A shock absorber is a damping device that is used on a car to effectively absorb shocks and shocks, dampen vibrations, etc. Also, the shock absorber (car strut) allows you to press the wheel to the road when driving on rough roads, thereby improving traction properties, increasing braking efficiency, vehicle stability, etc.

Today there are several types and types of shock absorbers, which differ not only depending on the axis on which they stand (front shock absorbers or rear shock absorbers), but also in design terms.

Next, we will look at what a shock absorber is and what a car's shock absorber is. So, within the framework of the article, a separate emphasis is placed on what types of shock absorbers there are on cars, types of struts, how they differ, and also the advantages and disadvantages of various types of struts, etc. are considered.

What it is?

A shock absorber in a car is a piece of equipment in the car. The element is designed to dampen the force of vibrations, shocks, or possible impacts of elements that differ in movement dynamics. The shock absorber helps keep the body of the car under control. If a shock absorber is installed in a car, the operation becomes smooth, uniform, and comfortable. Functioning is carried out by converting mechanical energy into thermal energy while the machine is running. Shock absorbers function in combination with other elements, such as springs or leaf springs.

The first hydraulic shock absorber appeared on the parts market in 1908; Louis Renault received a patent for its development. After 30 years, horizontal parts entered the market, the operating principle of which was to twist a spring.

Shock absorbers help the vehicle move smoothly without sudden movements. If you remove a part from the car, the movement will be similar to moving on a cart, that is, passengers will feel every bump and bump in the road surface.

The standard vehicle model comes with four shock absorbers to balance movements on all sides.

The car parts form a connection with the shock absorber elements and can perform the following fundamental options:

- stop vibrations in the area of the wheels and vehicle body;

- control of wheel contact with the support surface;

- the vehicle can move smoothly.

The principle of operation of the part is that the energy that occurs during fluid friction is converted into thermal energy. The rod moves in combination with the piston, causing oil to flow through specially designed holes. The work is designed to withstand resistance while moving. The rod can stop the shock absorber bump stop. The main stress goes to the apron of the part, so they are made stronger.

Purpose of the front pillars

Any type of elastic metal from which the spring is made, when exposed to one or another mechanical factor, forms automatic residual vibrations, which cause serious discomfort to passengers and the driver. It is to dampen such shaking and vibrations that the shock absorber was developed and is widely used. It can completely transform sharp shocks into almost imperceptible soft vibrations. Shock absorber struts play a major role in the structure of the entire vehicle suspension. Due to the relatively small size and ease of maintenance, the manufacturer produces structures at minimal cost. Due to their small dimensions, the racks take up minimal free space. Due to this, you can easily place additional levers and other structural elements that can make the trip as comfortable as possible. At the same time as increasing the level of comfort, the front shock absorber strut is designed to perform the following functions:

- maintaining vehicle weight;

- transfer of adhesion force with asphalt pavement to the body;

- maintaining the optimal position of the body in relation to the car wheels;

- eliminating excess roll;

- taking on serious lateral loads.

The price of the struts is an order of magnitude higher compared to the shock absorbers themselves. The reason is a more complex design, as well as the fact that high quality materials are used in production.

Device

The shock absorber is a coherent system in which each part provides the work of another element. The design of the equipment is related to the type of part.

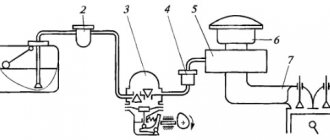

Two-pipe design:

- gas storage cavity;

- compensation cavity;

- capacity of the cylinder working area;

- valves (bottom and piston);

- cylinder;

- piston;

- stock;

- frame.

Elements of a part with one pipe:

- valve for performing compression;

- piston for separating the cavity;

- cavity for containing gas;

- release valve;

- piston;

- stock;

- container for storing liquid for work.

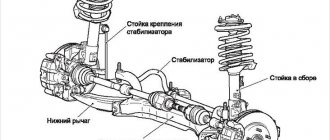

The options for attaching stabilizers to a car have not changed since the period of their introduction. The upper area of the part is attached to an area of the body or frame of the vehicle, the lower area is attached to a suspension part in the form of a lever or axle beam. Therefore, installing new equipment is not difficult; the task is to unscrew the lower bolt in turn, and then the upper one.

