Refinement of the cooling system on the Lada Kalina

can be produced either in-house or at a car service center. However, in the latter option, experts usually recommend replacing or repairing the thermostat, which is not always practical or effective.

The main causes of problems in the cooling system:

- Coolant leak. It is recommended to check the clamps and integrity of the radiator. If necessary, elements are replaced or repaired. You can check the circulation of refrigerant in the system by making sure that liquid enters the tank. If this does not happen, you should replace the pump or clean the SOD with special means;

To solve the problem of airing, you should open the expansion tank, start the engine, press the gas pedal several times until the sensor arrow reaches the red zone. If the fan turns on, you need to squeeze the gas all the way several times and turn off the ignition. If this method is ineffective, the following procedure is used. The plastic motor protection is removed, the clamp is lowered and one of the fitting tubes is dismantled. The expansion tank cap is opened and the system is purged until coolant begins to pour out of the removed tube.

In the version with an electronic gas pedal, the cooling system is looped with a hose that was previously used to heat the throttle assembly. Using an additional hose, tee and clamps, a connection of a smaller diameter is mounted to vent the system. The air vent is installed as close as possible to the thermostat using a tee cut into the supply hose to the radiator.

Since the system in question is absolutely sealed, getting rid of air is not so easy. The car must be placed on any inclined surface with the front facing up (the steeper, the more effective). You should warm up the power unit until the second circulation circle opens, move the temperature regulator to the maximum position, direct the air flow into the cabin and activate the fan at second speed. Next, increasing the engine speed to 4.5-5 thousand, we hold it for some time.

The cooling system of the Lada Kalina is one of the main elements of the car’s design. Its structure and layout are quite typical for all cars, and are almost no different. The main purpose of this design is to ensure timely cooling of the main power unit and prevent it from overheating.

Video about the basic principles of operation of the cooling system on a modern engine:

Video materials on the Lada Kalina cooling system, devices and malfunctions.

Cooling system Lada Kalina: diagram and modification of SOD Kalina

The Lada Kalina car is a fairly popular model, which has recently been actively in demand in the secondary market. In general, the car is quite simple and reliable, but there are some “childhood diseases”.

Moreover, such problems can be eliminated at minimal cost. The main thing is to take into account the nuances and scope of modernization work in advance. Next, we will look at what to do if the Kalina heater does not work well, the engine cooling system (ECS) becomes airy, overheating occurs, etc.

Problems and methods for solving them

There are few actual reasons for failures and deviations in the functioning of the cooling system in LADA Kalina. Liquid leaks are the most common. They can arise from loose clamps on the pipes, through the gasket or seal of the pump, a broken radiator (also in the heating circuit), etc. Copper radiators used to be subject to repair, but it is unlikely that it will be possible to successfully restore a modern aluminum product. The clamps can be tightened, and if it doesn’t help, they can be replaced, fortunately this is a cheap idea. The radiator is much more expensive, so replacement may be burdensome, but there is no other way.

How to change the running light bulb on a Grant

Granta gearbox with cable drive

Installation of alarm system on Lada Granta

Sometimes the engine cooling system can become clogged. This will require cleaning followed by a complete fluid replacement.

We will also consider other problems that arise in the cooling circuit of the Lada Kalina.

- Thermostat. An effective diagnostic measure would be to manually touch the pipes connected to the radiator. If the lower radiator hose does not warm up on a warm engine, then we can safely state that the thermostat has failed. The valve stopped opening, preventing the liquid from circulating in a large circle. The only way out is to change the part.

- The radiator honeycombs are clogged. Here you also need to resort to cleaning. In spring and summer, debris clogs the honeycombs, making the radiator ineffective in terms of cooling.

- The fan has failed. The first step is to check the integrity of the wiring and the serviceability of the relay in the Lada Kalina with an 8 or 16 valve engine. Most breakdowns point to these components.

