Video: Why the VAZ 2109 Engine Detonates

Consequences of detonation

Don't expect detonation to increase engine power because the blast wave travels nearly 100 times faster. You can highlight the main disadvantages of detonation:

- The blast waves last 1/10000 seconds less, as long as the pressure acting on the piston increases. There is extremely little time to significantly increase engine power. But detonation will cause a lot of damage in such a period of time.

- When the engine is running, an oil film forms on the cylinder walls, which helps the pistons slide more smoothly, and the blast wave destroys it, leading to increased wear and deterioration of corrosion resistance.

- The pressure of the blast wave reaches 70 kgf/cm². Such pressure can cause destruction of the elements of the cylinder-piston group.

- Heat transfer to the cooling body is enhanced by blast waves. The engine overheats, the pistons crack, the head gasket fails, and the spark plugs fail.

If detonation of the VAZ 2109 engine has occurred, it must be eliminated, otherwise the service life of the engine and its components will be significantly reduced, and the cost of servicing the vehicle will become higher.

Detonation factors

There can be many reasons for their appearance, but they have one thing in common: the delay in spontaneous combustion of the air-fuel mixture (unburnt fraction) removed from the spark plug electrodes is reduced. If it is simpler, then all the conditions for oxidative processes take place in the combustion chambers. The occurrence of detonation is influenced by:

- Qualitative composition of the combustible mixture. If the air/gasoline ratio = 0.9, the fuel mixture, when entering the combustion chamber, forms pockets in different places. It is in them that oxidative reactions begin to occur, and later they become inflamed.

- Increasing the ignition time leads to the fact that the maximum pressure during combustion of the mixture is observed at the moment when the piston is almost at top dead center. As a result, pressure increases and detonation occurs.

- Too low octane number of gasoline affects the appearance of characteristic knocking sounds. If you fill up with AI-92 gasoline, then when AI-80 gets into the tank, the engine will change, and significantly. To avoid such problems, you need to buy fuel at a trusted gas station. Or option 2. Installing an octane corrector.

- The higher the compression ratio, the higher the octane number of gasoline.

The design features of the engine affect the occurrence of detonation, but to a lesser extent.

Preventing detonation

To avoid the appearance of blast waves in combustion chambers, it is necessary to eliminate all the factors described in the previous section. It is necessary to accelerate the combustion of the fuel mixture and slow down oxidation reactions, which are a source of spontaneous combustion. Explosive waves are detected by a VAZ 2109 knock sensor (injector), which is installed in the engine block between cylinders 2 and 3. This affects the phenomenon of the piezoelectric effect. When it hits an active element (membrane), a certain potential is generated. The stronger the impact, the greater the potential difference (voltage).

The electronic control unit reads the data and compares it with the fuel map (firmware). The readings of other sensors are analyzed in a similar way. As a result, the computer selects the most optimal engine operating mode from the fuel map and transmits signals to the actuators. Ignition timing, injector opening timing, etc. But if there is no knock sensor (on carburetor engines), the crankshaft speed must be increased. The oxidation reaction lasts less, the likelihood of spontaneous combustion decreases.

The VAZ 2109 knock sensor is installed only on injection engines. They are not on the carburetor, so you need to discover this phenomenon yourself. A common malfunction of nine is the appearance of detonation after turning off the ignition. The engine continues to run and the speed may change even if the key is removed. The reason is improper regulation of the quality composition of the fuel mixture. This happens in the following cases:

- Pollution of the energy system.

- Twisting the screw.

- Sensor malfunction (valve on carburetor engines) at idle speed.

On engines with injection, an idle speed regulator is installed, failure of which can cause detonation after shutdown; on carburetor valves, the valve cuts off the flow of gasoline into the combustion chamber at idle.

Engine detonation when the ignition is turned off and after

First, it’s worth understanding what the detonation process is, what signs it is characterized by, and whether there is a normal detonation mode, and if so, within what limits? This process is extremely undesirable, especially during engine operation, since it represents accelerated and uncontrolled combustion of the combustible mixture, which leads to sudden shocks and, accordingly, additional loads on the cylinder-piston group, as well as the crank mechanism.

