DPF regeneration

The principle of regeneration is simple: microparticles that clog the membrane burn out at temperatures above 500°C. Therefore, the cleaning process is to raise the temperature in the system to such a point that the exhaust gases can burn off the contaminants. This is only possible when the engine is at full load.

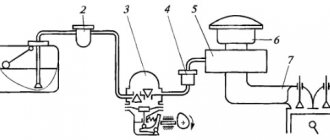

There are two types of membranes, differing in location: FAP and DPF. The first type is located at a distance from the engine, and the exhaust gases cannot sufficiently heat the particles. Therefore, a fuel additive is used for this task.

Since exhaust gases travel a long way from the engine to the cleaning element, they simply cannot burn the clog. The temperature is not enough for this task, so it is necessary to increase it. For this purpose, special cerium-containing additives are used. Cerium microgranules allow you to heat the gases to the required level, thereby destroying the blockage.

The additive itself consists of cerium microgranules in a special substance. This shape allows it to retain its structure until it reaches the filter. Initially, the gases only evaporate the shell of the granules, releasing cesium. When it hits an already heated membrane, it ignites sharply, raising the temperature of the surrounding gases to 1000°C. This bar is safe for the system, because heating occurs locally.

Interesting! Although this temperature may destroy the ceramic grate, the duration of heating is minimal. This makes this method safe for the system.

The second type of filter is located near the engine, so the required temperature level is achieved without additional tools. Exhaust gases almost immediately enter the filter, thereby burning out the blockage and continuing on its way.

It is important to note that in both cases it is recommended to increase the exhaust gas temperature through the engine control unit. This will improve cleaning efficiency

This cleaning procedure occurs only at full speed, so it is important to periodically squeeze the engine to full power. But it is worth remembering that regeneration does not need to be carried out daily, the frequency depends only on the intensity of soot formation

How to burn

The outcome of the conversation at this point is quite clear - the diesel particulate filter can be cleaned. Method number 1: do this, as they say, passively. Method No. 2: carry out cleaning using the active method, which is included in the standard electronics.

What is regeneration

There has already been a conversation about what regeneration of a particulate filter is and what goals it pursues. Let us remind you that the main task of this event is to burn out the soot accumulated in the soot channels. An empty matrix allows the engine to “breathe”, which means it takes a minimum of power.

To burn off this very soot, it is necessary to increase the temperature of the exhaust gases. This can be done in two ways:

- Passive. As the speed increases, the exhaust temperature increases, but the excess fuel consumption increases. The optimum is constant average speed: the gases are hot, the proportion of unburned diesel fuel is minimal. An example from operation is driving along a highway at a constant speed.

- Active. Increasing the temperature in the filter due to the afterburning of diesel fuel in front of it. Before exhaust gases are released from the cylinder, post-injection of diesel fuel is carried out. Due to the low temperature of its self-ignition, we have a flame torch and a hot exhaust flow right in front of the soot, causing the latter to heat up to 600...650°C.

Let's return to the passive method to separate the two competing technologies - FAP and DPF. Machines with FAP are distinguished by the presence of a tank with a special additive containing cerium. By adding it to the fuel, we can carry out passive regeneration at a lower temperature. In everyday life, this means that burning on the highway is more productive. That is, the time it takes to empty the filter is reduced, which has some advantages.

A platinum catalyst is applied to the walls of the DPF matrix. Its job is to promote a series of chemical reactions that ultimately rid the container of soot. Unlike FAP, the gases must be fairly hot (400...500°C versus 300...350°C), otherwise there will be no combustion. This means you will still have to “drown” on the highway.

Active burning

A lot has been said about the passive method. All that remains is to specify how to burn through the particulate filter while moving without the help of electronics, namely the approximate speed of movement and engine speed. So, a pace of 70-90 km/h and more than 2,500 rpm on the tachometer is quite enough to empty the soot filter a little. How often and how much time to devote to the process depends on the frequency of use of the machine. Start from the standard cycle: for 5 days of city traffic, 2-3 weekend trips lasting at least 40 minutes.

Let us repeat that the goal of active regeneration is to heat the particulate filter matrix to 600...650°C. To do this, it is necessary to change the operation of the turbocharger, turn off the exhaust gas recirculation (EGR) system, and inject fuel before the exhaust stroke. Let us warn you right away, the situation is fire hazardous.

- Exhaust gas temperature sensor. (there are two of them - one is mounted at the inlet of the filter element, the second - at the outlet).

- Differential pressure sensor. Measures the pressure difference between inlet and outlet.

Active burning is launched in different ways. On some cars (for example, VW) this happens unnoticed by the driver and regardless of whether you are in the city or on the highway, on others (for example, Toyota) a lamp will light up, indicating that you need to stop and press a special button.

Still, it’s not worth comparing cars based on the electronics operation algorithm. So, the same VW has a pre-crash mode, which we described (DPF icon). The only difference is that the owner of VAG products needs to go out onto the highway and drive until the light goes out, and Toyota will do everything on the spot.

What else is worth talking about are the signs of active regeneration:

- Engine temperature increases.

- Fuel consumption is increasing.

- The oil temperature increases.

- The red-hot jar begins to click loudly, which can be clearly heard from outside.

- The exhaust color takes on a thick white tint.

- At idle speed the engine starts to get loud.

Check Engine Mode +…

On some machines, the manufacturer provides emergency regeneration. Usually, in order to start it, the soot counter must count a certain threshold value (for VAG this is at least 58 g), and the computer must enter the “check” mode.

Launching such a cleaning program is only possible at a service station. This procedure is often called resetting the Diesel Particulate Filter Restricted/Clogged MIL ON error or forced burning of the particulate filter, which is not much different from the Toyota model of starting active regeneration through a button.

Heat treatment of the diesel particulate filter

Air filter corrugation

The filter is dismantled and placed in an oven, where the temperature is maintained at about 600-700 degrees Celsius. Under the influence of high temperature, contaminants are gradually “burned out”. The entire procedure takes from 8 to 12 hours. The following set of tools is required for heat treatment:

- — tester for determining the pressure level

- - bake

- - compressor.

The clear advantage of this method is the maximum removal of contamination. Among the disadvantages are the following:

- — risk of damage to the integrity of the housing due to dismantling and subsequent installation

- - Possibility of damage to the housing due to high temperature

- — risk of thermal damage to metal parts.

Ultrasonic cleaning

Read How to choose a repair service

The filter is dismantled and lowered into an ultrasonic bath filled with water. In this environment, many micro bubbles are formed, inside which high pressure and high temperature are achieved. Under their influence, all contaminants are “detached” from surfaces. The time for the procedure is 12-24 hours. Required equipment: ultrasonic bath, compressor, oven. The advantage of this method is the deep cleaning of all the smallest filter cells. There are also a number of disadvantages:

- - low efficiency on particularly contaminated surfaces, as well as on large filters

- — risk of damage to the walls due to the active action of high-pressure bubbles

- - a large amount of water consumed (it must be completely replaced periodically).

