Torsion bar suspension - what is it?

The torsion bar is a shaft made of special spring steel, thermally treated. The alloy is subject to very stringent requirements. It must withstand prolonged loads without losing its original properties. The reliability and durability of the suspension as a whole depends on this. To reduce the negative impact of the external environment, the torsion bar is coated with an anti-corrosion compound and paint. The shafts that are coated with a rubberized compound are most protected from rust.

Popular brands:

Acura RSX, Citroen C5, Skoda Yeti

When a car overcomes uneven surfaces, the torsion bars work to twist in one direction. Depending on the design features they are:

- round;

- square;

- rectangular;

- assembled from several layers of metal.

The ends of the torsion bar are rigidly attached to:

- support arm;

- car body or frame (depending on the design).

Fixation occurs through slots. Fastening to the body can be realized using a profile other than round. For normal suspension operation, the rotation axis of the lever and the torsion bar axis must lie on the same line.

Torsional resistance is calculated so that the torsion bar supports the weight of the car, but at the same time allows the arm to move, providing an elastic connection between the wheels and the body. The stiffness of the suspension is affected by the shape, elasticity of the alloy, length and other performance characteristics of the torsion bar.

Work process

From this video you will learn how torsion bar suspension works.

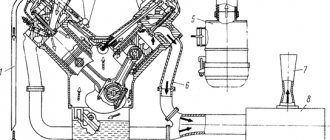

Due to the fact that the torsion shaft is rigidly fixed to the body or frame of the car, it is subject to torsional forces during suspension operation. But the torsion shaft is made from a special alloy and has a certain hardening, which allows it to work as a spring element.

At the moment of twisting, the shaft tends to return the car wheel to its original position. So, the operating principle is similar to a spring or sprung version of this car part. Semi-independent suspension is a suspension system made in the form of two trailing arms connected by a cross member of the longitudinal arms.

The main advantages of this mechanism:

- ease of installation;

- light weight;

- compactness.

The key disadvantage is that it can only be used on a non-driving axle.

Suspension adjustment

In case of a loose suspension, it is possible to adjust the positions using an ordinary wrench. It is enough to get to the bottom of the car and tighten the necessary bolts. The main thing is not to overdo it in order to avoid excessive rigidity at the moment of movement. Adjusting torsion bar parts is easier than adjusting spring types.

Car manufacturers change the torsion beam to regulate the driving position depending on the weight of the engine.

Design and principle of operation

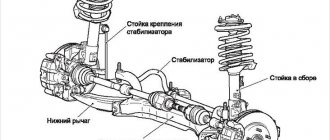

The figure below shows a torsion bar suspension, the principle of which is to protect the car body from excessive loads transmitted from the wheels by damping them with a spring shaft. As the car overcomes uneven road surfaces, the torsion bar twists, ensuring maximum smoothness. Upon completion of moving through the obstacle, the torsion bar returns to its original position.

The load is evenly distributed throughout the mechanism. According to the principle of operation, it is similar to a spring - but at the same time, the torsion bar demonstrates better efficiency.

The torsion bar suspension design assumes the constant presence of torsional stress on the elastic shaft during the action of lifting and lowering forces on the wheel. Therefore, the absence of deformation changes in the torsion bar is the main requirement for the product.

What is torsion bar suspension

In this type of suspension, the role of an elastic element is performed by a torsion bar. This is a kind of metal rod of round or square cross-section that produces torsional work. It can be either solid or composed of several metal plates; at its ends there are slots for connection with other elements.

In general terms, the torsion bar suspension diagram looks like this. One end of the rod is fixedly connected to the body, the other to the lever. The operating principle is based on the elasticity of the torsion bar. The car wheel, moving in a vertical plane, twists it, resulting in an elastic connection between the wheel and the car body. Unwinding to its normal state, the torsion bar returns the wheel to its original position. In the video you can see how this design works. These elastic elements have two features:

- their rotation is possible only in the direction of twisting;

- with their help you can adjust the vehicle's ground clearance.

Types of pendants

There are 2 options for the location of torsion bars:

- transverse;

- longitudinally

The transverse arrangement of the torsion shaft has found its application in passenger vehicles. Typically, this type of suspension is used in rear-wheel drive vehicles. Its peculiarity is the placement of shafts along the car body.

Longitudinal torsion bars are used on large, heavy trucks. There have been attempts to use them in passenger vehicles, but this practice has not become widespread.

Currently, the automotive industry uses suspensions of 3 main designs:

- The front is independent using transverse shafts.

- The rear is independent with transverse torsion bars.

- Semi-independent rear.

Front independent

The front independent torsion bar suspension includes the following elements:

- Longitudinal torsion bar. Provides high smoothness.

- Lever arm. Transmits force and causes twisting of the torsion bar.

