The operation of cars, both domestic and foreign, is sometimes accompanied by an unpleasant whistling sound. The generator drive belt whistles. This phenomenon occurs more often in cold or rainy weather, when the engine is not warmed up.

It is possible to operate such a vehicle, but the whistle means that the drive is slipping on the pulleys without rotating the generator shaft. Accordingly, the battery does not receive the required charge.

The problem may be caused by other, more serious reasons. Why does the alternator belt whistle? What is the problem and what needs to be done to fix it?

Reasons for whistling

The cause of the whistling may be hidden both in the belt itself and in nearby units. When a car owner asks for help, it often turns out that the generator is whistling.

Belt faults

There may be several reasons why the VAZ-2110 alternator belt whistles. However, the first place in terms of frequency of occurrence is the wear and tear of the material from which it is made. The rubber stretches, loses its shape, and begins to slip.

Diagnostics is carried out visually, based on the degree of belt tension. If it sags and can be easily turned by hand (while the pulleys remain motionless), then the cause of the malfunction can be considered found.

In addition to the above, the belt drive whistles when the pulleys are oiled. This usually happens on older engines, where oil seeps through seals and gaskets. The generator drive on Priora and other VAZ models is not geared. Therefore, it easily slides over oily surfaces. Diagnosis is carried out visually.

The drive may not whistle constantly, but periodically whistle for some time after a cold start in winter. In general, if the situation returns to normal after warming up, no intervention is required. The fact is that the rubber from which the element is made becomes hard in the cold and does not adhere tightly to the surfaces of the pulleys. As it warms up, it takes on a working form and the whistling stops.

Generator faults

The problem with the whistling of the VAZ-2107-VAZ-2101 generator and the entire front-wheel drive line of cars usually lies in a collapsed front cover bearing. In this case, both the bearing itself and the belt slipping along the jammed pulley can make noise. The malfunction is determined “by eye”.

In some cases, alternator drive slippage may be caused by a misaligned alternator pulley or crankshaft pulley. The belt begins to move at an angle, touching the side surfaces. At the same time, even a new alternator belt will whistle. A breakdown can be determined by severe wear on the belt drive. The drive “eats” on the sides.

How to visually check the condition of the timing belt

To prevent serious damage, diagnostics of the condition of the gas distribution belt of a car engine should be carried out monthly.

During the inspection, small cracks in the material from which the timing belt is made may be detected, but this does not always mean that it is urgent to buy a new spare part. Thanks to the reinforcement, the inner toothed part of the belt can remain intact, and replacement of the part may not be necessary. At the same time, if the reinforcing component is damaged, the belt is considered unsuitable for use. This condition of the timing belt can be confirmed by extraneous noise during engine operation and difficulty starting the engine.

A sign of a malfunction in the gas distribution system may be black exhaust or vibration of a running power unit. If the above-described signs of improper condition of the timing belt appear, you should contact a car service center. If necessary, you can diagnose this element yourself.

Most often, before checking the timing belt tension, it is necessary to remove the protective casing. The procedure for carrying out this operation differs for each car brand and engine modification. When the protective casing is removed, it is necessary to rotate the crankshaft, which will allow the timing belt to rotate and assess its condition.

You should make sure that the belt teeth are not damaged (there are no cracks or breaks on their surface). Then the timing belt tension is checked. If oil stains or traces of coolant are found on this part, you need to find the location of the leakage of technical fluids and eliminate the cause of this malfunction.

Here are various signs indicating the need to replace the timing belt:

Worn material. Timing belt wear occurs in much the same way as with tires. If the belt material is severely worn, it may slip off the pulleys or break. Such situations occur at high engine loads (for example, while towing a trailer or trailer), as well as at high air humidity.

Abrasion of timing belt teeth occurs when the tension roller or pulley is displaced from the desired position, at high temperatures, or due to bearing wedging. Such wear on the teeth can be detected during inspection by the appearance of the fabric base of the belt (fleecy fabric fibers, uneven texture, etc.).

