Mileage: 249,000 km

In my review I would like to share my experience of using a car such as the Gazelle GAZ-3302. I am very glad that my life connected me with this car, because since childhood I dreamed of transporting something. Let it be people or any other cargo - I like to transport and deliver. I took up this business because my father was in the same business, and I just decided to continue his work. Today, many people use a car like the Gazelle 3302. After driving this car for 7 years, I have a certain opinion that I want to share.

While working with my car - Gazelle 3302 - I was convinced that this car has a load capacity of 1.5 tons. In addition, I had the opportunity to deliver cargo over long distances, to places where there is virtually no road, but I did not have to refuel for this so often, since the car has a tank with a capacity of 70 liters. The mass of my car itself is 1800 kilograms, and its length is as much as 5.5 meters.

During what period of work did problems arise with the front suspension? In general, alarming messages began 4 years after the purchase, and this is not a short period of time. The hub bearing failed, as well as the steering rods. To fix all this and restore the car, I decided to buy the first spare parts I came across, which I regretted two months later. The parts were not original. The condition of the car deteriorated twofold, and then we had to buy additional bushings and stabilizer struts. Only this time I decided to buy original spare parts for my car. Today, several years later, I continue to use my Gazelle 3302 car, completely enjoying its performance.

Overall - I am very pleased with the car, which performs its functions much better than most other cars. If you are planning to buy this car, then listen to your heart, not your money, because this car requires the care of its owner.

Another review about the model:

Two weeks ago I received this device: side length 6 m, height 2.20 m. I can immediately say “many thanks” to those who assembled this unit, but first things first. As soon as I arrived at the salon to pick up the car, they immediately rushed to assemble the frame, well, not at all. read more →

The designation ZMZ-402 hides a whole line of power units produced by the Zavolzhsky Motor Plant. These 4-cylinder gasoline engines are installed primarily on Gazelle and Volga passenger cars. You can find information about their use on Latvia minibuses and some models of the Ulyanovsk Automobile Plant.

History of engine development

The 402 engine began to be installed in cars in 1958. At that time it had a different designation - ZMZ-21A and ZMZ-24D, but it was still the same engine. The prototype was an even earlier modification, which the designers worked on in 1954-1955. Then it was a completely new engine option for the GAZ-56 car, which did not even leave the assembly line. The 402nd unit began to be called only in 1980.

The main representatives of the 402 line are:

- ZMZ-402.10 as the main basic option for AI-92 gasoline.

- ZMZ-4021.10, consuming A-76 fuel.

- ZMZ-4022.10, which has a new type of ignition, the so-called pre-chamber-torch.

During the operation of 402.10 engines, they often tried to use cheaper fuel. To do this, the car owners converted the engine to run on gasoline with a lower octane number. As for the flagship of the 402 line - ZMZ-4022.10, there are opinions that the idea of \u200b\u200bprechamber-torch ignition was taken from Honda's Japanese colleagues.

Historical information

The first version of the engine was created for the GAZ-21 Volga by designer G.V. Evart, but due to a lot of comments, the project was reworked. Subsequently, the unit was upgraded to the ZMZ-24D standard, and the index 402 first appeared in the early 80s.

Engine assembly continued until October 2021; stable demand from consumers remained despite the appearance of the new generation ZMZ-406 with an injector.

The reason for its popularity was its simple design and the ability to be repaired in the field.

Description and technical specifications

ZMZ 402 series engines are unpretentious in operation and quite easy to maintain. Gasoline engines with a carburetor have 4 cylinders arranged in a row. They were installed mainly on GAZ cars: Volga and Gazelle.

The working volume of the power unit is 2.445 liters, which allows it to develop a power of 100 hp. With. or 73.5 kW. The compression ratio is 8.2 - this allows the use of AI-92 gasoline. The cylinder diameter and piston stroke are 92 mm. The total weight of the unit is 181 kg. The exhaust system includes exhaust gas recirculation, which significantly reduces environmental pollution and allows you to comply with regulations.

How often does it need to be tuned?

