After starting, the engine stalls immediately: why does this happen?

During the operation of a car, a common situation is that after turning the ignition key, the car starts, the engine starts to work and stalls after a few seconds. As a rule, 3-5 seconds pass from the moment of starting to stopping the internal combustion engine. Before the engine stops completely, engine vibrations are also noticeable, the power unit shakes and operates very unstable.

This happens as a result of a decrease in speed, the resonance effect of a rotating crankshaft, etc. When you try to start the engine again, the engine may no longer start, or the situation described above may repeat again.

The reasons for this problem vary. The main thing is that if the car starts and stalls, this indicates that in-depth diagnostics are needed. Next we will talk about what to do in such a situation, as well as how to find the reason why the engine stalls after starting.

Read in this article

Carburetor car engine starts and stalls

In this article we will take a closer look at the situation when a carburetor engine of a passenger car (VAZ 2108, 2109, 21099, 2105, 2107 and their modifications) starts and stalls due to a carburetor malfunction. Malfunctions of carburetors 2105, 2107 Ozone, 2108, 21081, 21083 Solex and their modifications will be considered.

Symptoms of a problem

The engine starts, runs for a few seconds and then stalls; repeated starts are unsuccessful.

The engine starts with difficulty, after running for a short time it stalls, after restarting it starts and runs

The engine starts and immediately stalls, restarts and stalls again, and so on several times, but then it still starts running.

Causes of the malfunction “carburetor engine starts and stalls”

There is no fuel in the float chamber

Pump it up using the manual pump lever on the fuel pump.

The fuel pump or power system may be faulty. Remove the hose from the carburetor fuel supply fitting and press the manual primer lever on the fuel pump several times. A strong pulsating stream of gasoline should come out of the hose hole. If it is missing or weak, check the fuel pump or power system.

Checking the VAZ fuel pump

The strainer at the carburetor inlet is clogged

Remove it by unscrewing the cap, clean it (you can use a toothbrush), rinse with acetone or gasoline and blow with compressed air. At the same time, clean the filter seat in the carburetor cover.

Details of strainer filters for fuel purification of carburetors 2108, 21081, 21083 Solex, 2105, 2107 Ozone

The solenoid valve is faulty or the fuel jet of the idle system is clogged

Check whether the solenoid valve or the idle air system fuel nozzle holder has become loose due to any circumstances. Turn it on. Remove the wire from the valve and then put it back on. You should hear the click of the valve being activated. If it is not there, we connect a piece of wire plus the battery and the valve outlet. There is no click - we change the valve. There is a click - we check the EPH system.

Solenoid valves for carburetors 2108, 21081, 21083 Solex, 2105, 2107 Ozone

Check the serviceability of the valve itself by unscrewing it from the carburetor and removing the fuel jet from it. The jet should be carefully inspected for contamination and deformation. We also check the ease of movement of the valve shut-off needle, the presence and integrity of the rubber O-ring on the valve body.

Carburetor solenoid valve design

Unscrew the idle air system fuel nozzle holder (on carburetors with a holder instead of a solenoid valve), rinse, clean the fuel nozzle and blow with compressed air.

“Suction” of foreign air into the carburetor

In this case, the fuel mixture is lean. If the engine starts and immediately stalls, it is most likely very lean. The image shows probable places where foreign air is “sucked in” on the 2108 Solex carburetor.

Places of possible “suction” of foreign air into the carburetor 2108, 21081, 21083 Solex

Read more about the “suction” of foreign air in the article “Suction of foreign air into the carburetor.”

Trigger diaphragm damaged or out of adjustment

Disassemble the starter housing and replace the diaphragm with a new one. Adjust the starting device.

Starting devices for carburetors 2108, 21081. 21083 Solex, 2105, 2107 Ozone

Fuel and air jets, emulsion wells and tubes of the main dosing system are clogged

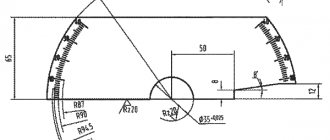

It is necessary to remove the carburetor cover, unscrew the jets, remove the tubes, rinse and clean them, clean the wells, blow everything out with compressed air and put it back. The image shows what should be cleaned on the carburetor 2105, 2107 Ozone.

