Description

The camshaft is an important component of the engine management system. It rarely fails, but if it does, repairs are often very expensive. Especially if you do not monitor the technical condition of the engine and do not recognize the signs of a camshaft malfunction in time. Here's the most detailed information about this important engine component.

Engine duty cycle

The period when the intake and exhaust valves in each cylinder must open once is the engine operating cycle. It is carried out in 2 revolutions of the crankshaft. At this time, the camshaft should make one revolution. It is for this reason that the camshaft gear has twice as many teeth.

Camshaft function

The camshaft in a four-stroke engine controls the opening and closing of the valves in the cylinder head and thus controls the gas exchange in the engine. To do this, there are cams on the camshaft (usually their number corresponds to the number of valves in the engine), which convert the rotational movement of the camshaft into valve stroke movement. If the camshaft cam pushes the valve down (via a pushrod or rocker arm), an inlet or outlet in the engine's cylinder head opens.

The camshaft is driven by the crankshaft. The camshaft rotates at half the crankshaft speed. The crankshaft and camshaft are usually connected via a timing belt or timing chain (in older cars the connection was via a gear reducer).

Linear motors (flat power units) can have a maximum of two camshafts. V- and W-engines can rotate up to four camshafts in the cylinder heads.

Operating principle of camshaft

The camshaft is located in the camber of the cylinder block. Using a gear or chain drive, the camshaft is driven by the crankshaft.

The rotation of the camshaft ensures that the cams influence the operation of the intake and exhaust valves. This occurs in strict accordance with the valve timing and the operating order of the engine cylinders.

To correctly set the valve timing, there are timing marks located on the timing gears or on the drive pulley. For the same purpose, the crankshaft cranks and camshaft cams must be in a strictly defined position relative to each other.

Thanks to the installation carried out according to the marks, the sequence of alternating strokes is observed - the order of operation of the engine cylinders. The order of operation of the cylinders depends on their location and the design features of the crankshaft and camshaft.

OHC and DOHC - what does it mean?

Volkswagen Beetle camshaft: The cam (left) transmits movement through a long plunger to the valve rocker arm

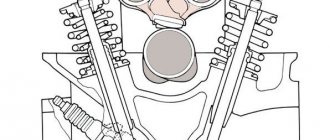

Modern engines only use overhead camshafts (OHC = overhead camshaft). Often modern engines have two camshafts. One serves for the intake valves, the second is responsible for the exhaust valves (DOHC = double overhead camshaft).

In older engines, engines were typically designed with a single camshaft. Also in them, the valves in the cylinder head were controlled by plungers. This motor design results in a lot of mechanical friction, making these types of power units less efficient and less powerful.

Below in the graphic animation you can see how two camshafts work in a modern four-cylinder engine (DOHC principle).

About the design of the camshaft

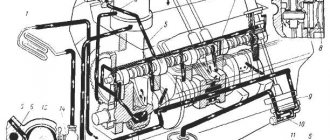

The structure and drawing of the timing belt, including the camshaft, are shown below.

Structurally, the camshaft can be located either in the cylinder block or in the head of the power unit. Depending on its location, the drive also changes, thanks to which the force is transmitted from the cams to the valve. The camshaft drive is connected to the crankshaft. The drive can be made using either a chain drive (see drawing above) or a flexible belt drive. In addition, there may be other ways to transmit control force to the valves, but this is already determined by the drawing and documentation of the motor.

Which camshaft drive is best to use is determined by the design of the engine. In cases where the camshaft is located in the cylinder block (the so-called lower position), a gear drive may even be involved. The latter, however, has not been used recently due to its bulkiness and increased noise during operation. Both chain and belt drives are quite reliable, but each of them has its own operating features that must be taken into account when servicing the engine.