- Shock absorber. Serves to dampen vibrations that occur in the vehicle's chassis.

- Anti-roll bar. Minimizes car body roll while driving. Improves car handling.

Front independent torsion bar suspension is used on heavy SUVs. This frees up space for powerful wheel drive.

Advantages and disadvantages

An undeniable advantage of a torsion bar suspension is the compactness of the system. Due to the fact that it has small dimensions, passenger car manufacturers can make a larger trunk or increase the interior. Cars with a spacious interior are purchased much more often.

The second advantage is that you can independently adjust the hardness or softness of the torsion bar. This parameter directly depends on the length of the torsion bar. Each driver can make it softer or harder independently.

The third advantage is that on cars on which such a suspension is installed, you can independently adjust the ground clearance. Thanks to this, you can independently make the car more obedient on the road and easier to drive.

There is also a fourth advantage - simplicity of design and inexpensive maintenance. This is an undeniable advantage over spring suspension. In addition, the torsion bar suspension is lightweight, so the vehicle's fuel consumption is reduced.

Despite the large number of advantages, this system also has disadvantages. Due to the fact that the system has a certain operating principle, additional vibrations are transmitted to the body, which are felt in the back seat. Therefore, it is impossible to achieve complete sound insulation on a car with this system. Based on this, we can conclude that the first and main disadvantage is vibration during movement.

The second disadvantage is that the operating principle of the torsion bar exposes it to self-destruction, as a result of which this part will have to be replaced.

The last disadvantage is that torsion bars can be more expensive to maintain. It all depends directly on the design of the machine. The fact is that some manufacturers install a torsion bar where it is impossible to get it without dismantling other devices. But there are also systems where everything can be replaced without difficulty.

Rear independent

The transverse torsion bars of the rear suspension are installed in tandem with the trailing arms. An example of the design is shown in the image below.

An interesting example of a car with transverse torsion shafts and trailing arms is the Renault 16. The car has a different wheelbase on the right and left. The distance between the front and rear wheels on the right and left differs by several centimeters. The reason for this engineering solution is the sequential arrangement of the shafts one after the other. This slightly worsened the car's handling, but made it possible to increase the luggage compartment.

Semi-independent rear

This type of suspension is based on a torsion beam, which has a U-shape. The trailing arms are located one on each side. The beam connects them together. The levers are attached with one side to the body, and the other to the wheel hub.

The beam resists bending well. At the same time, its shape does not prevent it from curling at all. The wheels may move slightly in the vertical plane relative to each other. The location of the torsion beam can be seen in the figure below.

Semi-independent suspension is used in budget cars with front-wheel drive. This is due to the simplicity of the design and low price of such machines.

Application of the torsion model

The torsion beam can be positioned longitudinally or transversely. The longitudinal arrangement is used on large, heavy trucks. Passenger cars use a transverse arrangement, usually with rear-wheel drive.

In these two cases, the mechanism is designed to ensure a smooth ride, regulate roll when turning, ensure optimal damping of vibrations of the wheels and body, and reduce vibrations of the steered wheels.

For some vehicles, torsion bar suspension is used for automatic leveling using a motor that tightens the beams for additional rigidity, depending on the speed and condition of the road surface.

The height-adjustable design can be used when changing wheels. This is when the vehicle is raised with the help of three wheels, and the 4th is raised with the help of a jack. The main advantage of this type of suspension is considered to be durability, ease of height adjustment, and compactness in the width of the vehicle.

It takes up much less space than spring suspensions. Of course, the torsion bar configuration is easy to operate and also easy to maintain.

Pros and cons of using torsion bars

Torsion bar suspension has its advantages and disadvantages. The advantages of torsion bar suspension are:

- smooth running of the car;

- the ability to adjust the height, making it easy to change the ground clearance;

- compactness and simplicity;

- good maintainability;

- less load on wheel bearings;

- reliability.

The disadvantages of torsion bar suspension are:

- a large dependence of suspension stiffness on the quality of torsion bars;

- the complexity of manufacturing elastic shafts;

- Driving a car is difficult - turning is too easy.

Pros and cons of torsion bar suspension

Like any other design, torsion bar suspension has its pros and cons.

Its main advantages are as follows:

- compactness compared to spring suspension;

- simple device and high reliability;

- light weight;

- the ability to quickly change the vehicle's ground clearance without making changes to the design;

- good maintainability;

- long intervals between maintenance.

Disadvantages of torsion bar suspension:

- worse handling compared to multi-link suspension (cars tend to oversteer);

- complex technology for the production and processing of elastic elements;

- limited service life of needle bearings in the attachment points of the trailing arms to the torsion beam (about 60-70 thousand km); If the failed bearings are not replaced in a timely manner, the torsion beam will have to be repaired or replaced.