What about detonation, which occurs when the engine is turned off, in this case we are talking about a situation in which the engine is running after the ignition is turned off. Most often, it lasts no more than a few seconds, but sometimes this time can reach 10-15 seconds. In general, there is no normal detonation mode, and if such a process occurs, then you should contact specialists or try to solve this problem yourself.

Do you want to reduce the consumption of your car? We recommend you a special fuel saver.

What is detonation of an internal combustion engine

Engine detonation is not a pleasant phenomenon. We will look at the causes of detonation at the end of the article, but first let’s understand what detonation is and what happens to the engine when it occurs.

Normal combustion of fuel in a cylinder is a chemical reaction that occurs in a mixture of gasoline vapor and air. In order for the process to begin, it is not enough to simply mix fuel with air in the required proportion; this substance must also be given the necessary energy.

In diesel engines, this creates a very high pressure on the combustible mixture and the temperature at the end of the compression stroke promotes ignition of the fuel. In gasoline engines, the mixture must be ignited with a spark, which is created using a car spark plug. The formed flame spreads from the electrodes of the car spark plug to the walls of the entire combustion chamber.

As long as the flame front moves from the spark plug to the distant zones of the combustion chamber, self-ignition may occur before the fire arrives. Undoubtedly, because of this, a weak shock wave arises, which meets the fuel prepared for ignition on its path.

When compressed, the combustible mixture immediately ignites. Simply put, this wave is detonation, the speed of its propagation in the engine cylinder reaches about 1000 m/s. This is several times faster than an ordinary fire front. You may hear a metallic sound when doing this.

This phenomenon manifests itself, as a rule, at medium and high engine speeds. Light and short-term loads do not have serious harmful effects. In addition, the closer the combustion conditions in the engine are to detonation, the higher its efficiency.

In diesel engines, the compression level is much higher, causing the fuel to heat up to five hundred degrees and self-ignite without the help of a spark. In gasoline engines, the compression level is much lower, and accordingly, the temperature in the cylinders is lower. In addition, the ability of gasoline to spontaneously ignite is lower than that of diesel fuel.

What is detonation?

Self-ignition in the combustion chamber of a combustible mixture, which has the nature of a blast wave, is a detonation process. Most often it appears during a sharp increase in load, for example, when driving uphill or during sudden acceleration. In these situations, the driver, as a rule, greatly increases the pressure on the gas pedal, which ensures that a rich mixture is supplied to the engine cylinders. After entering the cylinders and filling all its volumes with a rich combustible mixture, the action of high temperatures and pressure begins. Two reasons contribute to the creation of high pressure in the combustion chamber:

Engine detonation on VAZ 21093

A loud metallic knock, or “knock of fingers”, and theoretically - detonation, appears as a result of a large number of repeated impacts on the walls of the cylinders of the blast wave.

What can detonation lead to?

It is a mistake to think that increasing the speed at which the flame front propagates leads to a positive effect on increasing engine power. Everything happens exactly the opposite:

Such excess detonation of the VAZ 2109 engine significantly reduces the engine life of the unit, which means the cost of maintaining the car increases. Its consequences are clearly visible in the photo.

What to do if the engine knocks?

Detonation, as a rule, occurs under certain engine operating conditions, characterized by high engine speeds and increased load.

This could be a sudden start from a standstill, driving uphill, driving with a full load, etc.

To combat detonation, modern engines use a special sensor called a knock sensor. It monitors engine operating parameters, and in the event of detonation, changes the engine operating mode by changing the composition of the fuel mixture and ignition timing parameters.

However, if while driving you notice that the engine is knocking, then the first thing you need to do is change your driving style. Pressing the gas pedal as smoothly as possible, try to move off as smoothly as possible, reduce the speed, and climb hills in a lower gear (compared to the normal mode).

