DRIVING DIRECTIONS

+7-916-119-99-08

The PARKMOTORS company sells from a warehouse in Moscow Gazelle (gas distribution mechanism) “ Ideal phase ” for engines ZMZ-405, ZMZ-406 and ZMZ-409 of environmental class Euro-2 and Euro-3. A special feature of these timing belts is the presence of split camshaft sprockets. We also have timing cover 406-405 406.1002058-10 in our warehouse

Particular attention should be paid to the length of the timing chains. For engines ZMZ-405 and ZMZ-409, chains with a number of links of 72 and 92 links are used, respectively. For ZMZ-406 series engines, chains of 70 and 90 links are used, respectively.

The Euro-3 timing drive repair kit is completely interchangeable with the standard timing drive for ZMZ engines manufactured before 2008, Euro-2 standard!

Timing kit Gazelle ZMZ 406, ZMZ 405.

Timing belt ZMZ 406 . Timing belt ZMZ 405 .

A set of parts for routine repairs of the gas distribution drive mechanism of the ZMZ-406, ZMZ-405, ZMZ-409 “Professional Series” engines produced by OJSC ZMZ of EURO-2, EURO-3, EURO-4 standards.

Price 5000 rub.

Replacement of chains and gears of the gas distribution mechanism ZMZ-406

You will need: a 6-point hex key,

12-point, 13-point, 14-point sockets, a small chisel, and a hammer.

Drain the oil and coolant from the engine, remove the splash guard and the auxiliary drive belt.

We remove the radiator, fan, coolant pump and generator.

Remove the crankshaft pulley.

The block cover can be removed without removing the head.

But in this case, damage to the head gasket is possible, since during assembly, adhesive sealant was applied to the upper end of the cylinder block cover. In addition, the head interferes with the installation of the cover - it is difficult to achieve accurate alignment of the cuff on the crankshaft bushing, which will lead to its rapid wear.

Therefore, when disassembling the gas distribution mechanism drive, we remove the cylinder head (see Replacing the cylinder head gasket of the ZMZ-405, ZMZ-406 engine).

Using a 14mm socket, unscrew the four bolts securing the clutch housing amplifier to the block.

Using keys “14” and “17”, unscrew the two bolts securing the amplifier to the clutch housing and remove the amplifier.

Using a “13” socket, unscrew the four nuts and with a “12” wrench, the eleven bolts securing the oil pan to the cylinder block.

Carefully, trying not to damage the gasket, remove the pallet from the studs and place it on the beam.

Using a 6-point hex key, unscrew the seven screws securing the cylinder block cover.

Using a screwdriver, remove the cover.

Using a 6-point hex wrench, unscrew the axis of the upper chain hydraulic tensioner shoe.

Remove the tensioner shoe.

Remove the upper chain from the intermediate shaft sprocket.

If necessary, use a 14mm wrench to unscrew the shoe axle extension.

Using a 6-point hex wrench, unscrew the axis of the lower hydraulic tensioner shoe and remove the shoe.

Use a chisel to bend the edges of the locking plate.

Using a screwdriver, holding the intermediate shaft sprocket, use a 12mm wrench to unscrew the two bolts.

Remove the sprocket along with the lower chain from the intermediate shaft axis.

Using a 6-point hex wrench, unscrew the two screws and remove the lower chain guide.

We carry out assembly in reverse order.

Before assembling the gas distribution mechanism drive, we clean the mating surfaces of the cylinder block and chain cover from gasket and sealant residues.

Installation

If the crankshaft gear was removed, press it onto the crankshaft, install the O-ring and bushing.

Install key 1 into the groove on the crankshaft.

Rotate the crankshaft so that mark 3 on the crankshaft gear coincides with mark 2 on the cylinder block. In this case, the piston of the 1st cylinder will take the TDC position.

Install the chain guide 4, but do not tighten the tensioner mounting bolts 5.

Place chain 6 on the crankshaft gear, having previously lubricated it with engine oil.

Place the chain on the driven gear 1 and install it on the intermediate shaft 2 so that the wheel alignment pin fits into the hole

intermediate shaft. In this case, mark 4 on the gear wheel must coincide with mark 5 on the cylinder block, and the chain branch passing through damper 3 must be tensioned.

Install the drive gear of the intermediate shaft so that its alignment pin fits into the hole on the driven gear.

Tighten the two bolts securing the intermediate shaft gears, placing a locking plate under them.

Timing Gazelle. LLC NPP "Lux Service" Euro-3.

timing belt ZMZ , timing belt 406 , timing belt 405 , timing belt ZMZ 406 , timing belt gazelle ,

Completeness:

- Crankshaft sprocket marked 23 teeth - 1 pc.

- Intermediate shaft drive chain 72 links - 1 pc.

- Intermediate shaft drive chain damper L=196 mm - 1 pc.

- Hydromechanical chain tensioner L*=17 mm - 2 pcs.

- Chain tensioner lever with sprocket on bearing 17 teeth - 2 pcs.

- Intermediate shaft driven sprocket with mark 38 teeth - 1 pc.

- Intermediate shaft drive sprocket with pin 19 teeth - 1 pc.

- Camshaft drive chain 92 links - 1 pc.

- Camshaft drive chain damper, middle L=127 mm - 1 pc.

- Upper camshaft drive chain stabilizer L=113 mm - 1 pc.

- Camshaft sprocket marked 23 teeth - 2 pcs. Set of insulating gaskets: a) intermediate shaft locking plate b) noise-insulating gasket for hydraulic tensioner c) gasket for hydraulic tensioner cover d) left chain cover gasket e) right chain cover gasket f) front cover gasket

Price 5000 rub.

