The design of modern cars is a single, metal-electronic mechanism, all elements of which are closely interconnected. The failure of one seemingly insignificant part can lead to problems in the internal combustion engine and other critical systems.

An example is the failure of the throttle position sensor, which plays one of the leading roles in the area of the internal combustion engine intake system. When the damper sensor is faulty, this affects the principles of regulating the supply of air masses, affecting the formation of the fuel-air mixture. In other words, a faulty sensor can cause a car to sharply increase its consumption of consumable fluids with a simultaneous decrease in engine power.

What is this sensor responsible for and its importance?

The throttle valve in a car is part of the internal combustion engine system. This element is involved in regulating the supply of fuel masses. The main purpose of the damper is to be responsible for supplying the required volume of processed air masses to the cylinders.

The state of the throttle valve is transmitted using a separate element - a sensor, which transmits information about the position of the device in a specific time period to the electronic unit. Data transmission is carried out thanks to the work of two elements that convert alternating and direct current.

Diagnostics and troubleshooting

Let's consider the most common option, when the car has an electronic throttle control system. In the presence of the above-described malfunctions, an additional warning light on the “Check Engine” dashboard is provided. It indicates problems with engine operation.

To perform self-diagnosis of the damper sensor, you must follow this algorithm.

- Turn off the ignition. In this case, the “Check Engine” indicator light should not be active.

- Using a multimeter, the presence of a “minus” on the sensor is monitored.

- Checking the power supply. Performed using a multimeter with the ignition on. Typically the voltage value is 0.7 V. When manually opening the throttle, this parameter should increase to 4 V.

- Checking the state of the slider. You need to turn off the power and disconnect one of the connectors. By turning the slider the resistance readings are controlled. They should change smoothly. An erratic result indicates a sensor malfunction.

If a malfunction is detected in the throttle sensor, the best way out of the situation is to replace it. The brand of the device and the correct connection of the new model must be taken into account.

The role of the throttle valve and its sensor in the car spare parts system

The throttle valve is responsible for all changes in contact voltage, which allows you to regulate the supply of fuel, which is used to create the fuel-air mixture. For the damper to work properly, data transmission must be carried out in a timely and correct manner.

When the sensor breaks, a voltage surge occurs. This negatively affects the operation of many systems in the car, especially the internal combustion engine. The most negative scenario, which entails a breakdown of the throttle sensor, is associated with the failure of the car engine, followed by the replacement of the device with a new unit, without the possibility of restoring spare parts.

How to troubleshoot

The throttle potentiometer cannot be repaired. If it is damaged, a new element should be installed. However, in some situations partial recovery is possible:

It is advisable to install expensive contactless sensors. Their price is higher, but they are distinguished by increased reliability and long service life.

New throttle sensor

The main signs of breakdown of the throttle position sensor

When a sensor is broken, this is reflected in the operation of many systems. Signs of a malfunctioning throttle sensor:

Deterioration of engine performance at idle speed. If previously the internal combustion engine worked stably and reliably when switching to neutral speed, then when the damper sensor fails, switching to “idle mode” becomes a real test for the vehicle owner. In some cases, failures in the internal combustion engine system lead to the car literally stalling while driving, which can lead to an emergency situation on the roads.

Engine failure when trying to switch to another speed, including neutral. This is one of the most characteristic signs of a malfunctioning damper sensor, which occurs in almost every car owner who is faced with this problem.

The engine instantly “dies out” when a certain speed is turned on. Most often the problem is associated with the transition to “idle mode”. But sometimes failures occur when changing a different speed.

Deterioration in the smoothness of vehicle movement. It is important for all car owners that their car drives confidently, is highly maneuverable and has a certain degree of reliability. But if the throttle sensor fails, you can forget about smooth driving. As the speed increases, the car will literally jump from one speed mode to another, which also risks creating an emergency situation during the next jerk of the car. The movement of the car in such a situation is often accompanied by alternating jerks and dips.