The engine starts and stalls: troubleshooting

So, if a similar problem appears, then it is necessary to take into account a number of features. First of all, the operation of the internal combustion engine after startup will be influenced by the following factors:

- fuel supply;

- air supply;

- spark on spark plugs (for gasoline internal combustion engines);

- correct operation of glow plugs (for diesel engines);

- proper operation of the ECM and electronic sensors;

With that said, you should first start by checking the main possible causes:

- Quite often, malfunctions in the operation of the alarm system and the anti-theft system can cause the engine to fail to operate after starting. In other words, the immobilizer does not turn off and continues to block the start of the internal combustion engine, which is its main function to prevent vehicle theft. If the alarm blocks the engine, then you need to check the operation of all elements, try to reset the error, turn off the anti-theft system, etc.

- Problems with the IAC and idle air valve often arise due to contamination of these elements. You should also pay attention to the cleanliness of the throttle valve. As for the crankshaft sensor, incorrect data that it transmits to the ECU can cause the engine to stall immediately after starting.

- Poor quality fuels and lubricants can also cause problems. As a rule, problems begin in cases where low-grade fuel was filled or the engine uses motor oil that does not meet the recommendations/has lost its properties.

- A faulty fuel pump, air leaks in the fuel line, the formation of air pockets and dirty fuel filters do not allow creating the required pressure in the power system or supplying fuel in the required volume.

- The air filter and its contamination leads to the fact that the working mixture is significantly over-rich. In other words, the engine does not have enough air to burn fuel, and the spark plugs flood.

- Problems with ECM sensors (EGR sensor, oxygen sensor, DPKV, etc.) can lead to both unstable engine operation at idle and a complete engine stop after starting.

Now let's look at the most common problems and how to fix them, looking at them in detail.

- First of all, the culprit may be the low level of fuel in the gas tank and its quality. If gasoline or diesel fuel runs out, then the engine will start using the remainder in the power system, but further operation will be impossible.

Water is heavier than gasoline and settles to the bottom. If this is the case, then the problem has been identified. To solve this, it will often be enough to dilute the existing fuel with high-quality fuel, after which the engine can usually be started.

However, this doesn't always work. It is possible that the supply of low-quality fuel in the tank will need to be completely drained, after which the power system will be thoroughly cleaned and flushed.

If the malfunction occurs on a diesel engine, then problems with fuel can lead to more serious consequences. For example, if a diesel engine starts and stalls in winter, then the cause may be waxed and frozen diesel fuel. In this case, diesel fuel needs to be heated, filters cleaned, etc.

It is much worse if gasoline accidentally gets into the tank of a diesel car. In such a situation, there is a high risk of serious damage and failure of expensive diesel engine fuel equipment (fuel pump, injectors).

- The next reason why the engine starts, runs and stalls may be the battery. The fact is that many systems and actuators require sufficient battery charge for normal operation.

- Another element that is worth paying attention to in the event of a sudden stop of the internal combustion engine after starting is the fuel pump. On modern fuel-injected cars, the fuel pump is located in the fuel tank.

In order to check its operation, you need to turn the key in the lock, turn on the ignition and listen carefully. In the first seconds after turning the key, a characteristic light hum/buzz should be heard. This sound lasts for several seconds, indicating that the fuel pump has started working and is building pressure in the fuel system.

If such a sound is not heard, then it is necessary to determine the reason why the gas pump does not pump gasoline. The pump motor itself, the fuel pump relay, fuses and other electrical circuit elements may fail. Let's also add that the ECU can turn off power to the pump if the crankshaft sensor does not send a signal.

It is also important to consider that the filter mesh on the fuel pump may become clogged. For accurate diagnostics, it is advisable to measure the fuel pressure in the fuel rail using a pressure gauge.

Another common cause may be the fuel filter. If it is contaminated, then a decrease in throughput leads to the fact that the pump cannot pump gasoline in the required volume for normal engine operation. As a result, the unit stalls after starting.

- If there is fuel in the system and the pressure is normal, then the problem may be related to the ignition system. Most often, spark plugs and spark plug high-voltage wires fail. A typical symptom for wires is that the engine stalls after washing or in wet weather.

One way or another, you need to unscrew the spark plugs, clean the elements, and check them for a spark. If the spark plugs have not been changed for a long time, then it is better to immediately install a new set. As for armored wires, they also need to be checked for functionality and replaced if necessary. At the same time, on some cars you need to check the ignition timing.

- The synchronous operation of the valve mechanism may be disrupted due to the fact that the timing belt or chain may be incorrectly installed, stretched, worn out and may jump on the pulleys. As a result, the opening and closing of the intake and exhaust valves does not correspond to the engine strokes.

In this case, to eliminate the problem, you need to check the indicated elements, align the timing belt to the marks and perform other necessary procedures.

- ECU malfunctions are less common, but this possibility should not be ruled out. Cases where the controller was reflashed, chip tuning was performed, or LPG was installed on the car deserve additional attention.