At the first opportunity, fill the tank with guaranteed good gasoline, purchased at an official gas station of the same Lukoil or BP. If the detonation does not stop, then go to a service center for diagnostics.

Why does the engine not stall after stopping it?

Although glow ignition is not fuel detonation, the appearance of a short circuit is often a consequence of engine detonation and the result of overheating of the power unit. The engine continues to run after the ignition is turned off for two main reasons:

- one of them is the so-called dieseling;

- the other acts as a short circuit (glow ignition);

Note that many car enthusiasts mistakenly confuse the concepts of glow ignition, diesel ignition and detonation. If the engine continues to operate after the ignition is turned off, the cause may be either a short circuit or diesel leakage. This phenomenon is somewhat different in nature from glow ignition, although it has similar symptoms.

Malfunctions of systems for cutting off fuel supply

To neutralize the effect when the engine does not stall after turning off the ignition, special devices are installed on carburetor cars. Such solutions are solenoid valves in the idle system, which turn off the gasoline supply.

Further development of the system led to the appearance of forced idle economizers on cars with a carburetor. The solution was created to save fuel, which is achieved by turning off the supply of the fuel-air mixture at the moment when engine braking occurs. This valve also shuts off the mixture supply after the ignition is turned off, which prevents further operation of the power unit as a result of self-ignition of the fuel. If such a system is installed on a car and the engine is running after the ignition is turned off, diagnostics of the economizer will be required. The EPH valve may jam, there may be a diaphragm rupture, etc.

This setting involves reducing the volume of the supplied mixture, as a result of which the temperature and pressure in the cylinders will decrease. When taking into account the use of the appropriate brand of gasoline, self-ignition of the mixture is excluded.

Spontaneous combustion of fuel and carbon deposits

One of the consequences of detonation and prolonged driving on low-octane fuel is increased carbon formation in the combustion chamber. A heavy layer of carbon deposits can cause a glow effect. In such conditions, the engine continues to operate even after the ignition is turned off.

This occurs due to the fact that ignition of the fuel mixture does not occur as a result of the formation of a spark, but from contact with the hot electrodes of the spark plug. The effect of spontaneous ignition as a result of smoldering carbon deposits or contact with a hot exhaust valve head is also possible.

To remove carbon deposits without serious intervention, various fuel additives are actively used, which are added directly to the fuel. Additionally, you can “clean” the engine by driving for 5-10 minutes in high gear and maximum speed. Note that these solutions are effective only under the condition of mild forms of coking. For more serious contamination of the combustion chamber, it is necessary to use the method of decoking the engine using active reagents or disassemble the internal combustion engine for mechanical cleaning.

Glow ignition and spark plugs

Often a short circuit occurs as a result of excessive heating of the spark plug insulator or electrode. The temperature of these elements directly depends on the surface size of the spark plug insulator skirt. A large surface area will mean that such candles are “hot”.

Highly accelerated units (atmospheric, low-volume with high power or equipped with turbocharging), as well as engines with high operating temperatures, require the installation of so-called “cold” spark plugs. Let us add that in order to prevent the occurrence of glow ignition and normal operation of the internal combustion engine, it is imperative to install spark plugs, the heat rating of which is recommended by the manufacturer for installation on a specific type of engine.

Other causes of short circuits

Intervention in the design (engine tuning) or repair work may be a reason that affects the glow ignition. Most often, a short circuit occurs as a result of an upward change in the compression ratio. An increase in the compression ratio may occur after an engine overhaul. Boring of cylinders, milling of the adjacent plane of the cylinder head and other manipulations can lead to an actual increase in the compression ratio, short circuit on a running engine and dieseling after it is stopped.

Purpose of the knock sensor

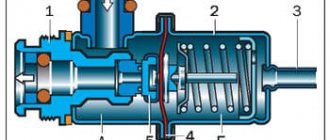

The VAZ 2109 car uses two types of knock sensors, depending on the controller used and the year of manufacture of the vehicle. Earlier vehicles used a single-prong resonant meter.

