The operation of any internal combustion engine is based on the conversion of the energy released during the combustion of the air-fuel mixture into mechanical action.

At the same time, it is very important that ignition occurs at a strictly defined moment, and in gasoline engines the ignition system is responsible for this.

At the same time, you can often hear that the ignition of the power plant is “knocked down”, and it is either early or late.

What kind of phenomena these are and what they are fraught with - we will try to figure it out, and also consider what to do in such cases.

How to determine early or late ignition

The operation of any internal combustion engine is based on the conversion of the energy released during the combustion of the air-fuel mixture into mechanical action.

At the same time, it is very important that ignition occurs at a strictly defined moment, and in gasoline engines the ignition system is responsible for this.

At the same time, you can often hear that the ignition of the power plant is “knocked down”, and it is either early or late.

What kind of phenomena these are and what they are fraught with - we will try to figure it out, and also consider what to do in such cases.

Determination of OZ on cars with LPG

Gas cylinders have become widespread recently. They are installed on cars equipped with gasoline engines. As a result, you can save a lot on fuel. Gas costs much less than gasoline.

However, installing HBO also brings the car owner problems associated with setting the ignition timing. A priori, fuel consumption increases (for gas it is an order of magnitude higher), and the afterburning of the fuel assembly occurs during the exhaust phase and lasts much longer.

What is a UOZ variator?

If you take into account all these nuances, then setting the OZ will be as easy as shelling pears. In this case, the gas will be converted into energy before the exhaust system starts operating, and the overall efficiency will increase significantly.

To set up the OZ on cars with LPG, it is customary to install automatic regulators such as a variator. They are purchased complete with gas equipment.

We hope that you will no longer have the question of how to determine the ignition timing and set a certain OZ.

Why is ignition timing necessary?

Let's look a little at the theory of internal combustion engines.

So, in automobile engines, the piston in the engine cylinder moves back and forth, that is, up and down.

In this case, the entire movement is divided into 4 parts (cycles), the so-called strokes (there are also 2-stroke engines, but we will not consider them).

One of these strokes is the power stroke, during which the piston moves down.

It is the most important, since this stroke carries out the transformation (ignition is accompanied by the release of a large amount of energy, which puts pressure on the piston, causing it to move, which in turn ensures rotation of the crankshaft).

All other strokes are preparatory, that is, the remaining three strokes do everything to ensure that the working stroke occurs, namely, they fill the cylinders with mixture components, ensure their compression and remove combustion products.

Read the operating principle of a two-stroke and four-stroke engine here https://autotopik.ru/obuchenie/851-princip-raboty-dvigatelya.html.

Theoretically, in order to obtain maximum efficiency, ignition of the mixture - the ignition moment - should occur when the piston reaches TDC (it will begin to move down), then the released energy will have a maximum impact on it.

In reality, everything is somewhat different. Fuel combustion does not occur instantly, and this process takes time.

And if you ignite the mixture with the piston position at TDC, then before the moment when the maximum amount of energy is released, it will already go down, and the beneficial effect of the entire process will be reduced, and significantly, since the energy will work “to catch up”.

To obtain maximum efficiency, the air-fuel mixture ignites a little earlier than the piston reaches TDC.

As a result, by the time the piston reaches the top point and crosses it, the mixture will have time to burn completely and the impact of the energy released in this process on the piston will be maximum.

This feature of the processes in the engine even received its own designation - ignition timing. It is also called the ignition timing because the measurements are made based on the rotation of the crankshaft.

That is, the ignition timing is the angle by which the crankshaft does not turn until the piston is at TDC.

How to determine the ignition timing and adjust it

How can you determine the initial ignition timing

? Ignition timing is a rather important point on which the engine operation of a carburetor and injection engine operating on gasoline or gas fuel directly depends. Knowing how to determine the OZ ignition timing on a car yourself, you can set everything up correctly.

So, what is OZ? In theoretical terms, this is the flashing of a fuel assembly (enriched fuel composition) inside the power plant at the moment when the piston reaches its apogee or TDC.

The ignition timing or ignition timing should be set skillfully, since it directly affects the functioning of the engine. The fact is that it is the gas pressure inside the engine system that affects the efficiency of the power plant and the efficiency of its operation. Gases are formed after the combustion of fuel assemblies, and their pressure must reach a maximum at a point after TDC, called by engineers the 10th degree. Thus, according to all theoretical calculations (which has been proven more than once in practice), the maximum gas pressure is ensured, which acts on the piston and pushes it down.

What is late and early ignition?

The advance angle must have strictly defined values and their violation is called late and early ignition.

We have already partially considered late ignition in theory. This term means that ignition occurs late, when the piston is already as close as possible to TDC or has already reached it.

As a result, the mixture in the cylinder does not have time to fully burn before the start of the working stroke.

Early ignition is the complete opposite of late ignition. That is, ignition of the mixture occurs when the piston is far from TDC.