You can do this diagnosis yourself. To do this, you will need an adapter for the OBD2 diagnostic connector, which will allow you to read error codes and display the received information on the screen of a tablet, laptop or smartphone.

The car starts and immediately stalls - causes and solution to the problem

High-quality operation of the vehicle is possible if all technical components and assemblies are working properly. Otherwise, you will have to try hard to get high reliability of transport and not get into an unpleasant situation. But problems can await you quite unexpectedly, and many breakdowns develop unnoticed by the driver until they show their effect on the main components of the car. Therefore, you need to regularly go to the service station, carry out diagnostic work and carry out important regular technical processes. You can easily maintain the reliability of your car if you comply with all the conditions for its normal operation and timely maintenance. Otherwise, the car will have to be regularly repaired, and in retaliation it will constantly show its character at the most inopportune moments.

What's the result?

As you can see, there are quite a few reasons why the engine starts running and stalls after starting. However, most of them are usually associated with the fuel system, ignition system and electronic control system.

In this case, it is appropriate to talk about low compression in the cylinders due to the fact that the engine has exhausted its service life (the cylinder walls, rings, etc. are worn out), that is, the unit needs major repairs. Compression can be measured at a service station or yourself using a compression meter.

The engine stalls at idle: what to check. Possible causes of malfunction on engines with a carburetor, injector, and diesel power plants.

At idle the speed “floats”: why does this happen? The main malfunctions associated with idle speed on gasoline and diesel engines.

The main reasons why the engine starts to stall after warming up. Frequent problems of carburetor and injection engines, fault diagnosis.

The reasons why, after pressing the gas pedal, dips occur and the engine begins to choke. Gas engine failures when switching from gasoline to gas.

Why the engine may not pick up speed: gasoline engine, diesel unit, car with LPG. Fault diagnosis, useful tips.

Reasons why the engine may stall when you press the brake. The power unit stalls during sudden braking, when the clutch and brake are depressed, etc.

UAZ Patriot starts and stalls engine 409 reason

Everything was in order, except for the fact that when you turn off the engine when it’s hot, if you start it right away, then everything is also in order. But if the car sits for about five minutes, then after starting the speed begins to drop and if you don’t accelerate, it stalls, but if you press the gas, the speed levels off.

I decided to look at the throttle valve, opened it slightly, and everything was black with soot, so I decided to wash it with carburetor cleaner. A friend turned the starter, and I removed the tube, or, as they call it, whatever the mass air flow sensor is on, and started spraying it from the can. But the car didn’t start, strangely, Toyotas and Nissans started. Well, in general, the washing machine has had enough. Then I put everything back in place and after that the car started up after a while, ran for five minutes and I turned it off. In the morning I start the engine, it picks up, starts, then immediately loses speed and stalls. The next time I try, it won’t start, but if I accelerate, it starts. I waited until the next morning, well, in the cold, and decided to try it like this, I start it, the engine catches up and starts to stall, and I immediately put on the gas and the engine starts and goes to warm-up speeds. If you let the car run for at least 30 seconds and turn it off, it starts up as expected. I almost forgot, this morning I washed the throttle body as it should be with it running, I thought it would help, but no. This is such an opportunity.

Today I bought and connected the BC, it showed me two errors #18 - high level of air temperature signal and #53 - malfunction of the crankshaft speed sensor, if #53 is clear, the sensor needs to be replaced, then with #18 I didn’t understand something, high What is the signal level like and where is it located?

It's in the intake receiver. here is an extract from the description of my BC SKAT-5:

“Appointment. The air temperature sensor (ATS) is used to measure the temperature of the intake manifold (intake air temperature). The ECU uses the measured air temperature to adjust fuel delivery and ignition characteristics. The air temperature sensor is similar to the coolant temperature sensor. Features of DTV operation. The sensor is a semiconductor device to which a 5 V reference voltage is supplied from the control unit. The output signal is the reference voltage drop across the sensor, which depends on the temperature; the higher the temperature, the lower the voltage drop. The ECU converts this voltage into the “air temperature” parameter (the “Air Temperature” parameter of the BC SKAT). DTV requires mandatory compliance with the polarity of the reference voltage.