- Airing of the system, the so-called air lock. Often air can get inside the circuit, forming plugs. Airing of the system can often be observed after replacing antifreeze. To combat this phenomenon, open the reservoir cap and raise the engine speed (accelerate). If the traffic jam cannot be removed, we try to raise it in front of the car (as high as possible) and continue to practice with the accelerator. Blowing out the tank until liquid appears from the fitting also helps.

The main causes of malfunction of the Kalina cooling system

As mentioned above, the engine cooling system on Kalina has certain shortcomings that can be eliminated. In fact, the Kalina 1 cooling system turned out to be the most problematic, although there are also complaints about the Kalina 2 SOD.

In any case, if there is overheating, airing of the system or the Lada Kalina stove does not heat, modification of this system is simply necessary. At the same time, you should not immediately change the Lada Kalina thermostat to a “hotter” one when the stove is cold, cut in fittings and “tees” for quick modification of the CO itself, etc., without understanding all the issues.

Owners note the following signs of air in the cooling system:

- the stove does not blow warm air at idle, low and even medium speeds;

- the motor overheats, although the temperature gauge shows normal;

- there is a feeling of “emptiness” in the pipes, there is no dense filling;

As a rule, there are several reasons for the formation of an air lock, starting from poor tightness in the area of connection of the pipes and ending with problems with the cooling radiator or heater radiator. At the same time, many people often overlook the expansion tank cap.

Please note that on Kalina this is a weak link, the valve mechanism of the expansion tank cap is not reliable, sticking of the “suction” valve causes airing, and malfunctions of the excess pressure relief valve cause depressurization of the radiators. Of course, it is better to change the cover.

Next, you need to wait until the antifreeze appears and put the tube in place. Next, you need to warm up the car until the thermostat opens, and then repeat the steps described above a couple more times.

In the event that the problem cannot be solved by deaerating and replacing the cover, the system needs a complete diagnosis. If, as part of the diagnostics, no obvious problems are identified, then revision will be required.

Symptoms of problems

There are a number of symptoms that indicate a malfunction of the cooling system; if at least one of them is detected, it is worth taking corrective action.

- When the engine is not started and has cooled down (more than 8 hours of inactivity), a residual pressure remains in the cooling lines (this can be understood when the rubber pipes are pressed, they will be hard).

- The release of coolant when the engine is running can be either a small amount or a significant column of steam.

- Coolant leakage from lines or radiators is accompanied by a decrease in the coolant level in the tank.

- When the engine is fully warmed up, cold air blows from the deflectors coming from the cabin heater. The effect may disappear when the crankshaft speed increases.

And if with the first three points everything is more or less clear, then with the last it’s not so simple. You can change radiators, thermostats and coolant as much as you like, but you still won’t achieve a positive result. The problem is the formation of an air lock that cannot be seen. The air in the lines prevents the normal removal of heat from highly heated parts, which can lead to serious damage to the power plant.

Engine cooling system: SOD Kalina and modification

Let us note right away that correct modification begins with the fact that it is necessary to slightly change the distribution of antifreeze flows in the cooling system of the VAZ-1118 Kalina. This will reduce the intensity of airing due to the jamming of the compensation valve of the expansion tank cap.

Please note that simply removing the valve from the cover, as many suggest, is strongly not recommended, as the engine may overheat. It would be better to lower the fan switch-on temperature in the firmware to 98 degrees.

In general terms, you need to do the following:

- you need to drain the coolant, and then put a plug in the pipe that connects the large cooling circle and the expansion tank;

- then the free fitting is connected to the lower heater hose through a tee. The VAZ 2110 tee is suitable for these purposes;

- the next step is to plug the distant hose (thin outlet hose) designed to heat the throttle assembly;

- then the released fitting must be connected through a suitable tube to the expansion tank. To do this, you need to cut another “nipple” into the upper cavity. You can also connect via a tee to connect to a thin input;

- then you should fill in the coolant, a little higher than that, start the engine and warm up the unit until the fan turns on. The final stage will be to de-air the system and adjust the level of antifreeze or antifreeze.

