Radiator fan runs constantly

This case is partially discussed above; the cause is a failure of the temperature sensor or a short circuit in the wires going to the fan. But if it is constantly spinning, then this may be caused by a stuck relay. This happens quite often, especially after the relay is triggered and the fan should turn on. Sticking relay contacts mean that they cannot open, which causes a constant voltage supply to the contacts, causing the electric motor to spin constantly. The consequences of sticking relay contacts include the fact that the radiator fan does not turn off.

Often the thermostat may be the reason why the fan shutoff does not work. The fact is that the sensor is located in the head of the unit; it determines when the fan should turn on. But the coolant can move in a large and small circle; when it moves in a small circle, it does not enter the radiator for cooling. The mode of water movement is determined by the thermostat.

If it is jammed in the position of water moving in a small circle, then it will continue to move and overheat, which will trigger the sensor and turn on the fan, but because... water does not enter the radiator, it will not cool, and the sensor will constantly signal a high temperature. As a result, the radiator fan does not turn off. This case can be determined simply - you need to touch the hoses going to the radiator. When the thermostat is stuck, they will be cold if the engine is overheated.

If the radiator fan does not turn off due to a jammed thermostat, then sometimes you can knock on the case to eliminate this phenomenon. Often this is enough and the defect disappears. If everything remains unchanged, then you will have to remove the thermostat, take out all the stuffing from it and then put the device itself back in place. Another option for the same defect would be the thermostat getting stuck in an intermediate position. This can also result in the radiator fan not turning off, but this situation is much more difficult to diagnose. Such difficulties are caused by the fact that a certain amount of water enters the radiator, but too little of it passes through, all the water does not have time to cool, which leads to overheating of the engine.

All of the above is not a complete description of the possible reasons why the radiator fan does not turn off. There can be many of them, sometimes quite strange and unexpected, but in each of these manifestations of malfunctions it is necessary to look for the reasons and conduct a thorough analysis.

How often should the engine cooling fan turn on?

In general, the following questions are quite common: “the fan turns on often,” “I’m getting warm,” etc. In this case, actual boiling does not occur. How to evaluate whether everything is ok with the car or not?

I suggest this option. Measure the operation of the fan at XX time and the time until it is turned on again. You can take several measurements in a row to average the values, since the numbers vary slightly.

If a lot of data accumulates, then it will be possible to judge the average statistical figures in general, and therefore, based on deviations from them, decide whether everything is in order.

So here's my data. I don’t know yet whether everything is good or not, since there is nothing special to compare it with.

Average downtime: 01:38 Average uptime: 00:53

It is also advisable to add the on/off temperature to the data (I have 101 and 97, respectively). Well, the outside temperature (in my case

Here, I took measurements in the parking lot, after 10 “immediate” km. around town. The machine said it was 11 degrees outside, she usually doesn’t lie. No wind, no sun, three drops of rain per hour. Thermos 21082, the thermocouple holds 90-91 along the route (the third in a row, in good condition). Some kind of Dzerzhinsky antifreeze (from a reliable store) + Felix was added several times during replacements; when draining the slurry, no dirt was noticed in it. The measurements were taken with an electronic stopwatch on a PDA, counting from the first switching on of the EVSO (electric cooling fan, just in case), all electrical consumers were turned off. The EVSO is turned on by the brain at a temperature of 100-101 degrees, after which it reaches 102 degrees by inertia. The fan turns off at 96 BC, then the system cools by inertia to 93 degrees. TOTAL: 1. 11 degrees without wind and sun overboard. 2. Measured in both tap positions, heater fan off. Always. 3. Thermos 21082 4. Regular antifreeze. Here is the table:

00:00 Off 01:43 01:43 On 00:25 02:08 Off 01:37 03:45 On 00:27

So far, only so much has been measured. The stove is turned off, the temperature is +18. This is fine?

I’m also thinking about installing an impeller on the cooling fan from Viburnum.

1.40 is within normal limits too.

1.40 is within normal limits too.

maximk

Today I measured it again: Average idle time 1.26, fan operating time 0.40

The temperature arrow also behaves strangely; when you stand still, it first stands still. time, then rises a little and drops a little, and then rises rapidly until the fan operates.

maximk

Today I measured it again: Average idle time 1.26, fan operating time 0.40

There is little data, of course, but I think it’s within normal limits. We need to encourage new users to share data

But I suspect that most people are too lazy to measure.

