What is an air filter for?

The engine air filter is a structural element of the engine power system, which is responsible for filtering the incoming air into the combustion chambers. As you know, not a single internal combustion power unit can function without air, which enters through the throttle (in new cars) or through the intake manifold (carburetor-type engines).

The filter element is designed to filter the incoming air into the combustion chamber. This oxygen must be clean, free of dust and dirt. It is this part that is responsible for ensuring that the air entering the engine is clean.

Historically, there are different types of filters, which will be described below. They all have a different design, but their purpose remains the same.

Types of car air filters

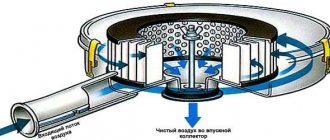

Automotive air filters come in a wide variety of types and compositions. Round filters are usually installed in cars with carburetor-type engines. They consist of a seal, a tube, and filter paper. The air passes through a round filter and enters the engine. Pre-cleaners can also be installed - additional partitions.

Panel-type automobile air filters are found in cars with injection-type engines. Such filters clean the air well due to their design. These are the most common filters because they have a flat design, which is much more convenient than a round one. This air filter has a more complex manufacturing technology, but has an increased service life.

Air filters in a plastic case . In such filters, synthetic non-woven material is used as a filter element. In terms of its filtering characteristics, it does not differ from filter paper. This material is not afraid of moisture, and is many times stronger than paper. By the way, the Russian manufacturer NORDFIL specializes in the production of such filters. Watch a video of how they are made.

Filters made of non-woven material . Such filters are created using the so-called hot pressing method. They use synthetic non-woven material as a filter element and housing, which is given the required shape using special equipment.

Automotive air filters for trucks have a larger volume because more air is consumed.

New filter models consist of a tube, a seal, adhesive seams, a shell and filter paper.

The task of an automobile air filter is to protect the engine from abrasive dust particles .

The consumable material reduces noise, increases the uniformity of air flow, and also reduces the likelihood of water getting into the cylinder-piston system.

Design features

Most air filters consist of three elements: a housing, a filter membrane and a rubber seal, which is located along the contour to prevent dust and dirt from passing between the housing and the filter element itself. The filter is placed in a special housing, which has an inlet for air intake and an outlet that leads to the combustion chambers.

Depending on the design of the car and the manufacturer, the filter housing may have different dimensions, location, and location of structural elements. There are mainly round and rectangular housings and filters themselves.

From paper

This is the most common type of air filter and the material from which it is made, used for almost all production cars off the assembly line.

See also: How does a particulate filter work?

The "paper" you use is slightly different from the material you put into your printer. Rather, it is highly compacted wood pulp made from large fractions. It is glued together with a special glue to create a single strong but flexible material and then folded into an accordion to increase the contact surface area. The sides of the rectangular structure are sealed with foam.

It's cheap and effective, which is why the use of such filters is so widespread.

However, over time, dirt will begin to lodge in the folds of the material, restricting air flow. With this in mind, it will eventually need to be replaced with a fresh one. Exactly when the replacement will need to be made will vary depending on the conditions in which you drive the car. The typical life cycle of a filter in urban environments is from 10 to 30 thousand km . By time: a year - maximum two.

Types of Air Filters

Air filters are divided according to the composition of the filter membrane. There are several options for making filter “fabric”:

- Paper. Quite common on old cars of domestic and foreign production. This type can be found on old Zhiguli and Volga cars. It was considered quite effective until the mid-90s of the 20th century.

- Cotton. It began to gain popularity among car manufacturers in the 90s. It replaced paper because it could easily let air through even when clogged.

- Fibrous type. One of the most common options because it perfectly filters polluted air. Of course, there is a limit to everything, so you should adhere to the fact that filters must be changed in due time.

- Carbon filters. They have become quite common recently, because in addition to filtration, they also saturate the engine with the necessary oxygen. Also, they filter not only dust and dirt, but also gases with which the air is saturated.