Presence of cracks and delaminations visible to the naked eye

When inspecting the timing belt, you need to pay attention to its front and rear surfaces.

Hardening of the material on the back side of the timing belt. It becomes shiny, hard and loses elasticity

Loss of elasticity leads to poor contact with the timing pulley. How to check a timing belt for hardening of the material using a screwdriver was described in previous sections.

Timing belt stretching. As a result of material wear, a significant increase in the working length of the belt can occur. As a result, the tension roller may move beyond its permissible limits. Such changes help reduce the degree of tension and stiffness of the timing belt.

Timing belt deviation from the required position. This may be due to a faulty bearing or tension pulley. Further operation of the gas distribution mechanism will lead to increased noise, vibration and overheating of the mechanism.

Possible repairs

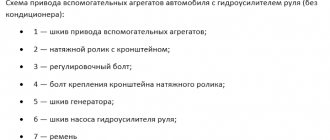

What to do in this situation? The solution depends on the identified malfunction. A loose drive should be tightened. Kalina cars and other front-wheel drive VAZA models have a tension bolt that allows you to adjust the degree of belt tension.

To carry out the manipulation, loosen the fastening bolts, then tighten the adjustment bolt a few turns, achieving optimal tension. A correctly tensioned drive should bend no more than 1 cm under hand pressure. If this cannot be achieved even with the bolt tightened to maximum, the belt should be replaced.

If the pulleys become oily, the drive should be removed and the inside should be wiped with alcohol or gasoline. Pulleys are cleaned in the same way. If the belt has been in an oily state for a long time, it is recommended to replace it, since fuels and lubricants destroy rubber. Also, current seals and gaskets must be changed.

In cases where the alternator belt whistles “when cold,” repair is not required. It is permissible to slightly increase the belt tension. However, if the whistling noise disappears after warming up, this is not necessary.

If, as a result of diagnostics, it was revealed that the front bearing of the generator is whistling, it is replaced. To do this, remove the unit from the car, dismantle the front cover and, after removing the faulty bearing, press in a new one. This is also done when the pulley is skewed and the generator shaft is jammed.

Prevention

You can prevent slipping of the generator drive by timely checking and correcting its tension level, replacing the belt if there is damage or severe wear.

It is important to monitor the condition of the engine seals and the cleanliness of the engine compartment. At the first sign of wear on the generator bearing, it is necessary to replace it.

Many people are familiar with the situation when a car starting up nearby suddenly emits a strained and nasty whistle, attracting the attention of all passers-by. It seems that a little more and the car will either fly vertically upward, or something very terrible will happen to it.

Meanwhile, everything is banally simple. This is how the alternator belt whistles. And if such a whistle appears, it will not be able to go away on its own. It is necessary to carry out diagnostics, determine the cause and replace worn parts.

It happens that the belt makes sounds during a cold start, and then, after the engine warms up, it returns to normal. In this case, they say that the alternator belt whistles when cold.

And it happens that the whistle does not stop even after the engine has been running for a long time. In this case, we are talking about the belt whistling under load.

Signs of alternator belt wear

Before answering the question of how to change the alternator belt, you need to know when it is best to do it. The electric generator is a hinged unit and has its own housing, attached to the engine using a special bracket, and can move in the desired direction.

This is done so that the degree of tension of the drive can be adjusted. To transmit rotation to the generator on the crankshaft, a pulley is provided.

There is a pulley similar in appearance, but of a different diameter, on the generator shaft. The drive firmly connects these pulleys, transmitting rotation from the power unit to the generator. For proper operation, the drive tension must be carried out with a specific force, regulated by a special bolt or plate.

The fact that the generator drive belt needs to be replaced is indicated by the following factors, if detected, it is better not to delay replacement:

- specific whistle when starting the engine or at high speeds;

- sensor readings indicating that the generator’s performance has decreased;

- drive breakage.