Where is the chain located

Getting to the timing chain is not so easy. A complete disassembly of the engine will be required. And this is a serious process. If the car owner does not understand the design of the timing belt, it is recommended to contact a service center. Let's take a look at the timing belt layout.

The belt itself is installed on the crankshaft and camshaft. When the pulley rotates, the rotation is then transmitted to the camshafts. And the tension is adjusted thanks to a damper inside the unit.

Similar article Markers for setting the ignition on the 405 ZMZ timing engine

If the operation of the damper is disrupted, the device is faulty, then the belt can jump from one to three or four teeth. The operation of the engine will be unstable, and wear on the unit will increase with every kilometer.

Timing Gazelle. LLC STC "SET"

timing belt ZMZ , timing belt 406 , timing belt 405 , timing belt ZMZ 406 , timing belt gazelle ,

Contents: 1. Tensioner 406.1006000-SET (with plain or rolling bearing) - 2 pcs. 2. Timing chain Gazelle I stage 432-1006040 — 1 pc. 3. Timing chain Gazelle II stage 432-1006040-01- 1 pc. 4. Hydraulic tensioner 406.1006100-SET - 2 pcs. 5. Tensioner mounting bolt (406.1006098-10) - 2 pcs. 6. Tensioner mounting bolt extension (406.1006099) - 2 pcs. 7. Passport 406.1006000 Purpose: The tensioner is designed to work as part of the distribution mechanism drive instead of the standard chain tensioner shoe (406.1006090-11).

gas distribution mechanism gazelle

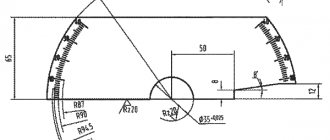

Diagram of the camshaft drive (timing mechanism, gas distribution mechanism) with a tensioner lever for engines of the ZMZ-406.10 family

Technical characteristics of the tensioner (timing gear for Gazelle). A set of parts for the gas distribution mechanism (TIM) drive of engines of the ZMZ-406.10 family on the Gazelle (see Figure 1), produced by , includes: - two chains of 90 and 70 links, or 92 and 72 links (manufacturer Daugavpils Drive Chain Plant, commissioned by LLC "STC "SET"); - two hydraulic tensioners manufactured by STC SET LLC; - two tensioning devices, which consist of a lever and an asterisk and are installed instead of shoes, manufactured by STC SET LLC; - two bolts for fastening the upper and lower tension devices, a bolt extension, manufactured by STC SET LLC; Tensioner, i.e. lever and sprocket are available in various versions: - steel lever and sprocket on a rolling bearing; -lever made of aviation aluminum alloy and steel sprocket on a bronze-graphite bushing.

Timing belt ZMZ 406, situation

I have changed several dozen timing belts on these engines with my own hands and have a fairly good idea of the situation in my region (St. Petersburg and the surrounding area). What clients brought in “factory boxes” or with magical names of double and tenfold resource, I, of course, installed, but I took a receipt from people in which I warned that I did not like the quality, even visually. Very often they brought kits. But they have their own problem. Almost every set was individual. There were no identical sets. Either different manufacturers of chains, or not the same gears that were “yesterday”. Accordingly, quality floats like a “violet in an ice hole.” Rusmash produces good kits, but they do not make adjustable stars. The best, in my opinion, are the Rhodes-M kits (Medvedev I.A.), but unfortunately they are poorly available for logistical reasons. Today there is, and then for a couple of months there may be a failure in delivery. Sometimes more. Based on these reasons, it was decided to assemble a kit for clients and services, which can be given a decent guarantee, and most importantly, meets modern technical requirements. And I also tried to implement what was asked from all over Russia. The kit should include EVERYTHING that may be needed for replacement, including a cuff, gaskets, half-rings, and you can even additionally order a chemical kit for installation .

That is, to carry out a major overhaul of the gas distribution mechanism and forget about it for a very long time.

Replacing the timing chain of a gazelle 405 engine

As already mentioned, timing marks are set after the timing chain is replaced. Typically, engines are equipped with a chain with a lifespan of up to 150 thousand kilometers. However, during operation this resource may decrease.

For example, when operating a motor under extreme conditions, the chain stretches faster, as it almost wears out. In addition, belts from different manufacturers may vary in the number of kilometers they can travel before the chain breaks or stretches.

Attention! The chain must be monitored. Every forty thousand kilometers, the car owner must check the tension of the device and inspect for chips and damage. If any are found, it is advisable to replace them.

Why does the timing chain fail?

The timing belt can quickly fail because it was purchased on a regular market where you were sold a fake. Original devices are sold only in specialized car markets. Such a chain costs from six thousand rubles.

Most often, the chain fails due to improper engine care. The device may also reach the end of its lifespan. By this time it has stretched and become useless.

The timing chain number for the ZMZ 405 engine is 040900100011800. The device is double-row. There are several ways in which you can distinguish a fake from the original. I'll tell you about them:

- no hologram on the chain;

- the letters written on the device packaging are not readable or are read with great difficulty;

- the box in which the chain lies is made poorly - there are places where glue is visible, the sticker is glued incorrectly or upside down;

- The print itself is hard to read.

If you have not found the problems described above, then you can safely buy a chain.

Replacing a 405 gazelle chain: how to determine the need

The chain needs to be replaced when you find chips or cracks on it. When the device is stretched, it is also advisable to change it as soon as possible on the ZMZ 405 engine.

Knocks and noises while idling will also tell the owner that it is time to change the timing chain. This is also evidenced by the unstable operation of the power unit.

The main thing is not to forget about setting the timing marks. Since they play a major role in the operation of the engine. Without them, the phase distribution cannot be normal. This means the motor may not work correctly.

How to replace the timing belt Gazelle 405

To replace the timing chain, the car owner will need the following materials and tools: