The car's automatic transmission is controlled by an electro-hydraulic system. The process of shifting gears in an automatic transmission occurs due to the pressure of the working fluid, and the control of operating modes and adjustment of the flow of working fluid using valves is carried out by an electronic control unit. During operation, the latter receives the necessary information from sensors that read the driver’s commands, the current speed of the vehicle, the workload on the engine, as well as the temperature and pressure of the working fluid.

Causes

If the signs of an automatic transmission malfunction are clear to you, then before we look at how to eliminate them, let’s look at the main reasons. A list of the main causes of automatic transmission failures is presented below. Only based on the reasons can you determine what to do next with the car.

Automatic transmission planetary gear disassembled

Lever link

If you own a car with an older type of automatic transmission, in which the selector and transmission are directly connected mechanically, then know that the lever linkage often causes problems. The gear selector lever sometimes breaks, making it impossible to change the automatic transmission operating modes. As practice shows, in most cases such breakdowns are solved by replacing the lever and rocker.

As for the signs, problems associated with the rocker are manifested by difficulty moving the automatic transmission lever. As a result, the selector may stop moving altogether, and accordingly, activating one or another mode will be impossible. In some units, work to replace the rocker can be carried out without removing the transmission.

Oil leak

Often in practice, automatic transmission malfunctions are caused by transmission fluid leaking from the system, and the leakage is mainly observed from under the rubber seals. Therefore, we recommend that all motorists periodically perform a visual inspection of the unit in a pit or overpass. If you notice any signs of a leak, this indicates the need for urgent repairs. As a rule, such problems are solved quickly; their elimination is not difficult, since it is solved by replacing the rubber bands and replacing the working fluid.

Always visually check the condition of the unit, this will help identify a transmission malfunction.

Control block

Sometimes incorrect operation of the automatic transmission may be due to problems in the operation of the control unit. In particular, this block may incorrectly select the speed for switching modes, or it may completely block the operation of the unit. As practice shows, repairing the control unit usually does not help much. Therefore, such problems are usually solved solely by replacing the device, as well as the cables adjacent to it.

Valve block failures

Valve block failure is also a common problem. For example, if the transmission is used incorrectly. If a motorist does not warm up the car in cold weather before leaving, but immediately starts moving, then the valve body will be the most vulnerable unit in this case. Such malfunctions manifest themselves in the form of shocks, jolts or vibrations, and sometimes the vehicle may not start at all. If you have a modern car, then you can find out about a valve body failure from a message from the on-board computer.

Torque converter malfunctions

As practice shows, such breakdowns can only be solved by repair. As for the cost, in the case of a torque converter it will be significantly lower than with a valve body and ECU. If the torque converter is not working correctly, then you will hear knocks, vibrations, rustling, you will notice how the dynamics have deteriorated, and when replacing the working fluid, you will notice metal shavings in the pan.

Is it possible to diagnose grenade malfunctions yourself?

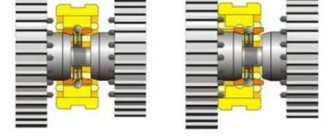

Since the grenade is a simple hinge, it can easily fail. The principle of its operation is very similar to the operation of a bearing - two surfaces, between which balls made of durable metal are located. The difference is that grooves are cut out on the surfaces, due to which you can change the position of the drive axle shaft relative to the driven one. If you take a used CV joint, you can rotate the two axle shafts with your hands without much effort and see how the unit works. You won’t be able to turn them on the new one, since there are no gaps and you need to make a lot of effort to turn them.

Several forces act on the hinge at once. Firstly, when driving, torque is transmitted from the gearbox to the wheel. Secondly, the relative position of the axle shafts is constantly changing, as you rotate the steering wheel while driving or drive over an uneven surface. And there is always friction in the mechanism, which destroys it. In some place, a development may appear, as a result of which the gap between the surfaces increases and extraneous crackling and noise become audible.