Factors indicating that the alternator belt needs to be replaced:

- the pulley has moved;

- malfunctions with the tensioning device and, as a result, weakening of the tension;

- the drive resource is close to exhaustion;

- Poor quality belt installed.

You can also visually determine that the alternator belt needs to be replaced, this is indicated by the following factors:

- cracks;

- abrasions;

- frayed edges;

- threads are visible;

- oil stains on the surface.

If you detect any of the signs, it is better to replace it immediately. This video shows how to change the alternator belt on VAZ cars. On foreign cars, the change occurs according to the same principle.

Causes of alternator belt whistling when cold

Unpleasant sounds can occur due to 2 things:

- starting the car engine after prolonged inactivity;

- starting the engine at sub-zero temperatures.

The main reason why a belt whistles when cold is belt slippage. This may be due to a number of factors:

- The alternator belt is not tensioned enough. The belt transmitting torque from the crankshaft is simply not able to accelerate the generator pulley and systematically slips on it;

- The generator bearing grease has thickened. This happens at low temperatures and an incorrectly selected lubrication option. The generator pulley is difficult to unwind, but then, having reached the required speed, it does not delay the rotation of the belt;

- the belt is too worn;

- the generator belt or pulley is contaminated with oil, gasoline, antifreeze and other substances;

- belt of poor quality;

- There was a problem with the generator, resulting in a jammed pulley.

Diagnosis of the cause of belt whistling

An inspection is necessary to try to determine the cause. To do this you should:

- Find the alternator belt and check it for cracks and the integrity of the tracks. The belt should not be worn out or frayed;

- Check belt tension. If the belt tension is weak, it should be strengthened using the Add to Dictionary roller or an adjusting bolt. An over-tensioned belt also causes noise and wears out the alternator and crankshaft parts faster;

- Check contact parts for cleanliness. There should be no dirt on them. The better the adhesion of the belt to the pulleys, the better the torque is transmitted and the higher the efficiency.

This is the initial necessary inspection. However, it happens that it does not give results. Then the reason should be sought deeper:

- Check the condition of the generator by trying to unscrew the pulley manually. If it rotates with difficulty, in fits and starts, or does not rotate at all, then, most likely, the generator bearing has failed and will need to be replaced;

- Check the belt tensioner pulley. It should turn easily and have no play. In case of any non-compliance with this requirement, it must be replaced;

- check the parallelism of the pulleys. They should be on the same line, without bending or other deformations.

All of these factors are the main causes of whistling when the belt rotates. However, this does not eliminate the possibility of the presence of secondary indirect causes. The main thing is to listen to the operation of your car and notice the slightest deviations from normal operation.

Types of belts

The design features of the engine mean that the belts are also different. In particular, the size of the alternator belt and its shape may change. The price of the product also depends on the design.

The size depends on the specific car model, and not all belts are interchangeable.

By form:

- wedge-shaped;

- toothed;

- polywedge.

V-belts are the simplest. They are installed in various VAZ models and other domestic cars. The name is associated with the trapezoidal shape of the product. Such a belt is capable of transmitting enormous forces and withstanding heavy loads. However, it is not prone to kinking and its use is limited to one or two knots.

Toothed belts are a variation of the previous type with transverse grooves. This design has increased transmission accuracy and can be used in timing operation.

Poly V-belts have several longitudinal grooves on their working surface. Their design resembles several V-belts. They have greater flexibility and are used to provide torque to several units. The installation pattern of such belts depends on the design of the car.

How to eliminate belt squealing

Having carried out diagnostics and knowing exactly the cause of the sounds, you can easily make repairs. Let's list what is done first:

- Purchase and installation of a new alternator belt. It is important to choose the original. Purchasing Chinese analogues of dubious quality leads to rapid replacement;

- Cleaning the belt and adjacent elements from dirt;

- Tension or loosening of the alternator belt. This is done using a roller or adjusting bolts;

- Replacing the generator bearing grease;

- Replacing the generator bearing;

- Replacing the tension roller;

- Replacing the generator pulley;

- Generator repair.