Later on the VAZ 2109 they began to install a broadband DD injector. Despite the difference in design and operating principle, the sensors serve the same purpose: to promptly detect the occurrence of detonation.

The wideband knock sensor is designed in the shape of a torus. In its center there is a mounting hole through which a pin passes. There is a terminal block on the side of the meter. It is designed to connect the sensor to the engine control unit.

The resonant sensor has a thread on one side, thanks to which it is screwed into the hole for the pin. Therefore, this type of meter does not require additional fasteners.

Design of broadband and resonant DD sensors

Both knock sensors have a sensing element inside the housing that generates voltage when exposed to vibration. A resonant DD is capable of operating in a narrow range. Broadband picks up vibration during the entire operation of the power unit.

The ECU receives a signal from the DD. The module analyzes the incoming voltage, namely its amplitude and frequency. When a deviation from the specified range is detected, the ECU understands that detonation has occurred. In this case, according to a pre-established algorithm, the operation of the engine is adjusted and the non-optimal combustion of the air-fuel mixture goes away.

Eliminating detonation combustion allows you to reduce the load on the engine, which increases its service life. Therefore, the main purpose of DD is considered to be to extend engine life through timely detection of detonation.

Why do my fingers knock in the engine when accelerating? Let's understand the problem"

Why do my fingers knock in the engine when accelerating? Let's understand the problem Why do the fingers knock in the engine during acceleration?

To answer this question, you need to understand why this phenomenon occurs. In normal conditions, ignition of the combustible mixture occurs evenly. Explosive combustion of fuel begins near the spark plug and simultaneously spreads in different directions. The explosion propagation speed is about 20-30 m/sec. In the event of detonation, the over-enriched mixture begins to explode immediately after entering the combustion chamber. The blast wave moves chaotically, colliding with the walls of the cylinder, the remainder of the mixture explodes. The wave speed can reach 1000 m/sec.

Consequences

. As we have already found out, detonation is essentially uncontrolled combustion of fuel. At the same time, the cylinder walls heat up unevenly; in places where the blast wave hits, the temperature rises significantly. This can lead to deformation of the cylinder block. The piston may also overheat and become deformed. A blast wave under certain conditions can damage the valves. It can also damage the connecting rods. In any case, systematic and severe detonation will lead to the need for major engine repairs.

This phenomenon can be caused by a large number of factors. They have varying degrees of danger. Sometimes, a small detonation is quite acceptable. All possible options for the occurrence of this phenomenon will be discussed below.

The most harmless is detonation, which occurs with a sharp increase in speed. If you sharply press the gas pedal at 1000 rpm, accelerating the operation of the power unit to 4000-5000 rpm, you can hear a short-term detonation. This is quite a common occurrence. There is no need to be afraid of this; in this case, detonation will not lead to dire consequences. The reason is a sharp increase in the fuel supplied to the engine; the amount of air initially remains at the same level, this causes premature oxidation of the fuel, which is accompanied by explosions. The only way to combat this phenomenon is to avoid a sharp increase in speed.

But sometimes detonation can appear during normal operation of the power unit. In such cases, it is necessary to identify and eliminate the malfunction as quickly as possible. Otherwise, it will lead to engine repair. So, detonation may have the following reasons:

- Incorrectly set ignition timing. As this indicator increases, the point with maximum pressure during fuel combustion shifts to TDC. Because of this, increased pressure occurs in the cylinder, and accordingly appears. If you experience unexplained knocking noises, be sure to check that the ignition is working correctly;

Error in operation. If the fuel consumption sensor fails, the on-board computer may give erroneous commands. As a result, the engine begins not only to twitch, but also to detonate;

Almost all modern cars are equipped with a knock damping sensor. If you observe the phenomenon regularly, then check the condition of this small device. If necessary, you need to replace it;

Low octane number. Each car has its own compression ratio; accordingly, this indicator is calculated based on the fuel that will be used in the engine. The higher the compression ratio, the higher the octane number should be. If you fill the tank with fuel with a lower rating, an uncontrollable reaction will occur in the cylinder. If, in order to save money, you have filled with lower quality gasoline, then it is advisable to drain it and fill with fuel with a suitable octane number. Sometimes, a similar phenomenon may occur.