As a result, it turns out that the energy has already been released, but the piston has not yet passed the TDC, and instead of a useful effect, it performs a negative one - it counteracts the piston (it is still moving upward, and the energy is already pressing on it).

Why does the OZ go astray?

Such situations occur quite often. The standard parameters are lost because they are not suitable for specific operating conditions. And here the OZ must be adjusted independently, manually.

Why does the OZ go astray?

However, you should first check whether the intervention procedure is really necessary. As was written above, to test the correct OZ, the car needs to be accelerated on the highway to 35-45 km/h, then sharply press the accelerator pedal.

If short-term detonation noise occurs and strong acceleration occurs, you don’t have to do anything with the OZ. The angle is set correctly, everything is clear. You can also verify this if detonation disappears after the speed mark of 60 km/h.

Otherwise, if the detonation sound does not stop or the car does not accelerate, this indicates a faulty ignition. The first option - the OZ is set to an early moment, in the second - to a late moment. And accordingly: you need to rotate the distributor against the movement of the slider or in the direction of its rotation.

Why are such violations dangerous?

With both of these phenomena, the normal functioning of the power plant is disrupted.

Moreover, late and early ignitions have their own specific signs that indicate a mismatch in the advance angle.

If the engine has a delayed ignition, then the power plant:

The signs of early ignition are somewhat different, namely the power unit:

And these are just signs of an incorrectly installed ignition. The consequences of continuing to operate a car with an incorrectly installed ignition can be very serious.

With a late advance angle, one of the conditions for normal fuel combustion is not met - at the moment of peak combustion, it is no longer under pressure (the piston moves down and the volume of the combustion chamber quickly increases).

Because of this, it can no longer burn completely, and unburned components settle on the internal surfaces in the form of soot.

Ultimately, this leads to severe coking of the engine and its breakdown.

The early advance angle is even more dangerous. With such ignition, the energy released provides resistance to the piston, which leads to the appearance of shock loads on the CPG and the crankshaft (they are accompanied by a metallic knock).

Where is the VROZ located and what is the danger of its failure?

VROZ is installed on the distributor. The latter consists of a body with a lid made of fabric. The two elements are separated by a special diaphragm. VROZ includes springs and other components.

How to check ignition timing

A malfunctioning regulator can easily result from problematic engine operation. There will be no ignition adjustment.

It is enough to look at how the crank shaft rotates after insulating the hose with VROZ to understand the importance of the operation of the regulator. The cause of failure of the VROZ may be jamming of bearings or loosening of fasteners

The tightness of the VROZ is a very important thing, and it can easily be damaged if the tube leaks air somewhere. Also, the loss of tightness will be affected by low tightness of the fitting, critical damage to the diaphragm and much more.

The cause of VROZ failure may be jamming of bearings or loosening of fasteners. The tightness of the VROZ is a very important thing, and it can easily be damaged if the tube leaks air somewhere. Also, the loss of tightness will be affected by low tightness of the fitting, critical damage to the diaphragm and much more.

You can clearly see what happens to the engine when the VROZ is damaged or loses its tightness in the table below.

| Causes of malfunction | Remedies |

| Insufficient gap between breaker contacts | It will be enough to adjust the gap |

| Contamination of the distributor slider and cover, the appearance of cracks in them, leading to greater leakage of high voltage current, burning of the sockets in the cover | Wipe the slider and lid. If there are cracks or burnt sockets, the faulty slider or cover must be replaced |

| Burning breaker contacts | Clear contacts |

| Excessive wear of the roller bushings, uneven wear of the distributor cam, severe wear of the moving contact axis | Disassemble the distributor, replace worn parts, assemble and adjust the distributor |

| The engine does not develop full power | |

| Breaker lever spring weakening | Check the pressing force of the breaker contacts and, if it is lower than required, replace the spring |

| Ignition installed incorrectly | Check that the ignition is installed correctly |

| The centrifugal ignition timing regulator is faulty | Disassemble the distributor and fix the problem |

| The vacuum ignition timing regulator is faulty | Check the condition of the vacuum regulator tube and, if damaged, replace the tube. If there is no damage, check the vacuum regulator on the stand and replace if necessary. |

Difference between injection and carburetor ignition systems

Therefore, it is very important that the ignition timing is set correctly. And you can do this yourself.

Let us immediately note that gasoline power plants use different power systems - carburetor (outdated and no longer installed on new cars, but still very common) and injection.

In modern injection cars, such an operation as setting the ignition angle is not required. This is because the electronic control unit is responsible for the operation of the ignition system.

It contains all the information regarding the ignition timing, and it follows it completely.

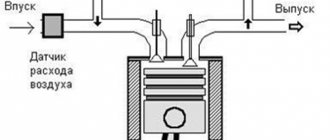

In such a car, everything works like this: numerous sensors installed on the engine transmit data to the ECU.