Drive belt: types, faults, markings.

A car drive belt is an element of a belt drive, a working part of vehicles and mechanisms, which serves to transmit engine torque.

The transmission of torque occurs due to frictional forces or engagement forces (timing belts, V-belts).

There is a misconception that the timing belt (the timing belt drive) does not belong to the drive belts. But actually it is not. The timing belt also falls into the category of drive belts.

Drive belts are divided into several types:

— Timing belt (timing belt drive)

— Drive belts for auxiliary components (engine attachments)

There are three types of car belts:

1. Timing belt - usually toothed

2. V-ribbed belt transmitting engine torque to engine attachments

3. V-belt transmitting engine torque to engine attachments

Belts No. 2 and No. 3 in our country also have additional names: flat belt (V-ribbed belt) or ripple belt (V-belt).

Characteristics of drive belts

The belt drive is easy to install and replace; overloads are compensated by the elasticity of the drives. This type is indispensable when working at high speeds.

Drive belts differ in a number of characteristics, primarily:

- type geared or not;

- length;

- width;

- form;

- rigidity;

- material.

Marking

Traditionally, the marking of such belts indicates the following data:

- manufacturer;

- cross section;

- size;

- Date of issue;

- GOST;

- drive class;

- appointment.

Dimensions

The sizes of drives can be very different and are produced for a specific model of car or equipment. Before replacing this part on your vehicle, be sure to compare the new part with the part you are replacing.

Choosing a drive belt for your car

To choose the right drive belt, you need to take into account the make and model of the car, the type of engine, its volume, engine code and the purpose of the drive belt itself , be it, for example, a timing belt that drives the pump and camshaft of the engine's gas distribution mechanism, or a poly-V-ribbed one-way belt , driving the air conditioner.

Malfunctions of poly-V-belts of attachments and methods for their elimination

Operational wear is inherent in any structural element, and moving parts exposed to friction and under load are more susceptible to wear than others. Belt damage poses a high risk of an accident.

The main safety measures are monitoring the condition of the belt and timely restoration of its functionality (cleaning, tightening, etc.).

- An unpleasant sound (squeaking) while driving indicates a weakening of the belt tension. In this case, it is necessary to perform a tightening without delay.

- If dirt and traces of fuels and lubricants are found on the belt or pulleys, the system requires cleaning.

- When inspecting, pay attention to the appearance of the drive belt - the presence of mechanical damage (frayed belts, tears, worn edges, etc.).

To ensure trouble-free operation of the system and extend the service life of the poly V-belt, it is also important to monitor the auxiliary devices, primarily the idler and tension rollers. They directly affect the driving behavior, the degree of wear and the likelihood of damage to the belt, and therefore must be kept in good condition.

The rollers are constantly under pressure and wear out as a result. Roller wear affects the degree of belt tension and the quality of the system as a whole. The drive belt, pulleys and rollers are checked at least every 15 thousand km. mileage The rollers are replaced when significant wear is detected and when the suspension belt is replaced.

Checking the drive belt

Evidence of irregularities in the operation of the poly-V-belt is not only a whistle, but also other extraneous noises occurring in the engine compartment. These sounds clearly indicate that the likelihood of the belt breaking has increased significantly.

This gap, in turn, can lead to much more serious problems, the most minor of which is the lack of light.

Rules for replacing a poly V-belt

The drive belt must be replaced:

- in case of a break or significant damage is detected indicating a high probability of break,

- after 50 thousand km. mileage since the start of operation or since the previous replacement.

When replacing a belt, it is recommended to follow certain rules:

- Before installing a new belt, it is carefully inspected for defects.

- When replacing a belt, the roller system is also changed along with it.

- The belt tension should ensure a deflection of no more than 5 mm.