The temperature arrow also behaves strangely; when you stand still, it first stands still. time, then rises a little and drops a little, and then rises rapidly until the fan operates.

On Nexia, the fan turns on several times less.

On Nexia, the fan turns on several times less.

In general, the following questions are quite common: “the fan turns on often,” “I’m getting warm,” etc. In this case, actual boiling does not occur. How to evaluate whether everything is ok with the car or not?

I propose, for the convenience of comparing the results obtained, to use a dimensionless coefficient equal to the ratio of the duration of the fan on (operation) to the duration of the entire “on-off” cycle.

MikhaylenkoPA wrote: MaratZ wrote: On Nexia the fan turns on much less.

That's why they suffer

I’ll throw in my 5. Now I’m driving on water (like 2nd week), after replacing the thermos, the temp sensor from the classic to the fan and another pump, it hasn’t boiled even once

the fan in the traffic jam turns on at exactly 90, runs for 10-15 seconds max and is silent for 2 minutes, cruising speed without large traffic jams is 1-1.5mm below 90 at this rate the engine will leak slightly, the car does not matter

The temperature arrow also behaves strangely,

Cold sensor from Muscovite 2141 (92 degrees) Outside temperature + 15. Idle time: 1 minute. Idle time at idle: 30 seconds. The temperature on the tidy is stable and does not go above normal. When the engine is warm it stays put.

Where does the cooling fan blow?

In this article we cannot ignore the question of where the mechanism that interests us blows. This is exactly what users ask experts and fellow car enthusiasts on dozens and hundreds of forums dedicated to vehicle maintenance.

In fact, the answer to this is very simple.

If in your car the air flow is directed not to the engine, but to the radiator, this only means that the fan was connected incorrectly after maintenance or repair work. Most likely, the terminals were simply mixed up. Install them correctly and never again wonder where the fan should direct the flow of cooled air.

Home →

Device → Cooling, heating and ventilation system → Fan →

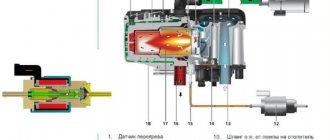

Electronic drive device

Modern car brands equipped with automatic control systems have begun to install an electric radiator cooling fan motor. The advantage of the drive is its independent operation and ease of configuration.

The engine cooling fan is controlled via coolant temperature modules. Based on data from the sensors, the engine cooling fan control unit adjusts the speed of the impeller, changing the rotation speed and operating period.

Power to the fan motor is supplied through the vehicle's electronic devices (battery, generator).

Methods for controlling the engine cooling fan:

- thermal switch;

- Control block.

Technical indicators.

| Name | Engine | ||

| 88 kW/5500 rpm | 104 kW/6000 rpm | 122 kW/6500 rpm | |

| Cooling system type | Water with electric drive | ||

| Pump type | Belt driven centrifugal | ||

| Thermostat | |||

| Operation temperature, C° | 80,0 — 85,0 | ||

| Maximum opening, С° | 97 | ||

| Stroke at maximum opening, mm | From 8 | ||

| Valve opening pressure in the lid, kPa | 112,9 — 142,5 | ||

The thermal switch was used in the early stages of automobile production. Based on the readings from the temperature sensor in the radiator, the mechanism determines whether the engine cooling fan will turn on or off. In units with a thermal switch, the engine cooling fan operates within a narrow temperature range. The cooling fan turns on when the unit warms up to 85 C°, and turns off when it cools down to 70 C°.

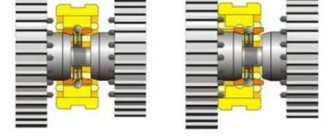

Using viscous couplings for wheels of one axle.

Another option for using the coupling is possible - for wheels of the same axle. In this application, the device is installed between the axle differential and the axle shaft. In this case, when cornering or one of the wheels slips, the device helps to redistribute the torque between them, ensuring safe maneuvering or passing through a problem area.

There are solutions in which a pair of parts are placed on the wheels of one axle. This design allows you to abandon the axial (cross-wheel) differential. At the same time, the use of a pair of viscous couplings makes it possible to provide all modes - both differential rotation and blocking of the axle wheels.

