Technical characteristics of the ZMZ 511 engine

The technical characteristics of the ZMZ 511 engine are given in the table.

| Parameter | Meaning |

| Cylinders | eight pieces |

| Diameter in millimeters | 92 |

| Piston stroke in millimeters | 80 |

| Compression | 7,6 |

| Horsepower | 125 |

| Torque | 294 Nm |

| Nutrition | Carburetor K 135 |

| Fuel | AI 80 |

| Ecoclass | Euro 0 |

| Weight | 262 kg |

| Life resource | 250 thousand km |

Attention! The manufacturer stated that the engine will be able to travel 250,000 kilometers without major repairs. However, in practice it has been found that the engine can run longer if you take care of it and do preventive maintenance on time.

How to install the ZMZ 511 engine on gas 24

winter » 24 Jan 2012 21:05

Re: Give ZMZ 511 to GAZ-24!

Bulbash » 24 Jan 2012 21:26

Re: Give ZMZ 511 to GAZ-24!

Bulbash » 24 Jan 2012 21:46

Re: Give ZMZ 511 to GAZ-24!

secret sunshine » Jan 24, 2012 10:23 pm

Re: Give ZMZ 511 to GAZ-24!

serg6033 » Jan 24, 2012 10:29 pm

Re: Give ZMZ 511 to GAZ-24!

Vadim777 » 24 Jan 2012 23:53

Re: Give ZMZ 511 to GAZ-24!

Artefact » 24 Jan 2012 23:56

Re: Give ZMZ 511 to GAZ-24!

Deutschcpu » 25 Jan 2012 13:06

Began . Again, 8 pages about nothing, and MadMax is the hero of the day. Does anyone even know that a cargo block climbs into the Volga without cutting off the jibs? Does anyone know that "vegetable" 125hp. at 3200 rpm they turn into 180-190 forces at 4500 and into 215-225 forces at 5500-6000, if you just cut off 2 mm from the heads and remove the rev limiter from the original carburetor. Does anyone know that these engines have an intake seat diameter of 42, and the channel in the cylinder head at the narrowest point is 34 mm (there is too much metal near the valve guide) and if the channels are made at least 40 mm, then the engine will immediately have the potential of 300+ forces .

“ZMZ-511” and “ZMZ-513”: briefly about the main thing

The first production engines of the Zavolzhsky Motor Plant of the 500 series appeared in the late 80s. The 3M3-511 engines for the GAZ-ZZ07 family trucks were developed on the basis of the 3M3-5Z, and the 3M3-51Z engines for the GA3-66 all-wheel drive trucks and PAZ buses were developed on the basis "3M3-66". The 511th and 513th engines have a fundamentally identical design and very similar technical characteristics.

“3M3-511” is a gasoline carburetor eight-cylinder V-shaped engine with cylinders installed at an angle of 90 degrees and an overhead valve arrangement. The working volume of the power unit is 4.254 liters. Its power is 125 horsepower, or 92 kW (at 3.4 thousand rpm). The compression ratio is 7.6. According to modern classification, this engine has an environmental class of “Euro-0”.

The 3M3-51Z engine has the same characteristics, but it has a reinforced design for operation in more difficult conditions. The differences between the 3M3-51Z and 3M3-511 engines are a different configuration of the oil pan, as well as the presence of shielding of the ignition system. The weight of the 3M3-511 motor is 262 kg, the 513th motor is 275 kilograms. Both of these power units are equipped with a clutch housing for the same unified GAZ gearbox.

The “3M3-511” (“-51Z”) engine runs on low-octane gasoline A-76 (currently branded A-80). These engines are suitable for adaptation to operation on gas, when installing a set of gas-cylinder equipment.

General information and consumer reviews

The ZMZ-511 engine is a carburetor V-shaped gasoline engine, which has eight cylinders, has a volume of 4.25 liters, and a power of one hundred and twenty-five horsepower. The power unit complies with the Euro 0 environmental standard, weighs 262 kilograms, and has a speed of three and a half thousand rotations per minute.

As user reviews confirm, the unit has good boosting potential. In this regard, many craftsmen, after modification, install it not only on trucks, but also on Volga-type cars, as well as on boats and other vehicles.

Modification "ZMZ-511.10"

In the 511th (and 51Zth too) engines, in the “3M3-511.10” modification, the following technical changes were implemented:

- cylinder heads with highly turbulent combustion chambers and helical intake ports are installed;

- an exhaust gas recirculation system was used to reduce harmful emissions into the air;

- the phases and location of the camshaft cams were changed;

- the clutch driven disc has been strengthened;

- The upper compression piston rings began to be made from more durable and high-quality cast iron of a different brand.