A sharp drop in traction and acceleration ability. This symptom is not a 100% guarantee that when it occurs, we are talking exclusively about a broken throttle sensor. But if the car begins to pick up speed significantly more slowly when climbing onto any surface, noticeably reduces speed when there is a load weighing up to 70% of the maximum load, or takes too long to accelerate at the start, most likely the cause of the problem is the throttle sensor.

An error code appears on the instrument panel. In models that are maximally equipped with electronics, it is sometimes easier to determine the cause of a malfunction than in outdated mechanical predecessors. So, if a Check Engine error message lights up on the panel, it is recommended to connect a device to scan the code. If error P0120 is detected, you can confidently say that the problem is exclusively related to the throttle sensor.

Fuel consumption increases. When the throttle valve fails to regulate fuel, this has a bad effect on the operation of the internal combustion engine. Gradually, depending on the degree of failure of parts, gasoline or diesel consumption will increase.

When the throttle sensor is not working, one or more symptoms may be present. Regardless of the problem that arises, you should consider what exactly contributed to the breakdown of the part, and also whether there are ways to quickly and efficiently solve the problem, eliminating the replacement of elements in a car service.

Electronic throttle - how does it work?

Human nature forces him to look for more profitable ways of existence. Agree, we all, if possible, prefer to avoid complications and choose the “simpler” option, and this applies to both work issues and everyday life. So it turns out that one of the main trends in the automotive industry today is the maximum elimination of the human factor in those places where electronic systems cope perfectly well without it. Of course, quite often, when driving a vehicle, the driver may make some mistakes: he does not fully depress the clutch pedal or does not change gear in a timely manner, and although, at first glance, these are not serious offenses, however, their systematic repetition has a detrimental effect on the operation of the engine and transmissions.

With the development of the technological side of our existence, the design of machines is also improving. Therefore, it is not at all surprising that electronic systems capable of controlling various mechanisms with great precision have gradually been introduced into the design of modern cars. The list of the first successful devices of this kind includes an electronic throttle valve (throttle), which domestic developers, along with their foreign colleagues, recently began to install en masse on vehicles. If this issue interests you and you would like to delve into its essence in more detail, then take a few minutes of your time to read this article.

Purpose of the electronic throttle

The throttle valve is one of the structural elements of the intake system installed on vehicles with a gasoline internal combustion engine. Its main purpose is to regulate the amount of air flow entering the engine to produce a fuel-air mixture. The throttle valve is located between the intake manifold and the air filter.

A more advanced version of the standard throttle is the electronic version of this device. The electronic throttle valve, like the traditional mechanism, controls the volume of air flow entering the internal combustion chamber of the engine. When the driver presses the gas pedal, the position of the damper installed in the housing changes (opens) and a variable air flow passes through it. The use of such a mechanism makes it possible to achieve greater efficiency and operational stability, because human error (human factor) when operating the unit is completely eliminated.

Automotive gasoline systems using an electronic throttle valve are now not uncommon in our country, and they first appeared on German cars produced in the second half of the 90s. They came to the domestic space through the secondary market, leaving behind such popular cars as the Golf, Volkswagen Passat B5 and some others.

The first time an electronic throttle system was used on a racing car was back in 1985. At that time, Volkswagen was experimenting with the second generation of Golf cars, trying to make it a racing sports car. For this purpose, the car was equipped with two engines at once, and the E-Gas system was used to synchronize their power. The throttle of one of them was controlled traditionally mechanically, but for the operation of the other they used an electric drive that synchronized the position of the damper. As a result of the experiment, the developers managed to achieve a total engine power of 500 horsepower, with acceleration of up to 100 km. took only 3.4 seconds.

In general, the essence of the electronic throttle system is full automatic (electronic) control of the throttle actuator. Of course, this was done not at all in order to remove the mechanical connection between the device and the gas pedal, but in order to ensure better preparation of the fuel-air mixture. It was thanks to the electronic system that it became possible to significantly change and better regulate its preparation, which, in turn, affected the reduction of fuel consumption and greater efficiency of its combustion, thereby reducing the amount of harmful emissions.