The Importance of Air Filter Maintenance

The dustiness of roads only increases with the number of vehicles, and modern engines are quite demanding in terms of operating conditions. An old or dirty filter will increase resistance, which will negatively affect engine performance. Moreover, the diesel air filter is the most demanding in terms of such indicators. The consequence of a clogged air purification device can be increased fuel consumption and loss of power when engine speed increases. In this case, the air filter unit must be urgently replaced to avoid more serious malfunctions.

Source

Principles of replacing the air filter

Replacing the engine air filter is a fairly simple process. As practice shows, most motorists try to perform this procedure on their own, without resorting to the help of a car service.

Many motorists ask the question: how often does it need to change the engine air filter? The answer is quite simple: according to the technical documentation of the car, as well as the recommendations of the manufacturer. As a rule, the period for replacing an engine air filter is 15-20 thousand kilometers.

So, how to actually change the air filter:

- Remove the top cover.

- We take out the filter.

- We install a new filter element.

- We close the case.

Based on the short replacement instructions, you can understand that replacing the air filter is a simple process that will not take much time.

Engine air filter, operating principle, types, purpose

Today we will learn what is called a car air filter

,

why it is needed

,

what functions

and

tasks

it performs, and also

when

it is necessary

to replace

this important

consumable element of an

internal combustion engine.

In addition, we will tell you about the basic principle of operation

of this part and

why

it was

invented

by automakers.

In conclusion, we will determine which type of air filter

does a better job of

cleaning the incoming air

into

the engine injection system

and has a

longer service life

compared

to

others.

Air filter

- is a simple, but quite important

consumable component of an

internal combustion engine, which

protects the key

components

of the engine from the penetration

of

dust

,

stones

,

dirt

,

insects

and other

debris

that can

harm the stable operation

of the main

components

of the car.

Please note that you should not neglect replacing the air filter ,

but

maintain

this important

consumable item

in accordance with the manufacturer’s regulations and recommendations.

To understand what tasks performs

and

what role it plays

for

the engine,

you need to understand how it

functions

.

We will examine this question in our story so that we have a detailed understanding of this key consumable part

of any car.

Why does a car need an air filter?

Let's note interesting statistics: on average, a vehicle absorbs from 10 to 15 cubic meters of atmospheric air

.

If the consumed air is not cleaned

the pollen

,

dirt

and other

debris

contained in it enters directly into

the engine system

.

And what does this lead to, we hope everyone understands for themselves that it does not lead to anything good. The engine

dirt into it, deteriorates

its

performance

and in the end it will simply have to undergo

premature

, expensive

repairs

.

In connection with this, a consumable device

called

an air filter

, which serves

to protect engine systems

from such troubles.

This part

not only performs

the function of protecting the engine from sources of pollution

, but also ensures

the task of reducing noise

that spreads through

the intake system

of the machine.

In addition, in gasoline engines

,

the air filter

also plays the role of

a temperature regulator of the fuel-combustible mixture

.

That is why the role of

this important

consumable element of

a vehicle engine is simply invaluable.

When in the air filter

begins to

become clogged

,

air flow resistance

increases and

the amount of air

that enters

engine system

.

In some cases or modes, this situation leads to an enrichment of the fuel-air mixture

, consequently to its

incomplete combustion

in the working areas

of the cylinders

, resulting in

an increase in fuel consumption

and

a decrease in engine power

, as well as

an increase in the concentration of toxic elements

in

the exhaust gases of

the vehicle .

Types and types of air filters

Today, filter consumables

are produced

in 3 main structural types

or

shapes

, such as:

panel

,

frameless

and

cylindrical

.

The type

or

shape of the air filter

does not greatly affect

the efficiency of the consumable part

relative to

the engine systems of

the vehicle.

The main relation to the effectiveness

of a given

part

relates to its

type

, or more precisely,

what the engine filtration element is made of

.

These features

are directly related to

the operation of air filters

.

The most common type of material

from which

modern

air filters

are made is

cardboard

.

Cardboard

is the most common and

cheapest raw material

for the production of these

consumable elements of

a vehicle engine system.

The next type of material

from which

replacement motor elements

is

synthetic fibers

.

This material is more expensive to produce than cardboard

, but slightly more

efficient than

its

competitor .