Anyone who has experience operating a front-wheel drive car is familiar with how to check the CV joint and the sounds it makes when it breaks. The first sign that grenades need to be replaced is the appearance of this kind of noise during sudden acceleration, moving over obstacles, and also when turning. But if a crunching sound is heard even when moving in a straight line, then this indicates that it is necessary to urgently change the CV joints and operating the car in this condition is not only undesirable, but even dangerous.

Unfortunately, many symptoms of grenade malfunctions are very similar, for example, to the symptoms of a broken ball or steering joint. Therefore, you should once again make sure that the diagnosis is correct. Thus, the presence of subtle jerks at the moment of starting off clearly indicates a breakdown of the hinges. The presence of significant shaft play between the CV joints can be determined by hanging the wheel and trying to move it in different planes. If there is play, then the CV joint has become unusable and should be replaced.

Diagnostics of the external hinge is simple: just turn the steering wheel to its extreme position and drive off. At the maximum angle between the axle shafts, a characteristic crunch will appear - this is a sign of failure of the outer hinge.

It is best to check the internal CV joint on a lift

But the internal mechanisms also have a peculiarity - they can crunch during linear movement. To check, it is not necessary to have special skills, since you can check the internal CV joint by driving off-road - when you get into holes and ditches, the sound is amplified many times over. But the most accurate diagnosis can be made as follows:

- drive the car onto a lift;

- in a suspended state, engage first gear, allowing the wheels to rotate slowly;

- in this position, the faulty CV joint will produce a clearly audible crunch;

- again, when you try to move the shaft by hand, you will feel significant play.

If the symptoms are obvious, then you need to buy a CV joint and install it on the axle shaft. Anthers, clamps and lubricant are usually included in the kit.

Automatic transmission input shaft speed sensor

The measured speed of rotation of the automatic transmission input shaft is converted into electric current. Information can be transmitted by either direct or alternating voltage, proportional to the rotation speed.

A common malfunction is mechanical damage to the housing, as a result of which the device ceases to be sealed. The cause of destruction lies in prolonged exposure to temperature or poor quality manufacturing. Repair in this case consists of replacing the sensor with a new one.

Under the influence of an aggressive environment, the contacts in the assembly oxidize. This causes the signal to disappear and an incorrect value may be sent to the ECU. To eliminate the problem, you can clean the contacts. In case of severe oxidation, it is recommended to replace the device with a new one, since as a result of removing plaque, the protective coating is erased and the contacts are damaged at an accelerated pace.

Types and principle of operation of automatic transmission sensors

The main goal of the automatic transmission control system is to determine the optimal moment at which a gear change should occur. To do this, it is necessary to take into account many parameters. Modern designs are equipped with a dynamic control program that allows you to select the appropriate mode depending on operating conditions and the current driving mode of the vehicle, determined by sensors.

In an automatic transmission, the main ones are speed sensors (determining the rotation speed on the input and output shafts of the gearbox), pressure and temperature sensors of the working fluid and a selector position sensor (inhibitor). Each of them has its own design and purpose. Information from other vehicle sensors can also be used.

We recommend: Why the engine does not start if the starter turns

Selector lever position sensor

Selector lever position sensor

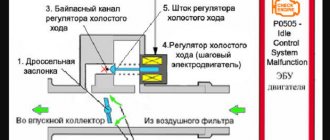

When changing the position of the gear selector, its new position is recorded by a special selector position sensor. The received data is transmitted to the electronic control unit (often it is separate for the automatic transmission, but at the same time has a connection with the car’s engine ECU), which launches the corresponding programs. This activates the hydraulic system according to the selected driving mode (“P(N)”, “D”, “R” or “M”). In car instructions, this sensor is often referred to as an “inhibitor”. As a rule, the sensor is located on the gearbox selector shaft, which, in turn, is located under the hood of the car. Sometimes, to obtain information, it is connected to the drive of the spool valve for selecting driving modes in the valve body.