Chemical additives

In this option, chemical compounds are added to the fuel tank to “melt” the soot while the engine is running. Chemical cleaning is a simple and relatively cheap method. On the auto parts market you can select additives from different manufacturers with a wide range of prices.

New generation cleaners

Chemical additives for cleaning particulate filters were gradually improved, which resulted in a whole range of special cleaners - washers. Washing liquids effectively dissolve soot, which subsequently helps the contaminants burn out naturally.

The last two methods are perhaps the most effective and accessible today. Regular use makes it easier to maintain diesel particulate filters and helps keep them clean and functional for as long as possible.

Signs of contamination

The particulate filter has its own output. The soot itself is formed as a result of the combustion of diesel fuel and air; it settles on the filter honeycombs. Afterwards, the hydrocarbons burn out, resulting in the formation of resins. They then stick together, which leads to clogging of the filter. The main reasons for failure are:

- use of fuel with a large amount of harmful impurities, or low-quality fuel;

- use of low-quality motor oil;

- mechanical damage, including impacts from the bottom of the car or collisions;

- incorrect regeneration or inability to carry it out.

Benefits of regular maintenance, cleaning and rinsing

Communities Second Life Auto Blog Dent Removal. PDR School. Lesson 15. Hail damage. The best job for a beginner.

The service life of the diesel particulate filter directly depends on the total number of self-cleaning cycles initiated by the ECU. The more often a part self-cleans, the more platinum catalyst burns out under the influence of elevated temperature.

The main advantage of constant maintenance of a diesel exhaust system is the economic aspect, as well as the ability to operate the engine with consistently optimal performance. If a diesel internal combustion engine is in conditions that lead to increased carbon formation, then preventative cleaning of the particulate filter is much more profitable than driving without servicing it until replacement. This is clearly expressed in financial terms. A serviceable diesel engine with a cleaned filter always delivers full power, consumes fuel moderately, starts easily, does not harm the environment, and the reliability and overall life of the internal combustion engine are increased.

It is advisable to additionally clean the element at each scheduled maintenance, after troubleshooting problems with fuel equipment or repairing the engine itself. In a word, cleaning is required both for prevention and after eliminating the causes of prolonged malfunctions in the diesel engine, which lead to the formation of soot on the soot filter mesh.

Additionally, you can extend the “life” of the part by using special additives in diesel fuel. Such additives make it possible to improve a number of parameters during diesel operation. A separate group of additives is aimed at making the carbon formation process less intense, and is also aimed at reducing the total amount and lowering the temperature during the automatic self-cleaning of the cleaning element.

The diesel additive helps diesel fuel burn fully in the cylinders, which reduces the amount of soot in engine exhaust gases. When self-cleaning, there is no need to heat the diesel catalyst for a long time; in this case, catalyst burnout becomes less intense. If the engine is in good condition, good quality diesel fuel is poured in, and the additive is regularly used once every 2-3 thousand kilometers, then additional filter cleaning may not be required at all.

Signs of filter element contamination

In a working car, the driver is warned about the contamination of the particulate filter by a special display on the dashboard. Having seen it, the driver must drive out onto the main road and create conditions for the launch of the built-in regeneration system.

Sometimes the indicator does not light up. In this case, the car owner can determine the contamination of the filter element by the following indirect signs:

- When the diesel engine is running, a loud hissing sound is heard.

- The engine oil level rises on its own.

- The engine speed begins to “float”. This can be clearly seen on the odometer at idle.

- Diesel fuel consumption increases.

- Engine power decreases.

How to clean the DPF

Renault Logan Silver Logbook 016 Replacing the air filter. TO1-1

There are two main ways to clean the DPF from carbon deposits. The first implies the need to remove the filter element from the car, and the second involves performing actions directly on the car. Both methods have their advantages and disadvantages, so we will consider them separately.

Cleaning the particulate filter with removal

The complexity of this method lies in the need to dismantle the diesel particulate filter, as well as the duration of the procedure. On average, it will take about 8 hours to clean the filter.

For cleaning, special particulate filter flushing fluids are used, which can be purchased at automotive stores. It is better to choose formulations from proven brands such as Luffe, Pro-tec, Liqui Moly and the like. These liquids are compositions of petroleum components and various additives that can dissolve soot deposits. Liquids are supplied in 5-liter canisters; on average, the entire canister will be required for one flush. Canisters may have a place on top to attach a hose, some of them have a hose included. The hose makes it easier to fill the particulate filter with flushing liquid.

The housing of the removed particulate filter must be completely filled with washing liquid and left for the time specified in the instructions for use of the composition (about 8 hours). After this, it is enough to rinse the filter with a stream of water to remove any remaining dirt, as well as any remaining cleaning agent.

Please note: Flushing with water must be taken seriously as the cleaning agent is flammable and can ignite if exhaust gases enter. After washing the particulate filter with water, all that remains is to dry it and install it in place.

After washing the particulate filter with water, all that remains is to dry it and install it in place.

Cleaning the particulate filter without removing it

The method of washing the particulate filter without removing it is faster, since the work is carried out directly on the car. The design features of the filter make it possible to supply cleaning liquid through the hole for installing a pressure or temperature sensor, having previously removed them.

It is important to note that a different composition is used to clean the particulate filter without removing it. This is due to the fact that the work is carried out directly on the car, and there is no way to ensure that petroleum products will be completely removed from the particulate filter

Therefore, a water-alkaline based composition is used for cleaning. with washing liquid. The liquid will allow the remaining alkali to be neutralized after cleaning.

To wash the particulate filter without removing it, you will need to get a spray gun.

Please note: You can also initially find cleaning fluids in aerosol cans. To effectively use the liquid in the can, be sure to read the instructions for it

Before washing the particulate filter, the car engine must be warmed up, after which it is necessary to wait until the temperature in the filter element reaches about 40 degrees Celsius. This must be done to increase the efficiency of the alkaline composition.

The composition is sprayed onto the particulate filter under a pressure of about 8 bar. In this case, the spraying process should be interval: the liquid is injected for 10 seconds, then you need to wait 10 seconds before injecting a new dose. This will require about 1 liter of cleaning fluid.

It is also important to rotate and move the spray probe to clean the entire particulate filter. After washing with an alkaline composition is carried out, clean water is sprayed in the same way

After completing work on cleaning the particulate filter with liquid agents, it is recommended to carry out the procedure for burning off the remaining soot by operating the vehicle at high speeds for 20-30 minutes.

Flushing

This procedure requires special liquids.

The procedure itself as a whole depends only on the type of product.