However, the operation of air filters

made of

synthetic fibers

requires more strict

adherence to replacement intervals

.

Quite often at sports

cars install

air filters made of gauze

, which includes about

5-7 layers

of this material.

In addition, the gauze is impregnated

a special

oil

, which promotes

effective filtration of sucked in atmospheric air

from the environment.

Compared _

with

cardboard filters

, in

gauze

,

the initial air resistance parameter

is much less.

The main advantage of gauze air filters

over

cardboard

and

synthetic fiber

is that after

special oil treatment

they can be reused

up

to

3-4 times

.

We recommend: Why and how often do we change brake fluid?

When to replace the air filter

To understand when to replace the air filter

in a car, the driver

does not have to

strictly

adhere to

certain

regulations

in order to make sure that

a consumable element

needs to be

updated

, you can simply

visually inspect

this

consumable

element.

To do this, you just need to remove the air filter element from the protective box

and

inspect

it in daylight.

If upon inspection

it is

clean

,

without darkening

or

stains

, especially

oil stains

, then you can drive it further without any problems.

If the air filter is dirty

,

clogged

or

in engine oil

, then this tells us that

the consumable element

must be urgently

replaced with a new one

.

Every driver can easily distinguish a clean air filter

from

a dirty

(

clogged

) one.

Typically, the time to replace the air filter is

First of all,

it depends

on

regulations

.

On average, the replacement interval for the consumable element of the engine filtration system

is

from 15 to 30 thousand kilometers

or once a year.

Before replacing the filter element

we recommend that you look at

the technical documentation

of the vehicle, where

the intervals

and

exact date for replacing

the part will be clearly indicated.

If technical documentation

or

manual

for the car, then you can simply use

the method of visual inspection of the filter element

.

This method

will help when we remember

when the current air filter was replaced

.

Based on recommendations

Most vehicle repair and maintenance specialists

replace the air filter

along with

changing the engine oil

, which, as a rule, is done approximately every

10-15 thousand kilometers

.

We also note that if after a visual inspection of the filter element

we have no questions about its condition, then

replace the consumable part

every other time.

This point directly depends on the specific conditions

in which

is used

or

operated

.

However, in most cases, the air filter is changed annually

or every

10-15 thousand kilometers

.

Regarding diesel engines

, and especially with

a turbocharging system

,

much more

stringent requirements

cleaning

entering

the engine than for

gasoline internal combustion engines

.

Many car enthusiasts will ask the question: “What could this be connected with?” The fact is that this is primarily due to the operating features of diesel engines

.

,

for diesel

cars, and especially with

a turbine

,

the period for replacing the air filter

should be reduced

to 10 thousand kilometers or once a year

.

Replacing the air filter in advance

is the key to maintaining

the reliability

and

service life of the main components of

a vehicle’s engine, without causing problems associated with

premature repairs

.

The fact is that a clogged filter element

cannot

clear the dust

and

dirt

that comes from the road into the engine; on the contrary, they

complicate the functioning of the engine

.

Therefore, there is no need to save on replacing the air filter

, because its

cost

is not comparable to possible

engine repairs

.

In addition, we note that it is strictly forbidden to operate

the vehicle

without a filter element

, as this may subsequently lead to costly

engine repairs

.

Filters for sports cars

Everyone knows that old American sports cars are structurally different from other cars. But not everyone knows that they have open-type air filters. This is due to the fact that the engine must breathe a large amount of air.

On some older muscle cars, the air filter element does not have an outer housing, but only has an upper and lower plate that cover the filter. With such power and torque, a large amount of air is needed. It was these filters that could provide the required amount of oxygen for the formation of an air-fuel mixture.

Topic 11. AIR FILTERS DESIGN

Currently, the following designs of air purification filters are widely used.

Air pre-purification filters . These filters are installed on the suction line in front of the compressor or pipe blower. With the inertial deposition method, the air is cleaned of particles larger than 5 microns at a filtration speed of 1.5-3.0 m/s. To prevent dry particles from being carried out of the filters, its filter layers must be oiled. Filters of this class are called oil or viscine. Periodic filters are divided into regenerable cassette, oil and dry type filters. Continuous type filters are divided into self-cleaning oil filters and those with continuous regeneration in an oil bath, and roll and fiber filters.