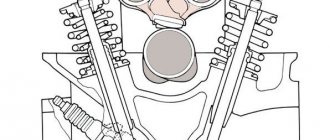

Monotube rack

The monotube type shock absorber differs from the previous version by valves built into the piston (De Carbon system). When using a hydropneumatic mixture, the gas is separated from the liquid by a floating piston. Cooling of this design is more efficient, however, the design of the valves becomes more complicated. In certain modifications, holes and grooves are used. A car using this shock absorber device holds the road more confidently. With the same dimensions, the single-pipe model has a larger working chamber volume. Gas separation by the piston allows any installation options (rod up/rod down). At the same time, the unsprung weight of the vehicle is reduced.

The disadvantages of such a stand are:

- vulnerability - the unit is sensitive to mechanical damage, any dent in the body guarantees the need for replacement

- intense heat transfer - single-tube struts are dependent on the ambient temperature, the characteristics change in different weather, the suspension becomes softer in cold weather, harder in hot weather

To improve the characteristics of the shock absorber, manufacturers use the displacement of the hydraulic and gas chambers outside the cylinder. Thus, without changing the dimensions, the volume of the working mixture increases, the dependence on the weather disappears, and the stroke of the rod increases. Compression valves installed in the oil passages allow you to change/adjust operating modes (speed, rod stroke length, stiffness).

Principle of operation

As the shock absorber smoothly compresses, the fluid under the piston flows from the cylinder area to an area where there is no high pressure. Part of the liquid lifts the bypass valve plate, and the second part is directed into the curtains through holes in the housing.

When the curtain feels a sharp pressure, the fluid pressure increases; after the valve opens, the spring compresses. The liquid passes to the top of the cylindrical system. The compression valve operates under the required resistance during sudden movement.

When the piston goes up, fluid passes into the piston and the holes of the throttle disc. The part remains free, where the liquid passes into the rod. At the same time, the intake valve plate rises, which is located with a weakened sprocket spring.

That is, when the vehicle hits an uneven surface, the pressure above the piston area increases. The liquid puts pressure on the discs and bends them, and the spring immediately bends, and the area for the passage of liquid increases. Hydraulic resistance dampens vibrations and ensures smooth running.

Shock Absorber Malfunctions: Signs and Symptoms, Check

Taking into account the above information, you can understand which shock absorber struts are best to choose in a particular case. Next, having decided on the type, you should select a manufacturer, study the catalog and buy shock absorbers from the available suitable options for replacement.

At the same time, not all drivers know exactly when it is necessary to change the car struts. You can hear from some car enthusiasts that the front shock absorber lasts 50-60 thousand km, while the rear shock absorber lasts up to 100 thousand km, a gas shock absorber lasts 30-50% longer than an oil shock absorber, etc.

In some cases, it is recommended to simply monitor the struts, pay attention to oil leaks, knocks, rocking and noise, while in others it is strongly recommended to visit a vibration stand or simply change shock absorbers based on mileage. Let's look at these questions in more detail.

First of all, there are several signs that indicate that the shock absorber struts have failed:

- rocking when driving even on a flat road;

- all irregularities are rigidly transmitted to the body, impacts are felt on the steering wheel;

- the car tilts when cornering and does not maintain its trajectory;

- knocking and extraneous noises appeared when driving in the area of the struts;

- decreased braking efficiency, pulls to one side or the other, etc.

Please note that this behavior of the car and the appearance of these signs is possible for other reasons. To accurately understand when shock absorbers are faulty or completely/partially out of order, you need to start with a visual inspection.

If drips are visible in relation to oil and gas-oil shock absorbers, this will indicate that the shock absorber is “sweating” or is completely leaking, the tightness is lost. If possible, to check the strut, it is better to remove it from the car and bleed it manually.

If this is not possible, just open the hood, rest against the pillar area and press the car body above the pillar as hard as possible, and then quickly release it.

In the case when the shock absorber is working (at least partially), the body will return to its initial position, and no more than one or two vibrations are allowed. If swaying (several vibrations) is noticeable, then the shock absorber does not perform its functions and the body swings on the springs.

In fact, oil leakage through the shock absorber seal, which manifests itself in the form of oil drips, indicates that the tightness in the area of the rod seal has been lost.

We also recommend reading the article about what a shock absorber support bearing is. From this article you will learn about the purpose of the strut support, as well as what signs indicate that the shock absorber support bearing has failed, how to replace the support bearing, etc.

This can happen as a result of damage to the shock absorber boot, after which dirt gets onto the rod. The rod itself may also be deformed after driving on bad roads, from impacts, etc.