So, the filter is removed and its holes are closed. Then the cleaning liquid is poured inside so as to fill the entire volume of the filter. Next, the product must be left alone for ten hours, while shaking the filter from time to time. After this, the part is washed with warm water and installed back on the car. There are several types of liquids, and each has its own method of washing. This should be kept in mind before performing these procedures.

Washing and cleaning will help prolong the operation of the element, because replacing a particulate filter is a very expensive pleasure.

But sooner or later the time will come. It is recommended to change filters after 180 thousand kilometers.

The wear of this structure is primarily affected by driving conditions, fuel quality, and driving style. If the machine experiences significant loads, replacement of this element may be required earlier.

So, we found out what this part serves in a car. The particulate filter, like other auto parts for foreign cars, is an important part of a modern car. This element improves the environmental situation in the world, and this improves human health. High-quality ecology means a healthy society and happy children.

Magazine " BODY"

»together with

LIQUI MOLY

tested a new product for cleaning and protecting particulate filters.

With modern diesel cars equipped with additional exhaust gas after-treatment devices (DPF particulate filters), problems have arisen in their operation. The smaller the difference in exhaust gas pressure at the inlet and outlet of the particulate filter, the more efficiently the engine operates, the more economical fuel consumption is and the minimal pollution of the environment.

However, during the entire period of operation, solid soot particles, which are unburned particles of hydrocarbons, enter the pores of the particulate filter walls, limiting the flow of exhaust gases. The fine soot powder seems to be supposed to burn, but as the filter clogs, it mixes more and more with non-combustible materials and forms resins. This sticky mixture, coupled with metal sulfates, which are formed during the combustion of low-quality motor oil, clogs the particulate filter, creating increased back pressure of the exhaust gases inside.

The particulate filter can become almost completely clogged after just a few hundred kilometers, so the developers have provided a clever system for its “regeneration” - a process that oxidizes the resins inside the filter, after which they burn out. When the gas pressure at the DPF inlet and outlet exceeds the permissible limit, the engine control unit turns on the burnout mode.

The computer enriches the fuel mixture, causing the exhaust gas temperature to rise sharply. The load on the catalyst increases, and it, in turn, heats up to several hundred degrees, oxidizing the vapors of unburned fuel. After this, a hot mixture enters the particulate filter, which burns out deposits and cleans the filter. The same process can be initiated chemically by adding a special additive that activates burn-through. At one time, the Volkswagen concern used this technology, and today designers from Peugeot and Citroen are passionate about similar developments.

For cars of various brands, the burnout mode is activated under quite standard conditions. To do this, the car must be in motion and the engine must be running at medium or high speed. In dense city traffic, it is not always possible to achieve suitable conditions, so the filter continues to retain soot without self-cleaning, which leads to its complete clogging.

Ideally, the service life of a particulate filter is 150,000-200,000 kilometers, and self-regeneration occurs only once every 500-700 kilometers. However, in city traffic this part becomes unusable much earlier. Long-term traffic jams, low-quality fuel, elevated ambient temperatures and aggressive driving style lead to the fact that the process of burning through the filter starts every 50-100 kilometers, which shortens the life of the unit to 50,000-60,000 kilometers. This is explained by the fact that during each regeneration, part of the platinum from the catalyst burns out along with petroleum products, which significantly affects its residual life.

In addition, in order to effectively burn out all the resins from the cavities, it is necessary to heat the catalyst to 600-650 ° C, which is almost impossible to do during a trip. As soot accumulates inside the system, the difference in gas pressure at the inlet to the filter and at the outlet from it will one day exceed the permissible values. As a result, when the particulate filter is more than 90% dirty, the engine will simply lose power and stall.

If a corresponding signal about a problem appears on the car’s dashboard, you must immediately contact a service station. An experienced diagnostician will check the system and issue a conclusion. Often, manufacturers do not regulate the repair of dirty particulate filters, offering only a complete replacement of the part. Thus, by systematically pouring low-quality Russian diesel fuel into his car, the car owner obviously “signs up” for constant and expensive repairs. The cost of particulate filters themselves from top brands alone exceeds 100,000 rubles.

Of course, the car owner cannot influence the quality of the fuel, but he can take care of the safety of the filter. To achieve this, LIQUI MOLY has developed a program for cleaning and protecting particulate filters, which includes two fundamentally different cleaning technologies and a special additive to facilitate filter regeneration.

The first technology allows you to work literally “on your knees” and not use scarce and expensive diagnostic devices. However, it is labor-intensive, requires a lot of time and involves removing the particulate filter. The second technology is faster, but requires the use of complex electronic equipment. As for the results, that is, the effectiveness of the product compositions, they are identical. According to LIQUI MOLY specialists, the cost of this service will not exceed 10,000-15,000 rubles, which is significantly cheaper than a complete filter replacement.

The editors of the KUZOV magazine decided to independently test the new system and demonstrate its operation to readers. For this purpose, the publication’s correspondents chose an independent service station specializing in Mercedes-Benz cars, where Dmitry Rudakov, a specialist from LIQUI MOLY

, proposed to show and prove the effectiveness of the system on the third generation Mercedes ML model.

The difficulty of working with Mercedes models is determined both by the inaccessibility of the particulate filter itself and by diagnostic features. For example, when checking Volkswagen cars, the filter status is displayed as a percentage on the diagnostic scanner screen, which greatly simplifies the decision-making process. Mercedes, on the contrary, only indicates a malfunction, indicating discrepancies in ideal and real values. Thus, the master must himself determine the nature of the upcoming repair.

To carry out the work, specialist Dmitry Rudakov will first of all need the LIQUI MOLY Pro-Line Diesel Partikel filter Reiniger cleaner and the Pro-Line Diesel Partikel filter Spulung wash/neutralizer.

The cleaning solution must be poured into a special tank onto which a gun with one of the attached probes is attached. Straight and curved manipulators allow you to work with almost all manufactured vehicles.

It is necessary to make sure that the temperature of the particulate filter is about 40 ° C, since it is under such conditions that the effect is most effective. The temperature can be seen on the screen of diagnostic equipment, but if it is not at hand, it is enough to measure the heating of the filter with an optical household pyrometer.

Next, you can remove the oxygen sensor located in front of the particulate filter, through which cleaning liquid will be supplied in portions. However, in our case, the specialist did not do this, since it is convenient to use a different hole on Mercedes. A LIQUI MOLY representative removed the catalyst temperature sensor, which is located in the middle of the filter, between the catalyst and the active DPF element. Access of cleaning fluid through this opening ensures proper distribution of the fluid in all cavities.

After test spraying, the cleaning composition is fed through the above opening into the filter in several stages. During this process, the probe must be rotated slowly, thereby ensuring uniform distribution of the product.

Now you need to wait 15 minutes and pour the remover/neutralizer inside in the same way. After finishing cleaning, replace the temperature sensor.