Fine filters (head). The head filter is designed to capture the bulk of contaminants that enter the system after air passes through the pre-cleaning filter of a compressor or turbo blower

In the domestic industry, until the 80s, to sterilize process air, depth filters were mainly used, which are a container with two perforated gratings reinforced inside, between which there are filter materials.

The first domestic filters with a ready-made filter element were filters using FP material (Petryanov fabric). These filters used filter elements with a capacity of 60 - 1000 m7h. The filter elements are presented in the form of corrugated cylindrical cartridges, in which corrugated plates were placed between the folds of the filter material. The material along the perimeter of the element was secured in the upper and lower parts of the cylinder with ties. The disadvantages of the filter were: the inability to sterilize the filter with live steam in the production line; the presence of individual parts in the element that complicate its inspection and sealing; lack of mechanical strength of the filter fabric itself. The advantage of the FP filter material in filter elements is its high efficiency (more than 99.999%) for particles with a diameter of 0.3 microns with low resistance to air flow (0.1 MPa at a filtration speed of 0.05 m/s).

Fine air filters (individual). There is a wide variety of designs of fine filters, which are mainly a cylindrical type device with air input through the upper fitting. To distribute it more evenly over the surface of the filter material, a grid is welded to the body. Air is exhausted through the lower fitting. For bioreactors of small capacity up to 10 m3, conical filters are widely used.

The operation of these filters must be especially reliable, because purification stage before air enters the bioreactor.

A promising filter material is also a porous material made from fluoroplastic powder (by sintering).

To ensure the required efficiency of fluoroplastic materials in the form of plates, their thickness should be 4 mm. They have high porosity and a high specific productivity of 60 m3/h for small elements and 250 m3/h for large ones. Filter design

using fluoroplastic filter materials, depending on their shape, they can be in the form of disks or bushings. For discs or plates, a filter design similar to that of the Eikoh filter is recommended.

The service life of filter elements made of fluoroplastic reaches 12 months.

Modern developments in the field of process air sterilization have been aimed at using metal-ceramic materials in filters, i.e. rigid porous metal partitions. Metal-ceramic materials are made from calibrated metal powders by sintering, pressing, and rolling. The pore size in products varies from 2 to 1000 microns. For the manufacture of metal-ceramic filter elements, bronze, nickel, stainless steel, and titanium are used.

A diagram of the deposition mechanism during air filtration through metal- and metal-ceramic filter elements is shown in Fig. 6.6.

For the manufacture of a metal element, the finest-grained powder is selected so that, with a sufficient length of the filter wall, the number of expansions and contractions of the flow exceeds 16,000 s-1. As tests have shown, this condition is met by elements made of titanium powder, providing a technical breakthrough coefficient for particles with a size of 0.3 microns equal to 5%.

Metal-ceramic elements made of titanium are also used for bacterial air purification. They consist of a porous metal-ceramic base, a filtering fibrous material covering the base in two or more layers, and a tubular shell. For the first time, a hydroresistant material has been used as filter elements for fine air purification, which can withstand sterilization with live steam up to 150 ° C for 40 - 50 hours. The material is hydrophobic, resistant to strong acids and alkalis, strong oxidizing agents, alcohols, saturated hydrocarbons, oils and can used for filtering air and gases at temperatures from -250 to +200 °C. The hydraulic resistance of the material at an air speed of 1 cm/s is 14.7 Pa.

The advantages of metal-ceramic filter elements for fine biological air purification are the following: a significant number of sterilizations with live steam, ease of regeneration and a long service life. (5-10 years).