Removing and replacing the fan resistor

To understand whether they work or not, you need to disconnect the connector from their motors, and connect a lamp to the wires through which voltage is supplied; we do the same with the sensor; if both lamps light up, then the problem is in the fans.

To remove them you need to do the following:

- Disconnect all wires

- Removing the upper pipe

- Removing the bumper

- If there is an air conditioner, bend the tubes (this must be done carefully, as they may burst) or drain the freon (filling it back will not be cheap), then remove the air conditioner radiator.

- You need to loosen the nuts on the radiator casing

- Tilt the radiator so that you can remove the fan unit

- Unscrew the bolts that secure the block and remove it

If the fan motors do not start when the wires from the battery are connected directly to the power terminals, the devices must be replaced.

Also interesting: How to check the phase sensor of a Niva Chevrolet - How to identify a problem with the phase sensor

To do this, you will need a set of wrenches ranging in size from 10 to 17 mm and a Phillips screwdriver.

Before starting work, you need to drive the car onto an inspection ditch or a lift and turn off the power to the on-board network by removing the negative terminal of the battery.

Fans are dismantled as follows:

- Remove the crankcase protection and mud guard.

- Unscrew the screws and remove the thick spider-shaped plate and a couple of tin covers that are located in front under the bottom of the car.

- Unscrew the radiator frame cross member.

- Loosen the tension and remove the power steering belt and pump.

- Remove the 4 bolts holding the power steering pump.

- Push the pump back, hanging it on the hoses.

- Remove the air conditioner drive belt.

- Remove the bolt holding the timing belt pulley.

- Remove the pulley and belt.

- Unscrew the four nuts at the corners of the electric fan housing and the two bolts securing it in the middle.

- Remove the fan unit from the studs and pull it down.

This method is probably suitable for restyled Niva Chevrolet models. On older cars, you will have to remove the radiator grille and bumper, unscrew the fasteners and move the air conditioning and cooling radiators forward. After this, access to the electric fans will be open.

During dismantling, you should carefully remember the procedure. Assembly is carried out in reverse order.

Before starting work, you must go to the inspection hole and remove the terminal from the battery. For repairs you will need 10-13 wrenches, a screwdriver and a new resistor. The part is installed in the beam below the radiator. The removal procedure is as follows:

- Unscrew the fastening bolts and remove the crankcase protection along with the mudguard.

- Remove the protective strip of the resistor and unscrew the part.

Assembly is performed in reverse order.

Search form

When the antifreeze in the radiator is heated to a certain temperature, the sensors are different, but, on average, it is 92 degrees, the contacts inside the sensor are closed and voltage is supplied to the fan relay. The light in the room and the fan work in parallel, i.e.

More articles from the Theory section. One is installed at the outlet of the radiator, and the other at the inlet. I take it they duplicate each other?

Yes, and I would like to somehow smooth out the sudden switching on of the radiator fan: There is a solution to the problem, and not even just one!

Let's look at the operation of the radiator fan in more detail: Stories from our readers “Fucking basin!!! Hi all!

The coupling may be blocked by the silicone fluid that is inside it. The circuit is used on a car with two fans. Of course, the dashboard may be lying here and according to the On-Board Computer the readings are completely different.

When the desired change in the contents of the clutch occurs, it will be blocked again and the cooling mechanism will start automatically. The TM sensor only works in conjunction with a relay; the TM, reinforced for high current, can work both with and without a relay. You will laugh, but I work right on the phone. If you want to change your life like me, then this is what I advise you to do right now: 1. When heating the antifreeze in the radiator to a certain temperature, the sensors are different, but, on average, it is 92 degrees, inside the sensor the contacts close and voltage is supplied to the fan relay.

The fan does not turn on.

There will be a large current at relay contacts 87, 30, on the wire from the battery to the fuse and the fan ground, and therefore we must use wires there with a cross-section of at least 2 mm, otherwise the thinner wire will not withstand it and will burn out. To connect, you only need to understand the operating principle of a 4-pin relay and minimal knowledge in installing additional equipment. Messages Yes, and judging by the chips as indicated in the diagram in my primer, it is so. How to make such a system?