This modernization allows for steam removal through a small circle, and aired liquid can be collected at the highest point of the cooling system. By the way, as for the version with an electronic gas pedal, in this case the thin thermostat fitting is connected to the top of the expansion tank.

The result of such actions will be active de-airing of the cooling system, the stove will heat normally at different speeds, and the engine temperature will always remain at a normal level, regardless of the mode and load on the engine.

At the same time, it is quite obvious that if the thermostat on the Lada Kalina is working properly, it is not necessary to change it. In other words, it is not the cause of overheating or a cold stove. In turn, a more comprehensive improvement of the cooling system of the Lada Kalina allows us to solve a number of problems.

Cooling system: design features

The engine cooling design is liquid, sealed with an expansion tank. The structure is filled with antifreeze, a substance that does not freeze at a temperature of -40.

The cooling system of all second generation Lada Kalina engines is similar.

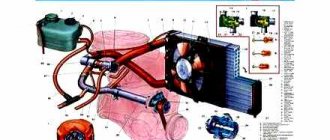

Location of the basic components of the cooling structure: 1 – water pump; 2 – radiator structure; 3 – electric radiator fan; 4 – thermostat; 5 – coolant temperature sensor; 6 – expansion tank

In this topic, we took as an example a car with a VAZ-21116 engine.

Due to the water pump, liquid circulates in the cooling structure. Fixed to the surface of the cylinder block. It is driven by the timing belt. The pump has sealed bearings that do not require additional lubrication. It is important to know that the pump cannot be repaired; if it breaks, it is replaced as an assembly.

A thermostat with a dense filler promotes an appropriate coolant temperature and also reduces the engine warm-up process. The thermostat contains the base and spare valves. When the temperature is 82-\+2 0C, the thermostat is closed, the coolant spreads through a small circuit, passing the radiator, this helps to quickly warm up the engine. When the temperature is 82+\- 0C, the thermostat opens, and when the temperature is 102 0C, it opens completely, this promotes the spread of coolant through the radiator.

An electric fan with a plastic wheel helps blow air through the radiator when the car is moving at low speed. To increase operating efficiency, the fan is fixed in the casing and attached to it at 3 points through rubber pads. The casing is attached to the radiator in 4 places.

Radiator with electric fan and expansion tank: 1 – expansion tank plug; 2 – steam breather; 3 – radiator; 4 – radiator support cushion; 5 – drain plugs sealing the ring; 6 – drain plug; 7 – fan casing; 8 – nut; 9 – fan; 10 – fan wiring harness block; 11 – bolt; 12 – expansion tank

The electric fan is controlled by the engine control unit, which receives information about the coolant temperature.

Cooling structure breakdowns and methods for repairing them

The motor has overheated

The reasons may be different, for example: low coolant in the radiator (fill in more fluid), broken thermostat or pump (change the part), dirty radiator (wash the radiator from the outside), dirty radiator tube, breathers and engine cooling jacket (wash the cooling structure and fill new fluid), the electric fan does not work due to the fact that the wires have come off, the fuse sensor, additional resistance, relay or electric fan motor has failed (change the fuses, resistance, relay or electric fan assembly).

The engine has overheated and there is a flow of cold air coming from the heater.

The cause of this malfunction may be a very strong decrease in the coolant level due to a defect in the cylinder head gasket, which contributes to the formation of steam obstructions in the water jacket of the engine (get rid of coolant leakage, change the cylinder head gasket).

The engine does not warm up for a long time, the temperature during movement is not stable

Most likely the thermostat is damaged (replace the part).

Lowering the coolant level in the expansion tank

The radiator or expansion tank is leaking (replace the part), coolant is leaking through leaky connections of pipes and breathers (replace the breather clamps), a defect was found in the pump seal (replace the pump), the cylinder head fastening bolts are not tightened properly (tighten the fastening bolts well), the heater radiator is leaking (change it).