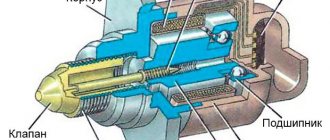

Electronic throttle device

As we have already said, on most modern vehicles, the mechanical throttle valve drive has been replaced by an electric one controlled by an electronic unit. This fact helps to achieve the optimal torque value in any operating mode of the car engine. In addition, not least among the advantages of using such a system is compliance with environmental requirements and safety of movement.

The main distinguishing features of an electrically driven throttle are:

— complete lack of connection between the throttle valve and the accelerator pedal (gas pedal);

— the ability to regulate idle speed by moving the corresponding damper.

When switching to electronic control, the damper mechanism remained the same, and only the drive system underwent fundamental changes. In the traditional design of this device, its axis is connected to the gas pedal using a cable and when the driver presses the pedal, it contracts, which, in turn, causes the damper to rotate, thereby opening it. The movement of the axis in the electronic throttle is controlled by a special electric motor, and there is no direct connection between the damper and the gas. In this case, the gas pedal acts as a remote control, and smart electronics help quickly and smoothly change the position of the throttle (as much as necessary for engine operation at a given load). As a result, a reduction in power loss, a reduction in fuel costs, and at the same time acting as a starting device for a cold engine.

The electronic component of the throttle control makes it possible to influence the amount of torque, even in the absence of physical impact on the pedal. The system itself includes all input sensors, an actuator and an engine control unit.

In addition to the throttle position sensor, the electronic control system also uses an accelerator pedal position sensor, a brake position switch and a clutch pedal position switch. The use of signals from the automatic transmission, air conditioning system, brake system and cruise control system also plays an important role in the performance of the throttle control system.

All these sensor signals enter the engine control unit, which converts them into control actions on the throttle valve module. To summarize what has been said, the main elements of the electronic throttle unit include:

— electronic control unit (“brain” of the system);

— the mechanism itself, which includes a body, an axis and a damper;

— an electric motor controlled by the throttle valve drive; gas pedal position sensor and throttle position sensor.

The damper position sensor is located on its body and as soon as the gear attached to the end of the axis begins to move, the sensor signal changes along with it. These data are recorded, and a signal about them, the voltage of which, by the way, changes depending on the position, is sent to the control unit. The latter, during processing of the signal voltage, converts it into percentages: a value from 0 to 100% - the damper is closed; 100% - completely open.

The sensor, which is installed on the gas pedal, records its position and then transmits this data to the control unit. Naturally, it processes them and, depending on the position of the pedal, starts the damper drive (opens it or closes it).

There is also feedback. The sensor monitors any position of the damper and transmits a signal to the control unit, which then compares the angle of its opening with the position of the gas pedal. Thanks to this connection, the electronic control can maintain the engine idling, while controlling the optimally advantageous (from the point of view of the specified parameters) throttle position. The use of an electric drive helped solve the problem of controlling multiple throttles.

Electronic throttle malfunctions

Sooner or later, any part fails, as evidenced by a number of characteristic signs. In this regard, the throttle sensor described above is no exception.

Typical malfunctions of this mechanism include:

— increased engine speed in idle mode;

— increase in fuel consumption; stopping the engine in neutral gear;

— in some cases, the “Check Engine” indicator light may light up and stay on for a long time;

— when accelerating the car there are sharp jerks; it becomes difficult to start the power unit.

All this indicates a malfunction of the damper position sensor, and therefore the need to replace it.

Given the complexity of the electronic throttle assembly, which adds significant complexity to vehicle design, it is not surprising that, like many other complex devices, it is a potential source of problems. For example, electronics are largely susceptible to negative influences and may not function properly in conditions of extremely low temperature or humidity.

If the breakdown occurs after the expiration of the warranty service period, then replacing the electronic throttle will result in significant financial expenses for the owner. As a rule, such a device is not subject to repair work and is replaced entirely. The damper mechanism, in the form of the throttle assembly described, is no different from the standard type, so the need for periodic cleaning remains. This is especially true in cases where the car is operated almost to the limit of its capabilities.

