary to select hoses for the oil drain, but in such a way that the hose is not kinked, otherwise oil starvation will instantly damage the turbine cartridge. The pipes are installed so that after the turbine, in front of the carburetor, an excess pressure relief valve is installed.

We remove the standard “pan” of the air filter; you will have to weld a square “birdhouse” box yourself, into which the inlet pipe will be installed horizontally and parallel to the inlet fuel line. The fact is that it will not be possible to supply air under high pressure otherwise, or the engine will operate unstable due to improper air flow. Then the jets are selected, at least three sets, and using the selection method we install the suitable jets.

What are the disadvantages when installing a turbine on a carburetor?

- the engine is not electronically controlled, which means that if detonation occurs, the engine will not stall, and any deviations in operating pressure will have a detrimental effect on the engine

- The carburetor does not allow you to adjust the fuel-air mixture ratio, so it will always be at the same level, which means it is suitable only for one load mode, otherwise it may also result in detonation and destruction of the pistons

- The cost of the investment does not at all justify what we got out of it. Converting a carburetor to an injector will cost around 10,000 rubles, provided that used components are installed, and there are a lot of possibilities for fine-tuning the engine

- constant turbine failures in the form of insufficient pressure supply, or the occurrence of suction due to poor-quality welding of the manifold

When installing a turbine on a carburetor engine, it is worth taking into account all of the above disadvantages, which are unlikely to cover those few advantages. The investment you will need for such an operation is at least 60,000 rubles, including engine repairs. In this case, it is better to spend money on high-quality modification of the engine with a reasonable increase in power by 20-30 horsepower, by installing an injector and proper tuning.

conclusions

As you can see, a carburetor engine with a turbine has a right to exist and may even turn out to be more profitable compared to a conventional atmospheric one, although such a conversion will cause trouble and require serious alterations and financial costs. For obvious reasons, in practice, turbocharged carburetor internal combustion engines are very rare, especially in civilian cars.

Also, before installing the compressor, you should first decide in what modes you plan to operate the car: high-speed driving on the highway or ordinary everyday trips around the city.

Turbine for a carburetor engine - pros and cons of the upgrade

Every car owner eventually thinks about improving the technical characteristics of his iron horse. Is it possible to increase engine power by installing a turbocharger?

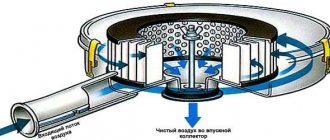

During operation, the turbine uses the energy of gases released from the exhaust manifold during engine operation. Air flows act on the impeller, spinning it and the blades of the compressor wheel. The engine receives a lot of air to saturate the fuel.

The amount of fuel in the cylinders increases several times, thereby increasing power and expanding the potential of the engine. At the same time, the high intensity of turbine rotation (rotation speed can reach up to 200 thousand revolutions per minute) increases the load on the turbine shaft bearing. Often it is the destruction of the bearing that causes the failure of the turbocharging system.

Turbine for injection VAZ 2107

The turbine on the VAZ 2107 is considered exotic among car enthusiasts. And the power advantages of turbo engines over their factory counterparts are driving the proliferation of passenger cars equipped with turbines. And not only among foreign cars...

In theory, their main goal is to achieve maximum horsepower. For fans of fast driving, this is the main argument for sure. Given the same displacement, a turbocharged engine is characterized by almost double power with standard fuel consumption. In modern conditions, small-displacement turbo engines are very relevant.

Turbocharging VAZ 2107

The conventional division of the turbine provides for 2 groups:

- With low pressure up to approximately 0.2-0.4 bar.

- With high pressure up to 1 bar and above.

Installing a high-pressure turbine requires significant modifications to the engine, and when installing a low-pressure unit, almost all factory elements of the system can be preserved.

- Visual installation

- Principle of operation

- Final result

- Is the installation justified?

Visual installation

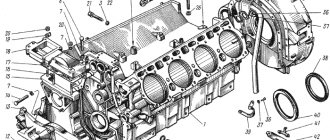

A sample with a low-pressure turbine and a VAZ 2107 engine with distributed injection involves the use of the following factory parts: cylinder block, crankshaft, connecting rods, camshaft and valves. The difference in additional components is associated only with the pistons and cylinder head due to the need to reduce the compression ratio during installation. This functional feature is achieved by enlarging the combustion chamber or special pistons. However, there is a theory that the pistons can be factory pistons and you can limit yourself to replacing the head.

The injector output also differs. The turbine fills the space between the exhaust pipe and the exhaust manifold. The factory model remains the resonator and muffler. If you need to obtain more power, still use the recommendations for installing a direct-flow exhaust. Injection requires an enlarged receiver and a non-standard control program. The lubrication system also undergoes minor changes. Summarizing the above, we can conclude that the turbine itself will be the most expensive and scarce part.

Principle of operation

Why is it that the turbine attracts vehicle owners to the injector? Everyone knows the fact that the volume of fuel that burns out in the cylinders is closely related to the amount of air absorbed into the middle of the engine when starting up by the injector. And the fulfillment of the mass ratio condition, numerically expressed as 1 kg of combustible mixture to 15 kg of air, is mandatory. After all, subsequent enrichment of the liquid implies a decrease in power. In order to remove this obstacle, the cylinder requires more air supply by pumping it into excess pressure. Thus, an increase in air pressure by 30% triggers an acceptable increase in power and acceleration dynamics.

The fundamental features of the operation of a gas turbine-type compressor on an injector are elementary. Its body is fixed to the exhaust manifold. In the middle of the unit itself there is a turbine wheel connected to a compressor wheel. The operation of the exhaust gas stream provokes the spinning of the turbine. Then, using the shaft, the torque is transferred to the impeller of the compressor sample, which sucks in air through an air-type filter and transfers it to the carburetor under pressure, thereby increasing the saturation of the cylinders.

Thus, the same volume of cylinders pumps a larger amount of working mixture. A regular VAZ 2107 engine is characterized by 25 percent combustion of the fuel pumped into the cylinder due to lack of oxygen.

An increase in air filling implies a uniform increase in fuel combustion. This factor affects the increase in engine efficiency. As a result, a gas turbine supercharger allows a larger volume of fuel to be pumped in the same period of time. Torque characteristics also increase, affecting acceleration dynamics.

Final result

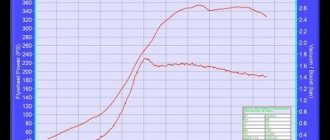

During the research, the turbine installed on the VAZ 2107 engine injector showed the following results: provided that the clutch and tires are of high quality, the acceleration time to 100 km/h is reduced by 5 seconds (compared to the base engine). The same principle applies to elasticity: acceleration time in 4th gear from 60 to 100 km/h is also reduced by 5 seconds.

The idea itself is simple. However, it is difficult to implement it on the VAZ 2107. Representatives of companies that will undertake the production of turbochargers are counted on the fingers of one hand. But turbine kits for installation on a conventional injector began to appear on the market. The kit includes all the pipes, a new block cover, the turbine itself and the intercooler.

The difficulties of installation and further adaptation to the injector are as follows:

- The exhaust gas temperature level that the turbine must withstand is theoretically between 900˚C and 950˚C.

- The working speed of the rotor injector with the impeller is numerically represented not only in tens, but in hundreds of thousands of revolutions per minute.

- The functional resources of the volume of engine compartments of passenger cars are limited, and therefore require the manufacturer to place the unit within a specific framework.

Based on the above, a turbocharger must have high heat resistance, be compact, well-balanced, and at the same time inexpensive.

Is the installation justified?

Tuning a VAZ 2107 carburetor in the form of installing a turbine requires a balanced decision. Do not forget that the VAZ 2107 is an outdated passenger car in all respects. For an adequate owner, modification of the engine with a gas turbine supercharger is purely theoretical. In practice, this is a series of problems unworthy of attention.

How to install a turbine?

Before starting work, you need to check whether the necessary consumables are available. The use of sealants when working with pipelines is strictly prohibited. When exposed to high temperatures, they liquefy and lose their original properties.

Pieces of peeling sealant will sooner or later get inside the turbine and lead to failure. A self-installed turbine is the result of painstaking work; you need to carefully monitor whether there are any foreign particles or liquids in the oil.

Disadvantages of the turbocharging system

Before installing additional equipment, you need to consider not only the pros, but also the disadvantages of such an upgrade. Often, with a detailed study of all the subtleties, the inappropriateness of improving power indicators becomes obvious.

If you have decided to upgrade your car engine with a DIY turbocharger, you first need to determine whether the selected equipment is suitable for your car.

The best solution would be to consult a specialist who will make the necessary calculations and select the desired turbine model.

Source

About the choice of turbocharging systems

Currently, car enthusiasts do not need to design turbines themselves, since a wide range of ready-made systems are available on the aftermarket. But with such abundance, the question will inevitably arise: which system to choose? To answer this question, the driver must decide how much he is going to modify the engine, i.e. how deep the modernization will be. Having decided on the degree of intervention in the engine, you can move on to turbines, which come in two types:

- reduced power turbines. These devices rarely generate pressure above 0.6 bar. Most often it varies from 0.3 to 0.5 bar. Installing a low-power turbine does not involve serious intervention in the engine design. But they also provide an insignificant increase in productivity - 15–18%.

- powerful turbocharging systems. Such a system is capable of creating a pressure of 1.2 bar or more. To install it in the engine, the driver will have to seriously upgrade the engine. In this case, the engine parameters may change, and not necessarily for the better (this especially applies to the CO level in the exhaust gas). However, engine power can increase by a third.

Turbine for carburetor VAZ 2109

VAZ 2109 is a car that is often found in the CIS countries. The history of this model began back in the 1980s and, despite subsequent improvements and upgrades, even the newest factory modifications can be considered outdated. It is not surprising that many owners of such cars, of which there are quite a few, are looking for options to increase power. And one of them is installing a turbocharger on a carburetor. What are the advantages and disadvantages of such a modification, why and who might need it.

Why do they put a turbine on a VAZ with a carburetor?

Ideally, owners of the VAZ 2109, like other carburetor cars, hope to increase engine power to the possible maximum in a similar way. And this thought especially excites car enthusiasts who love to drive. There is also an opinion that by correctly installing the turbine, you can achieve a reduction in noise, a reduction in the amount of fuel (standard consumption at higher power), a reduction in acceleration time and the ability to increase torque. The advantages and benefits here seem to be quite obvious, but is everything so good in practice?

Pros and cons of installation

First, it’s worth understanding what a turbo kit itself is. A turbocharger for a carburetor is very rare due to the complexity of the system itself, which must work perfectly and harmoniously both as a whole and in each individual unit. And high temperatures undoubtedly require the use of specific and expensive materials. And this despite the fact that the carburetor engine, even at the design level, was not designed for supercharging. If we talk about the possibility of such a modification appearing on factory VAZ models, then the probability of this tends to zero due to the cost of the compressor itself, which will add at least 10% to the final cost of the car. Which, in turn, is not possible, given the price segment of these cars.

Does it make sense to install a fly-by-wire throttle body on a car with electronic fuel injection?

A noticeable improvement in throttle response between gear changes can be achieved by installing the throttle body ahead of the turbocharger if the system does not use an intercooler. Closing the throttle valve cuts off flow from the turbocharger and causes a large loss of turbocharger RPM. These lost rpms must be regained before boost pressure can be built up again. An exhaust throttle body on a turbocharger with an intercooler will ultimately be the best option if the system has a compressor bypass valve.

Why are changes to existing fuel systems necessary?

Turbocharging systems with a carburetor do not impose any requirements on additional fuel supply systems. The greater the amount of air drawn through the carburetor, the greater the pressure drop in the venturi, and thus more fuel is supplied through the main jet. All you need is a properly selected and tuned carburetor, and that's all.