“CODE 18” (“CODE 0113” for the MIKAS11 ECU) - high signal level of the air temperature sensor - is detected by the ECU only when the engine is running, if the output voltage at the sensor is higher than 4.9 V. Conditions for checking - the engine is running, code 18 has the current state . Broken wire 44, Broken wire 30*, DTV malfunction. Stop the engine and turn on the ignition. Remove the connector from the DTV. Insert the probe between pins 1 and 2 of the connector. The lamp should not be lit. Using BC SKAT, check the parameter “Ex. T.air.” The parameter value has become less than 0.2 V - the sensor is faulty, if it remains the same - there is a break in wire 44 or 30, repair the break; *. A break in wire 30 in the 55-pin socket of the control harness is accompanied by the appearance of current faults with codes 18, 22, 24.

Conclusion. Intermittent DTV malfunctions can cause the car to jerk when driving evenly. If the DTV fails, remove the connector from the sensor. The ECU will switch to backup mode (the “Air Temperature” parameter will take the value 40 °C). The performance characteristics of the vehicle will not change significantly.”

what bookmaker do you have? (just wondering:) )

I myself am struggling with the problem of working on xx. Starting is difficult (it may not start at all). If through the ramp I forcibly increase the number of IAC steps (now at -5C to 200-250), then it’s normal. And if it started on its own with an IAC step of 180, for example, then for some reason after 30 seconds. work rcx closes, abruptly, to 116. What is this?

Starts and stalls - logbook UAZ Patriot Yellow Behemoth 2011 on DRIVE2

Today I was left without lunch - the canteen is not open, I wanted to go home to eat. And the Behemoth starts up and immediately stalls ((Where to dig, where to look? After a couple of hours, I’ll pump it into a warm box, the fuel pump is humming, it seems to be pumping.

I ordered fresh gasoline

Pysy: We rolled the car into the pit, looked at the pressure in the ramp, well, when I looked, I turned on the ignition and pressed the button. It splashes, gasoline flows in a vigorous stream. The car thaws out until 17:00, after work I’ll look for the cause. Last Tuesday, when starting the car, there was an emergency engine shutdown - it seems the problems started on Tuesday! There is a suspicion of a lost contact somewhere or, on the contrary, an extra one.

it was on Tuesday

more pysy: The car started - the main reason was running out of gas. The gauge showed more than a quarter of the tank was infected!

The main reason is a malfunctioning fuel gauge, and it works poorly because the tank at the bottom is completely dented, and the tank is dented because someone stormed the Red Navy hill on one rear-wheel drive with a long run. I won’t say who) (but not me)

Messages [1 to 25 of 29]

1 Topic from srgey 04/30/2016 14:27:11

- srgey

- Participant

- Inactive

- Registered: 30.04.2016

- Messages: 1

Topic: 409 engine stalls

The engine idles unstable, when you press the gas pedal it starts shooting at the air and stalls. I replaced the spark plugs, wires, coils, camshaft sensor, air flow sensor, checked the ignition, did diagnostics, no errors. No changes.

Edited by srgey (04/30/2016 14:45:41)

2 Reply from Zhek_013 04/30/2016 15:04:10

- Zheka_013

- Participant

- Inactive

- From: Krasnodar // Krinitsa

- Registered: 11.06.2010

- Messages: 2943

Re: ICE 409 stalls

3 Reply from dok2fox 04/30/2016 15:35:51

- dok2fox

- Participant

- Inactive

- Registered: 10.03.2014

- Messages: 329

Re: ICE 409 stalls

measure the fuel pressure. It looks like low pressure. As an option (the filter is clogged, the pump is dying, there is a jamb with a check valve, the hoses inside the pump module are leaking).

well, a clogged catalyst can also show (well, I think the first)

4 Reply from Crusher 04/30/2016 15:51:08

- Crusher

- Participant

- Inactive

- From: Belorechensk

- Registered: 22.05.2010

- Messages: 9072

Re: ICE 409 stalls

How does the operation of a 409 motor relate to legal issues?

5 Reply from Bort 777 04/30/2016 18:42:15

- Aircraft 777

- Participant

- Inactive

- From: 45°15'N 38°07'E

- Registered: 22.02.2012

- Messages: 1434

Re: ICE 409 stalls

Edited by Aircraft 777 (04/30/2016 19:52:43)

6 Reply from Milan23rus 05/02/2016 13:16:13

- Milan23rus

- Participant

- Inactive

- From: Krasnodar

- Registered: 25.12.2013

- Messages: 128

Re: ICE 409 stalls

Valve train chain. Check the phases.

7 Reply from Savely 06/04/2017 18:24:39

- Savely

- Participant

- Inactive

- From: Anapa

- Registered: 25.09.2009

- Messages: 13171

Re: ICE 409 stalls

Everything is the same, at idle it shakes and rumbles. Moreover, this does not happen for 5 seconds after starting. At first it started to “die” after 4 thousand revolutions, for example on the second after 60 mph (usually it turned up to 80 without any problems).

