Prerequisites for creating an SCR system

Since 2015, the Euro 6 environmental protocol has come into force in 28 EU countries. According to the new standard, strict requirements are imposed on automakers producing diesel engines, since diesel engines cause enormous harm to the environment and human health due to emissions of soot and nitrogen oxide into the atmosphere.

Why do you need Adblue for diesel?

If the use of a three-component catalytic converter is sufficient to clean the exhaust of a gasoline engine, then a more complex device is required to neutralize toxic compounds in the exhaust gases of a diesel engine. The efficiency of removing CO (carbon monoxide), CH (hydrocarbons) and soot particles from diesel exhaust increases at high combustion temperatures, while NOx, on the contrary, decreases.

The solution to this problem was the introduction of an SCR catalyst into the design of the exhaust system, which uses urea for diesel as a basis for the breakdown of toxic nitrogen oxide (NOx) compounds.

To reduce harmful emissions, engineers have developed a special diesel cleaning system - Bluetec. The complex consists of three complete systems, each of which filters toxic compounds and breaks down harmful chemical components:

- Catalyst – neutralizes CO and CH.

- Particulate filter – fights soot particles.

- SCR catalyst – reduces NOx emissions using urea.

For the first time, the cleaning system was used for trucks and cars at Mercedes-Benz. Today, many manufacturers are converting their vehicles to a new cleaning system and using urea in diesel engines to meet stringent environmental inspection requirements.

How to choose

When choosing urea for a diesel unit, several factors must be taken into account.

- It is almost impossible to make a solution yourself. Urea itself (urea) is sold separately and is used as a nitrogen fertilizer and in other applications. However, it is very difficult to obtain demineralized water at home, as well as to achieve the required ratio. Therefore, you should not take risks and try to make AdBlue liquid yourself, otherwise you can cause serious damage to your car engine.

- Up to 50% of the product sold on the domestic market is counterfeit and unsuitable for use in diesel car engines.

Therefore, when choosing AdBlue for diesel power units, you should pay special attention to the name of the manufacturer and whether it has a certificate of quality conformity.

- When purchasing urea, you must purchase specifically AdBlue liquid from licensed manufacturers. That is, the product must bear the AdBlue® trademark and comply with the European standard ISO 22241-1. Only such a product will not harm the engine, which cannot be said about uncertified products sold under the names “urea for diesel engines,” etc.

- You can purchase urea sold under the brand names of automakers, including using it to fill a car of a different brand. In fact, such products are absolutely identical and differ only in their name - the automakers themselves do not produce the product, giving the manufacturing plants the right to use their trademark. AdBlue VW is quite suitable for use in Mercedes engines, etc.

- There is no difference between urea for cars and trucks - these products are completely identical.

- There is also no difference in the characteristics of Russian and imported AdBlue. However, when purchasing a domestic product, you need to make sure that it meets the quality standard GOST R ISO 22241.

In Russian conditions, many owners of cars equipped with SRC catalysts are forced to disable the cleaning system or use its emulator. The main reason for such actions by domestic owners of diesel cars is the inability to effectively use the system in winter - at temperatures below -11 ° C the liquid simply freezes. Therefore, the feasibility of using SRC catalysts and AdBlue liquid in Russian conditions at the moment remains a big question.

Modern environmental standards impose strict restrictions on the emission of harmful substances in the exhaust gases of a diesel engine. This forces engineers to look for new solutions to meet the standards. One of them was the use of urea for diesel engines in the SCR (Selective Catalytic Reduction) exhaust gas purification system. Daimler engines using this technology are called Bluetec.

Content

What is urea

The end product of mammalian metabolism, urea, has been known since the 19th century. Carbonic acid diomede is synthesized from inorganic compounds and is widely used in agriculture. In the automotive industry, a solution of Adblue technical fluid is used as an active reagent in the purification of toxic nitrogen oxide exhausts.

Adblue liquid

Adblue liquid consists of 40% urea and 60% distilled water. The composition is injected into the SCR selective cleaning system into the pipe through which the exhaust gases pass. A breakdown reaction occurs in which nitric oxide breaks down into harmless nitrogen and water molecules.

Technical urea for diesel Adblue liquid has nothing in common with urea urea, which is used in the agricultural sector and pharmacology.

What does urea improve besides the environment?

- Urea is actively used in the agricultural industry for the production of various fertilizers.

- It is also used as a main product in the manufacture of resins and plastics.

- A number of consumer and cosmetic products contain urea to help keep emulsified ingredients from separating. A small amount of urea is added to toners and makeup removers, as this substance can help moisturize the skin.