Device and equipment

The simplicity of the ZMZ-511 engine design determines its practicality and reliability. The installation is based on an aluminum block on which a pair of cylinder head with a camber angle of ninety degrees is mounted. The frame houses a camshaft with cams, the force from which is transmitted to the valves through a special rod.

The collector is installed between the heads. It houses a carburetor, an oil filter element and auxiliary components (ventilation system, recirculation unit and other elements). The outer surface of the heads is equipped with intake manifolds. At the top of the engine there is a distributor connected by a common adapter from the oil pump to the camshaft. In the rear compartment of the unit there is the oil pump itself, which is aggregated with the fan and generator, as well as a V-belt drive that interacts with the crankshaft gear.

Customer reviews and ratings:

The rating is calculated as the average of all customer ratings for all time

You can leave your review on the website:

WE WILL CHOOSE and SEND by transport company taking into account the delivery time and cost acceptable to you

WE WILL DELIVER the spare part to the terminal for FREE (regardless of its weight and cost), you will only pay for the delivery services of the transport company

Delivery is carried out by logistics companies:

We always try to keep the prices on the website up to date, but sometimes they may differ from the actual prices. Please check the exact cost with the manager .

Design features and equipment of the ZMZ-511 engine

Structurally, the power unit of this brand is designed quite simply, which has a positive effect on its reliability and durability. The basis of the 3M3-511 engine is an aluminum alloy block on which two cylinder heads are installed with a camber angle of 90 degrees. At the base of this V, formed by two cylinder heads, is a single camshaft. The force from its cams to the valves, which are installed in the upper part of the heads, is transmitted through the rods.

Between the heads there is an intake gas pipeline (manifold), on which a carburetor, an oil filter and several auxiliary components are mounted (in particular, the crankcase ventilation system, the exhaust gas recirculation system). Exhaust manifolds are installed on the outside of the heads.

On top of the power unit there is a distributor, which has a common drive from the camshaft with the oil pump. An oil pump is mounted on the rear of the 3M3-511 engine (two-section - on engines produced before 2005, single-section - in later years of production). On the front of the engine there is a water pump, which is integrated with the fan, as well as a generator. The pump and generator are driven by a V-belt drive from the crankshaft. The camshaft is driven by a gear transmission from the crankshaft.

Description of the motor device

ZMZ 511 is an eight-cylinder engine with a power supply system not based on an injector, but on a carburetor. The power device includes a cylinder block, the latter are installed at an angle of ninety degrees. Unfortunately, according to modern qualifications, the engine belongs to motors with environmental standards 0.

Let's look at what's happening inside the business center.

Cylinder assembly

The cylinder head of the ZMZ 511 engine has powerful combustion chambers. Equipped with screw inlet channels. Engineers have developed a special system for removing exhaust gases.

The BC itself is made of aluminum alloy. Major repairs of the block are impossible due to the fact that the cylinders cannot be bored. The metal is soft and quickly deteriorates.

At the base of the V-shaped cylinders is the camshaft. The BC itself is covered with resin, which ensures its tightness. Additionally, the engineers provided three stiffening ribs. And inside of which there is a place for the crankshaft.

Similar article The principle of operation and design of a diesel engine

The water jacket, which is located around the cylinders, creates an excellent cooling system that does not fail the engine even in the hottest regions. Experienced mechanics classify cylinder liners as the wet type. Made from alloy cast iron, which is wear-resistant.

These sleeves are bottom-locking. This means that they are pressed from above by the cylinder head. The bottom is additionally sealed with copper rings. To make the BC more rigid, engineers positioned its lower part seventy-five millimeters below the axis of the crankshaft.

The clutch housing is attached to the block at the rear. All elements that attach these two devices to each other are processed strictly individually. This means that no other pallet will fit unless it is under-engineered. It is secured with pins, just like the lubricant tray.

The valve seats are plug-in and cast from cast iron. And their bushings are made of metal-ceramics. The valve spring and rocker arms are placed at the top. These devices are closed in the ZMZ 511 engine with covers.

The mass of the BC is equal to forty-four kilograms. And the run-up between the cylinders does not exceed 123 mm.

Piston part and crankshaft

The crankshaft of the motor is completely cast. Counterweights are installed on it. Made from cast iron, which is wear-resistant and highly durable. His brand is HF 50.

Attention! In engines produced in the nineties, the crankshaft journals were hardened. After the 2000s they stopped doing this.

The volume dimensions of the main journals are seventy millimeters, and the connecting rod journals are 60. There are oil seals in front and behind the crankshaft of the ZMZ 511 engine.