Then it started suddenly and when I lightly pressed the gas pedal. Obvious signs of lack of fuel/pressure, exactly the same as if you make a turn on an empty tank and press the slipper again. Only without a turn and a slipper. The pump is humming...

I found the relay block and pump fuse in a sad state; there was clay inside. I'll replace it tomorrow. The filter has not changed in my memory either. It all started after water was inflated into the left empty tank (cooked nearby). The water was drained, and from the right one too. But, apparently, this provoked the detachment of shit deposits in the old tanks.

How to wash tanks? I think the pump is alive, most likely the filter/mesh is clogged, the pump electrician is questionable.

8 Reply from Savely 06/04/2017 18:26:04

- Savely

- Participant

- Inactive

- From: Anapa

- Registered: 25.09.2009

- Messages: 13171

Re: ICE 409 stalls

We also replaced the hydraulics and the complete timing drive. But the signs were there even before the replacement, and the dying did not happen immediately after the replacement. The motor ran smoothly. I think the timing belt has nothing to do with it.

9 Reply from schum 06/05/2017 00:23:36

- schum

- Participant

- Inactive

- From: Adygea

- Registered: 09.03.2010

- Messages: 1584

Re: ICE 409 stalls

Check the fuel pressure in the rail, and check the compression, for starters

10 Reply from Savely 06/05/2017 07:56:54

- Savely

- Participant

- Inactive

- From: Anapa

- Registered: 25.09.2009

- Messages: 13171

Re: ICE 409 stalls

Compression is normal, the pump died after the tanks were disturbed. In principle, there have been calls to the pump before.

11 Reply from Savely 06/05/2017 11:36:35

- Savely

- Participant

- Inactive

- From: Anapa

- Registered: 25.09.2009

- Messages: 13171

Re: ICE 409 stalls

Yes, pump. Still factory. Just missed my 10th birthday)

12 Reply from sergey_400 06/05/2017 21:05:09

- sergey_400

- Participant

- Inactive

- From: Krasnodar

- Registered: 20.12.2013

- Messages: 601

Re: ICE 409 stalls

Yes, pump. Still factory. Just missed my 10th birthday)

Is it possible to put a non-submersible one on the street from the Volga?

Edited by sergey_400 (06/05/2017 21:06:11)

13 Reply from Vitalik Turbo 06/05/2017 21:10:45

- Vitalik Turbo

- Participant

- Inactive

- Registered: 30.06.2015

- Messages: 725

Re: ICE 409 stalls

Savely , as far as I know, tanks were washed with gravel and soapy water before. Only the gravel must be clean. You pour it in, pour in soapy water and shake until you turn blue. At least there is no other way to shake out deposits and rust from there. Well, then you rinse it several times with clean water, dry it, and that’s it. There is just one problem with this method. If a hole wants to form in the tank, that is, it is rotten, then it will definitely form and you will have to solder it.

14 Reply from PANZER 06/05/2017 22:18:53

- PANZER

- Participant

- Inactive

- From: Poltavskaya

- Registered: 21.07.2011

- Messages: 4597

Re: ICE 409 stalls

It all started after water was inflated into the left empty tank (cooked nearby).

Is this considered normal? on UAZ, remove it and leave it for 5 minutes

15 Reply from sergey_400 06/06/2017 08:53:10

- sergey_400

- Participant

- Inactive

- From: Krasnodar

- Registered: 20.12.2013

- Messages: 601

Re: ICE 409 stalls

Savely , as far as I know, tanks were washed with gravel and soapy water before. Only the gravel must be clean. You pour it in, pour in soapy water and shake until you turn blue. At least there is no other way to shake out deposits and rust from there. Well, then you rinse it several times with clean water, dry it, and that’s it. There is just one problem with this method. If a hole wants to form in the tank, that is, it is rotten, then it will definitely form and you will have to solder it.

The problem is that the gravel is then very difficult to remove from the tank

Blog about UAZ

The procedure and methods for starting an injection engine are the same at any outside temperature, but they have some differences depending on the temperature state of the engine itself. Problems with starting the ZMZ-409 engine may occur in the event of a malfunction or interruption in the operation of the following systems: starting system, ignition system or fuel injection system.

The procedure for starting the ZMZ-409 engine at an outside temperature of minus 20 degrees and above.