In any case, even if the shock absorber is still working, it will not last long and you need to prepare for replacement, since there is a leak of gas and shock absorber fluid, and the damping properties of the shock absorber have noticeably deteriorated.

Note that in practice, front shock absorbers on domestic roads on middle-class cars usually last no more than 60-70 thousand km, after which their performance begins to deteriorate.

It happens that even if the struts are dry on runs of about 90-100 thousand km, their performance still remains no more than 30-40% by such mileage. As for the rear struts, they usually run 30-40 thousand km more than the front struts.

Types of shock absorbers

The level of smoothness and general condition when driving depends on the choice of a specific stabilizer. Before inspecting the model, you should take into account the parameters and technical specifications. Among the main models are:

- two-pipe oil.

- single-pipe gas.

- two-pipe gas.

- adjustable.

- sports.

- pneumatic.

Each part has design features and distinctive technical characteristics.

Double pipe oil

The kit includes two cylinders, which are placed one inside the other. The inner cylinder is filled with oil, and a piston is installed there, which combines the work with the suspension arm. The outer cylinder is filled with air, but only partially. Liquid is placed in the free area, which is displaced under the action of rod tension. Among the disadvantages is the possibility of overheating.

Single pipe gas

The stabilizer has only one cylinder. The cylinder acts as a housing to hold the rod and piston. To compensate for the volume of the rod, the model is equipped with a gas storage chamber. As a rule, the models are installed on racing car classes.

Two-pipe gas

Adjustable options are similar in design to two-pipe models, but the outer cylinder is filled not with air, but with gas, which is under pressure. The models operate with a high level of efficiency. Low cost is possible due to a simple assembly procedure. The models are not susceptible to high temperatures, and the shape is compact.

Adjustable

Adjustable ones come in two designs, but magnetorheological fluid is always used during operation. Models help evaluate coverage and select the mode required for operation.

Sports

Sports models are designed for driving in a sporty style. Sports models require high speeds over long distances. Stabilizers have a high level of rigidity. There is an immediate reaction when uneven road surfaces occur. Sports type options allow you to control the situation at high speeds.

Pneumatic

Pneumatic models include pneumatic cylinders in their design, that is, hard cushions made of rubber and plastic. Most often, such a system is used on trucks. Thanks to the model, drivers can notice the effectiveness of braking and improved braking performance. Thanks to the pneumatic system, the machine quickly reacts to unevenness on the road surface.

What is the front shock absorber strut made of?

Many drivers mistakenly draw a parallel between concepts such as a shock absorber strut and the shock absorber itself. Some of them believe that this is an ordinary spring, or call all the elements of this system assembled together a strut. To understand that this is a mistaken opinion, it is worth studying in more detail the question of what racks are, what

there are features of their device. A shock absorber strut is a component that is required to connect components such as the body and wheels of a vehicle. This support is connected to a spring and a damper, which, by the way, is the main component of the shock absorber. This design contains the following elements.

- Cylinders containing a piston and special hydraulic fluid.

- Hydraulic fluid, which can be presented in the form of a mixture of liquid and gas, as well as a certain mixture of gases. The composition is necessary to transfer forces between two types of shock absorbers.

- Stock. Designed to hold the piston on itself and is required to transmit serious pushing forces.

- A piston with a special bypass valve. It moves in the inside of the cylinder. Used for smooth transmission of vibrations.

- Seals, seal and high-quality sealant.

- An enclosure designed to house the various components of a rack inside.

- Fasteners necessary to connect the main parts of the shock absorber to the car body.

If you study the design of the elements, you can understand that the front shock absorber struts (AS) may or may not be equipped with springs. The choice of one or another option must be made based on the design features of the suspension and an acceptable budget. Like all car parts, front shock absorber struts wear out over time, break and become completely unusable. If this phenomenon is detected, the front strut shock absorber should be replaced as soon as possible.

How to choose shock absorbers?

When choosing stabilizers, you should take into account some technical characteristics of the car model and evaluate the properties of the element. Shock absorber evaluation criteria:

- View. The type can be gas or oil.

- Compliance with environmental requirements.

- Road surface assessment.

- Expert assessments.

- Own experience.

- Recommendations and reviews from car owners.

- Production.

- Price category.

- Driving style. For quiet driving, it is better to choose oil-based options, and for high-speed driving, models with high levels of rebound and compression forces are suitable.

- Set. There cannot be parts of different types on opposite axes, since the factor affects the controllability of the vehicle.

What is a shock absorber?