- in front there is a self-moving oil seal;

- behind the crankshaft - the oil seal is created on the basis of asbestos cord.

A flywheel is attached to the rear side of the crankshaft, and a camshaft drive gear is installed at the front. The connecting rods, made of high-strength steel, are placed on the shaft.

The V-shaped eight-cylinder engine ZMZ 511 does not differ in valve arrangement from other engines of its contemporaries. The gas distribution mechanism is driven by piston-controlled rocker arms. Installation of such a mechanism is carried out in two-stroke engines. Two pistons move towards each other. One of them opens the inlet windows, and the other opens the outlet windows.

cylinder head

The ZMZ 511 power mechanism uses two cast aluminum cylinder heads. They are made from aluminum alloy. The cylinder head contains improved combustion chambers. They create powerful vortex and mixing of the fuel-air mixture.

Similar article Technical characteristics of the Toyota Estima engine

Ignition

The main ignition element is the tumbler. Driven by the camshaft. There is a common axis with an oil pump. The distributor itself contains eight high-voltage wires. They go to the spark plugs.

And the spark plugs are screwed directly into the cylinder head. To find the distributor, you need to look at the rear of the intake manifold. The element is located next to the carburetor.

The lubrication system of an internal combustion engine consists of a single-section and a two-section pump. The oil pump drive is located at the camshaft; lubricant is taken from the sump using a special oil receiver.

The lubricant is cleaned from dirt from other fuel combustion elements using a special filter device. This filter is installed in front of the carburetor.

Attention! Previously, in ZMZ 511 engines you could find a centrifugal filter device. Replacement devices are currently being manufactured.

The lubricant is supplied through the engine through channels, and from filter to filter through special metal tubes. Many experienced mechanics install a cooling radiator on the ZMZ 511 engine, which cools the lubricant. The engine's resistance to high temperatures increases.

Which cars were equipped with the ZMZ 511 power unit?

Let's look at what vehicles the ZMZ 511 unit was installed on. It can be seen on the following car brands:

- Gazelle;

- UAZ;

- GAZ 53;

- GAZ 3307.

Despite the good reviews about the ZMZ 511 engine, it has a number of disadvantages. And also some engine breakdowns can lead to complete incapacity of the motor in the future. In this case, you will need to replace or swap the engine.

Disadvantages of engine breakdowns and problems

The disadvantages of the GAZ 511 engine include the following frequently occurring malfunctions:

- knocking valves when engine speed increases. This happens due to poor quality fuel being poured into the unit. Experienced mechanics advise using only high-octane fuel. If the valves are knocking, then they need to be replaced, otherwise this will lead to major breakdowns or complete failure of the engine;

- there is not enough pressure in the lubrication system. The problem is a faulty pump. This is also a common malfunction of ZMZ 511 engines. Since car enthusiasts try to save on fuel and lubricants, which leads to disastrous results;

- the engine doesn't pull. The problem comes from the deformation of the intake manifold. Therefore, it is necessary to replace this device. But such a malfunction only occurs on engines that have traveled more than four hundred kilometers. If it happens earlier, then you should watch the temperature of the engine during operation. Overheating can also negatively affect the intake manifold and the engine as a whole. High temperatures often lead to deformation of the cylinder head;

- Lubricant leak at the bottom of the motor. The problem is with the main bearing. On ZMZ 511 engines it often leaks. To correct the problem, the bearing must be replaced. It is better to do this procedure at a service center. It will be necessary to completely remove the protection of the ZMZ 511 engine;

- Lubricant leakage at the top of the motor. The problem is a bad cylinder head gasket. Therefore, during repairs, this gasket must be constantly replaced with a new one. At the same time, it is necessary to inspect the valves for clogging and clean them;

- The temperature of the coolant increases constantly. This means that the thermostat and the coolant circulation pump have failed. Both devices will need to be replaced.

Similar article Technical characteristics of the Mercedes OM 612 engine

Otherwise, judging by the reviews of experienced mechanics and experienced car owners, the ZMZ 511 engine is more than good. It will easily cover more than half a million kilometers if it undergoes regular technical inspection and preventive maintenance once a year with the replacement of consumables - filters, lubricants, coolants.

Information for legal entities

The goods are paid for by bank transfer.

How to get an invoice?

You send us your company details by email, we issue an invoice and draw up an agreement. The contract is signed by both parties and after that the client pays the invoice.

How to pay the bill?

Payment by bank transfer to the company's bank account using the details specified in the invoice. All accounting documents are sent along with the goods. Deferred payment is possible (by agreement with management).