When operating a vehicle under high load - transporting heavy loads, driving in the mountains and at low speeds - the adjustment period is reduced to 8-10 thousand km. And if gasoline that does not match the cylinder head is poured into the tank, the valves need to be adjusted every 5-6 thousand kilometers. Otherwise they will burn out and the engine will lose compression.

To avoid stripping the threads while adjusting the valves, the nut must be rotated very smoothly with a wrench at the beginning of unscrewing and at the last turn of tightening. The tips of the valve mechanism rods of the ZMZ-402 engine are made of duralumin, and not steel, as on the ZIL-130, for example. Therefore, it is extremely difficult to adjust the valves by ear. Rattling and knocking noises can be made by:

- worn camshaft cams;

- unevenly operated rocker arms;

- worn out axis;

- loose springs.

Components

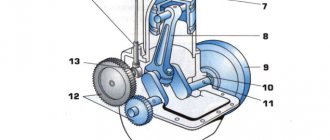

The 402 engine cylinder block and upper crankcase are one piece and made of high-strength aluminum alloy. Cast iron cylinders are represented by removable liners. To fasten the block head on the upper surface, 10 “lugs” are provided. At the bottom, the engine block is divided into 4 parts by partitions. They house the crankshaft main bearings.

Each cast iron bearing cap is secured to the block using two 12mm studs. Since the block is bored together with the covers, they cannot be swapped. Therefore, for convenience, they are assigned numbers stamped on all except the 1st and 5th.

A timing cover made of aluminum alloy is attached to the front of the block. And to the rear is the clutch housing. All connections are tightened with fastening bolts through paronite gaskets. The 402 engine has an aluminum head common to 4 cylinders. Fastening to the block is done with ten 12 mm studs. The cylinder head gasket is made of asbestos coated with graphite and surrounded by a reinforced frame. Its minimum thickness is 1.5 mm.

Modifications 402.10 and 4021.10 have block heads of different thicknesses. This is due to the different volumes of the combustion chambers. Essentially, the 402.10 head is made by milling the bottom edge of the 4021.10 head by 3.6mm.

During maintenance, special attention is paid to the car engine. After 20 thousand km, it is recommended to stretch the head, as well as adjust the valve clearances.

Valve ZMZ 402 original

These valves are used on many ZMZ and UMZ engines, and not just on the 402 engine. It’s just that in this case I took him for consideration as the ancestor of the family. Of the valve manufacturers known to me, I can name four:

- Chinese valves Keno, Tanaki and everything that lies in factory boxes with magical inscriptions about double, quadruple and tenfold life. All from one barrel. The main problem is the material of the valves. They sharpen on the machine at such a speed as if there was a wooden blank.

- Polish AMP valves. The quality is a solid “four”.

- Russian Sollers. The pedigree raises some suspicions, the packaging even more so. These valves were brought in for modification several times. The metal is a “4”, but the production and quality of the bud is a “3”.

- Severe Chelyabinsk valves. In my humble opinion, the best that is on the market for this engine. Metal quality is 5. We'll finish the rest with a file))) The downside is pricing. Standard set of 8 pcs. will cost twice as much as the “Chinese” version.

- I will not consider all sorts of different “no names” and brands for the Russian market (such as Herzoga).

Maintenance

In order for the 402 engine, whether it is a Gazelle or a Volga, to work long and efficiently, it is necessary to carry out timely maintenance. The engine, as you can already see, does not have complex electronic components and does not require highly qualified maintenance. What points should you pay special attention to?

- As already mentioned, every 20 thousand you need to pull the head to the block. This is due to the natural collapse of the cylinder head gasket. In this case, the nuts are pulled from the middle to the ends of the head and always on a cooled engine. A hot engine means a hot block and head and, naturally, a slightly smaller gap between them. In addition, it is recommended to first simply tighten the nuts, and then perform a control tightening with a given torque as a second step.

- Be sure to inspect it, and if it is loose, tighten the timing cover. The bolts turn starting from the middle. The gaps between the valves are checked.

- As engine consumption increases and power decreases, attention should be paid to deposits inside the combustion chambers. This happens more often on worn engines when the oil rings leak a lot of oil. In this case, it is best to remove the head and clean the carbon deposits. Don’t forget that if the head is removed, the valves must be ground in.