The automatic transmission selector position sensor can be called “multifunctional”, since the signal from it is also used to turn on the reverse lights, as well as to control the operation of the starter drive in modes “P” and “N”. There are many designs of sensors that determine the position of the selector lever. The classic sensor circuit is based on a potentiometer, which changes its resistance depending on the position of the selector lever. Structurally, it is a set of resistive plates along which a movable element (slider) moves, which is connected to the selector. Depending on the position of the slider, the resistance of the sensor will change, and therefore the output voltage. All this is located in a non-separable housing. If malfunctions occur, the selector lever position sensor can be cleaned by opening it by drilling out the rivets. However, setting up the inhibitor to work again is quite difficult, so it is easier to simply replace the faulty sensor.

Consequences of a lack of transmission fuel in automatic transmissions

What happens if you continue to drive with a low oil level in the automatic transmission? First of all, the service life of the crankcase is reduced. Experiencing oil starvation, the gearbox will overheat and fail faster.

Due to insufficient oil, gears engage with a delay. If you continue to move, the clutches will soon “burn out” due to lack of oil in the automatic transmission.

The next manifestation when the transmission level is low is that the car will begin to slip. If you continue to move with this problem, the box bearings will quickly wear out. Signs of their breakdown are the appearance of a grinding noise when changing gears, a whistle.

Overheating of the box is one of the signs that the oil is below the required level. The cost of automatic transmission repair is high due to the complexity of its execution. That is why the driver needs to adhere to a measured driving style and visit the service station in a timely manner.

Thus, several signs of a low transmission level stand out:

- the appearance of grinding noises;

- The automatic transmission does not work stably;

- overheats.

How to avoid problems?

We have talked about the causes and signs of breakdowns, now we will dwell in detail on how to eliminate them. It should be noted right away that all the reasons are conditionally divided into those caused by mechanical wear and those that appeared as a result of improper operation of the car. In practice, many car enthusiasts do not always change the working fluid in the box on time; over time, the lack of lubrication can cause the unit to overheat. As a result, all moving components of the transmission break down much faster; the only way to eliminate them is to replace them. Therefore, car enthusiasts with an automatic transmission should periodically diagnose the lubricating fluid in the system.

Another way to eliminate possible problems is to regularly warm up the gearbox in winter, which will relieve the car owner from problems associated with the lubrication of moving components. As a result of using low-quality oil, solenoids suffer, and replacing them can take not only a lot of time, but also considerable financial costs. Do not forget that such transmissions are always sensitive to aggressive and fast driving styles. Moreover, when the engine is constantly running at high speeds, the transmission clutches wear down and burn out very quickly. Therefore, we recommend that you refrain from this driving style.

Another difficulty in eliminating transmission breakdowns is that in most cases the fault can only be identified by dismantling and disassembling the automatic transmission. Accordingly, the transmission will need to be removed from the car. As practice shows, it is very difficult, almost impossible, to carry out high-quality repairs at home, so in such cases it is better to contact specialists. Repair of transmission elements consists of replacing failed components. It should be noted here that, regardless of the method of eliminating the breakdown, repairing an automatic transmission will always be more difficult than a “mechanical” one due to the design features of the unit.

Fault prevention

The best way to solve a problem is to prevent it. Having briefly talked about common problems (a more detailed analysis will be given below), we will highlight certain preventive measures - rules, the observance of which, while not guaranteeing the absence of automatic transmission malfunctions, seriously reduces their likelihood:

- Working fluid.

Regular replacement of the lubricant is the key to avoiding problems with the automatic transmission. By ignoring this rule, you significantly reduce the service life of the gearbox. - Warm up

It has already been said above that breakdowns often occur in winter. Be sure to warm up the car: this will minimize the likelihood of malfunctions associated with the lubrication of the moving elements of the system.

Riding.

The automatic transmission wears out much faster with an “aggressive” driving style. You shouldn’t “increase your speed” in vain, even when the situation on the road is conducive to this. Regular operation of the engine at high speeds leads to grinding of elements and burning of transmission clutches.

Recommendations for operation and maintenance of automatic transmission

An automatic transmission is quite demanding to operate, although, when compared with a manual transmission, it gives the driver more “liberties” and provides better “foolproofing”.

You should start driving with an automatic transmission only after the box has warmed up for 2-3 minutes, and at temperatures below -25°C - up to 10 minutes. You need to move away smoothly, without wheel slipping (that is, you don’t need to press the gas pedal sharply), and while driving, you should never press the gas and brake pedals at the same time. During short stops and when driving down hills, you should not switch the automatic transmission to the neutral position.