A shock absorber

is an element that dampens vibrations caused by forces acting on the vehicle and coming from two sources, such as the road surface (potholes and pits) and the movement of the vehicle (turning, braking, acceleration). This separation is important because essentially the two sources generate different vibrations. Driving on uneven roads creates vibration. It is a sudden force that is completely absorbed by the spring element and hence the wheels relative to the vehicle are calmed by the shock absorber. In professional jargon, we talk about the operation of a high-speed shock absorber. The point is to free the wheel as quickly as possible from the vibrations it causes after hitting a bump, in order to ensure the longest and strongest grip of the wheel with the ground.

The situation is different when the vehicle is performing maneuvers, especially one after another, or driving through a portion of the road with a long but smooth curve that reduces or increases the weight of the vehicle. Then it is not so much the wheel that vibrates, but the entire car. We are then talking about low shock absorber speed. As with bumps, spring elements also play a major role, and shock absorbers are designed to soften the movement of the entire vehicle in relation to the wheels.

To be clear, the two situations described above are not independent of each other and there is absolutely no boundary between them. It is very rare for a shock to only operate in the low or high speed range because one affects the other. When a car travels over a rough section of road, shock absorbers work primarily in the high speed range, but excessive bumps can cause the car to sway, which also means damping at low speeds.

The second important factor is damping force, which can also be called damping efficiency. This is the ability of a shock absorber to suppress vibrations as quickly as possible - whether from a car or a wheel. We often talk about the stiffness of a shock absorber, but in practice it’s all about the damping force, because it doesn’t have such a characteristic as stiffness, only springs do. The fact that when you push the car you can't rock it is not because of the stiffness, but because of the damping efficiency.

However, it is true that with shock absorbers with a higher damping force, the car feels stiff in certain situations because the shock absorber quickly calms body sway and causes the wheel to stick to the road, so you feel the bumps more. On the other hand, the lower the damping force, the higher the ride comfort. Then you feel a soft ride over bumps and rocking, which not everyone likes. However, everything comes at a price. The lower the damping force, the longer the oscillations last, the larger they are, and the successive factors causing these oscillations can cause them to exceed them.

For example, a car driving around an obstacle makes three opposite turns. This means that it swings in a different direction every time. If the shock absorbers have high damping force in the low-speed range, they will at least partially dampen the sway after the first turn, before the second, and then after the third. Shock absorbers with low damping force cannot do this, and after the second turn the car may sway so much that it will be difficult to complete the third maneuver. The same goes for high speed damping. After hitting a bump, the wheel vibrates, and if bumps occur one after another, each subsequent one causes the wheel to vibrate even more with a low damping force. After some time, the wheel may move completely uncontrollably in relation to the road and thus become off the road for too long, which can be dangerous if you need to perform any maneuver. What's more, it may be surprising that if you drive fast on a potholed road, you'll feel more comfortable with so-called firm dampers.

The best European models

The quality of assembly of shock absorbers made by Germans and Dutch is valued throughout the world. Despite the high prices of manufacturers, stabilizers are valued for their reliability and durability. Models are manufactured in accordance with established international standards. European models can act as replacements for the original options.

Bilstein

The company began producing parts in 1954. The device helps to increase the level of controllability and comfort when moving. The car moves smoothly, despite uneven road surfaces. Service life is long.

Advantages:

- The adjustment can be selected based on the quality of the road surface.

- Exchange rate stability is at a high level.

- Fits with standard springs.

- The suspension can be controlled electronically.

- The screw-shaped pendant can be customized.

Flaws:

- High price.

Koni

The company has developed more than 2.5 thousand models, so the vehicle owner can choose the option for himself. Models are equipped with color coding, which helps you choose an option for a specific car, technical conditions, and driving style.

Advantages:

- The progress is smooth.

- It demonstrates a high level of stability when cornering.

- Suitable for aggressive driving style.

- Statistical loads are not scary.

- High level of comfort.

- Stable handling.

Minuses:

- The rigidity is insufficient.

Boge

The company prioritizes the production of parts to ensure safety while driving on the road. The model range is wide, more than 4 thousand options. The models are easy to install and work for a long time. The Boge company produces shock absorbers for Audi, Mersedes, Renault, Volvo, and other well-known brands.

Pros:

- Welding of parts is carried out in a spot manner.

- The rod goes through the hardening stage.

- The oil operates in the range from -40 to +180 degrees Celsius.

- Duration of operation.

- Relatively low cost.

Minuses:

- In off-road conditions, oil-based options operate softly, which leads to a loss of shock-absorbing properties.