Modified valves ZMZ 402

intake valves, comparison

exhaust valves, comparison

When modifying the valves, two goals were pursued. Increase the flow area and reduce the weight of the valve. The second goal is of priority importance, because the valve-seat flow area, taking into account the rather strange shaped cylinder head channels, will not be of decisive importance. The valves are of course quite archaic, especially considering the 9mm stem. But on standard valves, my hand does not rise at all to assemble the cylinder head. I usually take Chelyabinsk valves as a donor. As I said above, valves from different manufacturers were brought to me for modifications, but subjectively I liked these ones. Despite their price and the fact that in their native St. Petersburg you have to run around to find them. The result of the improvements is shown in the photo. Probably no special comments are required.

Other ways to increase power

Simpler, but no less effective options would be:

- flywheel groove;

- replacing the standard piston with a lightweight one;

- increasing valve diameters;

- replacing the standard K-151 carburetor with more modern analogues;

- new tuning camshaft;

- installation of more expensive and high-quality spark plugs from a foreign car with replacement of high-voltage wires;

- use only synthetic or semi-synthetic oil in the lubrication system;

- reconfiguration of the exhaust system.

To summarize, it can be noted that the ZMZ-402 engine increases its power in various ways. However, a car with such an engine will never be a racing car. This is, first of all, a reliable and high-torque unit for workhorses.

Installation. Results.

When it comes to the ZMZ 402, there is no need to talk about a highly pumped engine. On the “drive” website and other similar sites, there are examples where good performance indicators are taken from a given engine in terms of power, and most importantly, torque. But the approach is closer to me when this engine is used in Volgas, gazelles or UAZs, as a workhorse. Considering this concept, the following cylinder head configuration showed itself to be very good: these modified valves, titanium plates with a 1mm flare and single springs from UMZ 421. With the carburetor adjusted, the engine easily spins up to 3500-4000 rpm, and this exceeds the average rpm range required for the standard cars with this engine. And at the same time it works quite quietly and softly, in contrast to the standard 2 springs per valve in ZMZ 402.

Possible faults

Let's consider possible options for the main problems of the GAZ-402, the engine of which is no longer new and has problems.

- Doesn't start. There can be many reasons for this. The main ones are problems with the carburetor and fuel system.

- Unstable revs, poor idle. Again, the problem is most likely in the carburetor or incorrect valve clearances.

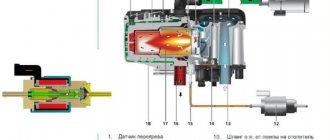

- Engine overheating. Here the focus is on the water cooling system. These are the thermostat, water pump and radiator.

- Oil consumption. In this case, the seals are checked first, and then the oil rings and valve seals.

- Engine knock. Most often, this reason can only be eliminated by a thorough engine repair.

Repair of 402 engine

With any operation, the 402 engine begins to malfunction sooner or later. You shouldn't be afraid of this. There are no eternal mechanisms, but there are good specialists and a wide range of spare parts. In this case, it is not necessary to wait for knocks that are unnatural for the unit. The indication for repair is a simple increase in oil and fuel consumption. For the GAZ-3110, the 402 engine, for example, should have a gasoline consumption in urban areas of about 13.8 liters per 100 km.

What might be needed for a normal engine overhaul? Replacements include: a set of gaskets, valves, valve bushings, piston rings, and sometimes the piston assembly. The head is always polished.

If the repair is carried out on your own, the costly part will be the purchase of various devices and materials. This is a torque wrench, lapping paste, a piston ring mandrel, a 9-mm reamer, a valve depressurizer, balls, paronite and a good cleaner.

Features of winter operation

The ZMZ-402 engine is quite easy to operate in the summer. When preparing it for winter, you should first check all technical fluids. These are engine oil, coolant, brake fluid and windshield washer fluid. The oil should be changed to semi- or full synthetic. Pour antifreeze into the cooling system at the required freezing point.

The weak link of winter driving is the carburetor. It needs to be configured in a certain way. The adjustment is made on a hot engine. The idle speed is set with a special screw. After tuning, it is important to practice the operation of opening and closing the carburetor choke.