To evaporate the remaining composition from the filter, you need to start the engine and warm up the filter to an operating temperature of 300°C. After this, using a diagnostic scanner, you need to start the forced regeneration mode. Then, within 10-20 minutes, you should drive 10 kilometers by car.

If it is not possible to leave the service station, you will have to simply press the gas pedal for the same time interval, but this must be done either on the street or with the exhaust gas removal system connected. After just a couple of minutes of running the engine under load, thick white smoke will pour out of the exhaust pipe. This indicates that the procedure was carried out correctly.

A diagnostic scanner will also help determine how well the filter is cleaned. To do this, it is enough to check the readings of the exhaust gas pressure sensors at the inlet and outlet of the particulate filter as a percentage before and after the procedure. The effectiveness of the solution can also be judged by temperature values.

In our case, a reliability check showed that the catalyst temperature of 190°C is almost equal to the temperature inside the particulate filter - 180°C. According to standards, these readings should not differ by more than 60°C.

According to LIQUI MOLY estimates, the cost of the procedure for cleaning the particulate filter can vary between 10,000-15,000 rubles. This amount includes wages, consumables and self-sufficiency of equipment, the price of which is 15,000 rubles. However, this is significantly cheaper than completely dismantling a damaged particulate filter, purchasing a new filter and then installing it.

According to Dmitry, on business-class cars it is advisable to carry out the procedure for cleaning the particulate filter together with changing the oil and cleaning the injector; it is advisable to include it in the list of routine maintenance every 10,000-20,000 kilometers. On budget cars, this should be done only as needed when a corresponding error appears.

As we have already said, the service life of a particulate filter is determined by the frequency of its burn-through. The more often this procedure occurs, the more catalyst (platinum) burns out irrevocably. Today it has become possible to increase the mileage between burns and reduce the process temperature. For this purpose, LIQUI MOLY has developed an additive to protect the diesel particulate filter Diesel Partikel filter Schutz, which we will discuss in detail in a separate article.

Your car has lost power, has trouble starting, and you suspect the particulate filter is to blame? Flushing the diesel particulate filter is one way to solve your problem, as well as an excellent preventive procedure that can extend the life of an expensive part.

Every day, cars are subject to more stringent requirements for the level of emissions of harmful substances into the atmosphere. To comply with established environmental standards (Euro 4, Euro 5), cars are equipped with special filters that capture soot and burn it safely.

According to manufacturers, the particulate filter resource is enough for the entire service life of the machine. You do not need to carry out special maintenance or replacement of parts. But why then do you need to flush the diesel particulate filter?

Reasons why the particulate filter gets clogged?

Unfortunately, not everything is so rosy. Russian fuel has become famous for its low quality. In addition to sulfur, it may contain dirt and various resins. If you also refuel at dubious gas stations, you can get a low-quality surrogate, diluted with octane-boosting additives. When such fuel burns, resins are formed, which not only settle on the walls of the combustion chamber, but also enter the particulate filter, where powdered soot is glued together. As a result, the filter gradually becomes clogged and cannot pass exhaust gases, which leads to a drop in engine power.

Manufacturers provide that when the difference in pressure at the inlet and outlet of the particulate filter reaches a certain threshold, the burnout mode starts. But there are nuances here too. The mode is activated only while driving and only at high (or medium) speeds. When moving around the city, the car sits idle more, which means the filter cannot be cleaned in a timely manner. Gradually, the pollution goes beyond controlled limits and at one point the car simply won’t start. Even if you manage to start the engine and accelerate to the required speed, burning will not help. Too late…

Flushing the diesel particulate filter

You can replace the particulate filter with a new one. But the part will have to be ordered directly from the manufacturer, and this takes time. The replacement price reaches 100 thousand rubles or more. The second option is to remove the filter and reflash the ECU. But no one guarantees that the new firmware will work. Sooner or later you will also have to pay a fine for environmental pollution.

We offer the best solution - rinse the filter

. A special wash from Liqui Moly dissolves accumulated resins. After cleaning, the particulate filter is completely cleaned and all its characteristics are restored to 100%.

Let us warn you right away: trust washing the particulate filter only to professionals. The procedure is carried out using specialized and quite expensive equipment. If you deviate from the technology, there is a risk of clogging the filter even more, then you will have to change it. In addition, the cleaning agent is very aggressive and, if it comes into contact with the skin, causes severe burns, or can deprive of vision if it gets into the eyes.

Particulate filter washing price

How to extend the life of the diesel particulate filter?

In Russian conditions, it is possible to extend the service life of the particulate filter. It is enough to add a special fuel additive – Disel Partikelfilter Schutz – once every 2000 kilometers, and refuel only at proven gas stations.

Don’t forget to regularly stop by the Dvizhok car service center on Varshavka - this is a guarantee that everything is always in order with your car.

At the end of the last century, environmentalists began to vigorously fight the owners of automobile companies and oil rigs, accusing them of excessive environmental pollution. In order to somehow calm down the indignation of the fighters for a clean atmosphere, the designers developed such a part as a particulate filter. With the beginning of its use in the automotive industry, we stopped breathing soot, which is released during combustion.

Why does the particulate filter become clogged?

The pollution process begins as a result of the combustion of diesel fuel in the cylinders of a diesel engine. A by-product of combustion of a mixture of diesel fuel and air is soot. This soot does not cause any particular harm to the filter, since it is a fine powder. During filtration, these particles are simply retained on the mesh.

The problem arises due to the presence of hydrocarbon particles in the exhaust that were not burned in the working chamber. Hydrocarbons lead to the active formation of tar deposits. Soot microparticles are literally glued together with resin, resulting in accelerated formation of carbon deposits. Carbon deposits also contain components of diesel engine oil in the form of metal sulfates, which are formed after combustion of the oil that has entered the cylinders.

Sulfates appear in the exhaust due to the fact that metal-containing additives are included in the basic composition of the additive package for diesel oils. This especially applies to universal motor oils, which can be used equally for both diesel and gasoline internal combustion engines. The result is that the diesel self-cleaning system is unable to remove dense deposits on the particulate filter.

Method one

First, we will purchase a means for washing the diesel particulate filter. To carry out high-quality cleaning from contaminants, one particulate filter will have to use up to 5 liters of the washing mixture. These mixtures operate in this way: over a certain time, the chemical composition of the washing mixture can dissolve a certain amount of resins on which the resulting carbon deposits are held. Therefore, you need to familiarize yourself with the requirements of the manufacturer of the cleaning fluid and maintain the specified time.

Clogged filter device

You can clean the particulate filter as follows:

- remove the device from the car;

- pour the cleaning mixture into it;

- wait for the time specified by the manufacturer of the mixture (about 8 hours) for the resins to split;

- drain the mixture from the unit;

- wash off the separated soot with a stream of clean water;

- dry the filter device;

- install the unit in its original place.