Accurate and correct installation of the belt that transmits torque from the engine ensures the correct operation of a number of systems, since the flexible design of the poly-V-belt allows you to assemble a vehicle generator and a whole range of auxiliary equipment into a single system.

The performance of each element of this system directly depends on the operating parameters of the drive belt:

- no sagging,

- no vibration,

- motion trajectory accuracy,

- uniformity of movement.

We eliminate the whistling temporarily with auto chemicals

It is worth mentioning special air conditioners and belt tensioners separately. In the cold season they are very effective. The active substances included in their composition soften the belts and make them more elastic, thereby increasing adhesion to the pulleys.

If the belt looks good enough and the alternator rotor is turning, the first step is to use a conditioner spray. It may simply be that the belt hardened at a low temperature.

Share the link with your friends on social networks:

We also have interesting e-mail newsletters, subscribe ! (once a week)

Every motorist in his life has at least once encountered the whistling sound produced by the alternator belt. In this article we will try to answer why the alternator belt whistles, what causes it and how to solve the problem.

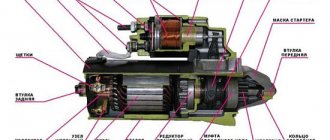

Alternator belt device

The whistling of the alternator belt cannot be confused with anything else - this sound, in principle, cannot be confused. Those who want their vehicle to attract the attention of others now need not worry. This is sure to happen with a whistling alternator belt. Of course, this is a joke, then we will try to understand the structure of the element in order to understand how to solve the problem.

The generator is designed to ensure that all vehicle systems stably receive the required level of energy; it is impossible to do without it. A generator device such as a rotor must constantly rotate to generate energy, which is achieved through a belt connection and crank pulley action.

Car alternator belt device

Additional shafts are installed on the device pulley and crankshaft, connected to each other using a ring-shaped strap. Actually, it is from the strap that the rotation is transmitted to the generator. As you understand, the unpleasant sound that often appears when starting the engine in wet weather appears precisely as a result of the operation of this element.

If you open the hood and get to the generator, you can see that the design of the straps can be completely different. However, the principle of their operation and relationship will be identical. As you understand, when the car engine is not running, there can be no sound of any kind; accordingly, it only appears when the parts rub against each other. Thus, it would be quite logical to assume that the shaft slipping occurs as a result of the pulley tensioner being weakened, but we will talk about the reasons further.

When is it necessary to replace the alternator belt?

First you need to make sure that the alternator belt really needs to be replaced. This can be evidenced by a characteristic whistle that appears when the vehicle’s electronics are under load, for example, when you turn on the radio or headlights; the indicator on the dashboard can also indicate that the belt is worn out. Have any symptoms appeared? Then replacing the belt is inevitable. It should also be noted that the recommended replacement of the alternator belt is carried out in the interval between 60,000 km - 85,000 km, by the way, experts advise changing and at the same interval.

So let's begin! First you need to purchase the necessary parts and prepare the tool. Open the hood. The alternator belt is usually located to the left of the engine. Of course, before inspection, you must turn off the engine, remove the key from the ignition and disconnect the negative cable from the car battery.

A visual inspection of the belt will allow you to make a final decision regarding the need to replace it - if any defects (cracks, breaks) are noticeable, then the belt needs to be changed without hesitation, since otherwise it may break at the most unexpected moment, and this threatens destruction, both the piston group and the valves. The cost of such repairs will cost the owner a decent amount, and the worst consequence of a broken alternator belt is replacing the engine.

If signs of wear are not visible on the belt outwardly, then it would be a good idea to check its tension, since this is also a fairly common problem.

Remember: before removing the old alternator belt, you must carefully study its location and attachment points, this will help to avoid unnecessary difficulties when installing a new belt. To be on the safe side, you may even need to draw a rough diagram of the location of the belt.

Reasons why friction occurs and a squeaking sound is made

So, for what reasons does the alternator belt whistle? We will now try to talk about this. According to many motorists, the main reason for the appearance of third-party sounds is wear of the element. However, this is not true in all cases.