- Urea is sometimes used in livestock production in the production of livestock feed. Feed with added urea contains high concentrations of nitrogen, which promote rapid growth of animals.

Another benefit of using urea is that the engine efficiency achieved with SCR technology will save customers over 280 million liters of diesel and almost half a billion dollars in fuel costs. At the same time, the environment will be freed from approximately 800,000 metric tons of carbon dioxide.

Why is it needed in a diesel engine?

A liquid emission control system, or SCR converter, is a closed system through which soot-free diesel exhaust passes. Edblue liquid is poured into an autonomous tank and supplied to the exhaust pipe in a dosed manner before entering the converter.

The mixed gas enters the SCR neutralizer unit, where a chemical reaction of nitrogen oxide decomposition occurs due to the ammonia contained in urea. Ammonia molecules, combining with nitric oxide, split the latter into components that are harmless to humans and the environment.

After a full cleaning cycle, a minimum amount of harmful substances enters the atmosphere; the emissions parameter complies with the Euro-5 and Euro-6 protocols.

What is AdBlue?

AdBlue is a mixture of urea and deionized water that is sprayed into the exhaust system of diesel engines, helping to reduce nitrogen oxide levels in the exhaust. The use of this fluid is necessary to make diesel engines comply with the latest environmental standards.

AdBlue is used as an additional working fluid in diesel engines using selective catalytic reduction (SCR) technology. The presence of SCR is mandatory for diesel cars, starting from the Euro-4 standard.

The system was first used mainly on MAN, DAF, Iveco, Scania, Kamaz trucks, Volvo and Renault commercial vehicles, and later reached passenger cars - BMW X5 and X6, VAG diesels with TDI engines, Citroen and Peugeot with BlueHDi engines, Mercedes with engines BlueTEC and other cars.

Main disadvantages of the system

- High cost of spare parts and components;

- The need to use liquid AdBlue reagent (its consumption is 4–6% of fuel consumption + in Russia it can be difficult to find a good quality reagent);

- The liquid reagent freezes at a temperature of –11C°;

- Significant increase in the price of the car due to the installed system;

- Expensive service.

Causes of malfunction

Two main reasons associated with system failure:

- The system has a fairly large number of components that periodically fail and require replacement.

- Using a low-quality liquid reagent.

Problems with AdBlue lead to unpleasant consequences:

- engine speed is reduced by 40–50%;

- the car limits power;

- emergency mode is activated.

If problems occur, CHECK ENGINE will light up. On some car models, one of the warnings will appear on the dashboard:

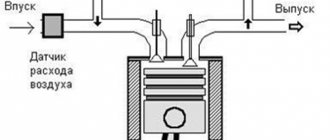

How the system works

A complete exhaust gas purification system for a diesel engine consists of a catalyst, particulate filter and SCR system. How does urea work in cleaning step by step:

- Exhaust gases enter the catalyst and particulate filter. Soot retention occurs, fuel particles burn out and carbon monoxide and hydrocarbons are removed.

- A certain amount of AdBlue liquid is injected into the pipe between the particulate filter and the SCR converter using a nozzle. Urea molecules break down into ammonia and isocyanic acid.

- Ammonia combines with nitrogen oxide, the most harmful component of spent diesel fuel, and the molecules break down, resulting in the formation of water and nitrogen. Harmless exhaust is released into the atmosphere.

SCR system diagram

What happens if you don’t pour urea or add water?

When using a vehicle with an empty urea tank, the engine control unit will go into emergency mode. Engine power will be reduced by approximately 30-40%, and, as a result, traction will drop. Driving will become uncomfortable and uneconomical and, accordingly, fuel consumption will creep up. This applies to Euro 4 and Euro 5 cars; on most Euro 6 cars the maximum speed will still be limited to 20 km/h. To get to the repair site, we can offer an error eraser - it is installed in the OBD connector and you can come to us and solve the problem with urea.

Let's consider the option of using plain water or low-quality Adblue liquid instead of urea, the following scenarios are possible:

- The exhaust gas after-treatment system, based on the readings of the NO2 (nitrogen dioxide) content sensors located at the inlet and outlet of the exhaust tract, will understand that the purification is ineffective and will increase the supply of the reagent (in our case, water). Since the after-treatment reaction will not start anyway, the system will first display an error “increased reagent consumption”, then an error of a malfunction of the after-treatment system with, again, a limitation of power, and an order to contact service. This is the best option.