These manipulations can be carried out using special cleaning mixtures that have an effect on the resins and are also easily washed off with water. Using other substances will damage the fragile layer inside the filtration device.

How does a particulate filter work?

Any particulate filter operates in three modes:

- soot capture;

- soot oxidation (regeneration);

- forced regeneration.

Soot collection occurs thanks to small filter channels, the size of which is comparable to the size of soot particles and amounts to hundredths of microns. During engine operation, soot settles in the filter channels, due to which it is captured. The transition to regeneration mode depends on the temperature of the exhaust gases. When their temperature reaches 400–600 degrees, soot oxidation begins, as a result of which it decomposes into nitrogen and carbon dioxide. In this case, the material of the filter channels acts as a catalyst for the oxidation reaction. If the driver uses the car for short trips, then the exhaust gases do not have time to heat the filter to the required temperature, which is why soot begins to clog the channels. When this happens, engine power begins to drop, because part of the rotational energy of the crankshaft has to be spent on forcing exhaust gases through clogged filter tubes. In this case, it is necessary to carry out forced regeneration.

This process is performed differently and depends on the car model. On some it must be activated manually, on others the electronic engine control unit (ECU) is responsible for this. For forced regeneration, an over-enriched mixture is burned in the cylinders, the composition of which does not ensure the formation of soot. As a result, the exhaust gases burn out in the catalytic converter, heating up by 500–700 degrees, after which they immediately enter the particulate filter and put it into regeneration mode.

Diesel particulate filter clogged: signs and consequences

The role of the soot is such that it only takes power away from the engine. The fact is that soot constantly accumulates inside it, creating resistance to the movement of exhaust gases. You won’t notice this in the city, but on the highway a car with a barely filled filter will accelerate less readily. However, driving on a suburban highway is very useful for a diesel engine, we will explain why later.

One way or another, a slight drop in traction is difficult to notice. It is much easier and more useful to pay attention to the instrument panel, where a special lamp or combination of LEDs will outline the severity of the problem. The exact answer to what this or that icon means can only be found in the instructions for the machine. As an example, we suggest considering the algorithm for signaling problems with DPF on VAG cars:

There is only one explanation for these events - unsuccessful regeneration (burning off soot using standard means). The purpose of burning is to increase the temperature in the particulate filter so that the soot burns out (converts into carbon dioxide) and the matrix channels become free again. They increase this very temperature mainly due to post-injection of fuel, so that the diesel fuel burns out in the “soot”. If you do not follow the manufacturer's instructions regarding the driving mode during the regenerating event, you will not get a successful result. Attempts at burning will be repeated often, which will ultimately lead to the things mentioned - an increase in diesel fuel consumption and oil level.

We recommend abandoning the idea of letting everything take its course. When the particulate filter is almost clogged, the car does not behave in the best way, because emergency mode means continuous restrictions on speed and current fuel consumption. If this fact does not stop you, then the result of “ignoring” the emergency alert will work in any case: when the purifier is completely clogged, the car stalls and does not start, or starts and immediately stops.

Forced regeneration and manual cleaning

If the filter has been used in unfavorable conditions, thereby becoming clogged, it should not be used. It will simply destroy the system and the engine, which will result in a major overhaul. Therefore, if the blockage is complete, it is necessary to undergo a forced regeneration procedure.

Forced regeneration can be triggered by special equipment, often found in service centers. It allows you to quickly remove the blockage by connecting the cleaning system. However, it is not always possible to enable it. In cases where the filter is filled above normal, it will not be possible to turn on the cleaning system.

If this happens, then washing with special means will help. Often it allows you to eliminate most of the soot, after which regeneration can be activated.

Washing is carried out using two methods:

- without removing the element;

- complete washing and removal.

In the first case, you need to take a spray gun and a flexible tube, as well as a filter cleaning product. For such tasks, TUNAP MP 131 fluid is suitable. A pressure source is also required - a compressor. The filter is accessed through a previously removed temperature or pressure sensor. It is necessary to thoroughly clean this element, the approximate consumption for one cleaning is up to a liter of liquid.

Next, you need to remove the liquid with TUNAP MP 132 concentrate. After this, the cleaning procedure is completed, you need to return the sensor to its place and regenerate the filter using standard methods. If the procedure does not help, then it is necessary to carry out a complete wash and remove the element.

The second method is to completely remove the filter and wash it. First you need to remove the filter from the system and open it. Next, it must be washed with special products like DPF Cleaner. They remove soot and oil residues, making them easily removed under water pressure. Such cleaning agents are washed off with water. Cleaning can be supplemented with special cleaning products such as PRO-TEC DPFCatalyst Cleaner. However, this depends on the situation.

Advice! Using a compressor can improve filter cleaning efficiency. It is enough just to push the cleaning agent through with compressed air.

After completing the procedure, you need to dry the filter and install it in the car. Next, you should check its condition and start regular regeneration. But it is worth considering that flushing is not always able to help against blockages. If the available methods do not help, you will have to purchase a replacement.

Important! Gloves must be worn when using cleaning agents. It is important to remember that these are aggressive substances that can harm the skin. It is recommended to replace the filter after passing 180 thousand kilometers

This point can be delayed through cleaning and regeneration, but this element cannot serve forever, and using a clogged or bad filter will lead to soot getting into the system, which will certainly result in high repair costs

It is recommended to replace the filter after passing 180 thousand kilometers. This point can be delayed through cleaning and regeneration, but this element cannot serve forever, and using a clogged or bad filter will lead to soot getting into the system, which will certainly result in high repair costs.

And for a better understanding of the effectiveness of washing particulate filters, it is recommended to watch this video. Here the clogged filter segment was cleaned using Luffe. The stages of the procedure and the effectiveness of such washing are clearly shown:

- The starter relay clicks but the starter does not turn over.

- How to change the generator on a Priora

- Replacing the tension roller of the generator belt on a Priora

- How does a mini-wash work?

Methods for cleaning the particle filter

DPF cleaning can be done at any service station. But this procedure is not cheap, so you can clean the diesel particulate filter yourself. There are several ways to do this.

Use of additives

Some brands of cars have additional additive reservoirs next to the main fuel tank. The latter include special substances that accelerate the deposition of soot in the filter. Additives are added to the fuel under electronic control.

Most additives are based on zinc oxide. It is capable of binding the smallest soot particles into a dense layer that settles in the cells of the filter element. When the layer is formed, it is saturated with oxygen. This significantly increases the efficiency of afterburning.

Even if a diesel car does not have a special tank for additives, the car owner can add them directly to the gas tank. However, the effectiveness of such cleaning is questionable. The fact is that long-term use of additives leads to the appearance of plaque on the walls of the channels that remove exhaust gases. Over time, sediment can completely clog them. Because of this, the catalyst has to be changed not at 120,000 km, but after only 80,000 km or even less. The negative effects of additives can be avoided by flushing the channels.