Engaging reverse gear in an automatic transmission can only be done when the car is completely stopped. And when maneuvering in a confined space (or while parking), it is better to change the speed of the car using the brake pedal (with the gas pedal depressed). Finally, you should not operate the car if the CV joint is faulty (as evidenced by a characteristic crunching sound in the area of the front wheels) and the gearbox itself. If any signs of a malfunction of the box appear, including when the indicator lights up on the dashboard, you should carry out diagnostics and repairs or contact a service station.

Automatic transmission maintenance comes down to checking the oil level every 10-15 thousand kilometers, and changing the oil and filter every 40-60 thousand kilometers (depending on the make and age of the car). If the car is operated in difficult conditions, then it is recommended to change the oil more often - every 25-30 thousand kilometers. The procedure for checking and changing the oil in each specific car is described in detail in its operating instructions.

When checking the oil level, you should also pay attention to its appearance and smell. If the oil has darkened and even has a burning smell, then it should be replaced - these signs indicate oil contamination due to burning of the friction mechanisms in the box, and contaminated oil clogs the oil channels and negatively affects the operation of the automatic transmission

It is important to use only gear oil recommended by the manufacturer in the gearbox. Under no circumstances should mixing oils of different types be allowed, as this can lead to more wear and tear and failure of the transmission.

Changing the oil to another is allowed, but only on cars with significant mileage and after consultation with a specialist. The new oil will provide better performance and protection of worn parts, reducing the likelihood of breakdowns. It is also allowed to add additives to transmission oil (revitalizant gels, conditioners, etc.) created specifically for use in automatic transmissions.

Regular inspection and maintenance of the gearbox is a guarantee of its reliable operation for many years. Keep an eye on your car's transmission and it will give you a comfortable and safe driving experience.

Temperature sensor

Transmission temperature measurement is not used on all vehicles. The main functions that the sensor provides:

- preventing torque converter overheating and thermal damage to clutches;

- optimal heating of the automatic transmission in winter conditions;

- adjusting the operating mode of the gearbox when approaching a critical temperature;

- more precise selection of settings for chip tuning;

- display of information to the car owner.

The main symptoms of incorrect temperature measurement are:

- The automatic transmission cannot be taken out of emergency mode;

- when the operating temperature is reached, the emergency mode is triggered;

- constant indication of automatic transmission overheating;

- Shocks when driving when cold.

For accurate diagnosis, reading the error with a special scanner is required. If the equipment is missing, you can check the sensor by replacing it with a known good one. You should also visually inspect the contacts and housing for mechanical damage.

It is prohibited to use a vehicle with faulty automatic transmission sensors. In addition to the loss of comfort from driving a car, as a result of the ECU receiving unreliable information, the car's power plant can suffer serious damage. The safety of the car is also reduced, since slipping and jerking while changing gear ratios can cause the driver to skid and lose control.

A whole year has passed since I wrote here, I burned so much gasoline!

I drove more than 40,000 km in a year. on my swallow. She still runs just as great for me. I can go 200 mph without any problems, but usually 180, I don’t want to force the engine. Still, the maximum speed of the car according to its passport is 175. But today is not about that. I want to tell you how I repaired the automatic transmission mode switch sensor on my own. I had a problem, the car did not always start after stopping. I searched for the reason for this on the Internet and came up with the information that the automatic transmission mode sensor is to blame. Well, of course, I don’t want to get into such a jungle again, especially since I found a way out, as it seemed to me. If the engine did not want to start, I moved the selector knob to the “NEUTRAL” position and in this case everything started to work. Sometimes it started up as expected in PARKING. But one not wonderful day nothing helped, the engine was silent, like a corpse. For some reason I immediately thought that the sensor had finally failed. Although I was hoping for something else, the sensor on an automatic transmission is, in my opinion, something very expensive and in short supply. Especially 25 years ago. In general, I don’t remember how I got home, I just remember that I got there myself. Or maybe it’s already at home and hasn’t started yet. That's not the point. I searched the Internet for information on the sensor, but found nothing. Neither buy nor repair. Although there was some repair work, there were no photos from other cars. I think I have nothing to lose, so I decided to take it off and have a look. In the photo, the arrow marks the bolt that secures the linkage from the automatic transmission selector to the sensor. I had some play there, because apparently there was a non-metal bushing that had dried out and fallen out. And instead of a bolt there was a rivet with a diameter of 8 mm. and it was impossible to remove it. By the way, I just remembered that I was repairing the car at work, and went home with the sensor for repairs. So, in order to eliminate the backlash, I first had to remove the nut, which is visible from above on the sensor. It holds the bar on the bolt to the selector rod. Then, using a small file, I spent about forty minutes cutting off the bottom of the rivet, where there is less metal. UV!!! Just as the Count of Monte Cristo strove for freedom, so I was determined: “Finish or die!” The rivet has been removed, the battery has been removed, and the stuck connectors on the cable from the sensor have been connected.