Unlike fibrous, non-woven and fluoroplastic filters, granular metal-ceramic materials have an unchanged structure, are chemically inert, amenable to any sterilization methods, have high mechanical strength, are easy to control, cheap and easy to manufacture. Structurally, they are made similarly to filters with fluoroplastic elements.

produces various filters for the pharmaceutical industry. Filter cartridges in filters for air sterilization are produced under the Ultipore AB brand. Single filter cartridges for air sterilization have a working surface of 0.5 - 2 m2. The seal between the cartridge and the body is made in the form of double O-rings. The efficiency of particle capture by filters is achieved by using membrane materials in the filter cartridge with a maximum pore size of 0.45 microns, which is maintained by the filter fibrous membrane even in a wet state due to the special hydrophobic treatment of the filter element. The filter housing is made of stainless steel. The inner surface of the filters is well polished. The filter housings are equipped with a Trickle-over connection and a bayonet lock for easy operation of the filters.

produces filters with a capacity of 45 - 850 m3/h, which is achieved by the presence of filter elements in the range of 1-20 pieces (the filtration area of one element is 0.5 m2). Operating filtration speeds of 0.15 - 0.2 m/s create a filter resistance of 0.115 - 0.12 MPa. When the speed increases to 0.5 m/s, the resistance of the filters increases by 3 - 4 times. Filter elements of the ARPK5, AHZK5 brands, together with the housing, are sterilized in live steam simultaneously with all other equipment in the production line.

Filters and filter elements have been tested at domestic bio-enterprises. The filter elements successfully withstood in-line sterilization with live steam without compromising their filtering properties. Ultipore AF filter elements have withstood 50 times or more steam sterilization. The service life of the filter element is one year.

Filters for air sterilization use “filter elements; in the form of smooth cylinders of different sizes.

The filtration surface of a standard 77.5 cm long element is 0.12 m2. Recently, for the manufacture of membranes, the company began to use fluoroplastic, a hydrophobic material with high heat resistance and chemical resistance. Corrugated elements with a developed surface made from this material are more productive. The effectiveness of filters of this class and the effectiveness of membrane materials is determined by the absence of particles behind the filter, the size of the nominal pore diameter of the filter membranes (0.45 or 0.22 microns). The filter resistance at a filtration speed of 0.05 - 0.1 m/s is 0.115-0.120 MPa. Due to the fragility of the membrane, the service life and reliability of the element in a single-cartridge filter is less than that of elements and “Eikoh”. recommends sterilizing the filter with live steam at a pressure of 0.2 MPa, supplying steam to the outer and inner cavities of the filter simultaneously to prevent deformation of the filter element. Steam is supplied to the line purified using a special filter.

Experience in operating filters and filter elements from leading foreign companies at domestic enterprises has shown great feasibility, convenience and reliability in the operation of filters with filter materials in the form of ready-made filter elements with specified filtration parameters: efficiency, air flow resistance, service life, etc.

An analysis of domestic and foreign filter designs has shown that the most promising designs are cartridge and cassette type filters with filter elements made of dense, effective filter materials. Such filters are easy to use, highly efficient, quick to remove and reliable in operation.

The analysis made it possible to modernize old and develop new filter designs with ready-made cartridge and cassette filter elements using new effective domestic filter materials.

It is recommended to use purified steam to sterilize filters. The most favorable way of passing steam is two-way supply into the outer and inner cavities of the filter.

Tuning options

Many modern car enthusiasts are tuning their cars, and therefore engine improvement is inevitable. One of the elements of modernization is the air filter. Over the last 10 years, no new innovations have been made in this improvement, so two types of filter elements are used:

- Zero resistance. This filter does not have air resistance, unlike the standard type, which allows more air to enter the combustion chamber.

- Direct flow type. These filters resemble “nuliviks” in their design features, but the essence of the design is slightly different. There are several membranes with different permeability, which makes it possible to more effectively filter the air that enters the combustion chamber.

How to change the air filter

The question is ambiguous. There is no consensus. Experts recommend listening to the manufacturer’s advice.

They agree on one thing: removing the air filter and replacing it is mandatory twice a year: before the start of the winter and summer seasons. And this despite the fact that the car is not used regularly.

This is necessary to avoid an increase in fuel consumption, which can increase up to 15%, and to protect the engine from problems with its operation. If you ignore the manufacturer’s recommendations and do not change the element for a long time, the power unit may fail prematurely.