Flushing the diesel particulate filter

Experienced car enthusiasts wash the particulate filter in their cars using conventional spray bottles equipped with a long and thin tube. The procedure takes place in several stages:

You can also wash the particulate filter yourself without using a spray bottle. To do this, you need to buy a special product in a can in the store. The capacity of the latter usually does not exceed 400 ml. This volume of foam cleaner is usually enough to completely clean the filter element. Since the cleaner is foamy, the filtration unit should be refilled with it in small portions with a temporary break between them.

After filling the filter with foam, wait 30 minutes. Then put the sensor in place and pour the additive into the tank.

DEVICE OF DARTICLE FILTER AND PRINCIPLE OF ITS OPERATION

The particulate filter has a simple device based on a cellular membrane. It is made of silicon carbide and consists of many small channels connected by jumpers. The use of such a design and material provides the filter with the following characteristics:

- high temperature threshold;

- resistance to temperature fluctuations;

- large resource of work;

- high strength.

- Thanks to this, it is able to perform its task for a long time, intercepting miniature soot particles in the exhaust path.

The principle of operation of such a device is no different from a conventional filter. The soot particles simply remain in the membrane system without escaping. Since all exhaust gases are passed through this filter, the system is able to block a significant portion of the soot during the exhaust process.

But it is important to remember that the filter is constantly filled with soot particles, which leads to a decrease in throughput. To eliminate them, regeneration is carried out, which is provided for by the structure of the element itself.

Diesel particulate filter, how it works and where it is installed

The particulate filter in a car is usually located behind the catalytic converter. In some designs, this part is combined with an oxidation-type catalyst and is located directly behind the exhaust manifold, where the temperature of the exhaust gases is maximum. It is called a catalytic-coated particulate filter.

The main structural component of a particulate filter is a matrix, which is made of ceramic (that is, silicon carbide). The matrix is located in a metal case. The ceramic matrix has a cellular structure consisting of fine-section channels, closed alternately on both sides. The side walls of the channels play the role of a filter and have a porous structure.

Cleaning the particulate filter

A particulate filter is a device in cars with a diesel engine designed to clean soot from exhaust gases. If the device becomes dirty, a number of problems arise in operation - the machine jerks or stalls, the motor starts to trip, and its dynamic properties deteriorate. A dirty particulate filter prevents exhaust gases from escaping normally, causing the car engine to stop working.

If the problem is identified early, cleaning the diesel particulate filter is hassle-free and can produce results. Below we will consider in what sequence to perform this work, when cleaning will be effective, and also what to do if the described manipulations do not provide the expected result.

Why is it necessary to clean the particulate filter?

Structurally, the node in question is somewhat similar to a beehive. It also features many small cells interconnected with each other and “corridors” arranged in parallel. Each cell has a cross-section not exceeding 1*1 mm. During operation, the cells gradually become clogged, and the throughput of the device deteriorates. The cause of pollution is an increased level of soot in combustion products, due to the poor quality of the fuel used or oil entering the combustible mixture. Pollutants remain on the particulate filter and, over time, completely clog it.

In what cases will cleaning the particulate filter be effective?

If problems arise in engine operation caused by a clogged filter element, act immediately. The faster the particulate filter is cleaned, the less risk there is for the engine and other components of the car. This procedure costs a small amount and does not hit the car owner’s pocket too much.

On the other hand, simply cleaning does not guarantee that the problem will be eliminated. Success largely depends on a number of factors - timely detection of a malfunction, level of contamination and quality of cleaning. When, during operation, there are already problems with starting, the engine has begun to stall and the dynamics have deteriorated, then cleaning is unlikely to help. In this case, it is easier to remove the particulate filter completely or replace it.

The problem can be solved if, after the Check Engine light comes on, the information from the ECU is immediately read and decrypted. If the system shows a clogged unit, and measures are taken immediately, cleaning the particulate filter is effective in 50% of cases. At the same time, the cost of the work is no higher than the price for repairing the filter.

What are the cleaning secrets?

Many car owners are interested in how the particulate filter is cleaned and what products are used for the job. Everything is simple here. A special additive is added to the fuel tank. The finished composition enters the engine, burns and exits through the exhaust system in the form of exhaust gases. In this case, the particulate filter is cleaned of soot and dirt gradually.

There is another way - dismantling the devices and subsequent cleaning using special “chemistry”. To do this, the liquid is poured into a deep container, into which the internal elements of the filter element housing are lowered. After some time, the part is taken out, washed and blown out under pressure.

The second method is used less frequently due to the need for machine downtime after cleaning. But, in terms of effectiveness, both methods are approximately the same. At the same time, the final cost of the work is also approximately the same.

What to do if cleaning does not produce results?

As mentioned above, cleaning the particulate filter is not always effective. If the measures taken do not produce results, there are two options:

- Change the filter. In this case, give preference to original parts or high-quality universal substitutes. Be prepared for the fact that such a purchase will cost you a tidy sum.

- Remove the device. Here the physical dismantling of the particulate filter takes place, followed by adjustments to the vehicle software. At the same time, the environmental class is reduced to EURO-3.

So, if the problem is detected in a timely manner, start by cleaning the particulate filter. Resort to drastic measures only if the mentioned work is useless.

Video: Cleaning the diesel particulate filter (DPF) with LUFFE liquid

How often should I wash?

Washing this filter component is necessary if the car owner feels that the engine of his car has become worse. The formation of soot in a diesel car engine is determined by fuel combustion processes, in particular:

- supplying air to the system;

- injection indicator;

- propagation of the combustion zone in the engine.

It is worth noting here that in certain areas of the combustion chambers, over-enrichment of the combustible mixture can be recorded, which appears as a result of a lack of oxygen in the system. If such a process occurs in the engine, the combustion process will be incomplete, which may result in the formation of soot.

The filter element needs to be washed if serious problems associated with the filter arise during engine operation. It is also recommended to do this during maintenance. To do this, you can use the services of specialists at a service station, but it is also worth remembering that you can also use a special particulate filter cleaner.

As for the frequency of element cleaning, it is determined for each individual car. In general, the service life of the soot cleaning component is determined by the frequency of its burning. That is, the more often the burning process occurs, the more catalyst can burn out irrevocably. In these cases, it is important to use an additive to clean the particulate filter, since the use of this substance can increase the service life of the element.

Special fluids for washing the component are especially relevant for those cars that are operated in urban environments. Do not forget that exhaust gases are dangerous not only for the environment, but can also be fatally poisonous to people. And the use of filter washing liquids allows not only to reduce the amount of soot in the exhaust gas cleaning system, but also to reduce the load on the element as a whole.

We cannot give exact recommendations for filter washing, since they are individual for each individual car. However, as practice shows, with the systematic use of additives, once every 2 - 3 thousand kilometers. Special measures to clean the element may not be necessary at all.