It is described in detail in the operating manual for the corresponding UAZ car model. When starting the engine, the control system will independently set the fuel supply and ignition parameters necessary for starting, and after it starts, it will automatically set high idle speeds and will gradually, as the engine warms up, reduce them to minimum. It is not advisable to start the engine if the electric fuel pump has not yet turned off or if the engine fault diagnostic lamp is on.

The procedure for starting the ZMZ-409 engine at an outside temperature of minus 20 degrees and below.

If the ambient temperature is below minus 20 degrees, then starting the ZMZ-409 engine without preliminary preheating of the crankcase oil and coolant is not recommended. As a last resort, before starting you need to at least warm up the engine intake receiver with warm steam or water. The starter cranking time should be no more than 10 seconds, and re-cranking is allowed no earlier than after one minute.

In addition, on a ZMZ-409 engine of Euro-2 environmental class, before starting it in cold weather or if two or three preliminary attempts to start the engine were unsuccessful, the cylinders can be purged with air. To do this, you need to press the gas pedal all the way and turn on the starter for 2-3 seconds.

The electronic engine control unit performs the “Engine cylinder purge mode” function. In this mode, there is no fuel supply and excess gasoline is removed from the cylinders by a stream of fresh air, and the spark plugs are dried. After purging, you must try to start again as usual.

If two or three starting attempts are unsuccessful, then in order to save the battery life, you must immediately proceed to analyze and search, and then eliminate problems with starting the engine or general malfunctions in the operation of its systems.

Problems with starting the ZMZ-409 engine due to a malfunction of the starting system, abnormal operation of the starter.

Malfunctions in the ZMZ-409 engine starting system usually manifest themselves in abnormal operation of the starter, and the following main malfunctions can be roughly identified:

The starter does not turn on.

In most cases, the cause is irregularities in the contact connections, an open or short circuit in the starter activation circuits, a malfunction of the additional starter activation relay, or a malfunction of the traction relay.

When the starter is turned on, repeated clicking noises are heard.

This is most likely a malfunction of the holding winding of the traction relay, the battery is severely discharged, or the contact connections in the starter circuit are loose.

The starter turns on, but its armature either does not rotate or rotates slowly.

In most cases, the reason lies in a discharged battery, broken contact connections of the circuits, burnt contacts of the traction relay, contamination of the commutator or wear of the brush, interturn or short circuit in the starter windings.

The starter turns on, its armature rotates, but the engine flywheel is stationary.

The reason is the weakening of the starter's attachment to the clutch housing, damage to the teeth of the flywheel or drive gear, slipping of the freewheel of the drive, breakage of the lever, drive ring or buffer spring of the starter drive.

The starter does not turn off after starting the engine.

The reason is a malfunction of the starter freewheel clutch or baked contacts of the traction relay. In the event of such a malfunction, the engine must be stopped immediately.

Problems with starting the ZMZ-409 engine due to a malfunction of the ignition system.

In most cases, the on-board self-diagnosis system immediately detects faults in the ignition system and displays them in the form of appropriate error codes. If no codes are recorded, then after checking, with the ignition off, the strength of the individual ignition coils and wiring harness contacts, or the integrity and fit of high-voltage wires in the two-terminal ignition coils, you need to check for the presence of a spark on the spark plugs.

In the case of an individual ignition coil, first, before checking the presence of a spark, it is worth inspecting the surface of its tip for breakdown of the insulator. Upon careful examination, the breakdown site is clearly visible and stands out in the form of characteristic black dots or dashes. If a breakdown is detected, the coil must be replaced with a new one.

Check for spark on spark plugs.

The procedure for checking the spark on spark plugs is quite simple and does not require any special comments. If there is no spark, then the individual ignition coil must be replaced with a new one, and in the case of two-terminal ignition coils, it is also necessary to additionally check the serviceability of the high-voltage wires, replacing them with known good ones. The procedure for checking the serviceability of a two-terminal ignition coil is described in detail in a separate material.

If no malfunctions are detected in the engine ignition system, then most likely problems with starting the ZMZ-409 engine are associated with malfunctions in the fuel supply system or fuel supply control system, or with incorrect operation of one or more control system sensors, for example, a crankshaft position sensor.

Problems with starting the ZMZ-409 engine due to malfunctions in the fuel injection system.

The vast majority of malfunctions of the fuel injection system, which directly affect the ability to start the ZMZ-409 engine in any thermal state and at any ambient temperature, are caused by a failure of the crankshaft position sensor or mass air flow sensor.

In addition, problems with starting the ZMZ-409 engine at negative ambient temperatures may arise due to a malfunction or incorrect operation of the coolant temperature sensor and the air temperature sensor entering the cylinders, on those engines in which it is installed separately in the receiver.