Based on them, it issues commands to the engine systems - power supply and ignition.

For the power system, the ECU shows how much and when to release fuel and air into the cylinders, and for ignition, at what moment to apply a spark.

But it is worth noting that damage to the sensors or a violation of the geometry of the position of the component elements of the motor can lead to a change in the advance angle.

Therefore, even on a fuel-injected car, signs of a faulty ignition may appear.

At the same time, it is not possible to change the angle manually, since the data is entered into the ECU, the only thing is that you can reflash the unit and “fill” information with the changed data into it.

As for the mechanical part, the car owner can only check the functionality of the sensors, as well as the coincidence of all marks on the crankshaft and camshaft.

Note that not all injection cars have an electronic unit that is responsible for the operation of the ignition system.

On older cars with such a power system, the ECU only controls the fuel supply; as for ignition, they have a separate system and all adjustment work is done separately, that is, the same as on a carburetor car.

Definition of OPP

Initial ignition timing

To be able to determine the timing, you should first become familiar with the following concepts:

- The SOP depends directly on the amplitude of rotation of the crank shaft of the internal combustion engine. The higher the engine speed, the earlier the fuel assembly ignites and the closer the peak of optimal pressure is to the desired point

- The temperature of the power plant and the fuel mixture combined also affects the SOP. The colder the motor, the slower the reaction (the speed of the chemical transformation). Therefore, the OZ in this case should be set at an early moment. And vice versa, if the temperature is high, then at a later date.

- In addition, it is affected by the load placed on the motor. The faster the engine rotates, the lower the SOP must be set so that detonation does not occur (this is due to the fact that at optimal engine load, much more fuel assemblies begin to flow into the cylinders).

The principle of operation of ignition on a carburetor engine

To understand how to adjust the advance angle on carburetor cars, you must first understand the structure of this system, and not completely, just the “ignition coil-distributor” section is enough.

So, the coil ensures the creation of high-voltage pulses, which are transmitted to the distributor, also known as the distributor.

There are 5 terminals in the distributor cover (for a 4-cylinder engine). The central one is designed to receive an electrical impulse from the coil.

The remaining 4 terminals (located around the circle) are for connecting high-voltage wires going to the spark plugs.

Under the cover there is a slider - a special element that transmits the impulse received from the coil through the spark plug terminals.

Everything is simple here: the central terminal, through a carbon electrode, is in constant contact with a metal plate mounted on the slider.

Rotating, the slider with this plate connects the central terminal with one of the side ones, and the discharge is supplied to the spark plug.

This slider receives rotation from the camshaft, which in turn comes from the crankshaft.

Having this information, you can understand that to adjust the ignition timing on a carburetor car, you just need to rotate the distributor body around its axis.

As a result, the contacts of the spark plug leads will shift relative to the slider, and it will either close them earlier or later (depending on where the housing is turned).

Installing the correct OZ on the injector and diesel engine

With an injection engine everything is also extremely simple. In this case, you should turn on the ignition and look at the instrument panel. If a light comes on on it, indicating a malfunction, then we take a laptop with a special program, connect it to the on-board computer and carry out diagnostics.

At the next stage, the throttle device is subjected to a thorough visual inspection. It is also recommended to check the voltage of the on-board network and the sensor that regulates the throttle position. They must comply with the standards. Thus, the optimal voltage for the sensor is considered to be in the range of 0.45–0.55 V, and for the network – 12 V. The damper opens only 1%. We sharply press the gas pedal. The throttle opening should exceed 90%, and the sensor voltage will drop to 0.45 V. Otherwise, it is necessary to urgently adjust the ignition timing.

Checking the throttle position sensor voltage

Carry out all work using non-conductive rubber gloves, as most elements are live.

Setting the angle begins with the fact that we disconnect the vacuum hose from the engine. Then we connect the positive clamp of the strobe to the positive terminal of the battery. The ignition is adjusted by switching the ground clamp, connecting it to the negative terminal and pulling the wire out of the cylindrical socket on the distributor cover. We insert the strobe sensor into the vacant space, simultaneously connecting it to the wire of the first cylinder of the power unit. Next, we start the engine and direct the beam from the strobe to a special hatch. A mark will appear on the flywheel; its optimal location is between the divisions. If this is not the case, then set the angle by slowly loosening the nuts securing the flywheel distributor.

Adjusting the ignition timing on a diesel engine is also not difficult. But this operation should not be underestimated, since a diesel engine can only operate when the fuel is completely burned. This will not happen with an incorrectly set ignition angle. The main difference of this system is the absence of candles. Basically, all actions are the same as for gasoline engines. Only in this case it is necessary to remove the decompression mechanism, the engine meter and the body of the neck through which the oil is poured. Be sure to check the fuel supply level. To do this, move the corresponding lever to the extreme position, install the torque scope and slowly turn the crankshaft.