How to clean the particulate filter

In order for its performance to be restored, it is necessary to clean the pores of foreign particles. The car manufacturer provides for a procedure such as regeneration for the particulate filter. She may be:

Passive cleaning

Cleaning the inner surface in this way is quite simple; this is provided for by the design of the filter element itself. The following methods are used:

- Afterburning of unburned fuel particles. To do this, a high temperature is ensured inside the filter (at least six hundred degrees), especially in cases where the engine load is maximum.

- Regeneration using special fuel additives such as urea and EOLYS, which ensure soot combustion at lower temperatures (no more than five hundred degrees).

- Regeneration thanks to a catalytic coating on the inner surface of the ceramic tubes. The use of catalysts and high temperatures leads to oxidation of soot particles (combustion).

Active or forced regeneration

In cases where the tubes become clogged, the power and torque of the engine drop, and the car, roughly speaking, stops moving. The system state is monitored by sensors:

- temperature;

- pressure in the cleaning system;

- air flow.

The particulate filter clogs most quickly in city traffic, as well as when in traffic jams, so this mode is the most harmful for diesel cars. This is due to the fact that with such movement the temperature of the exhaust gases is not high enough to completely burn the soot, so it clogs the pores in the tubes. To restore the car's performance when this happens, it is necessary to burn through the particulate filter.

Second way

Washing the filter unit directly on the car

This method allows you to clean the filter without removing it from the car. With this method, manufacturers of cleaning products take into account the possibility of ignition of the composition of the washing liquid. Therefore, solutions with a water-alkaline base are used for washing. They are used in tandem with a flushing mixture that can neutralize alkali after the cleaning process is completed.

For this procedure the following are used:

- set of liquids;

- gun;

- spray;

- probes.

All these elements are sold in a car store or on the market. Allows you to clean the filtration element on any model of diesel car equipped with a particulate filter device. Cleaning is carried out by step-by-step dosing of the incoming cleaner through the hole for the pressure and temperature measurement sensor. Before starting the procedure, the car is warmed up, after which the filter device is allowed to cool to a temperature of 40 0 C. This is the optimal temperature indicator for the effective operation of the alkaline mixture.

To rinse the filtration device, you will need a spray gun; it must be connected to a probe, which will be inserted into the sensor hole. The cleaning agent is sprayed inside the filter, then left for up to 10 seconds. and spray again intermittently. This procedure is repeated several times. To increase the cleaning efficiency of the probe, it is necessary to perform rotational movements around its axis. Then a rinsing agent is used, a second probe is used, and the procedure is repeated in the same way, maintaining a time interval. The result of these manipulations will be a uniform distribution of soot over the surface of the matrix, and it will be possible to burn it out more efficiently.

After the cleaning work is completed, the sensor is installed in its original place, the car engine is started and the car is operated for 20 minutes at medium and high speeds, then regeneration starts or this procedure begins in automatic mode.

Particulate filter, principle of operation, purpose After what period should the fuel filter on a diesel car be changed?

As for the particulate filter, in most cases it can be regenerated, which can be done by the office.

dealers connect their computers and “calcinate” it in a certain way, and during normal operation it should clean itself, if this did not happen, then the diesel engine has problems more serious than this filter because for us - diesel engines this is a filter, not a catalyst... therefore this is not a standard the diesel problem is a consequence... some people are completely collective farmers... they wash it with aviation kerosene and go... Well, as an educational program...The particulate filter is designed to reduce the emission of soot particles into the atmosphere with exhaust gases. In the exhaust system of a diesel engine, the particulate filter is usually combined with an oxidation-type catalytic converter. This type of filter is called a catalytic particulate filter. The catalytic particulate filter is installed behind the exhaust manifold in close proximity to the engine. The main structural element of the particulate filter is the so-called. matrix, which is made of ceramics (silicon carbide). The ceramic matrix has a cellular structure consisting of channels of small cross-section, alternately closed on one side and the other. The walls of the channels have a porous structure and act as a filter. A thin layer of catalyst – titanium – is applied to the surface of the walls. The matrix is placed in a metal case. Operating principle of the particulate filter:

When exhaust gases pass through the particulate filter, soot particles are retained on the surface of the matrix walls. The catalyst applied to the walls of the matrix promotes the oxidation of unburned hydrocarbons and carbon monoxide. The filter is cleaned of accumulated soot by regeneration. A distinction is made between active and passive particulate filter regeneration. With passive regeneration, continuous oxidation of soot occurs due to the action of the catalyst and the high temperature of the exhaust gases (350-500°C). The chain of chemical transformations during passive regeneration is as follows: nitrogen oxides react with oxygen in the presence of a catalyst to form nitrogen dioxide; nitrogen dioxide reacts with soot particles (carbon) to form nitrogen oxide and carbon monoxide; Nitric oxide and carbon monoxide react with oxygen to form nitrogen dioxide and carbon dioxide. Under certain engine operating conditions (light load, etc.), the exhaust gas temperature is not high enough and passive regeneration cannot occur. In this case, active (forced) regeneration of the particulate filter is carried out. Active regeneration occurs at a temperature of 600-650°C, which is created using the engine control system. At this temperature, soot particles react with oxygen to form carbon dioxide. The active regeneration of the particulate filter is controlled using the following sensors: air flow meter; exhaust gas temperature sensor upstream of the particulate filter; exhaust gas temperature sensor after the particulate filter; differential pressure sensor in the particulate filter. Based on electrical signals from the sensors, the electronic control unit injects additional fuel into the combustion chamber, and also reduces the air supply to the engine and stops exhaust gas recirculation. In this case, the temperature of the exhaust gases rises to the required value. What the dealer does is he controls the sensors in such a way as to put the engine into active (maximum permissible) regeneration mode. that's all…

Every diesel car has a particulate filter. If it is not cleaned, it will lead to serious consequences for the machine.

Its clogging leads to the release of particles into the environment, which is harmful to humans, and on the car this is reflected in problems with the electronic signal on the dashboard, a decline in traction and dynamic characteristics, interruptions in the functioning of the engine, and an increase in the oil level.

This is why diesel particulate filters are cleaned.

Do-it-yourself diesel particulate filter cleaning

The particulate filter of a diesel engine (as well as a gasoline engine) is washed in 2 ways:

- without dismantling the device;

- after dismantling.

To clean the unit yourself, remove it. The procedure is quite troublesome - it takes 8 hours. We remove the filter device and fill its body with flushing agent. Cleaning liquid is usually sold in 5 liter canisters. One procedure takes up to 4 liters. We pour the product through the hose that comes with the canister.

When filling the filter, the substance begins to dissolve soot deposits. The desired effect can be expected after the liquid has been inside the case for 8 hours. Do not neglect to read the instructions before using the product, as it describes the dosage.

After 8 hours, the soot deposits are separated and removed with a pressurized water jet. Then the soot is put in place.