The situation is completely different with fuel injection systems. It is generally stated that once a turbocharger is installed, the fuel injection systems will take care of themselves. This is absolutely not true. The fuel injection system is tuned for this engine. The control unit from a 2-liter engine will not work on a 4-liter engine. The reason for this is that the air flow sensors and fuel injectors are sized to match the air flow through the engine, and any significant increase in air flow from stock will be outside the measurement range of the air flow sensor. The air flow sensor from a 2-liter engine experiencing infinite air flow might think for a while that it is a 2.2-liter engine, but there is no telling how long that time might stretch out. Now add a turbocharger and you can easily make a 3 liter engine out of a 2 liter with just 0.5 bar of boost. Obviously, the fuel injection air flow meter will reach its measurement limit and will not be able to cope with the increased air flow. A turbocharged engine should never be allowed to run lean, so appropriate modifications to the injection system are necessary to provide the necessary amount of fuel for the additional air that will be introduced into the system by the turbocharger.

Which turbine should I install on a VAZ with a carburetor?

As for choosing a turbo kit, there is none directly for VAZ. But you can take universal models that fit the parameters. The most popular today are Garrett turbines. There are also other turbines that have proven themselves well with domestic cars, such as IHI, BorgWarner, Holset, Mitsubishi and Subaru. The choice is quite wide and varied both in terms of manufacturers and price categories.

If we talk about theory, fuel consumption depends on power, and power depends on the level of enrichment of the fuel-air mixture entering the cylinders. There are two types of systems: supercharging and turbocharging. The differences lie only in the mechanism that drives the turbine.

How to install a tractor turbine on a VAZ 2107

How to install a turbine! | Topic author: Alexander

Anyone who installed a turbine on a VAZ 211240, please write where and what can be purchased.

Ayrat (Swain) They put it on eights, compressors and turbines.

Tags: How to install a tractor turbine on a VAZ 2107

Other videos from TheWikiHow channel.

Car enthusiasts | Topic author: Temani

Zekera (Josiah) What suspension and what manual transmission will withstand such torque, so another prototype

Zhenya (Jokin) nihua se!

Anton (Tori) but looks solid

IVAROK) even an engine is unnecessary here, it will fly on turbines alone

Denis (Zayit) Overboost and pistons will fly out after the fuel, into the pipe! )))

Konstantin (Raiza) It seems to me that this car’s name is followed by the inscription “TURBO”

Veniamin (Enrico) It seems to me that this is a dummy, for intimidation, the air intake is tightly closed, and even if it opens, without an air filter it can only work in the pressure chamber, otherwise this vacuum cleaner will push so much sand and dirt into the cylinders, press the button a couple of times gas and no rings or pistons!

Mikhail (Himawari) is a Dragster, a specific cramp for professional drag, there is absolutely no need for filters because this crap drives on a very clean dragstrip and plus, the coating is not just asphalt, but is covered with a special glue on top. Well, something like this.

Mikhail (Himawari) Believe what’s there and it can’t withstand such a motor, the transmission there is capable of withstanding more than 10,000 horses, even the bridge is very short and the size of the pig is slightly smaller than that of a Kamaz

Michael (Himawari) hmmmm. Denis, there is such a thing as the quality of the fuel-air mixture, so if you choose the right injector performance and properly configure your brain, then even at 4 Bar you can shoot and nothing will melt in the piston

Denis (Zayit) Well, at 4 bar you need a knee and connecting rods and pistons. How much power does the GTR 1500 blow for info on the RB26?

Michael (Himawari) not necessarily, the knee is the connecting rods and pistons. Denis, we were talking about the large snail that is in the photo, and regarding the 4 kilogram of crush, I gave an example, I didn’t say anything about connecting rods and other things, but if it comes down to it, it’s 100% forged on the bottom and the shafts are at least 305. In fact, MAYBE in that dredge they blow less because the performance of this snail can already produce 1500 forces at 0.8 bar, and can give 1500 forces at 2 Bar (I don’t know the map of these turbines, so I don’t presume to say how many forces with they were approximately removed). As a rule, such cramps have +2500 forces.

Is it worth it to install the turbine yourself?

This smoothly leads to the next question: is it possible to install a turbine with your own hands? The answer is theoretically possible, but highly not recommended. Since the installation and configuration of such a system is quite labor-intensive and complex, complete tightness is necessary, and during the installation process the ingress of oil, sand and other small particles is unacceptable, since all this can clog the impeller and cause the turbine to fail, and not only from standing still.