Ignition installation methods

It is important to know where and how much to turn the housing in order to install the ignition correctly.

There are several methods for setting the ignition timing on a car, where the ECU is not responsible for the operation of the ignition system, and all work is done manually.

The most accurate method of setting the ignition is using a strobe light.

The technology for setting the advance angle with its help is very simple, and to perform it you only need:

Adjustment work should be performed on a warm engine. Let's look at how everything is done using the example of a VAZ-2107 with a carburetor.

Note that the described method is suitable for almost any car with a carburetor, as well as injection models in which installation is performed manually.

The principle of adjustment using a strobe light is almost the same for all cars. The only thing is that the marks can be combined not only along the pulley, but also along the flywheel (they are there too), this is more convenient for everyone.

Unlike the strobe method, the lamp will not allow you to accurately set the angle.

And yet this method is quite applicable, especially since it can be used to adjust the ignition even on the road. An example is the VAZ-2108.

The only tools you need are a 12-volt incandescent lamp, two wires and a set of keys.

To adjust the ignition by the light bulb you need:

. Additionally, you can check the correct installation by looking at the flywheel through the inspection window on the housing;

Some craftsmen do not use any devices at all to set the lead angle, but do everything “by ear”.

Moreover, everything is done very easily: start the car, set the idle speed.

And then the distributor mount is simply loosened, after which the body rotates in different directions, while listening to the behavior of the power plant. When rotating, due to the changing angle, the revolutions will begin to float.

How to set the ignition timing on the injector yourself

How to set the ignition timing on an injector

Long gone are the days when the world's first car rolled off the assembly line. It was equipped with a new injection system. The production of these machines today has increased 10-20 times. As you understand, we are talking about cars with injection systems. Let's find out how to set the ignition timing on the injector.

Today, 80 percent of people become owners of just such cars. Therefore, the ability to configure the ignition system is regarded as a very important advantage. It will allow you to always stay on the move, saving money on repair services and fuel.

Checking for correct installation

To check whether the advance angle is set correctly, you can do this: drive out onto a flat section of the road and accelerate to 50 km/h.

We drive a little so that the engine operation stabilizes, and then we accelerate sharply (press the gas pedal well), while listening to the behavior of the engine.

When accelerating hard, a metallic knock should occur. If this knocking noise disappears quickly, this indicates that the ignition is set correctly.

If it does not appear at all during acceleration, this indicates late ignition.

But if the knock is heard for a very long time, then the ignition is early.

Setting up OZ

Previously, many experienced owners of domestic cars adjusted the original OZ in the “old-fashioned” way, by ear. In fourth gear at medium speed while driving, if you suddenly press the accelerator pedal, you should clearly hear popping noises, and after that the car should confidently pick up speed.

Certain car ignition timing angles

In the absence of detonation, the ignition distributor is rotated at the advance point until popping sounds and confident acceleration appear. Conversely, late ignition is set when detonation lasts more than two seconds and acceleration does not occur.

In car service centers, a special device is used to regulate the OZ - a strobe light. As a rule, in all SZ equipped with a distributor, only the initial SOP is regulated.

A new opportunity to fine-tune the SPD appears with the advent of microprocessors. Thus, the advance angle is set for various operating modes of the internal combustion engine. If in distributors the VU and CR (vacuum and centrifugal type sensors) are responsible for changing the advance angle, then smart electronics itself calculates the required angle. This is done according to the firmware in the controller.

So, you should definitely start setting up the SOP with preparation. You need to arm yourself with a strobe light or test lamp, as well as a nut wrench. Also, in this case, you cannot do without a special tool designed to rotate the crank shaft. It is the position of this shaft that determines the value of the SOP.

Note. Recently, it has become fashionable to use a special corrector designed to change the SOP. This device determines the SOP automatically.

Here's how this operation is performed:

- The car is placed in neutral;

- The handbrake is applied;

- The cap-cover is removed from the distributor;

- Using a special tool, the crank shaft is rotated until the slider aligns with the mark on the timing belt.

Indicator lamp for SOP

Without an indicator or control lamp, it will be impossible to determine the SOP. The lamp should be connected with one lead to the bobbin and the other to the surface of the motor.

- The distributor drive lock is loosened (now the distributor can be rotated in any direction);

- The car ignition is turned on;

- The slider is clamped, and the distributor rotates against its direction.

Attention. You can determine the direction of movement of the slider as follows. While turning the crank shaft, look at the slider (it will be noticeable in which direction it rotates).

So, you should rotate it against the direction of the slider until the indicator lamp goes out. Then the distributor is turned back a few notches (very carefully) and a mark is made - this is the fixed ignition moment. The distributor body is fixed, the cap-cover returns to its place.

In order to somehow automate the adjustment of the VOP, a VR (vacuum regulator) is installed. This additional device makes it possible to transform the angle in automatic mode and depending on a particular load.