On domestic cars, replacing the air filter of a car engine can be carried out after 10 thousand kilometers and coincide with an oil change.

DETAILS: Replacing the cabin filter on Renault Laguna

General recommendations boil down to the fact that replacement should be carried out after 15-20 thousand kilometers. However, these terms are conditional.

Again, residents of megacities who actively use transport change the filter elements of the power unit more often than rural residents or drivers of small towns.

What signs can you use to determine that it’s time to say goodbye to the old filter?

If it is noticed that fuel consumption exceeds recommended standards or the % carbon dioxide content is high. When the power of the power unit is lower. In these cases, an urgent change of the auto air filter is necessary.

So to speak, a signal that it is time to replace the filter element. Yes, these signs indicate neglect of the element's maintenance. It shouldn't come to this.

It is necessary to periodically change the filter, otherwise you will have to do technical treatment of the engine. Regular maintenance of the air filter will prolong the normal operation of the engine and save you money.

There are two ways:

- Contact the service station.

- You can install the air filter yourself.

If an element has expired, it should be replaced. Many people believe that by blowing the filter or washing it, it can just as successfully retain dirt and dust as if it were new. This opinion is wrong.

Cleaning the element is a necessary measure, the effect is short-lived. If on the road the engine power sharply decreases, and at the same time fuel consumption increases, then you can resort to cleaning.

To do this, you need to remove it from the housing and blow it out using compressed air. You can clean the air filter with a soft bristle brush. But, having reached the service station, you should replace it.

Moreover, the filter is not too expensive. And there is always a supply at the service station. The only question is whether the item is suitable for your car.

Cleaning the air filter will not have a positive effect. The manufacturer indicates the service life, after which replacement is required.

Even a cleaned and outwardly suitable filter is not capable of trapping dust particles invisible to the eye.

Repairing the air filter and or reusing the element will inevitably lead to a loss of machine power and premature engine failure.

The housing is secured with clips or screws. You need to open the cover and remove the element. The filter has a bright color.

This helps to visually determine the degree of contamination and the need for replacement.

How to install an air filter. Installation is carried out in reverse order and does not take much time.

As you already understand, the quality and quantity of air supplied to the engine plays a huge role in the operation of the internal combustion engine. Therefore, it is very important to observe a certain frequency of replacing the air filter.

Answering the question: “How often should you change the air filter?” it is impossible to give a definite answer. Most car enthusiasts follow the regulations and replace them at every maintenance. Typically, the maintenance interval varies, depending on the vehicle, from 10 to 30 thousand kilometers.

Also, there are car owners who do their own maintenance. Very often they do not pay attention to such an element as the air filter, but only perform the usual replacement of consumable parts.

The frequency of replacing the air filter directly depends on the degree of use of the vehicle. If the air filter has not been replaced for a long time, then the main indicators signaling the need to replace it will be:

- Significant reduction in vehicle power

- Acceleration with noticeable jerks

- Increased fuel consumption

- Rare misfires

- The predominance of carbon dioxide in the exhaust

Of course, there is no point in waiting for such indicators to appear. It is much easier to take care of replacing one element in advance than to subsequently repair the power unit as a whole.

From all of the above, we can conclude that a dirty air filter can lead to undesirable consequences. Therefore, it is important to know how to select and how to change the air filter.

DETAILS: Replacing the vacuum brake booster of a VAZ 2121 Niva with your own hands

The air filter is usually made in the form of a cylinder or rectangle, the inside of which resembles an “accordion”. That same “accordion” serves as a filter element. This element is made from different materials, for example, cellulose, cardboard or synthetics.

To determine whether the air filter needs to be replaced, it is necessary to visually inspect it. It is located in the engine compartment, closed in a special plastic box. You need to remove the lid of the plastic box. Typically the cover is secured with latches or several screws.

If the filter is dirty and requires replacement, it will be easy to understand by its color changing to grayer shades of color, as well as by the presence of dirt and dust. For a more visual inspection, you can analyze the degree of contamination by examining the filter in sunlight.

Replacing the air filter does not require special knowledge, effort or time. As mentioned above, the filter is located in the engine compartment. If there are doubts about its location, you can refer to the technical documentation for operating the vehicle.