The radiator is aluminum, tubular-plate with plastic tanks, two-way with a baffle in the left tank. There is a plug at the bottom of the right tank. The tanks contain inlet and outlet pipes for breathers to the water jacket of the engine and a breather pipe that connects the radiator and expansion tank.

The expansion tank compensates for the changing volume of coolant, based on its temperature. The tank is plastic, transparent. It has o and “MAX” to control the coolant. There is a filler neck on top, tightly closed with a plastic plug, with 2 valves. The exhaust valve opens at a pressure of 110 kPa, guaranteeing a high coolant temperature and preventing the formation of vapors. As the temperature decreases, the volume of liquid becomes smaller and the structure is discharged. The inlet valve in the plug opens during a vacuum of 3 kPa and does not allow air into the expansion tank.

Note

The operation of the expansion tank plug valves is necessary for the operation of the cooling structure. But usually, when a problem arises, the driver takes into account only the functioning of the thermostat, forgetting about the valves. A leak in the exhaust valve can cause a drop in the boiling point of the coolant. This, in turn, will lead to high pressure in the structure, which will harm the radiator and breathers.

What's the result?

Taking into account the above information, it becomes clear that if the stove does not heat or the engine overheats, the Kalina thermostat is not always the cause of the problems. Of course, when such symptoms appear on Kalina, the thermostat and coolant level should be checked first. However, it often happens that the thermostat is working, as well as the antifreeze level is normal.

Finally, we note that the only disadvantage of the method of improving the Kalina SOD discussed above is that the engine may take longer to warm up. Moreover, against the background of the problems that arise when the standard system is aired (overheating of the internal combustion engine, cold stove, etc.), such a drawback practically does not manifest itself at all, even in the cold season.

Let's sum it up

If the owner of a Lada Kalina with an 8 or 16 valve engine does not have the confidence to independently correct the defects that have arisen in the cooling system, then the only effective action will be to contact a disinterested professional; a cooling scheme can also help. He will quickly diagnose the system, identify the cause and promptly eliminate it. Independent experiments are undesirable, since ignorance coupled with the desire to eliminate the malfunction can only add damage to the long-suffering cooling system.

Refinement of the cooling system on the Lada Kalina

Refining the cooling system on the Lada Kalina will help solve the problem of airing and the formation of traffic jams. There are several ways to eliminate this defect. The ineffective operation of the unit is associated with its design features. The operation of the engine cooling system (ECS) is associated with the interaction of various elements. The temperature of the power unit determines the passage of coolant through the large and small circles. At the first stage, the coolant circulates without passing through the radiator; after reaching the required temperature and the thermostat is activated, the liquid passes through the radiator. The normal functioning of the engine and stove depends on the correct operation of the system.

Causes of ODS malfunction

Refinement of the cooling system on the Lada Kalina

can be produced either in-house or at a car service center. However, in the latter option, experts usually recommend replacing or repairing the thermostat, which is not always practical or effective. The main causes of problems in the cooling system:

- Coolant leak. It is recommended to check the clamps and integrity of the radiator. If necessary, elements are replaced or repaired. You can check the circulation of refrigerant in the system by making sure that liquid enters the tank. If this does not happen, you should replace the pump or clean the SOD with special means;

- Failure of the thermostat or its elements;

- Contamination of radiator honeycombs;

- Fan malfunction;

- Presence of air pockets in the system.

Traditional Troubleshooting Methods

To solve the problem of airing, you should open the expansion tank, start the engine, press the gas pedal several times until the sensor arrow reaches the red zone. If the fan turns on, you need to squeeze the gas all the way several times and turn off the ignition. If this method is ineffective, the following procedure is used. The plastic motor protection is removed, the clamp is lowered and one of the fitting tubes is dismantled. The expansion tank cap is opened and the system is purged until coolant begins to pour out of the removed tube.

A standard modification to the cooling system involves installing a new 6-hole thermostat, coolant filter and heater valve. To maximize coolant flow and minimize the risk of overheating, you will need to install an additional pump.