For example, when the engine operates in the idle mode, the VR turns the OZ towards the late ignition, and when the load on the engine increases, the speed increases, the VR is turned off and another regulator (CR) is activated, which sets the advance angle to the earlier ignition.

Ignition on diesel installations

Above we looked at everything related to the ignition of gasoline engines.

But the ignition timing is also present in diesel engines that do not have an ignition system as such.

The theory of this internal combustion engine is this. Ignition of the air-fuel mixture in a diesel engine occurs due to the effect of high pressure at the moment of fuel injection into the cylinder. Air comes in earlier.

From this we can understand that the ignition moment is the moment of fuel injection into the cylinder. And the high pressure fuel pump is responsible for all this.

Then everything is the same as with a gasoline engine - to obtain maximum efficiency, ignition must occur before the piston passes TDC, that is, the injection pump plunger must supply a portion of fuel a little earlier so that the air-fuel mixture has time to fully burn.

A diesel engine also has late and early ignition, or more precisely, fuel injection. The symptoms of such phenomena are the same as those of a gasoline engine.

But with a diesel unit, early injection is accompanied by very distinct detonation and metallic knocking, and with late injection, the amount of exhaust gases increases greatly, and they change color.

This is due to the design and operating principle of the power plant.

But while the advance angle of a gasoline unit can independently change during operation, this does not happen with a diesel engine.

The injection angle can change in two cases:

The technology for adjusting injection timing on a diesel engine largely depends on the drive of the fuel pump. On passenger cars, a timing belt is often used for this.

On diesel trucks and other types of equipment, the injection pump can operate from rotation transmitted through a drive coupling or toothed gear mounted on the injection pump cam shaft.

Consequences of driving with incorrect settings

In addition to deteriorating vehicle performance, ignition too early causes other detrimental consequences:

- Detonation is the worst enemy of the engine. Due to constant impacts on the pistons, the fingers become loose and play forms in the connection. As a result, the connecting rod bushings are broken and the production of cylinders is accelerated.

- Shooting at the carburetor damages the bushings on which the valve axles rotate. The latter do not close tightly, causing the engine to suck in excess fuel at idle.

- The power unit tends to overheat and if the cooling system malfunctions, the cylinder-piston group may fail.

Modern electronically controlled engines are equipped with knock sensors. When the element detects vibration, the control unit automatically adjusts the ignition timing.

Early injection of diesel fuel into a diesel engine is fraught with damage to the high pressure fuel pump (HPF) and injectors. Imagine: a pump pumps fuel in one direction, and it is counteracted by a piston moving towards TDC. It's not hard to guess who will get the hit.

We recommend: Do-it-yourself refilling of car air conditioning

Signs of late ignition are no less dangerous. Ignition of the fuel mixture at the expansion stage leads to a decrease in engine efficiency and an increase in the load on the main parts - pistons with rings, cylinders and connecting rods. The result is easy to predict - intense heating and accelerated wear.

Shooting into the exhaust tract, caused by delayed sparking, destroys the walls of the exhaust pipe and the muffler partitions. Elements will have to be repaired by welding, or even replaced.

Types of injection timing adjustment

Let's look at several ways to adjust the timing of fuel injection.

The most common of them is by tags. It can be used for diesel engines with any type of drive, but the driver’s actions may differ.

The main condition for correct adjustment of the injection timing is the presence of all marks. Therefore, before starting work, you should find them and additionally mark them with paint.

As an example, let's look at the adjustment sequence on an engine where the fuel injection pump is driven by a drive coupling.

After all the steps, be sure to remove the lock and turn the crankshaft a little to make sure that nothing is stopping it. And only after that you can try to start the engine.

With the injection timing set normally, the power plant should idle “softly”, without knocking and stably.

If a strong metallic ringing is heard, which indicates an early injection, we stop the engine, set all the marks again, after which we slightly shift the body in the direction of shaft rotation, and if there is increased smoke, indicating late injection, we move it against the shaft rotation.

On those cars where the drive is carried out by a timing belt, you can try to adjust everything experimentally - by touch (about the same as adjusting the ignition “by ear”).

But in the case of a diesel engine, they focus on the behavior of the power plant.

This method can be used when there is no mark on the drive pulley.

The essence of the method comes down to the following actions:

This method is time-consuming, since you will have to move the pulley several times.

If the adjustment work does not give a positive result at all, that is, the operation of the power plant does not change, the pump pulley should be turned one full turn (after setting TDC on the 1st cylinder), and then repeat the adjustment steps.

Another adjustment option allows you to first identify the moment at which the injection ends, after which you can make the necessary adjustments.

Another method is used to adjust the injection timing on diesel engines equipped with a BOSH VE distribution pump.

To carry out adjustment work with such an injection pump, you will need a dial-type micrometer, as well as adapters and extensions for it. You will also need a set of keys and screwdrivers.