How to prevent engine detonation

In contrast to the factors that contribute to the occurrence of detonation, there are also factors that create obstacles to its occurrence. They, most often, accelerate the combustion of the unburnt amount of the combustible mixture in the entire flame front, which comes from the ignition spark, or slow down the process of oxidative reactions, which is the source of self-ignition. The instructions indicate that such factors may be:

- Increasing the speed of the power unit. This leads to a decrease in the time of oxidation reactions, which reduces the likelihood of spontaneous combustion.

- Creating turbulence or rotation of mixture flows in the combustion chamber. At the same time, the propagation of the flame front from the ignition spark is accelerated, which prevents the occurrence of detonation.

- Reducing the path for the flame front to pass. This is due to a change in the design of the unit. The modification is expressed in installing two spark plugs on one cylinder or reducing the diameter of the cylinders.

Why is detonation really so bad?

The inner surface of the cylinder is always protected by a layer of oil. The blast wave generated during detonation can destroy the oil film. And this is already a phenomenon, that is, “erasing” the oil in any case leads to overheating. And then the metal is destroyed under the influence of the following factors: heating, increased shock loads.

Now let's see which parts suffer more from detonation. Their list is small:

- Gasket between the engine block and the cylinder head;

- Piston edges;

- Spark plug housing.

It seems that detonation, even if it occurs periodically, cannot destroy the piston. But this opinion is easy to refute:

The nature of destruction on the pistons is very important

If it’s the edge that’s been “blown away,” we see the result of detonation. Here's what can happen to the cylinder head gasket:

Such destruction can be detected by measuring pressure

In general, the list can be continued. Let's move on to watching the video.

Adjusting the ignition by light bulb

If the strobe light does not turn on or you simply do not have one, then a malfunction of the switch or other element that led to the need for adjustment can be solved using a light bulb. By the way, switch malfunction is a problem for many. So, to set the spark moment on the module you will need a regular 12 volt lamp. The procedure itself consists of setting the module torque by loosening the spark regulator lock.

The procedure is carried out as follows:

- To correctly set the spark torque on an internal combustion engine module with a carburetor, using a special key, you need to turn the crankshaft until the marks match. If you don’t have such a key (you need a special key), then put the car in fourth gear and move it until these marks coincide.

- You need to connect the prepared lamp to the wire that connects the distributor to the coil. Using the second wire, you need to connect the lamp to ground.

- Now you can connect the central cable to the vehicle ground, that is, to the car body. You should loosen the fixing screws on the distributor body, and then activate the ignition - if there are no problems, the lamp will light up.

- Next, in order to correctly set the spark on the module, you should rotate the housing to the right until the lamp goes out. When the lamp goes out, start turning the distributor to the left. You only need to stop when the light comes on. Try not to move the devices anymore, just tighten the case screws. The spark adjustment circuit on the carburetor using a lamp allows you to solve the problem of adjustment yourself, and you will not need to spend money on a device. In principle, any motorist can cope with such a task (the author of the video is Nail Poroshin).

How to remove detonation and prevention methods

The choice of method for eliminating detonation depends on the reason that caused this process. In some cases, to get rid of it you have to perform two or more actions. In general, methods to combat detonation are:

- Use fuel with parameters recommended by the car manufacturer. In particular, this applies to the octane number (it cannot be underestimated). It is necessary to refuel at proven gas stations and not fill the tank with any surrogate. By the way, even some high-octane gasolines contain gas (propane or other) that unscrupulous manufacturers pump into it. This increases its octane number, but not for long, so try to pour high-quality fuel into the tank of your car.

- Set the ignition later. According to statistics, ignition problems are most often the cause of detonation.