Let's look at the operation of the radiator fan in more detail: Stories from our readers “Fucking basin!!! It is purely mechanical, that is, there is no electronics inside. Connection diagram for an electric car radiator cooling fan

Cooling fan malfunctions and their symptoms

Taking into account the fact that the fan is an electromechanical unit, the operation of which is ensured by a separate circuit, its malfunctions can manifest themselves in different ways:

- the device does not turn on at all;

- the electric motor starts but runs constantly;

- the fan starts working too early or too late;

- During operation of the unit, extraneous noise and vibration occur.

The fan doesn't turn on at all

The main danger posed by a broken cooling fan is overheating of the power plant.

It is important to control the position of the arrow of the temperature indicator sensor and feel the moment the device turns on. If the electric motor does not turn on when the arrow reaches the red sector, most likely there is a malfunction of either the device itself or elements of its circuit

Such breakdowns include:

- failure of the armature winding, wear of the brushes or commutator of the electric motor;

- sensor malfunction;

- break in the electrical circuit;

- fuse blown;

- relay failure.

Constant fan operation

It also happens that the device’s motor turns on regardless of the temperature of the power plant and runs constantly. In this case, the following may occur:

- short circuit in the fan electrical circuit;

- sensor failure;

- relay stuck in the on position.

The fan turns on early, or, conversely, late

Untimely turning on of the fan indicates that the characteristics of the sensor have changed for some reason, and its working element does not respond correctly to temperature changes. Similar symptoms are typical for both carburetor and injection “sevens”.

Extraneous noise and vibration

The operation of the cooling fan of any car is accompanied by a characteristic noise. It is created by the impeller, cutting the air with its blades. Even merging with the sound of the car’s engine, in the “seven” this noise is clearly audible even from the cabin. This is the norm for our cars.

If the rotation of the fan blades is accompanied by a hum, creaking or whistling, the front bearing or support sleeve in the cover may have become unusable. A cracking or knocking sound indicates contact of the impeller with the inner edge of the frame in which the electric motor is installed. This malfunction is possible due to deformation or misalignment of the fan blades. For the same reasons, vibration occurs.

Causes and malfunctions of the fan

During operation, the most unpredictable situations may arise. Beginners are often confused when the engine cooling fan does not work, turns on prematurely, or rotates constantly. Such problems can lead to engine overheating or, conversely, difficulties in reaching temperature.

In order to troubleshoot the problem in a timely manner and prevent more serious damage, it is important to know how to check the radiator fan and in what sequence to fix it.

As mentioned, the temperature at which the fan turns on may vary on each vehicle. For example, on a VAZ-2110-2111, the optimal operating temperature of the power unit is about 88-89 degrees.

In this case, the fan operates at 105 degrees Celsius. Next, the coolant temperature begins to decrease, and shutdown occurs at a temperature of 97 degrees Celsius and below.

Archive number No. 33 (567) dated August 16, 2005 - Auto Show

As soon as the thermometer rises above 30°C, you can see more and more cars on the streets standing with their hoods up: the cooling system has failed and the engine has overheated.

There are many reasons why an “aged” engine overheats: dirty radiator, faulty thermostat or temperature sensor, worn fan drive or pump. But the main and, oddly enough, the most common cause of malfunctions in the cooling system is a violation of the tightness of its components and connections. Therefore, it is necessary to regularly check for coolant leaks. Even a small but rapid decrease in the level of antifreeze should be alarming - the coolant simply does not disappear anywhere, and its losses due to evaporation do not exceed 150–200 grams per year.

Where can antifreeze, which is expensive in many senses, go, and what should you pay attention to when caring for the cooling system?

As a rule, a “tired” element (such as a “stiffened” hose or a worn pump) fails under load at the most inopportune moment - on a long road, in a busy traffic jam, etc. Regular inspection and preventive replacement of some parts will help keep the antifreeze level unchanged throughout for many years. And this means saved time, money and nerve cells.

Radiator

Time and the action of ethylene glycol are a destructive combination that eats through the radiator honeycomb, and the expensive part has to be replaced. Brass (and copper) radiators are preferable to aluminum ones because they are more durable and can be soldered. Many radiators have side tanks made of plastic, which becomes brittle over time and can burst - for example, when replacing supply hoses.

Radiators are susceptible to corrosion not only from the inside - the salt that is sprinkled on roads in big cities very readily “eats” aluminum. Radiator repair, if it helps, does not last long.

