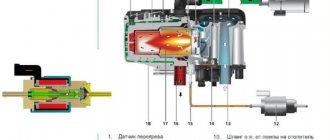

The operating principle of diesel power units is based on the ignition of the fuel mixture in the cylinders under high pressure. Unlike a gasoline engine, a diesel engine does not have a spark supply system using electrode tips on spark plugs: an oxygen-enriched mixture is supplied to the combustion chamber, where high temperature is generated during the compression process. Instead of generating an electric spark, additional pre-heating is provided by glow plugs.

The main parameter for diagnosing the condition of a diesel engine is compression, on which the power and stable operation of the mechanisms of the cylinder-piston group depend.

What is compression in a diesel engine

Compression is an indicator of the pressure in the cylinder that is created by the piston at the maximum highest (dead) point of the stroke. In technical literature, it is customary to use the abbreviation TDC (highest dead center). The value is measured in kg/cm² and depends on two main factors:

- Violation of the tightness of the combustion chamber: air leaks, pressure in the system drops. Worn valves, cylinder-piston units, or incorrect adjustment of the gas distribution mechanism leads to a decrease in compression.

- Condition of the crankshaft and its rotation speed: loss of stable speed leads to heat losses when air is compressed by the piston. The compression ratio becomes lower than normal, which directly affects the energy that is generated as a result of the formation of working gases during the combustion of the fuel mixture in the cylinders.

Rapid wear of CPG mechanisms (cylinder-piston group) depends on the quality of lubricants, the intensity of loads during operation, the number of cold starts at sub-zero air temperatures and hours of operation at maximum speed. Incorrect adjustment of the valve system contributes to the formation of carbon deposits on the walls of the combustion chamber, cylinder liners, and coking of the piston and oil scraper rings. As a result of insufficient pressure, the fuel mixture does not burn completely and mixes with oil residues, leaving burning products and soot on the CPG units. The first sign of wear in this case is a smoky exhaust and a drop in engine power.

During startup and activation of the starter, the crankshaft in a diesel unit rotates at a speed of 200-300 rpm: the higher the torque, the higher the compression. If the pressure in the combustion chamber is below 16 atmospheres, then starting the diesel engine in the usual way with the key becomes impossible. Heat loss causes a decrease in the compression ratio and disruption of the valve timing adjustment.

Important! Prolonged operation of a diesel unit with incorrect operation of the gas distribution mechanism leads to failure of the entire cylinder block. Up to the jamming of the pistons without the possibility of restoration and major repairs.

Mathematical calculation

The compression ratio of an internal combustion engine is equal to the volume of the combustion chamber divided by the working volume of the cylinder and is calculated by the formula (V + C)/C = CR, where

- V is the volume of the cylinder when the piston is at bottom dead center (BDC). To calculate, it is necessary to divide the sum of the volumes of all cylinders (indicated in the technical characteristics of the internal combustion engine) by the number of boilers;

- C is the volume of the combustion chamber when the piston is at top dead center (TDC). Includes the volume of the cylinder head cavity, cylinder head gasket and cylinder recesses. If the piston has a convexity, its volume is subtracted from the total volume of the combustion chamber.

Calculating the compression ratio mathematically is quite difficult due to the complex geometric shape of the combustion chamber. Therefore, in practice, 2 main calculation methods are used.

Video: How to measure the compression ratio correctly.

Compression rate in diesel engine cylinders

Depending on the power of the power unit, the type of design of its combustion chamber and injection system, the compression rate may be different. It must be looked for in the technical description of each specific brand. Below are the standard indicators for the ratio of starting temperature and compression at which starting a diesel engine of any type is possible:

- Less than 18 kg/cm² – engine starting is impossible even with forced heating of the system;

- 22-24 kg/cm² – starting is possible only on a hot unit; after the temperature drops below 0° C, failure to start from the starter is guaranteed;

- 24-26 kg/cm² – starts at air temperature – 10° C;

- 26-28 kg/cm² – maximum starting temperature – 15° C;

- 28-32 kg/cm² – cold start possible down to – 25° C;

- 32-36 kg/cm² – cold start possible down to – 30° C;

- 36-40 kg/cm² – cold start up to – 40° C is possible.

These compression standards are applied only if all other systems responsible for engine operation are in good working order: fuel supply (high pressure fuel pump), 100% battery charge, serviceable timing components. Modern types of diesel engines with a separate combustion chamber and a Common Rail fuel injection system have better results: for each compression indicator there will be an average of plus five temperature values. The error also increases with the number of cylinders in the unit and the type of layout: V-shaped ones with 6 and 8 cylinders have a greater advantage over conventional in-line four-cylinder ones.

Important:

The coefficient of filling the combustion chamber with air at the maximum compression ratio and sufficient pressure (compression) creates the operating ignition temperature of the fuel mixture.

Now let's look at the gasoline engine.