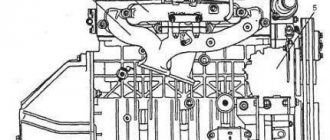

Its design may provide that there may be more than one camshaft in the engine. As a rule, in modern multi-valve engines it is located as close as possible to the valves to reduce the load on it. The design and drawing of, for example, a V-twin engine, provides for at least two shafts, while in a conventional in-line engine, as a rule, there is one camshaft. Although for multi-valve engines their purpose will be decisive - there may be separate exhaust and intake camshafts, i.e. they control the operation of the exhaust or intake valves.

Camshaft design

There are various materials from which camshafts are made. Basically, forged cam shafts have taken root in the automotive industry. But there are also cast camshafts, which are also called “hollow cast shafts.” Including new camshafts that have just begun to appear in the automotive world. We are talking about tubular shafts made of tubular steel.

Like all parts of a car, when designing a camshaft, engineers try to make it as light as possible without sacrificing quality or reliability. This also applies to all other moving components of the engine and other parts of the machine. Reducing the moving masses in the engine has a much greater impact on the overall efficiency of the vehicle's power unit than, for example, reducing the weight of other vehicle components.

Camshaft damage

Camshafts are considered wear-resistant engine parts and typically last the entire life of the vehicle. This is why camshaft damage is a rare occurrence. Especially when it comes to old cars. In more modern engines, the camshaft has a greater risk of damage, but nevertheless, defects in this part are also rare.

True, if a modern car is used in normal mode. If you often drive at high engine speeds (“screwing” the car), then the camshaft in a modern engine will fail much earlier than in an old car. But again, this does not apply to all cars. It all depends on what camshaft the automaker uses and what timing design is in the engine.

Significant signs of wear on the camshaft bearing liners: if the surfaces of the camshaft bearings are damaged, then it is enough to replace the liners.

The camshaft usually has bearings that have small holes in their housings. These holes are connected to the engine's oil circuit, providing a permanent film of lubricant between the camshaft sliding surfaces and the bearing shells, which reduces friction between these components. However, some engines are designed so that the camshafts operate without bearing shells.

In such engines, in the absence of oil supply or excessive engine voltage (for example, at high speeds), accelerated wear of the camshaft begins. Also, in such motors, under heavy load on the engine, the cams, which are constantly forced to press the valves against the force of the pressure spring), with insufficient lubrication, can change the valve opening time. Due to the valves opening and closing at inappropriate times, they no longer reach their maximum intended travel.

As a result, this affects the smoothness of the ride and power, which drops. Also, a similar problem of untimely opening and closing of valves can be noticed when the engine is idling. Unfortunately, improperly operating engine valves can cause engine damage.

Loss of oil due to damage to the camshaft oil seal

As we said, the camshaft is connected to the crankshaft through the camshaft gear, which is rotated by the timing chain or timing belt. At this point there is a rubber sealing ring (seal) that can harden or become porous over time. As a result, the oil seal will cease to function as a seal and oil will begin to leak from under the camshaft oil seal.

In this case, the oil leak must be repaired as soon as possible. Especially if your car uses a timing belt. The fact is that getting engine oil on the timing belt is undesirable, as this can lead to premature wear of the belt. As a result, it may suddenly break. Unfortunately, many modern vehicles use engines where, if the timing belt fails, the valves can collide with the pistons, causing severe engine damage.

The camshaft seal is very cheap. But it is very difficult to change it. Therefore, replacing a camshaft oil seal is an expensive proposition because in order to change it, you need to remove the timing belt or chain. In some cars, to do this, you will have to disassemble the floor of the car in the front. That is why many car enthusiasts are in no hurry to replace the oil seal, putting up with oil leakage from the camshaft, postponing replacing the seal until the moment when, according to the regulations, it is necessary to regularly change the timing belt or chain. After all, in this case you will have to take everything apart anyway. But this is far from the best solution.