All this is also true for the “stove” radiator, which is hidden under the dashboard and, if the seal is lost, fills the interior with hot “antifreeze.”

Expansion tank cap

Many motorists underestimate the importance of the expansion tank cap, which, being the exhaust and inlet valve of the system, allows it to create pressure above atmospheric pressure. But if this indicator reaches 1.1 kgf/cm2, the exhaust valve opens, thereby preventing damage to parts

It is unacceptable to remove the valve from the cap - this not only reduces the boiling point of antifreeze by 15–20 degrees, but also risks rupturing the expansion tank.

Water pump

The water pump (or pump, as it is also called) is an equally important part, because it is the one that ensures the circulation of liquid in the system. It also often leaks antifreeze through a worn oil seal. Many “pumps”, with increased wear, emit a high-pitched squeal - this means that the pump bearing is about to jam, causing the entire assembly to simply fall apart. However, some pumps have a conventional double-row bearing (for example, VAZ-2108), which is not lubricated by antifreeze and therefore less dependent on the quality of the coolant. True, the leakage of the seal in this case also does not bode well - the antifreeze that gets into the bearing washes out the factory lubricant, significantly reducing the service life of the pump. And stopping the pump leads to a break in the timing belt, which for many engines (in the VAZ-2108, -2112 and some foreign cars) threatens the valves “meeting” the pistons.

Hoses and connections

Under the influence of changes in temperature and pressure, rubber pipes gradually lose their elasticity and become covered with microcracks, as a result of which they can burst right on the road. When using a car for a long time (domestic - more than five years, foreign cars - more than ten), it is advisable to change all the cooling system hoses and clamps. Do not use band clamps - they do not provide the same tightness as commercially available screw clamps. And be careful - the edges of many cheap clamps are sharp and can damage the pipes when tightened.

The most vulnerable is the hose that goes from the cylinder block to the heater radiator and passes in close proximity to the exhaust pipe of the exhaust manifold.

Fan drive

Often the cause of engine overheating is a malfunction of the electric drive or fan clutch. In the first case, the cause of fan failure should be sought in the electrical connectors and the fan switch sensor. If everything is in order there, then you will have to replace the electric motor. If there is a fluid coupling, the cause of the failure should be sought in it itself.

Share link:

VKontakte, Odnoklassniki, Facebook, Twitter, Instagram.

Expansion tank cap

The last reason why the VAZ-2110 cooling fan does not work may be a malfunction of the expansion tank cap. The fact is that when the engine is running, a pressure above atmospheric pressure is created in the cooling system, due to which the water, which is part of the coolant, does not boil at 100 ° C. The expansion tank cap valve is designed to maintain the required pressure. If it fails, the pressure in the system will be equal to atmospheric pressure. This will cause the coolant to begin to boil already at 100 degrees. A sensor designed to turn on at a higher temperature will naturally not work.

It is unlikely that you will be able to check the operation of the cover at home, so if during a visual inspection you have doubts about its functionality, it is better to replace it immediately.

What to do if the radiator cooling fan does not work

Making sure that the radiator cooling fan has failed and is not working is quite simple. To do this, you need to start the car engine and let it idle for some time. When the dashboard shows that the coolant temperature is approaching the critical zone, the sensor will notify the radiator fan so that it starts working. At this moment, the driver will hear additional noise from under the hood, and when he opens it, he will see that the fan impeller is spinning near the radiator.

If the coolant temperature has reached a critical value, and the radiator cooling fan does not turn on, you need to find out why this is happening. The following are the main reasons why the radiator cooling fan does not work:

If the radiator cooling fan does not turn on, it is quite easy to find the cause of the problem; just perform the checks described above.

What are the consequences if the radiator fan does not work?

An internal combustion engine is a complex device, and its performance is optimal when it operates at a certain temperature. As noted above, it depends on the correct operation of the cooling system. In the case when it is not possible to maintain the required temperature, the consequences will be quite sad - if the engine overheats, it may well jam and then, at a minimum, a major overhaul is guaranteed.

The stability of the entire system should be created by a fan, allowing the water temperature to be reduced in any conditions. But if it doesn’t work, especially when it’s hot, then you need to look for why the fan doesn’t turn on or doesn’t spin. Nowadays, such devices are usually electrical, and failure of the product itself is unlikely, and a possible reason for this is often the failure of its wiring (sensor, fuse, connecting wires, etc.).