After turning on the ignition, the on-board self-diagnosis system of the electronic engine control unit usually informs about malfunctions or problems in the operation of all these sensors, issuing the corresponding error codes.

The warmed-up ZMZ-409 engine starts and stalls.

The reasons for this engine behavior may be increased or decreased fuel pressure. Increased fuel pressure may occur due to:

- clogged pipelines, hoses and drain circuit elements - faulty or leaky fuel injectors - faulty fuel pressure regulator

Low fuel pressure may be due to:

- leakage or clogging of pipelines and filters - malfunction, coking or clogging of fuel injectors - insufficient performance of the electric fuel pump or its malfunction - malfunction of the fuel pressure regulator

The ZMZ-409 engine starts only when the gas pedal is pressed.

If the ZMZ-409 engine starts only with the gas pedal partially pressed, and the self-diagnosis system of the electronic control unit does not record any fault codes, then most likely the reason is contamination of the bypass channel of the idle speed regulator or its malfunction.

UAZ Patriot won't start

The UAZ Patriot is equipped with ZMZ 409 gasoline engines and ZMZ 51432 and Iveco F1A diesel power plants. Regardless of the type of engine, during operation, the car owner may encounter a situation where his vehicle does not start.

Battery problems

If a car owner is faced with a situation where it is impossible to start the engine, then the reason for this should begin to be looked for by checking the battery. When it is discharged during startup, the boron voltage critically decreases. Because of this, the starter does not rotate the crankshaft well. The traction relay reacts to the voltage drop. It begins to create characteristic clicks that the driver hears from the engine compartment.

The starting situation worsens at sub-zero temperatures. In cold weather, engine oil thickens and it becomes more difficult for the starter to turn the crankshaft. It begins to consume more inrush current. At the same time, due to the slowdown of chemical reactions in the battery, its charge decreases. Therefore, in winter it is relatively easy to start the engine when it is hot, but difficulties may occur when it is cold.

To solve the problem with a dead battery, it is recommended to use one of the following methods:

- “light” from a third-party car;

- use a starter-charger;

- restore the charge of the original battery using the charger.

Engine starting is directly affected by the condition of the battery terminals. The presence of significant oxides leads to deterioration of electrical contact. To restore it, you need to clean the terminals. To prevent rapid subsequent plaque coating, it is recommended to protect the contacts with conductive grease.

- If the battery discharge occurs once, then it is enough to replenish the energy and you can continue to operate the car as before. If the battery dies periodically, the battery must be diagnosed. Based on its results, a decision is made on further actions regarding the power source.

- If the battery monitoring shows the health of the battery, but the battery still often runs out, then attention should be paid to the condition of the on-board network. Accelerated discharge of the power supply may be caused by short circuits or high leakage currents. If they are detected, it is necessary to promptly troubleshoot problems. Otherwise, the car may catch fire.

- Another reason why the car does not start may be mechanical damage to the battery housing. When electrolyte leaks, the battery charge and its starting current are reduced. For diagnostics, you should inspect the body. When defects are identified, a decision is made on the feasibility and method of eliminating them.

Security system and its influence on car starting

During normal operation of the security system, it protects the car from the actions of intruders and does not interfere with the owner starting the engine. Incorrect installation or failure of one or more modules can lead to the car alarm being unable to start the car.

To identify the reason for the inability to start the engine due to a problem in the security system, it is necessary to completely remove the car alarm from the car. After this, a test attempt is made to start the UAZ Patriot. If the start-up is successful, then each removed module is checked for functionality. The correctness of the installation diagram is also subject to control.

Problems in the ignition system

The weak point of the UAZ Patriot ignition system is the spark plugs. They often fail. The most critical effect on startup is the destruction of the electrodes. For diagnosis, it is recommended to visually inspect the turned out spark plugs. If defects similar to those shown in the image below are detected, it is necessary to replace the failed consumable.

During the operation of the UAZ Patriot, car owners are faced with flooded spark plugs. To solve the problem, you need to dry them in the open air. Blowing without dismantling is also possible. To do this, depress the gas pedal as much as possible and crank the engine with the starter for several seconds.

Malfunctions of the engine power supply system

For inexperienced car owners, the situation when the UAZ Patriot stalls while driving often occurs due to the end of the fuel in the gas tank. At the same time, the indicator on the instrument panel does not always show correct information. To fix the problem, simply refuel the car. Other problems in the power supply system of the power unit can be found in the table below.