Traditional methods of improvement

In the version with an electronic gas pedal, the cooling system is looped with a hose that was previously used to heat the throttle assembly. Using an additional hose, tee and clamps, a connection of a smaller diameter is mounted to vent the system. The air vent is installed as close as possible to the thermostat using a tee cut into the supply hose to the radiator.

The second end of the air outlet element is connected to the steam outlet near the RB fitting (using another tee). This modernization made it possible to achieve a stable temperature of 90-95°C when driving around the city, with the stove starting to warm up at 50°C. The costs for additional elements (refilling refrigerant, tees, clamps and 1 m of hose) amounted to about 600 rubles. It is worth noting that before the upgrade, the sensor showed the engine temperature was more than 100°C, while cold air was blowing from the stove.

Second way

modification of the SOD consists of installing a hydraulic intake on the steam outlet. To do this, a regular tube from a dropper is inserted into the steam exhaust channel with constant immersion in the coolant and touching the bottom of the tank. While cooling, the liquid will be drawn into the outlet hose according to the principle of communicating vessels, which will protect the system from the formation of air locks. Alternatively, you can combine both methods.

Eliminating air pockets in the radiator

Since the system in question is absolutely sealed, getting rid of air is not so easy. The car must be placed on any inclined surface with the front facing up (the steeper, the more effective). You should warm up the power unit until the second circulation circle opens, move the temperature regulator to the maximum position, direct the air flow into the cabin and activate the fan at second speed. Next, increasing the engine speed to 4.5-5 thousand, we hold it for some time.

Then the pedal is released until the idle speed appears. If the problem is not completely resolved, the procedure should be repeated.

Despite the fact that modern domestic cars have updated characteristics, some factory defects are still present. Modification of the cooling system on the Lada Kalina is available in several ways and helps to avoid the formation of air locks. Moreover, the procedure does not require significant financial investment.

Source

Cooling system diagram and operating principle

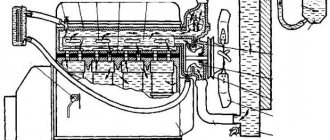

Engine cooling system diagram

So, many car owners are familiar with the main parts of the engine cooling system. But, it’s still worth examining in more detail what is included in this simple design, which prevents the power unit from heating up:

- Cooling radiator. It is used to cool the heated liquid that has entered it through a large or small circle with the help of a counter flow of wind.

General view of the cooling radiator

Cooling fan mounted on radiator

Engine cooling expansion tank

Engine Cooling Sensor

Cooling system thermostat

Cooling system pipes

Of course, in the cylinder block and head itself, there are also channels that serve as a cooler, where the liquid is heated. Let's consider the main stages of coolant recirculation through the system: from the radiator, through the line, the liquid enters the thermostat, which, depending on the temperature, releases the liquid in a small or large circle. Next, the liquid passes through the power unit, where it exits to the pump, which pushes it into the radiator.

Main problems and solutions

The main malfunctions associated with the cooling system include two parts that most often fail: the thermostat and the water pump (checking its operation).

The first is characterized by jamming in a small circle, which leads to frequent turning on of the fan and possible overheating of the engine. In the second - wear of the pulley, as well as the shaft, which, when worn out, begin to leak fluid out.

Design elements

The expansion tank of the Lada Kalina car is made of transparent polyethylene. The system in question is sealed due to the presence of inlet and outlet valves. The SOD scheme in Kalina provides for the presence of a coolant pump. The device body is made of aluminum. There is a control hole inside the unit, which can be used to detect fluid leakage if the pump breaks down.

The engine cooling system of the Lada Kalina car consists of 2 circulation circles:

- the liquid moves through the jacket and radiator (large circle);

- the liquid moves only along the jacket (small circle).

The SOD scheme provides for constant circulation of liquid. This does not take into account the position of the thermostat valves. The last device consists of 2 valves that redistribute the flow of coolant. When the engine is cold, the fluid circulates in a small circle.