Some motorists, based on their own experience, identify the following problems with electronic throttles:

— wiring often cracks and dries out, short circuits occur;

— the throttle valve either does not work at all or works with serious interruptions;

- the electric motor controlling the throttle may fail (error code 022 - throttle failure);

— the throttle valve stops “obeying” the electronics: a worn-out motor either reacts to it or not;

— problems arise with the potentiometers, and since they are hardwired into the board, it is almost impossible to get to them.

As you can see, everything comes at a price and the ability of the electronic throttle to improve the performance of the vehicle is fully compensated by the frequent problems that arise due to the complexity of its design.

Subscribe to our feeds on Facebook, Vkontakte and Instagram: all the most interesting automotive events in one place.

Was this article helpful?

auto.today

Causes of malfunction of the throttle position sensor

Before looking for what reasons lead to the breakdown of this unit, it should be noted that there are 2 types of such sensors:

Film resistive. They are also called contact.

Magnetic-resistive, or non-contact.

Film-resistive throttle sensors break down more often. This is due to the special design of the device, which is associated with the movement of the slider along resistive paths. The tracks have their own service life: when it comes to an end, they simply wear out, which leads to the failure of the film-resistive sensor. Other circumstances that lead to breakdown of the contact sensor are:

weak contact or lack of contact on the slider. The presence of electrical contact largely depends on the state of the resistive layer on the track, which gradually fails during the natural operation of the spare part. The contacts are broken, the sensor stops working;

lack of pollination on the base, which prevents the normal movement of the slider. This is reflected in weak line voltage readings that do not increase;

failure of connecting elements - gears from the slider drive;

ruptures of components - connecting wires. In this case, their type does not matter. Both the supply and signal elements can break and interfere with the operation of the sensor;

short circuit in the electrical circuit. Even the slightest malfunction in the vehicle's electrical system can lead to negative consequences for the throttle sensor, which will certainly affect the operation of the entire internal combustion engine system.

Failure of contactless sensors is most often associated with a break in the connecting elements - wires, as well as the occurrence of a short circuit in the electrical circuit. The absence of spraying on the tracks reduces the risk of malfunction due to failure of these elements.

Regardless of which sensor is installed on a particular car, you can check the serviceability of the throttle sensor using the same method. The test should be carried out using a special device called an electronic multimeter. Instructions for checking the throttle position sensor:

Activation of the ignition process. Only when you turn on the engine can you understand whether everything is fine with the sensor, and how this affects the operation of the entire internal combustion engine system.

Separating the device contacts from the chip. Next, you should take a multimeter and connect it to the sensor to determine whether the current is flowing to the device. The test continues only if an electrical connection is detected. If there is no contact, you should check the connecting elements (wiring) to find a break or identify the wires that have failed, which led to a lack of voltage in the throttle position sensor.

Check with a multimeter. If there is a contact, you should use an electrical device, namely: set the multimeter probe with the minus sign to ground, and the one with the plus sign to the contact with the output.

Measuring indicators. It should be remembered that when measuring, the damper must be completely closed, that is, when the gas pedal is released. In this condition, the normal measurement should be no more than 0.7 Volts. And, on the contrary, if you depress the accelerator pedal, that is, open the throttle, then the readings on the multimeter should approach 4 Volts.

Rotate the valve. To understand how the sensor behaves dynamically, you should open the damper, smoothly rotating the sector. The value of the indicators should increase as the device rotates.

It is noteworthy that sensor problems are often associated with low quality connecting elements - wires that fail 2-3 times faster than the end of their service life. Russian-made cars usually suffer from this, since a similar problem among owners of foreign cars is 4 times less common.

Electronic gas pedal, throttle valve.

Details

Design and principle of operation

With an electronic accelerator drive, the throttle valve is moved by an electric motor. This eliminates the need for a traditional mechanical connection between the accelerator pedal and the throttle valve. This means that the driver's intention from the accelerator pedal is transmitted to

Control block. Then the throttle valve moves.