- If you use plain water or low-quality liquid, the reagent filter will very quickly fail (clog). The reagent pump is designed in such a way that if there is difficulty in suction, it will fail and lose its seal. As a result of the leak, the housing of the pump module, which contains the pump itself, the dosing valve, temperature/pressure sensors of the reagent, heating elements and the electronic unit of the supply module itself, will be flooded with reagent (or water). Flooding will lead to corrosion of the mechanical part of the pump and corrosion of the electronic control unit, which is a three-layer printed circuit board and, unfortunately, as a rule, cannot be restored. The cost of replacing a flooded module with parameterization ranges from 80 to 225 thousand rubles, and the savings in this case will be very doubtful. Moreover, in the initial stage of flooding and closure, the module will transmit chaotic commands to the supply valve, which can lead to excessive pressure on the reagent injection nozzle and lead to the atomizing part of the nozzle being squeezed into the muffler cavity. The cost of a spray nozzle, depending on the brand of car, ranges from 35 to 80 thousand rubles. If any of these components fail, engine power will also be reduced by 30-40%, and consumption will also increase as a result.

- As a result of the evaporation of the supplied water and the deposition of impurities on the catalyst, the pores of the catalyst may gradually become clogged with solid deposits, and the engine will begin to “chokes” on exhaust gases. Also, when ordinary water evaporates in the hot supply part of the nozzle, the supply and return channels of the nozzle can also become coked with mineral impurities, which are always contained in the water. In this case, the system will also go into restriction mode.

It is important to understand that the mere presence or absence of a reagent does not affect power or consumption. A decrease in power and an increase in consumption are not a consequence of the lack of urea, but the results of the engine management program, which thus prevents the long-term use of a faulty vehicle

Liquid composition

Despite the apparent simplicity of urea for diesel, it is impossible to make the liquid yourself using organic fertilizer as a basis. The formula of the urea molecule is (NH2)2CO, physically it is an odorless white crystal, soluble in water and polar solvents (liquid ammonia, methanol, chloroform, etc.).

For the European market, the liquid is manufactured under the supervision of the inspection of the German Automotive Association (VDA), which provides licenses to manufacturing companies, some of which supply cleaning liquid to the domestic market.

In Russia, counterfeits under the AdBlue brand account for more than 50%, therefore, when buying urea for diesel engines produced in the Russian Federation, you need to focus on the “Compliance with ISO 22241-2-2009” marking.

Why fill it?

Global concerns about the growing negative impact of NOx emissions in the environment have led many countries to introduce strict controls on the levels of nitrogen oxide released and take measures regarding the production of new diesel vehicles.

The German Association of the Automotive Industry (VDA) ensures quality standards in accordance with ISO 22241 specifications. Thus, several leading car manufacturers include urea injection as a standard feature in their new diesel engine models. Currently, car manufacturers claim that emissions conversions of 80% or more have been recorded when using urea in diesel vehicles.

These reductions will certainly have a positive impact on the environment, but they can also significantly increase the cost of maintaining a diesel vehicle.

Advantages and disadvantages of diesel converters with urea

Periodic injection of urea solution into the exhaust tract is absolutely harmless to the environment, since urea is an organic product. The system independently selects the timing, injection speed and amount of urea supplied, depending on the operating mode of the internal combustion engine, the load on the engine and the intensity of exhaust gas formation.

- The main advantage of using such cleaning is the environmental friendliness of the engine without the need to reduce its power. Diesel exhaust after cleaning becomes water, nitrogen and carbon dioxide. Nitrogen oxides in the catalyst are converted into an inert gas that does not pose a threat.

- It is also necessary to note full compliance with Euro standards and other environmental standards in developed countries, which means free movement without fines and restrictions, as well as reduced taxation.

- As for the reagent consumption and the price of diesel urea, an average of 100-150 ml is required for passenger cars. urea for diesel per 100 kilometers. It turns out that 10 liters of reagent is enough for 10 thousand kilometers. Trucks naturally consume more solution, which will directly depend on the volume of the internal combustion engine. Heavy vehicles can use about 1.5 liters of urea or more per “hundred”, allowing you to travel only 1000-1500 km on a 20-liter canister.

- Note that a canister of urea for diesel will cost about 7-10 USD. The reagent is commercially presented in the form of a ready-made solution, which is usually packaged in 20-liter containers. Urea for diesel is offered by several manufacturing companies; both artificial and organic products are available.

Among the disadvantages of using urea for diesel, it is worth highlighting the additional costs of the reagent itself, as well as the need for maintenance of the equipment that ensures the operation of the liquid cleaning system.

Another feature is the increased demands of the system on fuel quality, since converters with urea injection assume normal operation only on low-sulfur diesel fuel. It is also necessary to separately take into account that the urea solution tends to freeze at temperatures of about -12 degrees Celsius. Taking into account this feature, cars with such solutions can be operated without problems only in regions with warm and temperate climates.