This means that when figuring out the reasons why the radiator cooling fan is constantly running or why it doesn’t turn on or spin, you must first check the wiring of the device.

Radiator fan device

A car fan for an internal combustion engine cooling system has at least four blades, which are mounted on a single common pulley. The blades are located at a certain angle relative to the plane of rotation. This is done for the most efficient intake and subsequent supply of air. There are no strictly established patterns in the design of the fan, although the most common design has become one that includes an impeller with 8 blades.

Drive types

The radiator fan may differ in drive design. Existing types are divided into:

- mechanical;

- hydromechanical;

- electric;

Mechanical drive

Such a drive is a design that is essentially a permanent drive from the crankshaft of the power plant. This drive is the simplest and is implemented using a belt drive. The main disadvantage of a mechanical drive is the power taken from the unit, which is spent to ensure constant rotation of the fan. Today, mechanical drives are practically not used in cooling systems on civilian cars.

Hydromechanical drive

This type of drive is a solution that is implemented by installing a viscous coupling (viscous coupling) or a hydraulic coupling. These couplings are constantly driven by the engine crankshaft. In order to keep the fan blades intact when the internal combustion engine is operating at maximum speed and high crankshaft rotation speed, the fan impeller is connected to the pulley via a hydraulic or viscous coupling. There is also a definition of a thermal coupling, which depends on the design features.

The clutch may become partially or completely blocked due to the increasing temperature of the fluid with which it is filled. Silicone is such a filling fluid. The increase in temperature occurs as a result of increased crankshaft speed and increased load on the engine. The clutch is blocked and the cooling fan begins to rotate. A hydraulic coupling differs in design from a viscous coupling and is blocked depending on the amount of oil in the coupling.

It turns out that the viscous coupling is often filled with silicone gel, which has the ability to change its properties under the influence of temperature. Silicone oil is poured into the coupling in an amount of about 30 or 50 ml. Clutch blocking affects the fan rotation speed regardless of the engine crankshaft speed. If the power unit reaches high speed mode, then the clutch slows down the rotation of the impeller, thereby protecting the fan from destruction at high rotation speeds. The main task of all types of couplings, which differ in operating principles and design features, is to maintain the fan rotation speed within strictly limited limits. The viscous coupling provides the speed range that the impeller needs for the most efficient cooling.

As already mentioned, mechanically driven fans have become rare, but have not completely disappeared. Such a device can still be found on some car models that have a longitudinally located power unit. Another segment of cars in which the installation of a fan with a similar type of drive is widespread and justified is powerful SUVs. Such machines are able to overcome water obstacles and are prepared for operation in conditions of extremely high humidity. The fact is that any electronics fails after contact with water, and viscous couplings are completely sealed devices and are not afraid of moisture.

Electric drive

The active development and implementation of electronic control and monitoring devices for various systems during engine operation has led to the emergence of an electrically driven radiator fan. This drive has a separate electric motor and its own control system. The controller allows you to set the intensity of the impeller operation and flexibly change the speed and duration of fan rotation based on the readings of the temperature sensor. The sensor measures the temperature of the coolant in the internal combustion engine. This solution not only increased efficiency, but also made it possible to achieve improved uniformity of engine cooling compared to systems that are based on the use of a viscous coupling.

How does it work

If your cooling system uses an electric fan, you most likely have a cross-mounted (side-mounted) motor. However, some longitudinal (front to back) motors also use electric, but they usually have a motor-driven cooling fan.

An electric cooling fan uses a direct current (DC) electric motor with a thermal switch, module, or computer control to turn it on or off depending on coolant temperature or AC operating conditions.

In older circuits, the thermostatic switch is connected to the battery on one side and the fan motor on the other. However, on most '90s and newer models, control was transferred to the car's computer or dedicated module. For example, when the coolant temperature changes, the thermal switch communicates this change to the computer through a voltage signal, which the computer or module uses to activate cooling through the fan relay.

An electric cooling fan not only helps save energy by running only when the system needs to remove excess heat from the engine, but it also helps protect other sensitive circuits and electronic components from thermal damage. During the winter months, your radiator saves even more energy when there is enough cool air flowing through the radiator on the highway.