Thanks to this, the control unit can influence the amount of engine torque by moving the throttle valve, even when the driver does not change the position of the accelerator pedal.

This makes it possible to achieve better coordination between engine systems.

Below you will see that the electronic accelerator drive is much more than a simple replacement of a mechanical drive.

Mechanical movement

Throttle valve The driver presses the accelerator pedal, and through the accelerator rod, force is directly transmitted to the throttle valve and causes it to move. In this case, the electronic engine control has no way to influence the throttle position. To change the engine torque, it is necessary to influence other parameters of the engine mode, for example, at the moment of ignition and fuel injection. Only in idle mode and when the cruise control is active

electronic control of engine operation.

Electronic-electric throttle movement

In this case, the movement of the throttle valve along its entire path is electronically controlled and electrically driven. The driver, in accordance with his intentions to change engine power, presses the accelerator pedal. The pedal position is monitored by sensors and the corresponding signals are transmitted to the engine control unit. Next, the throttle valve moves in accordance with the driver's intentions. If there is a need to change the engine torque for reasons of traffic safety or fuel economy, the engine control unit can change the position of the throttle valve without the driver changing the position of the accelerator pedal. The advantage of such regulation is that the control unit determines the position of the throttle valve in accordance with the wishes of the driver, environmental requirements, and the need to ensure

traffic safety and reduced fuel consumption.

System Description

Engine control “tools” in terms of engine torque are throttle valve, boost pressure, fuel injection timing, cylinder deactivation and

ignition moment.

Regulation of engine torque via a mechanical throttle drive Various signals regarding the amount of engine torque are sent to the engine control unit and processed there. However, the optimal torque cannot be achieved because the engine control unit cannot directly influence the throttle valve, which is controlled mechanically by the accelerator pedal. Engine torque control via electronic throttle control In this case, it is possible to achieve the optimal torque value

through electronic control of engine operation.

How does this happen? The engine control unit summarizes all external and internal requirements regarding the amount of engine torque and calculates the required value from them

moment. It's much more accurate and efficient than before.

Internal requirements are imposed from: - engine starting conditions; - catalyst heating; - idle speed control; - power limitation; - rotation speed limitation;

— regulation of the mixture composition based on the oxygen content in the exhaust gases.

External requirements are imposed from: - automatic transmission (at switching points); - brake system (traction control, forced idle mode); - air conditioning system (compressor on and off);

— cruise control.

Regulatory process

After assessing all internal and external torque requirements, the engine control unit calculates the optimal engine torque. The actual torque is determined by calculation based on the engine speed,

signal about engine load and ignition timing.

During regulation, the engine control unit first compares the actual torque with the optimum torque. If these values do not coincide, the engine control unit calculates the direction and magnitude of the required impact in order to achieve a match between the actual and optimal torque

moment.

The control unit has two ways to do this.

On one path, parameters that affect the filling of the cylinders are subject to regulation. In this case, we are talking about parameters, the change of which affects the direction of changes in engine torque for a relatively long time. These parameters are: - throttle opening angle and

— on turbocharged engines, boost pressure.

In the second path, parameters are subject to change that relatively quickly change the amount of torque, regardless of the filling of the cylinders. These parameters include: - ignition timing; - fuel injection timing;

- shutdown of the cylinder(s).

The electronic throttle valve consists of:

- pedal module with accelerator pedal position sensors; - engine control unit; - throttle valve control module;

— warning lamp for the electronic throttle actuator.

Pedal module

Using sensors, it continuously detects the position of the accelerator pedal and transmits the corresponding signal to the engine control unit.

Engine control unit

determines from this signal the driver's intention regarding changes in engine power and responds to this with a corresponding change in engine torque. To do this, the control unit sends a control signal to the throttle valve drive to open it slightly or, conversely, to close it slightly. In this case, other wishes regarding engine torque are taken into account, for example from the air conditioning system. This is the meaning of “electronic drive”

accelerator” (throttle valve).