TRW

The company is focused on creating high quality equipment that meets the standards of original spare parts. Stabilizers provide a high level of performance.

Pros:

- Advanced appearance.

- Guaranteed safety while driving.

- Good car controllability.

- Works under any environmental conditions.

- Reliability of the design.

Minuses:

- After a run of 100 kilometers, knocking sounds can be heard.

Front strut replacement process

If the bearing, upper support and the entire strut as a complete assembly have already served their useful life, there is only one way out - replacing the front shock absorbers. This operation on the front of the car can be done with your own hands. If the left or right strut is worn out, both will need to be replaced at the same time. When making a replacement, you must rely on a special repair manual. Despite the fact that there are certain differences in the design of different car brands, the algorithm of action is similar in all cases. The sequence of manipulations here is as follows:

- Access to the upper support of the rack is freed. Here you will have to remove the engine compartment seal.

- The plug is removed and the fastening nut of the AC rod is unscrewed. You will need a head, as well as an extension with a knob. It is advisable to carry out this operation when the rack itself has not yet been dismantled.

- It is worth loosening the wheel fasteners, and then jacking up the car to such a position that the tires do not touch the ground. Here you definitely need to ensure that the jack does not fall off.

- The wheel is being removed. Using a metal brush, you need to clean all the structural elements located there. It is advisable to treat them with WD40 and wait for the composition to take effect.

- The fastening nut is unscrewed from the installed stabilizer joint (read what a front stabilizer link is). This must be done simultaneously with the brake hose screw. If the car has ABS, you will need to remove the tube with wiring from the sensor, which is located on the rack.

- After this, the fist fastener is unscrewed. Many experts knock out bolts with a simple hammer. It is worth knowing that some cars have separate bushings. After this manipulation, nothing holds the stand anymore.

- Now it's time to unscrew the nut holding the upper support to the body. The front shock absorber strut is removed simultaneously with the support and spring.

- You will need ties that are designed to remove the spring. Here you will need to get a gap between the cup and the outermost turn.

- Previously, the nut on the rod was already loosened, now it can be completely unscrewed. Only then will it be possible to remove the support and spring at the same time as the cup.

- If the bump stop along with the anthers are worn out, they must also be replaced.

- It is advisable to seriously pump new front struts beforehand. This process is carried out strictly in accordance with the manufacturer's instructions.

- It is necessary to replace the gaskets and seals, since the old seals will no longer fit.

- Reassembly is in progress.

If you follow these instructions, you can quickly replace the front struts with new ones, ensuring comfortable movement of the car and ensuring a high level of safety. The support will become strong, the suspension will stop swaying and negatively affect the overall operation of the vehicle.

Top Asian Models

Asian manufacturers have focused on reliability. As a rule, vehicle owners choose Japanese and Chinese manufacturers. Japanese manufacturers combine the reliability of the internal design with an affordable price.

Tokiko

The company's factories are located in America and Europe. The manufacturer makes the product to high quality standards. During production, parts are checked at all stages of production. In 2004, Russian car owners were able to pay attention to the elements after a confident entry into the market.

Pros:

- Shock absorbers undergo certification testing.

- The valves are designed to operate under all conditions.

- The piston mechanism has been improved.

- The settings can be changed to suit your needs.

- Suitable for installation on trucks and SUVs.

Minuses:

- The specified resource is not always processed.

Kayaba

The company represents products on the Russian market and gives a guarantee of reliability and quality in an official form. Most models belong to the mid-price category, which makes the models in demand among buyers.

Pros:

- The valve system has three levels.

- The rods are plated with chrome, which gives a high level of durability.

- The cylinders are made without seams.

- The hardness can be controlled.

- The price is democratic.

Minuses:

- Rigidity may be unnecessary.

Sensen

The Chinese company produces parts that fit the Kayaba analogue. Enterprises operate using innovative technologies. Assembly plants are located in Thailand, Taiwan, and Malaysia. During production, models are tested, so the product is certified. Stabilizers are suitable for passenger cars and medium-sized vehicles.

Pros:

- The rods are made of steel with a high carbon content.

- Models are equipped with seals.

- The shock absorbers are supplemented with corrosion protection.

- The bushings are covered with Teflon.

- Welding is completely robotic, so it is carried out without seams.

Minuses:

- I work accordingly only during the warranty period.

Miles

The board of directors is located in Belgium, but the factories are located in Asia. In production, the company uses innovative technologies, which provides high reliability of parts at reasonable prices.