To monitor the temperature in the system, a special sensor is used. It is located in the BC head and is connected to the temperature indicator. The interior in Kalina is heated using a heating radiator. The device consists of 2 vertical tanks and tubes arranged in 2 rows (horizontally). The last elements are connected to the tanks using a rubber gasket.

Liquid enters the system through the upper pipe and is discharged through the lower pipe. There is a drain plug at the bottom of the tank. The fan starts based on a signal from the controller. Reasons for SOD failure:

- fluid leakage from the old clamp (install a new unit);

- broken radiator (repair work is in progress).

Composition of the cooling system?

In a Lada Kalina with an engine of 8 or 16 valves, this unit consists of a considerable number of components, each of which is endowed with a specific function. The coolant filling volume is 7.84 liters. To be able to independently troubleshoot problems in the cooling system, you will need to study it in detail. The cooling circuit can also help with this. The engine cooling system of the LADA Kalina car has the following components:

- Expansion tank. This component is connected to the radiator through one pipe, and its second hose serves as a filling vessel for the system. The top of this tank is closed with a lid, which contains a special valve to relieve excess pressure.

- Water pump. The element is made of aluminum, which prevents corrosion. The bearing of the product has a special lubricant designed for the entire service life. The pump housing is equipped with a control hole that allows you to determine antifreeze leaks. When this fact is evident, the pump must be replaced immediately.

- Thermostat. The component is equipped with two valves, which serve to regulate fluid flows depending on the amount of heating of the system. If the engine is cold, the valve blocks access to the radiator. Here the fluid circulates inside a small circle in the cylinder block. When the temperature in the system reaches 85 degrees, the valve opens and the liquid rushes through the radiator, which is also called “in a large circle”.

- Temperature sensor. This element of the on-board control and self-diagnosis system serves to continuously monitor the temperature level in the system. A similar element is mounted close to the thermostat housing.

- Radiator. The part is designed to provide effective cooling of a heated engine. Circulating inside a large circle, the liquid “carries” heat into the radiator tubes, which is removed through the honeycomb by an electric fan. The cooled antifreeze flows through the radiator return pipe into the small circle again, and the cycle repeats again.

- Heater radiator. This is a device similar to the main radiator, but smaller in size. The component serves exclusively for heating the interior space of LADA Kalina.

- Fan. It turns on periodically when there is a need to remove heat from the honeycombs of the main radiator unit. Controlled by a relay at the command of the controller.

DETAILS: Electrical diagram of Lada Kalina 1118: diagram of power windows, ignition and wiring As we can see, the structure of the system we are considering is not sophisticated. It is not difficult to learn, but it is useful. This will allow you to independently understand the essence of the malfunctions and quickly eliminate them.

Lada Kalina Hatchback 11193 Chernushka Logbook Unusual malfunction of the heating system

Hello! Let me remind you of the story, 2 months ago I bought a 2010 Kalina, I am the second owner. Already upon purchase there was a “malfunction” of the heating system; the fan did not work at second speed. Yes, yes, exactly the second one. The first, third and fourth worked. Isn't it strange? So it seemed to me, because two standard malfunctions are known in nature: 1. Only the fourth speed works -> then the additional heater resistor (more precisely, its fusible element) is 100% broken. The first speed does not work -> then the fan motor probably rotates poorly.

Why is the car index 111

Indexation starting at 1 indicates that the car is of a lower class, like the Zhiguli we are used to (2***).

The new car was originally conceived in the form of a line. In addition to the usual hatchback and sedan, we also planned to release a real minivan! This idea was later abandoned due to technological difficulties. Instead of a minivan, a station wagon was released under the index. This model was released as the latest in its series. I would like to note that initially the designers created the hatchback model 1119. However, in order not to repeat the mistakes of the VAZ-2108, marketers decided that the four-door sedan should be the first to go into mass production.