Throttle control module

provides the required mass of air entering the cylinders. The throttle valve actuator acts on the throttle valve in accordance with commands from the engine control unit. The throttle position signals are constantly received from the throttle position angle sensors into the block

engine control.

The electronic accelerator control lamp signals to the driver that there is a malfunction in the electronic accelerator drive system.

Electronic drive action

Idling

The engine control unit recognizes from signals from the accelerator pedal position sensors that the pedal is not pressed. Idle control mode begins

progress.

The engine control unit controls the throttle valve actuator; The throttle valve is moved using an electric motor. Depending on the difference between the actual and optimal frequency values

engine rotation, the amount of change in the throttle opening angle depends.

Both throttle position angle sensors continuously transmit information to the engine control unit. Sensors are located in the module

throttle control.

Moving the accelerator pedal

The engine control unit receives information about the position of the pedal from signals from the accelerator pedal position sensors. The movement of the throttle valve desired by the driver is carried out at the command of the control unit through the throttle valve drive. Additionally, the corresponding commands are received to change the ignition timing, injection and, if necessary, the value

boost pressure.

Both angle sensors detect the position of the throttle valve and report it to the control unit.

To calculate the required throttle position, the control unit takes additional requirements into account.

For example: - by limiting engine speed; - from the cruise control side (GRA); - from the traction control system (ASR);

— from the side of forced idle speed control (MSR).

If this ultimately translates into a need to change torque, the throttle position can be changed without any driver input

on the accelerator pedal.

The accelerator pedal module consists of:

- accelerator pedal; - accelerator pedal position sender 1 G79 - accelerator pedal position sender 2 G185. Two identical sensors are used to ensure the highest possible reliability. We are talking about a redundant system here.

This means that information from one sensor would be sufficient.

Using signals Using signals from both accelerator pedal position sensors, the engine control unit learns the position of the pedal at any given time. Both sensors are potentiometers with a sliding contact mounted on a common shaft. Each time the pedal position changes, the resistance of the sensors changes and, accordingly, the voltage that is transmitted to the unit

engine control.

Operation when there is no signal

In the absence of one signal - This is entered into the fault recorder and the warning lamp of the electronic accelerator drive is turned on. - The system is first controlled at idle speed. When the second sensor is detected at the input of a certain control period in idle mode, the vehicle will again be able to move. - When the pedal is fully pressed, the engine speed increases slowly. - Additional recognition of idle speed by pedal position is carried out by means of the brake light switch F or the brake pedal position switch F47. - Comfort functions such as cruise control or engine control

forced idle mode, turn off.

If both signals are absent, this is entered into the fault recorder and the electronic accelerator control lamp turns on. - The engine only runs at high idle speed (maximum

1500 rpm) and does not respond to the accelerator pedal.

Throttle control module

located on the inlet pipe. It serves to ensure that the required amount of air is supplied to the cylinders.

Device, Module consists of: - throttle body; - throttle valve;

— throttle valve drive G186;

- Angle sensor 1 for throttle valve drive G187; - Angle sensor 2 for throttle valve drive G188.

ActionThe opening and closing of the throttle valve is carried out by an electric motor according to a signal from the engine control unit. Both angle sensors send signals to the engine control unit about the position of the throttle valve.

Two sensors are installed to improve system reliability.

Operation in the absence of signals

If the engine control unit receives an indistinguishable signal from one of the angle sensors or does not receive any signal at all: - This is entered into the fault recorder and the warning light for the electronic accelerator is switched on. - Subsystems that to some extent determine torque (e.g. cruise control , engine regulation in forced idle mode) are switched off. - The load signal is used to monitor the remaining sensor.

— The accelerator pedal operates normally.