Even if your cooling doesn't have complex circuitry, you still need to know where to look when it's not performing as expected. The following are some key points to check when diagnosing problems with your electric cooling fan.

Historical reference

It should be noted that the viscous coupling invention is far from new. This principle was known back in 1917 in the USA. It was there that its creator, the talented engineer Melvin Severn, lived.

Unfortunately, in those days the principle of fluid viscosity in the transmission was not appreciated, and there was no particular need for it. The viscous coupling would have sunk into oblivion, but unexpectedly in 1964 it reappeared in the world automotive arena in the transmission of the British sports car Jensen Interceptor FF.

This was the debut of the viscous coupling in a production car and since then it has been actively used and used by various automakers.

Why does the engine overheat?

Thermostat failure.

A failed thermostat is the most common cooling system failure. The thermostat, despite its simple design, is in an aggressive environment, becomes covered in oxides and fails... The engine will overheat if the thermostat is stuck in the closed position, since antifreeze will not enter the main radiator. Such a malfunction can be treated by replacing the thermostat with a new one, which it makes sense to “weld” before installation.

Clogged radiator.

We have a separate article about a radiator clogged with dust and cleaning it. A clogged radiator with plastic tanks inside, if heavily soiled, is almost impossible to clean. Radiators with brass tanks used to be soldered and pierced with a cleaning rod, but in modern radiators this is not possible. If the contamination is not severe, it makes sense to flush the cooling system. If the radiator is heavily contaminated, it is usually replaced.

Faulty pump.

If you did not change the antifreeze in a timely manner and the corrosion inhibitors it contained stopped working, then you may well see this picture:

The pump is usually replaced.

Late ignition.

On old engines, if the ignition was adjusted incorrectly, overheating occurred, but today such engines are already rare.

Cooling system design features

I like. But these are trifles for a person who more or less understands electrics. This does not affect maneuverability and speed. The design uses a two-contact sensor, which, depending on the temperature, powers the electric motor directly or through resistors; a combination of parallel and series connection.

Place the tee so that the sensor contacts are at 90 degrees, and not as in my photo, I almost missed this moment, the stove body does not sit properly. Sawed by a Bulgarian's wife and rolled with a hammer and filed. In the modern world, they are increasingly using a fan control unit instead of a fan switching relay. They both must go to the normally open terminals of the electromagnetic relay. This option is quite complicated for a person who is not very versed in car electrics.

As for the latter, the permanent drive is carried out by the crankshaft. You should not use this option if the bathroom is located near living rooms, since night ventilation can create quite loud noise. The light in the room and the fan work in parallel, i.e.

It must be said that there can be several such sensors on one car. It should be based on what conditions are present in your bathroom.

It fits the thread, but it has a different feature. Of course, the dashboard may be lying here and according to the On-Board Computer the readings are completely different. Let's consider not only the operating principle, but also the connection option with the possibility of forced activation of the VCO cooling system fan. The relay connection diagram is simple - you need to connect two wires parallel to the sensor. 2-speed fan activation

Diagnostics of VDV

If, as a result of replacing the sensor, the functionality of the cooling system is not restored, then the new part may be defective.

To make sure that the DVV is working, you need to perform the following simple steps:

- Remove the sensor from the car.

- Place it in a metal container with water.

- Place the tank on the gas stove.

- Boil.

- Remove the DVV from the container and measure the resistance between the contacts.

You can use an inexpensive multimeter or tester to perform the diagnostic operation. If, as a result of measurements, the presence of insignificant electrical resistance is established, then the sensor is in working order and can be used for its intended purpose. How to check this part is now clear, so if you don’t find an inexpensive used part, you can also install it after a diagnostic operation.

Diagnosis and common causes of cooling system problems

Of course, any on-board computer error related to the cooling system will not be eliminated; after eliminating the malfunction, reset the errors from the on-board computer by disconnecting the power terminals from the battery for about 10-15 seconds.

Closing contacts

One of the most common causes of this breakdown is a banal short circuit of the contacts of the coolant temperature sensor. In this case, when the ignition is turned on, the cooling fan turns on, since electric current is constantly supplied to the fan due to a short circuit. The consequence of such a malfunction may be, perhaps, accelerated discharge of the car battery.