Some drivers think that chemical cleaners can be dangerous for the catalyst, but this is not the case. Modern additives contain safe elements that only destroy soot.

Be aware of the platinum layer covering the inside of the soot. It is quite fragile, and excessive exposure to it is unacceptable.

Washing the particulate filter without dismantling

The work will be completed faster if you do not remove the device. This is made possible thanks to a temperature sensor. After unscrewing it, a hole appears through which you can pour flushing fluid.

Do not forget about safety precautions - remember that the liquid can ignite. The product is applied into the hole using a gun or probe.

Here's how to proceed:

- We warm up the engine.

- Pour a liter of liquid into the hole and leave for 15 minutes.

- We connect the gun to the probe.

- We insert the probe into the hole. Spraying the liquid takes 10 minutes. Then we stop the procedure for 10 minutes, then resume.

There should be 4 or 5 ten-minute cycles (cleaning-stop). For better spraying of the composition, it is recommended to scroll and move the probe back and forth during the cleaning process.

After the procedures, fill the system with rinse aid (0.5 liters), which is needed to neutralize the remaining active substance. We rinse with a sprayer at the same time intervals.

Upon completion of work, screw the sensor into place and warm up the engine to operating temperature. Then we start the regeneration process, which will destroy the remaining soot deposits. The duration of the process is 15 minutes. Natural soot burning begins after the engine has been running at medium speed for some time (15-20 minutes).

The process may not start naturally due to problems with the electronics. In this case, you need to run it yourself using a diagnostic scanner.

Cleaning methods have their pros and cons, but it is better to dismantle the device. And this does not depend on what power unit is in the car - Diesel or gasoline engine.

Additional Methods

There are also two ways to clean the diesel particulate filter at home. They are not fundamentally different, just one is a little faster. To avoid fire, you should use water-alkaline mixtures, as well as special cleaning fluids. You will need about 1 liter of cleaning liquid and approximately 0.5 liters of rinsing liquid.

You need to warm up the engine and drive onto the overpass. Using a pressure gun, pour cleaning liquid into the hole. To do this, unscrew the temperature sensor or pressure sensor. Afterwards, you should install the sensors in place and drive the car for about 10 minutes. During this time, the soot will dissolve. Then you need to drain the cleaning liquid and fill in the flushing liquid in the same way.

Then you need to unscrew the temperature sensor or pressure sensor and use a pressure gun to fill in the cleaning liquid. You should wash for about 10 minutes, in short bursts of 10 seconds, while trying to get to all hard-to-reach places. Intervals must be taken between injections. Then close the hole and repeat the procedure after 10 minutes. After this, you need to use a washing liquid. The cleaning is completed, all that remains is to start the car and wait until the regeneration mode ends.

Fact! The car owner must understand that cleaning the particulate filter on a diesel engine is not a panacea. The filter is designed for a mileage of 150-200 thousand km with proper use.

To make a particulate engine last longer, you should follow simple rules:

How to clean the particulate filter

Cleaning products from Liqui Moly are considered high quality, but they are expensive. The product helps reduce the formation of soot. It is suitable for diesel vehicles. Constant use of cleaning additives will increase the filter life.

Another effective product is Diesel Partikelfilter Schutz. One package is enough for 2,000 km. This substance is added to the fuel tank before adding fuel. It is not recommended to use Diesel Partikelfilter Schutz together with other products. 75 liters of fuel require 1 bottle.

JLM is also a high-quality solution for washing soot. If you add it every 10,000 km, it can completely restore the functionality of the element. JLM can be used on any car.

The Russian remedy is “Security”. According to the manufacturer, it can reliably protect the DPF from clogging. The norm is 1 bottle per 10,000 km. The substance is added to the fuel tank. The cleaning process starts while the vehicle is moving. There is no negative impact on the elements of the fuel and exhaust systems. The use of the "Protection" product leads to a significant reduction in exhaust toxicity.

Purifier options

Next, we will look at the most popular and common liquids for washing particulate filters found on the domestic automotive market.

LM Diesel Partikelfilter Schutz

Liqui Moly product line

Additives from Liqui Moly are considered one of the best and most expensive that can be found in Russian and Ukrainian car stores. According to the manufacturer of the substance, these additives are not only highly effective, but also reduce the rate of soot formation. And this, in turn, helps to increase the service life of the element, and also facilitates the operation of the engine as a whole.

The use of this additive, as the manufacturer assures, is especially relevant for diesel vehicles that operate:

- in urban environments;

- in traffic jams;

- at short distances.

Such cars more often than others experience problems with filter element clogging. If the substance is systematically added to the fuel, the condition of the purification component will be maintained clean. This will enable the car owner to avoid expensive repairs and time costs that may arise if a component fails.

One package of Diesel Partikelfilter Schutz is enough to use for 2 thousand kilometers. The manufacturer recommends adding the substance to the car's fuel tank before refueling the car with diesel. One bottle of the substance is enough for 75 liters of diesel. Also, do not forget that overdoing it in this case can only do harm. That is, it is necessary to avoid overdose. In addition, the manufacturer categorically does not recommend using Diesel Partikelfilter Schutz together with substances of other brands.

JLM

JLM Flushing Agent

This type of additive is also one of the most common among domestic motorists. According to the manufacturer of the consumables, the use of this substance allows for maximum rinsing of the soot cleaning element if you add it once every 10 thousand kilometers. To wash the filter, you need to add JLM to the fuel, after which even the most contaminated element will be cleaned. In addition, JLM allows you to restore the operation of the element in case of regular use of the car in urban conditions.

As for the benefits:

- JLM allows you to extend the life of the exhaust gas treatment system;

- flushing liquid allows you to reduce the cost of unscheduled maintenance or repair work;

- consumables reduce the regeneration rate, which can subsequently lead to mechanical damage to the filter element housing.

It should also be added that JLM has been recommended for use in vehicles:

- Peugeot;

- Citroen;

- Ford.

So the owners of these cars can safely use JLM in their cars.

PROTEC DPF Super Clean additive

Flushing additive PROTEC

The consumable substance for cleaning the particulate filter element of the PROTEC brand has also managed to establish itself among domestic motorists. The manufacturer of the material assures its consumers that if PROTEC DPF Super Clean is regularly used, the car owner will be able to protect his vehicle from breakdown for a long time and reliably.

PROTEC DPF Super Clean, according to the manufacturer, is a highly effective consumable for cleaning the exhaust filter. To flush the element, you need to add a substance to the fuel tank. As for the benefits of using PROTEC:

- The cleaning itself takes place during the operation of the vehicle;

- consumables allow you to eliminate deposits that appear in the particulate filter as much as possible;

- PROTEC flushing liquid does not have a negative effect on the elements of the fuel system, as well as the exhaust gas cleaning system.

- The substance also helps reduce the level of toxicity of exhaust gases.