- Perform decoking, clean the engine, that is, make the volume of the combustion chamber normal, without soot and dirt. This can be done independently in a garage, using special decarbonization products.

- Inspect the engine cooling system. In particular, check the condition of the radiator, pipes, and air filter (replace it if necessary). Also, do not forget to check the antifreeze level and its condition (if it has not been changed for a long time, then it is better to change it).

- For diesel engines, the fuel injection timing must be set correctly.

- Operate the car correctly, do not drive in high gears at low speed, do not reflash the ECU in order to save fuel.

As preventive measures, it can be advised to monitor the condition of the engine, periodically clean it, change the oil on time, perform decarbonization, and prevent overheating. Similarly, maintain the cooling system and its elements in good condition, change the filter and antifreeze on time. Another trick is that periodically you need to let the engine run at higher speeds (but without fanaticism!), This needs to be done in neutral gear. At the same time, under the influence of high temperature and load, various elements of dirt and debris fly out of the engine, that is, it is cleaned.

Detonation usually occurs when the engine is hot. In addition, it is more likely on engines that are operated at minimal loads. This is due to the fact that they have a lot of carbon deposits on their pistons and cylinder walls with all the ensuing consequences. And usually the engine knocks at low speeds. Therefore, try to operate the engine at medium speeds and with medium loads.

Separately, it is worth mentioning the knock sensor. The principle of its operation is based on the use of a piezoelectric element, which converts the mechanical effect on it into electric current. Therefore, checking its operation is quite simple.

The first method is using a multimeter operating in electrical resistance measurement mode. To do this, you need to disconnect the chip from the sensor and connect the multimeter probes instead

The value of its resistance will be visible on the device screen (in this case the value itself is not important)

Next, use a wrench or other heavy object to hit the DD fastening bolt (however, be careful not to overdo it!). If the sensor is working properly, it will perceive the impact as detonation and change its resistance, which can be judged by the readings of the device

After a couple of seconds, the resistance value should return to its original position. If this does not happen, the sensor is faulty

If the sensor is working properly, it will perceive the impact as detonation and change its resistance, which can be judged by the readings of the device. After a couple of seconds, the resistance value should return to its original position. If this does not happen, the sensor is faulty.

The second verification method is simpler. To do this, you need to start the engine and set its speed to somewhere around 2000 rpm. Open the hood and use the same key or a small hammer to hit the sensor mount. A working sensor should perceive this as detonation and report this to the ECU. The control unit will then give a command to reduce engine speed, which can be clearly heard by ear. Likewise, if this does not happen, the sensor is faulty. This unit cannot be repaired, and it only needs to be replaced entirely, fortunately, it is inexpensive

Please note that when installing a new sensor into its seat, it is necessary to ensure good contact between the sensor itself and its system. Otherwise it will not work correctly

Source

Device and location

The knock sensor is enclosed in a housing, inside of which there is a plate - a piezoceramic element. This element is characterized by certain properties called the piezoelectric effect. Plus there is a resistor in the case. The power supply is connected to the sensor externally.

The device is located in the front part of the cylinder block of the VAZ 2109 power unit. It can be broadband or resonant. The first is located on a stud, secured with a nut size 22. The resonant type of sensor is screwed into the hole located under the stud.

Location

Can a car engine detonate when turned off: let’s understand the aspects

It is wrong to classify uneven engine operation or any other knocking as a sign of detonation. To avoid mistakes, the best option would be to find out what the detonation mode sounds like in practice. For example, watch thematic video files.

Dieseling

As already noted, an undesirable phenomenon can appear exclusively on a functioning motor. How then to qualify the operation of the power plant with the ignition off? The mechanics' answer is short - dieseling. Its nature is different: self-ignition of gasoline, identical to the working process of a diesel engine.

Beginners who have caught up on their knowledge base on gasoline internal combustion engines will immediately object, citing a couple of arguments “against”: high-octane fuel has poor self-ignition ability, and the compression ratio in a gasoline engine is lower. All this is true, but when the unit is stopped, favorable conditions are created for dieseling.