After dismantling the cover, the old air filter must be pulled out, the box must be cleaned of any existing dirt and debris, and then a new one must be installed in place of the old one. It is worth noting that the new filter is in most cases covered with a protective film, which must be removed when replacing.

In conclusion, it is worth saying that the air filter is an important element for the proper operation of a car engine. Timely replacement of the filter will not cost you a lot of time and money, and will also eliminate the possibility of unexpected breakdowns of the power unit.

To understand why changing the air filter in a car, you can state the following fact - during the declared service life it should allow no more than 1% of dust to pass through. If this indicator becomes higher, the engine life begins to decrease. The main part of the air does not provide for the possibility of regeneration.

The manufacturers themselves talk about this, pointing out the inadmissibility of various “washings”. However, many motorists can use the same air filter for several years, believing that by washing it they have completely restored its properties.

In fact, this is far from the case. After washing, it will look relatively clean in appearance, which misleads motorists. In practice, the resource of the filter element is limited purely physically - after a certain period of use, it becomes unable to retain dust, since the porosity of the material increases sharply, and the bulk of dust and dirt from the surrounding air goes directly into the engine.

The difference between filters

Many car enthusiasts begin to confuse filters, especially for modern foreign cars. Particular confusion arises with the cabin filter. It is worth understanding that the air filter elements in the cabin and the engine are different, they have different catalog numbers and even sizes.

Cabin filter – what is it? This is a filter element. which is installed in the car interior to filter heating and ventilation air, and in no way relates to an engine element such as an air filter. Therefore, before buying a filter, you need to understand exactly where it is installed.

ZERO RESISTANCE AIR FILTER

The design of a car air purifier may be different, but the principle of operation is almost the same for all. Passing through the filter element, the air can be purified by almost 99% - it all depends on the type of element. Naturally, as air passes through the filter, its flow slows down, and if it is old and heavily polluted, the engine may not have enough air. As an alternative to the standard ones, zero-resistance filters have been developed that have absolutely no effect on the flow rate of incoming air.

The design of such an air filter for a car is quite simple. Several layers of cotton fabric, after impregnation with special solutions, are fixed between two aluminum gratings. Such a design allows you to simultaneously pass twice as much air as purifiers of standard designs. At the same time, the quality of filtration remains unchanged

high - no matter how much dirt such an air filter retains, the quality and speed of cleaning do not change. Moreover, dust settled on the fabric itself takes part in air purification, trapping larger particles.

An equally important feature of a zero-resistance air filter is the ability to clean and reuse it. To clean it, you can purchase a special cleaner, after which it is washed with running water, and before installation on the car it is additionally treated with special oil. It is recommended to carry out such a procedure every three months, especially if the vehicle is used quite intensively, for example, in the summer.

Innovations

As always, let's look at some innovations. One of these is the air filter sensor, which is responsible for the contamination of this element. The first implementation and testing was carried out in 2015 on cars with a hybrid engine - the Dodge Challenger from GM. The first tests showed that this sensor has shortcomings, but improvement continues.

The difference between this device and the mass air flow sensor is that it analyzes the quantity and quality of air immediately after the filter and indicates the condition of the product, as well as when it needs to be replaced. Many car enthusiasts will say that this is a pointless feature, but one by one, car manufacturers are picking up this idea and developing their own innovations in this unit.

Panel type air filter and its replacement

It is not difficult to change the filter on an injection car. An example would be the VAZ-2110. The filter housing of this car is also located under the hood. It looks like a rectangular plastic box with a pipe emanating from it.

The filter housing cover of this car is secured with four screws in the corners. Other cars may only have latches installed. To prevent possible damage to the wiring going to the mass air flow sensor, it is better to disconnect the chip with the wiring going to it.

By unscrewing the screws with a screwdriver, the cover is removed from the housing, after which access to the filter appears. The used filter is removed and a new one is installed in its place. It is important to install it correctly. The sealing layer, which is present on only one side of the panel filter, should be located on top.

After that, the cover is put in place, fixed with screws, after which the chip is connected to the sensor.