Camshaft position sensor

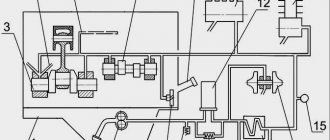

The camshaft sensor detects the current position of the camshaft. Depending on the readings of the crankshaft sensor and camshaft sensor, the engine control unit decides how to inject fuel and how to control the detonation of the power unit.

Camshaft sensors fail quite often. As a rule, if the sensor malfunctions, the engine idle speed begins to fluctuate. Also, a “Check Engine” icon appears on the car’s dashboard, and an error code for the engine control unit is recorded in the computer’s memory, which can be used during diagnostics to decipher the reason for the appearance of the “Check Engine” indication.

Replacing the camshaft sensor is relatively simple. Usually you don't even need to remove the engine valve cover to do this. But everything, of course, depends on the engine design, make and model. On average, it takes from 30 minutes to 2 hours to replace a camshaft sensor. The sensor itself costs approximately from 2000 to 6000 rubles. But the cost certainly depends on the car. You understand that a camshaft sensor on premium cars can cost a hefty sum.

The phenomenon of pitting occurs primarily in high-speed motorcycle engines. But sometimes this phenomenon is also observed in passenger car engines. Pitting translated from English means “pit”. Thus, camshaft pitting means that indentations begin to appear on its surface.

Damaged camshaft surfaces in these areas cause less than optimal lubrication, leading to premature wear of the camshaft and its components. In addition, flaking metal is a serious problem in the engine oil circuit, as these metal particles cause clogging of the engine and can cause engine damage.

Valve timing systems

Modern gasoline engines often have a camshaft adjustment system (Variable Valve Timing, VVT). This system allows us to achieve compliance with modern environmental standards adopted by the European Union and a number of other countries. Thanks to this system, the camshaft timing is adapted to the current driving situation. For example, when the car is stopped and the engine is idling, the camshaft control system adjusts the engine's valve timing system to operate more efficiently to reduce fuel consumption and, accordingly, reduce the level of harmful substances released through the vehicle's exhaust system.

On powerful engines, the valve timing system is usually common on both the intake and exhaust sides. The camshaft adjustment mainly consists of a hydraulic adjustment system and a control valve. Thanks to this valve timing system. For example, different engine operating modes require different valve timing values. So, when the engine is idling, the phases should be short. At high speeds the phases should be wider.

As a result, engines with variable valve timing constantly change the operation of the camshaft depending on the driving mode.

In addition to the hydraulic system, variable valve timing, the Variable Valve Timing, VVT system regulates engine operation using sensors on the crankshaft and using information about camshaft rotation.

One of the most famous types of camshaft adjustment is Porsche's "Vario Cam" system (now "Vario Cam Plus"). The chain tensioner acts as an adjusting element that raises or lowers the chain links between the two camshafts (DOHC) depending on engine speed. In this system, oil pressure is critical.

Here, in addition to camshaft phasing, the stroke of the valves through the camshaft can be changed. Automakers view the valve lift adjustment function differently. For example, some automakers implement valve operation through variable deflection angles. Others (Porsche Vario Cam Plus) use specially designed cams in combination with multi-point pushers.

Honda uses, for example, variable-size cams (i-VTEC), which, in combination with switchable rocker arms, allow valve lift to be varied in two stages.

What does the camshaft sensor do?

In engines with a carburetor, a distributor is connected to the camshaft, which determines which phase is performed in the first cylinder - intake or exhaust.

Injection internal combustion engines do not have a distributor, so the camshaft position sensor is responsible for determining the phases of the first cylinder. Its task is not identical to the functionality of the crankshaft sensor. For one full revolution of the timing shaft, the crankshaft will rotate around the axis twice.

DPKV fixes the TDC of the piston of the first cylinder and supplies an impulse to form a discharge for the spark plug. The DPRV sends a signal to the ECU at what point it is necessary to supply fuel and a spark to the first cylinder. The cycles in the remaining cylinders occur alternately depending on the engine design.