Pros:

- The cylinder is made without seams.

- The valves are of the disc type.

- The oil goes through several stages of purification.

- Thanks to additive technology, models cannot foam and undergo aeration.

Minuses:

- Under severe conditions of use, the front shock absorbers may leak.

Patron

The company has more than 70 assembly plants on five continents. The company opens testing centers to test new equipment.

Pros:

- Prevention of foaming thanks to additive.

- Models can change the level of rigidity.

- Dampers can be installed in various positions.

- Equipped with a cooling system.

- Environmentally friendly use.

Minuses:

The warranty period is short.

- Hardness increases automatically at elevated temperature conditions.

Gas-hydraulic shock absorber

The design of this car shock absorber has slight differences from the previous version. Gas under high pressure is held inside by cuffs and gaskets. Instead of air, manufacturers use nitrogen or other inert gases. Racks of smaller diameter are filled with high pressure gas, and vice versa. In addition, the gas pressure of the car's shock absorber in the front and rear units is also different. On the classic VAZ, the springs are installed separately; on other models, the struts are assembled into one unit with an external spring location and a special fastening. In this case, the spring is not always the main element of the unit, but only duplicates the hydraulics.

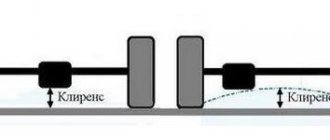

The height of the stand is adjustable with a nut, allowing you to change the vehicle's ground clearance. The following mounting of the car shock absorber to the body and suspension is possible:

- eye/eye

- pin/pin

- bottom eye/pin

- bottom crossbar/top pin

- plug-in shock absorber

The first three options are most often used, as they are the most convenient to install.

The best American models

American models do not take leading positions, but experts have a positive attitude towards the manufactured parts. The Tenneco Automotive Group corporation firmly took first place, taking control of the two largest production companies. When manufactured in American factories, assembly reliability is a priority. American models are distinguished by their versatility and practicality.

Monroe

The company has been in the automotive spare parts market for a long time, but every year it develops its technologies to meet modern standards. Developments are rapidly spreading around the world, due to the location of centers on all continents. The shock absorbers are equipped with electronically controlled suspension.

Pros:

- Practically no different from the original models.

- The valves are developed using an innovative system.

- Selection of elements for cars and SUVs.

- The suspension is equipped with an intelligent system.

Minuses:

- Overpriced.

Rancho

The company mainly focuses on producing parts for SUVs. Items are manufactured in the USA. A wide range of models allows you to find elements for both simple trucks and giants equipped in all plans. Stabilizers cannot be called cheap, but the level of reliability and durability is high.

Pros:

- The design consists of two circuits.

- The speed of the rod can be assessed thanks to sensors.

- Teflon covers all parts that are in motion.

- The system is protected against dust.

- The rigidity can be adjusted in 5 ways.

- The case has a protection system.

Delphi

The company produces shock absorbers in a wide range. Thanks to improved technology, the driver can notice ease while driving. During operation, the parts do not produce sounds. Users speak positively about the company's products.

Pros:

- There is no noise or vibration while driving.

- High level filtration.

- Environmentally friendly design.

- Long service life.

ACDelco

Shock absorbers help make the ride comfortable and smooth. The company produces stabilizers using cold rolling technology.

Pros:

- Chrome plated rod is included.

- The wiper can be changed.

- The piston valve is reliable.

- Equipped with a protective coating.

- Build quality extends service life.

Minuses:

- The warranty period may expire earlier.

The principle of operation of a car shock absorber

The principle of operation of a car shock absorber is as follows: a rod, which moves synchronously with the piston, directs the flow of oil and forces it to pass through small valves. This creates resistance to its movement.

The maximum stroke is limited by the bump stop. Most of the load while driving falls on the front shock absorbers of the car. Therefore, they are reinforced compared to the rear element. The design of a car suspension shock absorber is different and divided into:

- For lever elements that were popular in the 50-60s of the last century.

- Two-pipe. The most common option today.

- Single-pipe. They are just entering the automotive market and are not yet as in demand as two-pipe designs.

The operating principle of a car shock absorber can differ significantly in its characteristics. Therefore, when choosing an element, you need to understand in general terms what a shock absorber is on a car. How to attach a shock absorber and understand the types.

The choice is influenced not only by the characteristics of car coilovers. It is necessary to take into account the driving style of the car. Depreciation systems affect the vehicle's speed, acceleration and braking dynamics.