As stated above, this is only partly true; we will talk about other reasons further:

- Often the problem with extraneous sounds is that the pulley on which the strap is placed is dirty with some kind of lubricant. This could be either motor oil or any other lubricant that got there accidentally during any repair work. As a rule, this problem occurs not only during startup in wet weather, but at absolutely any time. When the lubricant gets on the element, it ceases to provide normal adhesion functions to the surface of the pulleys. As a result, an unpleasant sound appears.

- Another reason is component sagging. When starting in wet weather this is most noticeable. By the way, this problem is one of the most common, so when it comes to whistling, motorists are always advised to check the tension or condition of the belt.

- If the element is too tight, it will be at its stiffest, which can also lead to noise. If this is the case, then the strap will not be able to transmit sufficient rotation to the pulley, as a result: all elements that rotate with the strap will make a whistling sound. As a rule, car owners encounter such problems in the cold season, because if the strap is hard, then in cold weather it will shrink even more.

- Another reason is bearing wear. If this component is worn out, then the consequence may well be the appearance of third-party sounds when starting the motor, since the bearing itself is part of the drive structure.

- And, of course, the last reason is the wear of the strap itself, which occurs when its service life is exhausted.

How to deal with this?

Now let's talk about methods to solve the problem. Many vehicle owners are interested in the question - how to eliminate the whistling of the alternator belt in their car, which appears when starting the engine? We will try to explain the essence of the solution to the problem as clearly as possible. Below are methods that will allow you to overcome the problem.

Replacing the strap

To change an element, you need to loosen its tension. In most vehicles, the tension mechanism is adjusted using a bolt or a semicircular adjuster. To begin with, you should study how the component is positioned and what it is hooked onto in order to understand how to remove it. Our resource provides practical instructions for replacing the alternator belt - study them, perhaps you can find something for yourself. It should be noted that the new strap must be installed in exactly the same way as the old one.

Using a wrench, loosen the tension screw until the element can be simply removed. When this happens, remove the strap and replace it with a new one. It is advisable to know how long the new part should be tightened.

Removing dirt

If the strap is too dirty and whistles when starting for this very reason, then the element will also have to be dismantled. Loosen the tension screw and remove the strap. Wipe all sides dry so that there is not even a hint of grease on it. You can use acetone to make it more effective. Also, do not forget to wipe all the pulleys on which the belt is installed; it is quite possible that some of the lubricant got there too.

If there is sagging

This problem is also not particularly difficult to solve. You need to open the hood and check the mechanism. If a component sags even a little, then you need to tighten it; we discussed how to do this above. In addition, pay attention to all the pulleys: they must be located in the same line relative to each other, if this is not the case, then the shafts must be aligned in the right order. Check the technical documentation for the vehicle, it will help you understand this issue.

Sorry, there are no surveys available at this time.

If the strap is too tight

In this case, its position will also need to be adjusted, just not tightened, but loosened. If the starting whistling does not occur in wet weather, but in winter, then this problem usually corrects itself. That is, when the car warms up to the desired temperature, the strap expands slightly, which eliminates the whistling problem.

Bearing replacement

If a part is worn out, then there is only one way out - to replace it with a new one. If everything is fine with the belt itself and there are no signs of deformation on it, then spend time on the secondary components of the system. In this case, you can simply visually diagnose the bearings that affect the operation of the device. There should be no problems with this procedure - a worn part can be easily replaced with a new one by dismantling and installing. We hope that our recommendations will help you solve this problem. And remember - the problem of whistling does not always lie in the belt itself!

Before you begin repair work, it is important to correctly assess your strengths. Before performing the procedures for dismantling and installing the timing belt, it is important to thoroughly familiarize yourself with its structure so that subsequent installation is carried out correctly. If you are not sure of the correctness of your actions, then check the vehicle’s operating manual. At worst, you can always turn to a mechanic at a service station for help.