Adjustment on such a pump is done as follows:

As you can see, the method of setting the injection timing largely depends on the design of the pump itself, as well as the injection pump drive used.

We hope that the material presented in this article will make your life easier.

Video - the problem of early ignition from Nail Poroshin.

Source

Tools and Diagnostics

Tools are an important part of any job. They will be needed to make adjustments to the process of issuing SOP. Mandatory tools include screwdrivers, a measuring instrument, wrenches, and preferably a laptop with a specially installed program designed for diagnosing injection-type power units.

First, you should know that on an injection engine, electronics are responsible for driving the car. It is subordinate to the head – the computer system. Conducting quality testing of all components of the injection system is the first thing to do.

Here's how it's done:

- the ignition is turned on;

- the supply of fuel by the electric fuel pump is checked (the characteristic sounds of activation of the pump performing the injection should be heard).

If there are no sounds of the fuel pump operating, you need to check the relay that controls the operation of the pump.

Check UOS with a laptop

You should also pay attention to the instrument panel, on which the indicator may indicate. If this is the case, then you need to connect a laptop with a special program to the BC system. It will help you analyze errors and display them in a list.

If no problems are identified at this stage, then it’s time to start the internal combustion engine. On a functioning engine, the throttle assembly is checked first.

Here's how it's done:

- first, an external inspection of the sensor, which is responsible for the position of the damper, is carried out;

- then the wiring condition is tested;

- if everything is in order, it would not be superfluous to measure the voltage of the entire circuit and sensor using a measuring device;

- the obtained values must be compared with the standard indicators specified in the vehicle repair manual.

A normal current value can be considered to be in the range of 0.45-0.55V. The current value should not exceed 12 V, and the throttle opening degree should not be more than 1%. If deviations are noticed, then you need to adjust the throttle drive so that it closes the damper entirely.

Next, you need to press the gas pedal all the way, re-measuring the indicators this way. The damper open level should be 90%. As for the sensor voltage, the voltage must be 4.5 V.

Throttle actuator tuning is considered an important part of the work included in the diagnosis. It allows you to simultaneously set up a node and check the consistency of the values.

In order to adjust the drive you need to:

- disable the RDPV (sensor responsible for additional air flows);

- half open the throttle;

- make adjustments so that the damper completely covers the hole.

Determination of early or late ignition

The stability of the engine, its power, fuel efficiency, etc. directly depend on the correct settings and uninterrupted operation of the ignition system. Normally, on four-stroke engines, the fuel-air mixture should ignite at the end of the compression stroke, that is, just before the piston rises to top dead center. This ignition timing is due to the fact that the mixture requires a certain time to burn, after which the energy of the expanding gases pushes the piston down and the power stroke begins.

TRAMBER IS THE BASIC ELEMENT OF THE IGNITION SYSTEM

The distributor, or ignition distributor, is installed differently for each specific car model. Such brands as Moskvich, GAZ and ZAZ are distinguished by the greatest ease of installation. To install it correctly, you need to align the crescent-shaped marks on the distributor shank and on the drive in the engine block. Most foreign cars also have marks on the ignition distributor that allow it to be installed correctly and thereby avoid malfunctions in the ignition system.

Installation of the distributor on a VAZ is carried out on the 1st cylinder. For the ignition system to operate correctly, the cylinder must occupy a position prior to its top dead center (TDC) when the compression stage begins. The algorithm for correctly performing this work is as follows:

- on a cold engine, remove the spark plug belonging to the cylinder;

- the resulting hole is closed as tightly as possible (it is convenient to use a wine cork);

- when turning the crankshaft (by hand or with an x36 wrench), you need to select the moment of compression when air begins to displace the plug from the hole;

- Continuing to rotate the flywheel, you need to get a complete coincidence of the mark on the pulley with the mark present on the timing case - the resulting advance will be equal to 5 degrees, which is suitable for 92 and 95 gasoline.

In the future, to eliminate the question “how to set the ignition,” the distributor itself should be installed correctly. To do this, you can draw a “virtual” line through the latches of its cover and the engine axis. They must be strictly parallel, and the rotor of the slider must look towards the contact of the cylinder itself on the distributor cover. After all the manipulations, the spark plug returns to its place - the engine should start clearly and without delay. The video quite clearly demonstrates the distributor installation process:

How to understand that the ignition is late or early

Ignition of the working mixture of fuel and air in the cylinders with advance or delay leads to certain malfunctions in the operation of the engine. The list of main signs by which you can identify an incorrectly installed ignition includes:

An incorrect ignition angle can manifest itself in the form of characteristic pops that are heard in the exhaust system, carburetor, etc. It is quite obvious that further operation of an internal combustion engine with a broken ignition timing can lead to more serious engine damage, especially if persistent detonation occurs.

