Hello, dear guests and readers of the automobile blog Avtogid.ru. We are meeting with you to find out why the turbine drives oil into the intercooler and the reasons for the phenomenon. A common problem among various brands of diesel cars. In normal condition, the intercooler should not come into contact with engine oil. We need to look for the cause of the malfunction.

The appearance of engine oil in the intercooler, a symptom indicating that a malfunction has occurred in the car's turbocharging system. You need to pay attention, otherwise serious damage cannot be avoided.

Engine oil entering the intercooler is accompanied by loss of vehicle power. It is not advisable to use the machine until diagnostics are carried out and the cause of the problem is found.

At the end of the article there is an interesting video on how to clean the turbine and intercooler of oil without dismantling it. It will complement the text material and allow you to better understand the problem. Enjoy watching.

Oil in the intercooler. Reasons and what to do.

If you suddenly don’t know what an intercooler is, then read about it in the article - “What is an intercooler and why is it needed”

If oil is detected in the intercooler, it is necessary to determine the cause as quickly as possible. To do this, check the following:

-The amount of oil in the engine. If the level is above the drain pipe, then this can also lead to overflow. If you need to drain

-Oil drain line located between the turbine and the engine crankcase. If it is damaged or is severely bent. It will need to be straightened. Fix or replace depending on what problem you have

-If the problem is still not found, check the air duct for damage.

-After this, check the filter, most likely it is very dirty.

-Another most common problem caused by oil in the intercooler is bad sealing rings in the cylinder-piston group.

How to flush the intercooler after oil gets in

Before continuing to drive the car, it is necessary to clean the intercooler of oil. First you need to remove it.

If you have an air intercooler, simply remove the clamps; for a liquid intercooler, you will need to refer to the instructions for the specific model or contact a specialist.

Next, use specialized products to clean the intercooler. Typically, information about how to wash it can be found in the car's operating instructions. After you have cleaned the intercooler of oil, rinse off the remaining solution with distilled water and let it dry. After this, install the intercooler back into the car.

Don’t forget to like if you liked the article, and also subscribe to our channel so as not to miss new articles.

Source

Reasons for oil consumption in the turbine

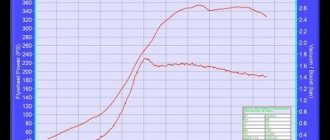

Before moving on to considering the immediate reasons why oil may leak, it is necessary to determine its permissible volume. The fact is that any turbine, even a fully functional one, will eat up oil. And this consumption will be greater, the higher the speed of both the engine itself and the turbine. Without going into the details of this process, it should be noted that the approximate normal oil consumption of a turbocharged engine is about 1.5...2.5 liters per 10 thousand kilometers. But if the value of a similar consumption exceeds 3 liters, then this is already a reason to think about troubleshooting.

High oil consumption

If the engine is consuming oil, this at least indicates a faulty CPG, worn oil caps or clogged crankcase ventilation. High oil consumption - signs, causes and what to do Read more

Let's start with the simplest reasons why a situation may arise when oil is driven out of the turbine. As a rule, the situation is due to the fact that the locking rings, which, in fact, prevent oil from flowing out of the turbine, wear out and begin to leak. This happens due to the fact that the pressure in the unit drops, and in turn, oil drips from the turbine to where the pressure is lower, that is, out. So let's move on to the reasons.

Clogged air filter . This is the simplest situation, which, however, can cause this problem. You need to check the filter and, if necessary, replace it (in rare cases, you can clean it, but it’s still better not to tempt fate and install a new one, especially if you use the car off-road). In winter, instead of or along with clogging, in some cases it may freeze (for example, in conditions of very high humidity). In any case, you definitely need to check the condition of the filter.

Air filter box and/or air intake pipe . The situation is similar here. Even if the air filter is in order, you need to check the condition of the indicated components. If they are clogged, you need to correct the situation and clean them. The resistance of the incoming air should be no higher than 20 mm of water column when the engine is idling (approximately 2 technical atmospheres, or about 200 kPa). Otherwise, you need to inspect and clean the system or its individual elements.

Air filter cover leakage . If such a situation occurs, then dust, sand and small debris will inevitably enter the air system. All these particles will work as an abrasive in the turbine, gradually “killing” it until it fails completely. Therefore, under no circumstances should depressurization of the air system of an engine with a turbine be allowed.

Poor quality or unsuitable oil . Any internal combustion engine is very sensitive to the quality of engine oil, and turbocharged engines are even more so, since their rotation speeds and temperatures are much higher. Accordingly, firstly, you must use the oil recommended by the manufacturer of your car. And secondly, you need to choose the lubricant that is of the highest quality, from a more well-known brand, synthetic or semi-synthetic, and not pour any surrogate into the power unit.

Heat resistance of oil . Turbine oil is usually more heat resistant than conventional oil, so an appropriate lubricant must be used. This oil does not burn, does not stick to the walls of the turbine elements, does not clog the oil channels and normally lubricates the bearings. Otherwise, the turbine will operate under extreme conditions and there is a risk of its rapid failure.