The photo shows a cross-section of the shock absorber. Here you can clearly see the “filling” of a single-pipe gas coilover and a double-pipe hydraulic design.

As you can see in the picture, the car’s twin-pipe shock absorber consists of:

- of two pillows located at the top and bottom points of the hydraulic element;

- oil seal;

- guide rod;

- piston rod;

- Shells (cases);

- tank body;

- working cylinder;

- working cavity;

- piston;

- bottom valve.

When considering the principle of operation of a car’s coilover, one cannot ignore the issue of aeration. Certain designs combine oil and compensation gas. When the ingredients are mixed, a foam-like consistency is obtained. Many people know that it is foam that can compress. Consequently, the damping efficiency is sharply reduced. The location of the automotive element plays an important role.

What intermediate conclusion can be drawn? A car coilover is a complex device where there are many layouts and design solutions for various engineering problems. The market offers us, motorists, a choice between single-pipe and double-pipe coilovers, which, in turn, are divided according to filling:

- For liquid ones.

- Hydraulic.

- Gas.

A separate niche is occupied by rarely seen coilovers that operate exclusively on high gas pressure.

Symptoms of a problem

Signs of system malfunction include:

- The vehicle drives rough and rough, or the steering wheel is in an unstable position.

- When braking or moving, the vehicle skids or tilts.

- In windy weather, you may notice vehicles skidding.

- Transport touches the road surface with the lower area.

- When accelerating, the car may sag.

- The vehicle does not enter neutral.

- Suspension parts have become loose.

- The rack supports are making unusual noise.

Why are there shock absorbers in a car?

At a time when cars reached speeds of no more than 30 km/h, there was no particular need for shock absorbers. But when the speed began to increase, it became clear that driving a car without a device that would dampen road unevenness and body sway was simply unsafe and, moreover, not comfortable.

This is how shock absorbers were developed. The first options were a rubber hose twisted into a spiral, then dry friction discs appeared (the prototype of today's springs).

But the pinnacle of high-quality shock absorption was the piston oil mechanisms developed in the 50s, which ideally contribute to a smooth ride, vibration damping and constant wheel contact.

Principle of operation

It is the last option that is most interesting, since most modern shock absorbers are developed on their basis.

Life time

Shock absorber life depends on road surface conditions, operating characteristics, and environmental conditions. In Russia, stabilizers should be changed every 60-70 thousand kilometers, but an inspection should be carried out every 20 thousand. When the warranty period ends, car owners must undergo a technical inspection. When parts go out of service, they require replacement. Improper use will lead to accidents on the road.

The choice of shock absorber depends on several factors. For example, operating conditions or driving style. If controllability is important, then you should pay attention to single-pipe gas devices, if comfort is important - oil ones.

Hydraulic shock absorber

Despite the simple design of the shock absorber, it can change its characteristics due to additional built-in components. Each brand of car has individual characteristics, therefore, the racks must take into account vibration amplitudes, driving modes, and driving style. With the valves closed and fluid moving through the bypass channel, an absolutely rigid system is obtained. The open valve of the compensation chamber adds “flexibility” to the system. Different sections of the intake and exhaust valves create an asymmetrical system. Center valves on the piston create a non-linear "soft" strut system.

Operating principle of oil shock absorbers

Oil shock absorbers appeared earlier than others. Photo: ffocus-help.ru

The operating principle is quite simple. A rod with a piston moves in the working cylinder, which is filled with special oil. The piston has clearly calibrated valves. With their help, oil is distilled from one part of the shock absorber to another. Moreover, the valves that open to reach out have a smaller diameter than the others. Due to this, the speed of liquid transfer is limited and a large energy consumption occurs.

Main elements of an oil shock absorber:

- Working cylinder;

- Stock;

- Piston;

- valves;

- Separating piston;

- Oil.

Oil shock absorbers have a large number of advantages:

- High strength and reliability;

- Excellent characteristics;

- Ease of manufacture;

- Possibility of repair;

- Low cost.

With very strong differences in operating conditions, the stiffness of the shock absorber changes greatly. This is due to changes in oil viscosity. The higher the temperature, the lower the oil viscosity, and breakdowns and oil leaks are possible. And vice versa. In winter, the oil viscosity is high and the shock absorbers do not press through potholes. All this affects ride comfort and handling quality.