Therefore, one of the most important points is the presence of an experienced technician who knows exactly what needs to be done and how and will be able to advise in detail on all issues in advance and during the tuning process. This is especially true for high-pressure turbocharging, where it is better for an amateur not to meddle at all, for the sake of his own safety and the safety of the vehicle.

It is also worth remembering that the simplest supercharging will most likely not give any noticeable result. And for something more effective, a number of other car systems will have to be modified. At a minimum, the brake system, transmission and air filter system, which will significantly increase the tangible financial investment.

How is a turbine checked?

Before installing the turbine, it is strongly recommended to change the oil. In addition, the oil and air filters must be replaced. The sequence for checking the turbocharging system is as follows:

- the turbine should be inspected for oil leaks (this applies to both the part through which oil is supplied and the part through which it drains from the turbine);

- All air ducts are also carefully inspected. None of them should contain dirt or foreign objects;

- if the machine is equipped with a catalyst, then it should also be checked for wear (excessive exhaust from a worn-out catalyst can significantly worsen the operation of the turbine; it simply cannot cope with the large volume of incoming gas);

- Finally, you should check whether the turbine rotor rotates normally. The hum produced by the rotor should be uniform. There should be no extraneous sounds in it: creaking, whistling, etc.

So, installing a turbine on a VAZ 2106 is a long and painstaking process. In some situations, instead of a full-fledged turbine, you can think about installing a turbocharger. This is the least expensive and simplest option. Well, if the car owner has firmly decided to install a turbine on his “six”, then he should prepare for a serious modernization of the engine and serious financial expenses.

Is the game worth the candle?

To sum up all of the above, there is practically no actual benefit in installing a turbine on a VAZ 2109. A full-fledged high-quality modification will be very expensive, but other options make no sense and the risk increases, at best, of saying goodbye to the car completely. It goes without saying that the engine must be absolutely in good working order and free of defects before installing the turbo kit. Otherwise, it will also have to be replaced.

The general disadvantages of installing a turbine on a VAZ carburetor also include the fact that the service life of the engine with such modifications is significantly reduced. And this is even with perfectly installed equipment according to all the rules. And also, it is worth observing the basic requirements for operation and preventive maintenance of the turbocharger itself. Since the most common cause of breakdowns is not factory defects or the fragility of the element itself, but rather improper use.

Source

Installation of a turbocharging system

There are two methods for installing turbines on the “six”:

- connection to the collector;

- connection to the carburetor;

The vast majority of drivers are inclined towards the second option, since there is less hassle with it. In addition, in the case of a carburetor connection, the fuel mixture is formed directly, bypassing the manifold. To establish this connection, you will need the following things:

- spanners included;

- flat screwdriver;

- two empty containers for draining antifreeze and lubricant.

Sequence of connecting a full-fledged turbine

First of all, it should be said that a turbine is a rather large device. Therefore, it will require space in the engine compartment. Since space is limited, many 6 owners install turbines where the battery is installed. The battery itself is removed from under the hood and installed in the trunk. It should be noted here that the sequence of connecting the turbocharging system depends on what type of engine is installed on the “six”. If the car owner has the earliest version of the “six”, then a new intake manifold will have to be installed on it, since the standard one will not be able to work with the turbine. Only after these preparatory operations can you proceed directly to installing the turbocharging system.

- First, the additional intake duct is installed.

- The exhaust manifold is removed. A small section of air pipe is installed in its place.

Video: connecting the turbine to the “classic”

Compressor connection sequence

It was mentioned above that connecting a full-fledged turbocharging system to an old “six” may not always be justified, and that installing a conventional compressor may be a more acceptable option for many drivers. So it makes sense to analyze the installation sequence of this device.

- The old air filter is removed from the inlet air pipe. A new one is installed in its place; the resistance of this filter should be zero.

- Now take a piece of special wire (it usually comes with the compressor). One end of this wire is screwed to the fitting on the carburetor, the other end is attached to the air outlet pipe on the compressor. Steel clamps from the kit are usually used as fasteners.

This sequence is the simplest and at the same time the most effective when installing a turbocharger on all VAZ “classics”. While installing this system, the driver himself can look for new ways to improve the tightness of the box and pipe connections. Many people use regular high-temperature sealant for this, which can be found at any auto parts store.