If the engine control unit receives indistinguishable signals from both angle sensors or does not receive any signals at all: - This is entered into the fault memory and the warning light for the electronic accelerator drive is switched on. - The throttle valve drive is switched off. - The engine only runs at a high idling speed of 1500 rpm.

min and no longer responds to the accelerator pedal.

boschdiagnost.ru

Checking faults using a special scanner

If a multimeter can be called a universal device that is designed to check voltage in electrical appliances, then to determine specific problems with a car, a special scanner is used - an OBDII diagnostic device, or auto scanner. Unlike a multimeter, which only allows you to find out what the voltage is in an electrical circuit and determine variability (jumps), a car adapter shows which error led to the malfunction, which allows you to find out the cause of the breakdown and the parts that require repair.

To check the sensor, you need to connect the device in accordance with the instructions and, examining the data in the closed and open states of the damper, measure the voltage readings, checking what information appears on the screen incorrectly. If there are problems, a specific code is displayed on the display.

As mentioned earlier, if the sensor malfunctions, error p0120 often occurs, which actually translates as “Switch malfunction at a certain damper position.” Code p0120 is not the only one in the list of symbols associated with the incorrect operation of this device. If the value p0122-p0123, P0220-P0223 appears on the screen, this also indicates problems with the sensor.

In addition to identifying faults in the internal combustion engine system, the auto scanner helps to identify a number of problems in other systems. But before using it, you need to study the instructions: a number of models of the measuring device are not suitable for specific types of cars, and therefore, before purchasing this accessory, it is recommended to carefully study which manufacturers’ cars this device is compatible with.

How to check TPS?

To confirm or refute the symptoms of a malfunction of the meter, you will need a multimeter or other device with a voltmeter function. The kit must contain pointed probes, otherwise you will have to strip the wires connected to the sensor. It is highly undesirable to strip the insulation from the conductors, so if there are no sharp contacts, make them yourself - they will come in handy in the future.

The sensor is diagnosed by measuring the voltage between the output wire and the machine ground. The operation algorithm is as follows:

- With the ignition off, remove the TPS connector and use the diagram to determine which of the three wires is the output. In VAZ cars, the required conductor is connected to the upper contact of the block.

- Put the connector in place and pierce the outside of the found wire with a pointed probe. Connect the second clamp to the negative terminal of the battery.

- Set the multimeter to measure voltage and turn on the ignition. Record your readings.

- Open the throttle all the way and remove the second voltage reading.

- Smoothly turn the damper, observing the voltage increase. The values should change gradually, without jumps or drops to zero.

Advice. If the diagram is not available, find the required wire by elimination. The first contact is the meter’s power supply, the second is the negative contact, and the third is the pulse output. With the ignition on, it is easy to find a wire with a constant supply voltage of 5 volts (for VAZ) and ground.

Now analyze the data. The voltage when the throttle is closed should not exceed 0.5–0.7 V (depending on the make of the car). When the specified threshold is exceeded, the controller “sees” the throttle slightly open, supplies more fuel and the speed increases, although in fact the throttle is closed. Compare the output with the symptoms of the malfunction.

Deviations with the air damper fully open and sudden jumps in voltage give the same effect. The ECU does not understand that the sensor is simply lying, and supplies the engine with fuel in accordance with its readings. This is where all the unpleasant moments arise - instability, failures, jerks. When the contact on the slider completely disappears, the controller goes into emergency mode, the display turns on and gasoline consumption increases.

So, a sign of a breakdown is a deviation from the upper and lower voltage thresholds and inadequate jumps when the throttle is opened smoothly. To be sure of the malfunction, you can disconnect the sensor connector and check its resistance in different throttle positions.

Replacing a non-working device is quite simple. Follow these steps:

- Remove the negative terminal of the battery.

- Disconnect the TPS connector.

- Unscrew the sensor and put a new one in its place.

- Connect the wires in reverse order.

Conclusion

When the throttle position sensor has signs of malfunction that become obvious to the naked eye, in most cases the device must be replaced with another, working device. You should not delay repairing the vehicle: this device has a direct impact on the operation of the engine. If the problem is left unchecked, it can lead to a sharp deterioration in the quality of the fuel-air mixture, which is formed due to the action of the throttle valve. The malfunction of these spare parts negatively affects the operation of the entire internal combustion engine system, which in 70% of cases leads to the need to replace the engine with a new unit.