Main Differences

Oil and gas shock absorbers differ from each other in their design features. To determine the type of system installed in the car, it is necessary to remove it and evaluate the behavior of the piston rod. Gas-based models do not have a compensation tank, and in the event of compression, the pressure increases, so the rod moves towards the working chamber. When the shock absorber is released, a rebound effect occurs, causing the piston to move upward. This causes oil pressure to increase and fluid to return to the valves and passages.

The oil mechanisms are of a 2-pipe design. When compressed, oil begins to flow into the reservoir above the piston, so the amount of space in the cylinder is limited. During rebound, the piston rod is pushed out of the cylinder, and the pressure above the piston rapidly increases. The substance contained in the expansion tank begins to flow, maintaining the normal volume of the rod.

Therefore, the key difference between the 2 types is the compensation chamber design. In oil devices it is in the open state, and in gas devices it is closed.

The merits of each

Oil units are characterized by a long service life, which is explained by their simple design. The likelihood of system failure without compelling reasons is minimal. But experts note that such dampers lose their effectiveness over time due to rapid foaming of the oil mixture. The problem is aggravated when driving at high speed or frequently operating the car on uneven surfaces.

Gas analogues help improve wheel traction with the road surface, providing good controllability and speed gain. Due to these qualities, the system is actively used in racing cars. But due to the complexity of the design, the frequency of malfunctions becomes higher.

Disadvantages of each

Oil shock absorbers have the following disadvantages:

- Increased weight.

- Insufficiently fast response to bumps.

- Reduced tire grip.

- Weak damping characteristics, especially on the rear pillars.

- The likelihood of changes in oil properties due to temperature exposure.

Gas dampers are much more expensive, have a complex design and are vulnerable to negative influences. You shouldn't expect the most comfortable ride from them.

Resource and cost of gas and oil shock absorbers

As for the price, gas shock absorbers are about 20% more expensive than oil shock absorbers. This difference in price is due to the fact that gas shock absorbers have a more complex design and, therefore, are more difficult to manufacture.

Differences between gas, gas-oil and oil shock absorbers - Video

How to replace shock absorbers

Replacing shock absorbers is carried out in the following sequence.

- Raise the car on a lift. If it is raised with the help of jacks, then when changing the front shock absorbers, the car must be put on the handbrake, and when installing the rear ones, the gear must be engaged (in rear-wheel drive cars, the front wheels must be blocked in a different way, for example, using wheel chocks).

- Unscrew the fastening on the steering knuckle.

- When replacing the front struts, the steering tip is removed.

- Unscrew the rod mount on the support bearing.

The rack is installed in the reverse order.

Recommendations from professionals:

- Before installing a new strut (applies to a two-pipe modification), the shock absorber must be pumped so that the air leaves the working cylinder. If this is not done, then “dips” of the piston will appear while driving. Pumping is carried out as follows: the shock absorber, turned upside down, is smoothly compressed, fixed for 2-3 seconds, in this state it is turned over and after 3-5 seconds. release smoothly. Then the rack is turned over with the rod down, wait a couple of seconds, and repeat the procedure three or four times. After bleeding, the shock absorber should be stored in a vertical position, just as it will be installed on the car.

- Do not use a pneumatic impact wrench to tighten the rod mount. Because of this, the rod may turn and damage the seal. If this does not happen, over-tightening will create tension in the shock absorber rod, due to which it may break over a large bump.

- It is strictly forbidden to fix the rod with pliers or other clamping tools. This will damage the rod mirror. To fix it, use a special key.

- Before final tightening of the rod nut, the vehicle must be lowered from the lift or jack. This way the rod will be twisted evenly and will not break or break the silent block while driving.

Motorists disagree about the comprehensive replacement of shock absorbers. Some believe that all the racks need to be changed at once, while others are sure that replacing the damaged part is enough.

Although each motorist decides for himself how to repair his car, experts insist on pair replacement - even if one is faulty, then replace both on the side (either front or rear). Due to fatigue wear, old parts combined with new ones can significantly reduce the efficiency of the entire assembly. In any case, remember: one faulty part can negatively affect other important suspension or chassis components.

When to change

Here are the cases in which it is definitely necessary to change the racks:

- as a result of a visual inspection, traces of liquid leakage were revealed on the body;

- deformation of the rack body;

- The stiffness of the suspension has increased - noticeable impacts to the body occur on potholes;

- the car sagged noticeably (most often one shock absorber fails, so the car will sag on the corresponding side).

If a knocking sound occurs in the suspension, you should immediately contact a service station. Such changes in the car cannot be ignored, because the safety of not only the owner of the damaged car, but also other road users depends on them.