Table - Manifestation of fuel system malfunctions

| Cause of malfunction | Manifestation |

| Injectors clogged with deposits | Starting a UAZ Patriot becomes more difficult over and over again |

| Filled with the wrong type of fuel | It will become difficult to start almost immediately after refueling. |

| Electric pump malfunction | The vehicle stalls while driving and then refuses to start |

| Damage to the fuel line | The machine does not start after receiving a defect |

Features of diesel engines

Some UAZ Patriot vehicles are equipped with ZMZ 51432 and Iveco F1A diesel engines. They are sensitive to fuel quality. Therefore, after refueling with bad diesel fuel, there is a high risk of being unable to start the vehicle.

A special feature of the UAZ Patriot with a diesel engine is that it is more difficult to start in the cold. If the starter turns poorly, then the crankshaft, rotating slowly, does not create the pressure required for self-ignition. This is due to the fact that the air-fuel mixture manages to partially leave the working chamber through the gaps even with normal compression. To solve problems with winter starting, car owners recommend using special aerosols with flammable substances.

Malfunctions in the starting system

If the starter does not turn the crankshaft, then the problem is in the form of a broken electrical connection to the battery. To control, you should check the condition of the mass attachment to the body and engine, and also check the voltage at key points.

If the starter rotates slowly, the malfunction may be due to:

- brushes getting stuck or worn out;

- contamination or wear of the collector;

- burning of the solenoid relay contacts.

To identify the above problems, it is necessary to dismantle the starter from the UAZ Patriot. Afterwards the unit must be disassembled and troubleshooted. Based on the inspection results, worn out and failed elements are restored or replaced with new ones.

Blog about UAZ

The procedure and methods for starting an injection engine are the same at any outside temperature, but they have some differences depending on the temperature state of the engine itself. Problems with starting the ZMZ-409 engine may occur in the event of a malfunction or interruption in the operation of the following systems: starting system, ignition system or fuel injection system.

The procedure for starting the ZMZ-409 engine at an outside temperature of minus 20 degrees and above.

It is described in detail in the operating manual for the corresponding UAZ car model. When starting the engine, the control system will independently set the fuel supply and ignition parameters necessary for starting, and after it starts, it will automatically set high idle speeds and will gradually, as the engine warms up, reduce them to minimum. It is not advisable to start the engine if the electric fuel pump has not yet turned off or if the engine fault diagnostic lamp is on.

The procedure for starting the ZMZ-409 engine at an outside temperature of minus 20 degrees and below.

If the ambient temperature is below minus 20 degrees, then starting the ZMZ-409 engine without preliminary preheating of the crankcase oil and coolant is not recommended. As a last resort, before starting you need to at least warm up the engine intake receiver with warm steam or water. The starter cranking time should be no more than 10 seconds, and re-cranking is allowed no earlier than after one minute.

In addition, on a ZMZ-409 engine of Euro-2 environmental class, before starting it in cold weather or if two or three preliminary attempts to start the engine were unsuccessful, the cylinders can be purged with air. To do this, you need to press the gas pedal all the way and turn on the starter for 2-3 seconds.

The electronic engine control unit performs the “Engine cylinder purge mode” function. In this mode, there is no fuel supply and excess gasoline is removed from the cylinders by a stream of fresh air, and the spark plugs are dried. After purging, you must try to start again as usual.

If two or three starting attempts are unsuccessful, then in order to save the battery life, you must immediately proceed to analyze and search, and then eliminate problems with starting the engine or general malfunctions in the operation of its systems.

Problems with starting the ZMZ-409 engine due to a malfunction of the starting system, abnormal operation of the starter.

Malfunctions in the ZMZ-409 engine starting system usually manifest themselves in abnormal operation of the starter, and the following main malfunctions can be roughly identified:

The starter does not turn on.

In most cases, the cause is irregularities in the contact connections, an open or short circuit in the starter activation circuits, a malfunction of the additional starter activation relay, or a malfunction of the traction relay.

When the starter is turned on, repeated clicking noises are heard.

This is most likely a malfunction of the holding winding of the traction relay, the battery is severely discharged, or the contact connections in the starter circuit are loose.

The starter turns on, but its armature either does not rotate or rotates slowly.

In most cases, the reason lies in a discharged battery, broken contact connections of the circuits, burnt contacts of the traction relay, contamination of the commutator or wear of the brush, interturn or short circuit in the starter windings.

The starter turns on, its armature rotates, but the engine flywheel is stationary.

The reason is the weakening of the starter's attachment to the clutch housing, damage to the teeth of the flywheel or drive gear, slipping of the freewheel of the drive, breakage of the lever, drive ring or buffer spring of the starter drive.