Lada Kalina Station wagon 080 Logbook Improvement of the Kalina cooling system

When the engine cools down, air is supplied through the steam exhaust hose from the expansion tank, this happens mainly in winter. And when the engine is started, air bubbles in the radiator of the stove and the heater does not heat well. The boiling on the stove got a little annoying, so I decided to get rid of it using a water seal on the steam exhaust hose. If in doubt, you can also read here www.lkforum.ru/showpost.p...?p=1158931&postcount=1455 here is also www.lkforum.ru/showpost.php?p=1256887&postcount=2

water seal on the steam hose

I took a bolt, cut off the threaded part as much as I needed, drilled it not straight through, and drilled it from the side.

We welded it with tubes (stainless steel), one long tube and one short.

I screwed a nut onto it and painted it for appearance.))

Now the expansion tank: I cut off the plug where the steam exhaust hose from the radiator is connected.

There is no need to drill anything, we cut the thread with an M12*1.75 tap.

And we tighten the water seal so that it does not let through, and we wind the fumka.

Now, instead of air, antifreeze is sucked in through a long tube and air does not enter the cooling system. — Drain the old antifreeze: Unscrew the cap on the radiator in the lower right corner, then open the cap of the expansion tank, and also unscrew the cap on the cylinder block, remove the top radiator hose of the stove interior and blow there to expel the remaining liquid from the heater radiator. — We wash: I tightened the cap on the radiator and in the cylinder block I began to fill in distilled water for flushing, when water came out of the heater hose I put it in place and tightened it. We start the engine to run for a while so that a large circle opened and drove distilled water through the system (rinse) then drained everything. — Fill in new antifreeze: Fill in the antifreeze in the same sequence as distilled water. We drive all the air out by placing the car on a hill in front and the left side of the car should be higher, and add gas until a large circle opens, this is somewhere around 102-105*C. This is the temperature when the thermostat is fully open, antifreeze begins to circulate through the radiator and expansion tank. We look at all the leaks, if there are any, we eliminate them (tighten the clamps). The water seal tube should not be long, it should reach up to mark the maximum on the expansion barrel, that is, they will be immersed in the coolant by 5-10 millimeters; if it is long, the system cannot expel air through it. I cannot promise that it will work for everyone, but if everything is done correctly, it will work , I have circulation through the water seal when a large circle opens. I’m happy as an elephant, the stove heats up perfectly. Thank you for visiting this page.

Self-tuning

thermostat failure. To check its performance, visually inspect the radiator pipes. If the top is cold and the bottom is warm, then the thermostat is stuck. In this case, you will need to install a new device; the honeycombs are clogged. In this case, the engine overheats in spring or summer. It is recommended to clean the radiator (from the outside); fan failure. The device does not start due to high coolant heating. It is recommended to check the functionality of the relay and wiring; air in the system. In this case, open the expansion tank. After starting the engine, periodically press the gas (until the red mark is reached). If the fan starts, then they “add up the gas” by first turning off the ignition. If the breakdown is not repaired, then the power unit screen is dismantled. First raise the motor and lower the clamp. One pipe is dismantled. The lid is removed and the container is broken through. The tube and cap are installed in place. The engine warms up and the ignition turns off. Then remove the heating tube

Since antifreeze is a toxic substance, it is recommended to drain it carefully (following safety precautions). The engine must be cold

The tube is put on the fitting, the air is removed.

If the engine gets hot, the Lada Kalina SOD will be upgraded. Refinement of the system consists of installing a thermostat with 6 holes. The device is designed to maintain a stable fluid temperature and normalize the operation of interior heating devices. If necessary, install a coolant filter or heater tap. To quickly pass antifreeze through the channel (with minimal risk of overheating), an additional pump is installed.

The system under consideration is suitable for the C/O and N/O stove on the VAZ 2110. In the first case, it will be necessary to throttle the output from the SOD. In this case, the stove will only work at high speeds. In order for hot air to flow from the heating unit, press the gas pedal. If you reduce the output from the C/O stove, then the pressure in the remote control will rise. To do this, use a throttle or ball valve. Before installing Kalina SOD in a VAZ, it is recommended to consult with specialists.