Of course, the most important advantage of the gasoline engine is its popularity. Due to the fact that gasoline cars are more popular, maintenance and repairs can be carried out at any nearby auto repair shop, and spare parts are easier to obtain and replace. And, as a result, the cost of maintenance is much lower than that of a diesel engine. In addition, the maximum power of a gasoline engine is undoubtedly higher than that of a diesel engine. A gasoline engine has a higher rotation speed, and at high speeds the engine suffers minimal damage. There are fewer problems with fuel; such a car is actually “omnivorous,” which can be important if there is no high-quality gasoline nearby. And, of course, a gasoline engine is not afraid of frost; there are significantly fewer problems with starting than a diesel engine.

The disadvantages of a gasoline engine include high fuel consumption due to the combustion system, as well as a higher risk of explosion. The gasoline engine has lower wear resistance, but this is compensated by the fact that finding replacement parts is not a big problem.

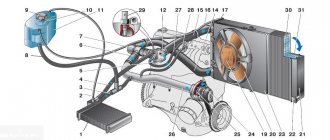

How to measure cylinder pressure

Compression readings are taken using a special device - a compression meter. The compression gauge works on the principle of a pressure gauge: an adapter with an injector or glow plug tip design is designed to be installed in the cylinder head and has a shut-off valve that prevents pressure loss during measurements. Simple devices are equipped with a regular scale with an arrow, more precise professional devices are electronic digital or synchronized with a computer.

Attention! The compression meter must be calibrated with an accuracy of 0.1 kgf/cm² - otherwise the measurement results will not meet the standards.

Before the measurement, the diesel engine is warmed up at maximum speed to the operating oil temperature, the operation of the starter and the state of charge of the battery is checked at 100%. Each cylinder is measured separately.

Why might compression decrease?

A drop in cylinder pressure is accompanied by the following characteristic symptoms:

- failure to start the engine at low temperatures or poor operation of the ignition system;

- during operation at idle speed, “triple” occurs;

- drop in power with unstable speed;

- increased fuel consumption;

- excessive oil consumption;

- foreign impurities in exhaust gases (smoky exhaust);

- strong noise, vibration when opening the throttle.

Reduced compression occurs due to air leaks in the gas distribution mechanism system, cylinder block, or wear of elements and assemblies of the cylinder-piston group. The timing belt may not work correctly due to the formation of carbon deposits on the valve cups or breakdown of the drive mechanisms (springs, seats). To identify a specific cause, the valve system is diagnosed - the valve clearances are measured.

In case of wear of parts of the cylinder-piston group (cylinder-piston group), dismantle the cylinder head in order to find the worn piston cup, gaskets, piston rings or working surface of the cylinders. Burnouts and cracks on the head housing can be determined visually.

Reasons for decreased compression

Reduced compression results from wear and tear of engine components and mechanical failures. The main reasons are:

- chips, scuffs, and other damage to the mirror walls of the cylinders;

- obstruction of compression rings, burnout or destruction of pistons;

- cracks on the cylinder block;

- accumulation of carbon deposits on the internal surfaces of the engine;

- problems with hydraulic compensators, destruction of the valve stem or damage to the guide bushings;

- destruction of the cylinder head gasket;

deformation of the surface of the head adjacent to the cylinder block.

Problems can be caused by the use of low-quality diesel fuel, untimely oil changes or mixing of incompatible types, frequent engine overloads (including forced operating modes), etc.

Troubleshooting solutions

If low compression is detected, a full check of all systems is carried out. Modern diagnostic methods using a special “G‑Scan” scanner make it possible to determine the cause of a breakdown with precision down to a specific component based on the analysis of fuel mixture data, compression values and various sensor readings. The scanner takes into account the ECM (electronic engine control system) log entries, where deviations in the operation of the systems are detailed, all failures in the timing mechanisms are taken into account according to error codes.

On-board computer diagnostics will provide accurate identification of violations that may be missed during a visual inspection. For example, in the process of insufficient supply of the fuel mixture to the cylinder due to a violation of the clearance of a valve, the block controller, based on the readings of the oxygen sensor, regulates additional injection to a specific cylinder, giving a command to the actuator. During a routine check with measuring the clearances of all valves, it may be impossible to determine the cause of carbon deposits in a specific area.

The reason for the decrease in pressure may be due to a slight air leak, when a simple adjustment or replacement of the gasket is sufficient to correct it. In case of serious wear of important CPG mechanisms, a major overhaul of the engine will be required.

How to start an engine with insufficient compression

At low compression rates, the diesel unit does not start by turning the starter normally. If the start is made at sub-zero temperatures on a cold engine, then more force is required for normal crankshaft rotation speed, since the oil becomes more viscous in cold weather. To heat the cardan, use a regular blowtorch, which is installed below and heats the engine systems with hot air.

You can also artificially increase compression for a one-time cold start by creating an oil film in the cylinders. To do this, turn out the glow plugs or injectors and pour motor oil using a syringe directly into the combustion chamber, with a volume of no more than 50 ml. Repeat the entire procedure on each cylinder separately. Afterwards, rotate the crankshaft so that a uniform oil film forms on the walls, which will ensure the creation of a tight seal during start-up. Using this method, you need to monitor the distribution of oil in the cylinder; before starting the engine, the piston must make several strokes with the starter to avoid hydrocline.