Oil change interval . In every engine, the oil must be changed according to regulations! This is especially true for turbocharged engines. It is better to carry out the corresponding replacement approximately 10% earlier than specified by the vehicle manufacturer. This will certainly increase the life of both the engine and the turbine.

After how many km should you change the engine oil?

The engine oil change interval should be considered based on operating conditions, vehicle mileage, quality of consumables and 7 other factors. Frequency 8-12 thousand km. overall indicator Read more

Condition of oil supply pipes . If you do not change the oil for a long time or use low-quality lubricating fluid (or the oil filter is simply clogged), then there is a risk that over time the oil pipes will become clogged and the turbine will operate in critical mode, which significantly reduces its service life.

(intake manifold) from the turbine This situation occurs infrequently, but its cause may be the already mentioned clogged air filter, its cover or pipes. Another reason in this case may be clogged oil channels. As a result of this, a pressure difference occurs, due to which, in fact, the oil “spits out” into the intercooler.

Oil getting into the muffler . This is similar to the previous point. A pressure difference occurs in the system, which is caused either by a clogged air system (air filter, pipe, cap) or oil channels. Accordingly, first of all it is necessary to check the condition of the described systems. If this does not help, perhaps the turbine itself already has significant wear and needs to be inspected, but before that you need to check the turbine.

In some cases, this problem may be a consequence of the use of sealants during the installation of the supply and drain oil pipelines. Their residues could dissolve in the oil and cause the oil passages to become coked, including partial failure of the compressor bearings. In this case, it is necessary to clean the relevant channels and individual parts of the turbine.

Often, the result of oil getting into the muffler and the exhaust system in general will be blue smoke from the car's exhaust pipe.

Now we move on to more complex reasons, and therefore expensive repairs. They occur if the turbine is very worn out due to its improper operation or simply because of its “old age”. Wear could be caused by excessive load on the engine, the use of unsuitable or low-quality oil, its replacement not according to regulations, mechanical damage, and so on.

Failure of the impeller . This situation is possible if there was significant play on its shaft. This is possible either from old age or from exposure to abrasive materials on the shaft. In any case, the impeller cannot be repaired; it only needs to be replaced. In this case, related repairs are usually carried out. It hardly makes sense to carry them out on your own; it is better to seek help from a car service center.

Bearing wear . In this case, significant oil consumption is observed. And it can fall into the cavity, in close proximity to them. And since the bearings cannot be repaired, they need to be replaced. It is also better to seek help from a car service center. In some cases, the problem is not so much the direct replacement of bearings, but rather their selection (for example, for rare cars you need to order spare parts from abroad and wait a considerable time for them to be delivered).

Impeller shaft jamming . At the same time, it does not rotate at all, that is, the turbine does not work. This is one of the most difficult situations. Usually it jams due to misalignment. In turn, misalignment can occur due to mechanical damage, significant wear or failure of bearings. This requires comprehensive diagnostics and repairs, so you need to seek help from a car service center.

Car turbine malfunctions. How to troubleshoot?

Useful recommendations for troubleshooting a car engine turbine. 3 common causes of turbine malfunction and the main signs of turbocharger failure. And also how to eliminate them Read more

Why does the turbine drive oil into the intercooler?

Engine oil is needed to reduce friction between the working surfaces of the turbocharger. In its absence, the elements would fail after a very short period of time. To produce working fluid, the turbine is connected to the engine. Experienced drivers advise changing the oil as often as possible.

Oil in the intercooler pipe is evidence of a turbocharging malfunction. The node must be examined immediately. Of course, it is possible to repair the turbine, but it will not cost less than a complete replacement. Therefore, it is worth taking preventive measures to prevent malfunctions.

Causes of turbine failures are serious problems

Sometimes it is not possible to get rid of the problems that have arisen so easily - oil in the intercooler pipe appears as a result of a disruption in communication with the engine crankcase. The reason may be the formation of various types of blockages in the oil drain pipe - from debris getting into it to the appearance of carbon deposits.

Very often, car enthusiasts who independently repair a diesel engine do not use special means to secure the oil line, but ordinary sealants, which, when heated, penetrate inside the tube and form plugs.

The solution to the problem is to remove the oil drain pipe, thoroughly clean it and rinse it, being careful not to damage the walls of the tube.

However, this is not the worst case scenario - it is quite possible that the lubricant in the crankcase rises above the level of the drain pipe, and as a result, the turbine throws oil into the intercooler.

It’s good if you simply went too far with the volume of oil used - but if the crankcase ventilation is impaired, the situation will not be so easily corrected. One of the reasons for the problem may be a violation of the integrity of the sealing rings in the cylinder-piston group, as a result of which exhaust gases will enter the crankcase and squeeze out the oil through the drain pipe. The solution is a major overhaul of the engine with replacement of rings.

Oil in the intercooler of a diesel engine: reasons

There are several reasons why this problem occurs. Let's look at each one.