- Fuel supply to the cylinders.

- Low crankshaft speed.

In reality the process looks like this. The power plant is turned off, the crankshaft rotation speed drops, fuel is supplied. The time allotted for ignition of the mixture increases.

Under such conditions, a spark from a spark plug is not needed to ignite the fuel - a gradual increase in pressure and temperature is sufficient. After completing the power stroke, the crankshaft speed increases, and self-ignition does not occur. Then the frequency drops again and dieseling occurs again. And so on for several cycles of “twitching”.

Harm or benefit

Unlike knocking when rocking the steering wheel, there is nothing dangerous about the engine running unstably after being de-energized. On the contrary, the presence of this effect indirectly confirms the good tightness of the combustion chamber, which indicates the general serviceability of the internal combustion engine. This phenomenon can only occur on carburetor engines, because on injection power plants the fuel supply stops when the ignition is turned off.

Hence the conclusion - the absence of twitching after stopping the unit is not at all a sign of poor condition. By the way, a properly tuned and well-maintained carburetor protects the engine from diesel build-up. This is realized using the electromagnetic valve of the EPH system, which, in good condition, shuts off the supply of fuel to the cylinders when the internal combustion engine is turned off.

Isn't this a glow ignition?

Experienced drivers often replace the concept of diesel engine with glow ignition (KI), which is fundamentally considered incorrect. Elementary differences are revealed by the definition of a short circuit - this is the ignition of the fuel-air mixture from a heated source, which can be:

- Overheated spark plug surface.

- Exhaust valve.

- Nagar.

As has already been determined, the engine shows signs of detonation during shutdown due to self-ignition of the fuel assembly during its compression (the spark plug is de-energized).

Glow ignition implies the presence of deviations precisely when the spark plug is working: heated surfaces or a layer of carbon deposits ignite the mixture earlier than necessary. The consequences of a short circuit are dangerous. It may cause:

- Melting of candles.

- Overheating of pistons.

- Valves melting.

It is noteworthy that the “glow” motors operate stably throughout the entire operating speed range. Stability is explained by the fact that the temperature of a heated source continues to increase and maintain.

Cause of engine detonation after turning off the ignition

Spontaneous outbreaks of a combustible mixture in combustion chambers

The process we call detonation is the uncontrolled active combustion of fuel both while the engine is running and after it is stopped.

If in normal mode the air-fuel mixture can burn and propagate the flame front at a speed of 25 to 30 m/s , then during the detonation process the front propagates at a speed 10–15 times faster. And this looks more like a destructive explosion. However, detonation is often confused with glow ignition.

Cause of engine detonation after turning off the ignition

Glow ignition occurs as a result of overheating of combustion chamber parts , mainly coke and carbon deposits on the piston bottom, spark plugs and the chamber itself. The process occurs as follows: we turn off the ignition, but the crankshaft, by inertia, continues to move the piston down, sucking in the fuel-air mixture. It ignites not from the sparking of a candle, but from the temperature of overheated parts. Thus, the combustion process can continue for several more seconds, sometimes up to 10–12 .

Glow ignition, or is it detonation?

The causes of glow ignition can be:

- In carburetor engines, the fuel supply must be shut off immediately after the ignition is turned off using a forced idle economizer. This may be the reason for the abnormal supply of the fuel-air mixture due to the valve stem jamming. This happens because the rod may wear out or become coked. As a rule, the problem is eliminated by cleaning the forced idle economizer valve and replacing it.

- In engines with an injector, the entire power system is controlled electronically, so the reason must be sought first of all in the malfunction of the idle speed sensors and the electronic engine control unit.

- In diesel engines, the cause of hot ignition may be a malfunction of the injectors, the high-pressure fuel pump, which also supplies diesel fuel to the combustion chamber. In diesel engines, this can often occur due to a change in the compression ratio as a result of significant carbon deposits, and in this case, indeed, it is worth talking about detonation rather than glow ignition.