The importance of correct ignition adjustment

The fidelity of the set ignition on carburetor engines is carried out using a strobe light

The quality and efficiency of engine operation depends on the nature of the ignition installation . Therefore, it is the installation of the ignition that is an important action that allows you to configure the power unit. If the ignition is installed incorrectly, both in the direction of increasing the advance angle and in the direction of decreasing it, the engine immediately feels a negative impact.

That is why setting the ignition timing should be approached responsibly and very carefully.

Ignition operating principle

A gasoline engine has certain factors that affect the quality and timing of the spark required to ignite the combustible mixture. These factors are combined into a separate mechanism called a distributor; it is also sometimes called a distributor-breaker.

Classic ignition circuit

It is installed in the area of the cylinder block; the distributor shaft is driven by the engine camshaft. There are cams located on the distributor shaft, they open the circuit at the required moment, and then a spark is formed.

The main disadvantage of the distributor is its tendency to mechanical wear, as a result of which the quality changes, as well as the timing of the spark..

Of course, this affects the performance of the engine, which will require further intervention and adjustment.

Consequences of an incorrectly set ignition angle

Both late and early ignition negatively affects the operation and service life of the engine. It should be added that not only power and fuel consumption depend on the correct ignition timing. If a spark on the spark plug forms earlier than expected, then the pressure of the expanding gases begins to counteract the piston rising to TDC (pre-ignition). Ignition of the working mixture after the piston has begun to move down from TDC leads to the fact that the released fuel energy “catches up” with the piston and enters the exhaust, rather than doing useful work (late ignition).

Signs of early ignition appear in the form of the following symptoms:

Late ignition also causes significant damage to the engine. In this case, combustion of the mixture occurs under conditions of decreased pressure and increased volume in the internal combustion engine cylinder. The combustion process of the fuel-air mixture itself is disrupted, which burns out during the working stroke of the piston. As a result, signs of late ignition are:

Signs of late ignition, if detonation did not occur at all.

If it was not possible to make the adjustment the first time, then you should repeat the procedure until the correct result is obtained. This will help not only to achieve the correct settings, but also to hone the skill of adjusting the internal system, without auxiliary devices, using only your own observation and hearing. These methods will help you use your favorite RV for the entire service life and save money on visiting auto repair shops.

Have a nice trip!

Setting the ignition timing yourself

The specified lamp is connected to the positive terminal on the ignition distributor, and is also connected to ground. Next, we will look at the main available methods for setting the ignition using the following example of a domestic “classic”:

Setting up strobe ignition

Setting the OZ according to the control light

If you use the light bulb ignition method, then you need to turn the engine crankshaft so that the mark on the crankshaft pulley matches the mark on the timing cover. In this case, the slider on the ignition distributor should point to the spark plug wire of the first cylinder.

Next, the distributor lock nut is loosened, after which one wire from the light bulb is connected to the wire that goes to the ignition coil from the distributor. The second wire from the lamp is installed to ground. Then you need to turn on the ignition and rotate the distributor body clockwise until the control lamp stops lighting. After this, you should carefully turn the distributor body back, that is, counterclockwise. Having determined the position at which the light bulb lights up, it is necessary to fix the distributor body in this position. Fixation is done by tightening the distributor nut.

How to check ignition timing?

The process of setting the required ignition timing is considered the most important point in the overall functioning of the vehicle. Ensures normal operation of quite important characteristics. This includes power, fuel consumption, and idle speed along with throttle response. Therefore, it is worth monitoring these indicators and checking regularly. By the way, it is recommended to perform this procedure when servicing a car.

To determine whether the above-described structure is working properly and whether it is installed correctly, you should take a test lamp and a strobe light. And then you need to follow specific instructions.

- You need to connect the device in parallel to the capacitor.

- Turn the crankshaft using the crank. This should be done until the spacer plate joins the contact on the distributor cap, which is additionally connected to the spark plug of the first cylinder.

- Turn on the ignition.

- Until the lamp lights up, gradually turn the crankshaft.

- The marks must match. If the lamp lights up before the marks match, it means that the ignition is installed incorrectly.

Car owners often use the following technique to check: they drive out onto a flat road, accelerate the car well and start moving in fourth gear at a speed of about 50 kilometers per hour. At a certain moment you need to press the brake hard and all the way. If, as a result, small, short-lived engine detonation sounds appear, it means that the ignition timing is set correctly. In the case where the sounds are incredibly strong, there is a problem with early ignition. If there is no noise at all, it’s too late.

Other methods of setting up and checking the ignition on a car

You can also set the ignition to spark or independently select the angle when the engine will operate most stably and smoothly. The simplest and least accurate method is to install based on the operation of the motor. To set up, start the engine, after which the nut securing the distributor housing is loosened. Next, you will need to turn the distributor housing clockwise and counterclockwise, finding the position at which the engine runs smoothly and the XX speed is the highest. After this, you should turn the breaker body a couple of degrees clockwise and tighten the distributor nut.