Malfunctions in the crankcase ventilation system

When a car drives off-road, when it accelerates and its engine runs unevenly, high pressure arises during fuel combustion. It is much greater than what occurs under normal conditions. A large amount of gases enters the engine sump. If the sump ventilation system works correctly, gases can freely pass into the intercooler, and then into the combustion chambers along with the fuel. The oil catcher and valve springs wear out over time. This leads to an increase in pressure in the pan, which in turn causes the injection of working fluid into the intercooler.

The main thing is timely detection

Remember that the longer the oil stays in the intercooler, the more difficult it will be to wash it with conventional means, without resorting to purchasing expensive professional auto chemicals. In addition, ignoring the problem will lead to its aggravation, which will force you to spend considerable money on restoring the normal operation of the engine and related vehicle systems. Therefore, as soon as you discover an oil leak in the intercooler, immediately stop operating the vehicle and diagnose it. If you cannot find the cause on your own, contact a professional who is an employee of an automobile service company. In any case, you cannot ignore the problem - it will cost you too much.

Consequences: is the oil in the intercooler dangerous?

The intercooler of an internal combustion engine whose mileage is more than 100,000 km contains at least 40 grams of lubricant. If the working fluid is below the level of the internal cells, this is not dangerous for the operation of the propulsion system. But if the radiator is filled with lubricant to the lower cells, it is actively drawn into the combustion chambers along with the air mass. This causes poor quality fuel burnout. Detonation appears in the cylinder head and exhaust pipes. The consequences can be serious - the valves will burn out and the same thing will happen to the exhaust manifold.

Diagnostics and troubleshooting

If there is working fluid in the intercooler, you need to identify the cause of its appearance. Perform the following operations:

- checking the pan ventilation system;

- filter replacement;

- Inspect the seals for damage.

In the absence of sufficient experience, it is better to entrust these works to professionals. If the inspection shows that the system is working properly, you may need to think about changing your driving style. Operating the engine at speeds above 2000 rotations per minute is fraught with overheating of the coolant.

How and with what to clean the intercooler

Drivers who are interested in how to clean the intercooler on their own will inevitably have to dismantle it, otherwise thorough cleaning, even if they try, will not work. Often this will not be much of a problem – just unscrewing a few bolts will be enough. In addition, cleaning the intercooler yourself will require purchasing a high-quality cleaning fluid. As a rule, it is not cheap, so we do not recommend buying too cheap automobile products. As for washing with gasoline, kerosene, white spirit or other “folk” remedies in your case, it is advisable to get the opinion of an experienced professional on this matter.

1 The principle of operation of the intercooler in a diesel engine system

Today, in the fight for environmental friendliness, engineers from leading car manufacturers are trying to maximize power at minimal cost. What is this device in the turbocharging system? The air in a turbocharged system passes through the supercharger and heats up to high temperatures, which leads to uneven expansion of the fuel-air mixture and, as a result, to incomplete combustion.

Similar articles

As a result, the power of the diesel engine rapidly decreases and fuel consumption increases. An intercooler is an intercooler (radiator) that is installed after the turbine and serves to cool the air that passes into the mixing and combustion chamber along with the fuel. Thus, the intercooler provides the diesel engine with:

- power increase,

- limiting the amount of harmful emissions into the atmosphere,

- reducing average fuel consumption and increasing engine speed.

Today, the intercooler is installed not only on diesel engines, but also on gasoline engines, this is especially practiced by various tuning studios. All intercoolers on cars are divided into two types:

- air-to-air. In this case, air under pressure passes through special honeycombs (like a radiator),

- air-water. The flow passes through a cold water tank. This type also requires the installation of a water pump and control unit.

Regardless of the type of intercooler, oil getting on this part gradually leads to malfunction of the entire turbocharged system.

What is an intercooler?

In recent years, the number of turbocharged engines has been increasing. They are beneficial for the driver. Turbocharged units use fuel efficiently and increase power without increasing engine displacement.

Power plants using turbines have received a second wind. By using compressed air with a turbine, the engine receives a good increase in power.

During operation, the turbine heats up significantly. This affects the quality of its work (hot air is more difficult to compress) and the mechanism wears out faster. The first turbochargers quickly failed for this reason. They could not withstand high temperatures, and the material wore out.

An intercooler was invented to cool the turbine. The main task of the device is to lower the temperature of the turbocharger to acceptable values. The intercooler cools the turbine to 50-60 degrees.

In appearance, the intercooler resembles a cooling radiator and has similar tasks. When using an intercooler, we had to sacrifice turbine power. The intercooler holds back air flow, acting as a barrier. This affects the boost pressure reduction.

There are 2 types of intercoolers in turbocharged engines:

Air vents - air flows are used to cool the turbine.

Coolants - coolant is used to reduce the temperature of the turbocharger.

Due to their simple design and reliability, air vents have become widespread. They are used in a lot of cars with turbocharged engines.

If the turbine begins to drive oil into the intercooler , then the turbocharger needs diagnostics. Requires close attention from repair specialists. You should not delay, as delay increases the cost of repairs.