I had to sweat! Now it’s clear why they charge more money for repairing an old car))) And with the sensor and bright hope, I headed home. We recommend: GDI engine – what is it and why is it good?

DISASSEMBLY PROCEDURE FOR THE AUTOMATIC TRANSMISSION SENSOR.

8. Lubricate the contact group with a little grease so that our new cylinders slide more easily. 9. We begin to collect. To do this, tighten our screw, which is screwed into the sensor cover, to its entire length. You need to contrive to fold all the parts as they should stand, press the cylinders of the contacts to the base so that they do not fly out. With one hand we press the entire structure, with the other hand we cover the sensor cover so that the end of the screw protruding from the cover (take the screw initially longer, mine was 30mm) rests against the bracket in which the contact cylinders are located and thus you begin to press the entire construction with this bolt and one hand. Now we need to use a previously prepared blade to cut the threads that tighten the contact group; we no longer need them. Just now don’t try to release the pressure with your hand on the clamp, otherwise you will lose all the springs. This means that with one hand we press the top cover of the sensor through a bolt with a diameter of 2 mm. to the rotating beam, preventing cylindrical contacts and springs from jumping out of their positions. With your other hand, you begin to slowly unscrew the screw, simultaneously pressing the cover and pressing on the beam with the contacts so that they do not fall out. The whole thing is on your table. There is no photo of this moment because... I was alone and my hands were full.))) You will understand everything yourself, I’m sure. This may seem difficult, but I assure you it is not. With the help of this screw (GLORY TO JAPANESE DESIGNERS!!!) the halves of the sensor are easily reassembled. The main thing is to gently press to prevent the springs and cylinders from flying out and unscrew the 2mm diameter screw. from the cover, pressing at the same time with your hand, align the halves of the sensor housing. 10. HURRAY! Please accept my congratulations. Now it's a matter of small things. Using three pre-prepared bolts, nuts and washers, we tighten the housing of our automatic transmission mode switching sensor. The arrows indicate new bolted connections on the sensor body. After assembly and tightening with locknuts, check the movement of the entire mechanism. It should move freely without getting stuck. If it bites, try loosening the bolts a little. Arriving at work on the weekend, I put the sensor in place. I was terribly worried! But everything worked out for the best))) The engine started right away, modes switched without problems. Everything worked! HOW HAPPY I WAS!!! Finally, my dear and beloved Mazda and I will once again be scaring away budget cars on the track. It's such a thrill! However, I am a kind person and I don’t want to offend anyone. That's just how I drive! Fast. I love driving fast. And let it be known that in order for the engine to please you with excellent performance for a long time, feed it with good oil, change the spark plugs on time and, most importantly, try to drive at high speeds. Somewhere after 2500 engine revolutions, a favorable engine lubrication regime occurs, the optimal pressure in the lubrication system. And then your engine will cover hundreds of kilometers without repair. And on my speedometer there are already almost 400,000 roads and no major repairs have been done to it yet. However, the same as with the automatic transmission. I’ll tell you the results of using an additive with revitalizant in automatic transmissions next time. Good luck on the roads! And be careful...