Then the wire contact should be placed near ground (distance about 5 mm) and turn on the ignition. After this, the breaker body should be rotated 20 degrees clockwise. Now the housing needs to be rotated back until a spark appears between the ground and the wire contact. In this position, the distributor body must be secured with the breaker fastening nut.

Upon completion, it is necessary to check the correctness of the OZ in motion. With a warm engine, the car should be accelerated to 40-45 km/h, after which fourth gear is engaged and the gas pedal is fully pressed. Next, it is necessary to assess the degree of detonation. It is considered normal when, immediately after engaging 4th gear, detonation is briefly present (2-3 seconds), but disappears as the car accelerates. If detonation continues after acceleration, then the likelihood of pre-ignition is high. If there is no detonation when the 4th gear is engaged, then the ignition is delayed. In such cases, the SOP adjustment should be repeated to obtain an optimal result.

Source

Is it necessary to adjust the OZ - check on the go

There are often situations when the factory settings are lost or simply do not quite suit specific operating conditions. In all cases, you will have to set the OZ yourself. True, you first need to make sure that this operation is necessary, which means we’ll figure out how to check the value of the ignition timing. To do this, we accelerate on a flat area to 40 km/h, then sharply press the gas and listen to our car. If a noise characteristic of detonation appears, which stops after the car reaches a speed of 60 km/h, then everything is in order and the angle is set perfectly.

If the detonation does not stop, then the ignition is “early”. But when the moment of ignition of the combustible mixture is slightly delayed, the detonation will end before the car accelerates to 60 km/h. To change the ignition timing, open the hood, slightly loosen the mount of the distributor-distributor and change the position of the distributor. In the first case, the adjustment involves a shift of several millimeters clockwise, and for late ignition - in the opposite direction.

Diagnostics

Adjusting the engine ignition can only be done if you are confident that the engine itself and the fuel injection pump are in good working order, so the technician always performs a check at the beginning of work. On cars with a mechanical fuel injection pump, a centrifugal advance angle regulator is used, and its malfunctions can give symptoms completely similar to late injection timing: when the speed increases, the angle does not change, injection becomes late.

If necessary, the gap between the ends of the pump plungers and the discharge valve seats in the centrifugal mechanism must be adjusted. These works are charged separately as repair of a high-pressure fuel pump.

Setting marks may not always give the correct injection angle, especially on an old and worn injection pump. In this case, the angle of the start of fuel supply (the required accuracy is up to 1 degree) is set according to the actual position of the crankshaft and the start of fuel supply to the injector of one of the cylinders.

Peculiarities

The ignition timing setting may differ even on the same engine model. In particular, the D16A engine (Volvo FH) when adjusted to Euro 1 environmental standards, the basic setting is 12.5 degrees, while for Euro 2 the angle is less - 8.5 degrees. In both cases, the installation accuracy is no rougher than 1 degree. For different modifications of the D0226 (MAN) engine, the ignition angle is set from 10 to 12 degrees, for D0824 engines the spread is from 4 to 18 degrees. Therefore, during operation, it is necessary to constantly check the service documentation for a specific modification, otherwise the ignition angle adjustment may be incorrect.

Engines equipped with pump injectors have a rigid connection between the timing of fuel injection and the position of the camshaft. Adjusting the ignition timing angle in them requires precise setting of the full stroke of the plunger (decreasing as the drive parts wear); the very start of injection is rigidly determined by the profile of the camshaft cam and the accuracy of its positioning relative to the crankshaft. The camshaft itself must be correctly aligned: as the timing gears wear out, it begins to “lag” from the calculated position specified by the marks. Accordingly, the moment of fuel injection into the cylinders is delayed relative to the TDC of the piston at the end of the compression stroke.

Adjusting the ignition angle of trucks in Moscow

Back in the days of contact ignition on gasoline trucks, the term “ignition adjustment” became so common in the colloquial language that it was transferred to diesel engines, although they do not have an ignition system as such. A diesel engine equipped with a mechanical injection pump or pump injectors allows you to adjust only the injection advance angle - the moment at which fuel begins to flow into the cylinder. Moreover, gasoline trucks, which are unprofitable in terms of fuel costs, and diesel engines without electronic engine control, which are outdated and no longer produced, are increasingly leaving the highways. In Common Rail systems, the injection timing is set by an electronic control unit and cannot be adjusted (only flashing the unit is possible). However, our company also offers its services for adjustment work on-site in Moscow and the region (both independently and as part of other repair work - for example, ignition adjustment on a KamAZ engine is necessary after the injection pump drive plates on it have been cut off and new ones were installed).

The technical assistance vehicle is equipped with all special devices for adjustment, if they are required for a specific engine (for example, Bosch fuel injection pumps require fixing the regulator flag with a shaped plate with a slot), so precise adjustment of the injection timing according to the service documentation is guaranteed.