All products in our online store have an extended warranty of 6 months (electronics have an extended warranty of 3 months). The warranty card is sent to the buyer along with the spare part.

What it includes:

Guaranteed replacement of spare parts in case of defects within 6 months

If a manufacturing defect is detected, you can exchange the part under warranty within six months after purchase.

For this:

- You must send the part back to us.

- Immediately after receiving the auto parts, we carry out defect detection of the goods (3-10 days).

- If the defect confirms a manufacturing defect, we will send you a new spare part. Our company will cover the shipping costs for sending the replacement part to you.

- If the defect shows that the spare part was damaged as a result of improper use, we can repair it with your consent at your expense. If we refuse to repair, we will send the part back to you. In this case, the transportation costs for sending the part are borne by you.

repair parts

If a malfunction is detected, you can have the part repaired in our company.

For this:

- Send the part back to us.

- Immediately after receiving the auto parts, we carry out defect detection of the goods (3-10 days).

- After a defect, we can repair the spare part according to our price list with your consent. If we refuse to repair, we will send the part back to you. In this case, the transportation costs for sending the part are borne by you.

Warranty terms and conditions

Leave a request using the feedback form, or call the toll-free number

Get advice from a specialist and discuss the details of your order

Select the delivery method that suits you (by phone)

Choose a convenient payment method and confirm the order (by phone)

Our store service allows you to place an order very quickly and easily!

Consultation and product selection

If you don’t know exactly what auto part you need, you can get advice from our specialist by phone. To do this, leave a request for a free consultation using the button in the header of the site (a specialist will call you back within a few minutes), in addition, you can call the number indicated in the header of the site.

Placing and confirming an order

By going to the card of the selected product, you can place an order by clicking the “buy” button. Placing an order involves filling out the following fields: name, mobile phone number. To quickly order, you can use the call back form by clicking on the red circle with the handset and entering your phone number.

Attention! An incorrect telephone number, inaccurate or incomplete address may result in delays! Please check your personal information carefully when placing an order.

Within an hour after placing your order, our manager will contact you to agree on the order, timing, method and place of delivery.

Fuel system "ZMZ-511"

The fuel system is based on a 2-chamber K-135 carburetor (previously, K-126 carburetors were also used on 3M3-511 (“-513”) engines). The carburetor is installed at the top of the intake manifold. Each of the carburetor chambers supplies the fuel-air mixture to one of the two rows of cylinders. A fine gasoline filter is mounted close to the carburetor. Vacuum is removed from the carburetor for the operation of the distributor and the crankshaft speed limiter. Under the carburetor, in the intake gas pipeline, a vacuum outlet is also provided for the functioning of the crankcase ventilation system.

Fuel and lubrication system

With proper maintenance, a major overhaul of the ZMZ-511 may not be required soon, since the motor has a decent service life. The fuel part is based on the K-135 carburetor. It is located in the upper compartment of the intake gas pipeline. Each working chamber supplies the air-fuel mixture to one row of cylinders. The unit is equipped with vacuum outlets for ventilation and conductive passages.

The lubrication system includes a gear oil pump driven by the camshaft. The liquid is purified through a filter, and supplied through an oil receiver. The power unit has protection against lack of oil. If the pump jams, the pin in the drive is cut off and the motor stalls completely.

Motor oil for ZMZ engines

The engine of the ZMZ 511 series is filled with 10 liters of motor oil. Zavolzhsky Motor Plant has specially developed oil for engines of its own production. The following types of oils have been developed:

- ZMZ-Professional. Semi-synthetic oil with viscosity grade 5W40 and 10W40;

- ZMZ-Master. Semi-synthetic oil 10W40 for all ZMZ engines, except Euro 3 class;

- ZMZ-Original. Mineral oil (15W40 and 10W40); for all ZMZ engines, except Euro 3 class;

- ZMZ-Standard. Mineral oil (10W40 and 20W50); for motors ZMZ-402, ZMZ-511, ZMZ-513, ZMZ-523.

Reviews from motorists and experts

As for the reviews of experienced drivers, many speak positively about this engine. In particular, they note the unpretentiousness of this internal combustion engine and its fairly high service life with proper operation and proper care. ZMZ-513 was boosted many times for use on military equipment. The compression ratio was changed to operate on low octane fuel. All this speaks of the great potential of the Soviet V-8.

Many drivers note that this engine is not without its drawbacks. But it is extremely maintainable. So, if you had all the necessary tools, the problem could be solved in the field on your knees. With modern engines, where electronics are responsible for everything, this approach does not work. In general, the 13th is loved by drivers and many even use it today due to the low cost of maintenance.

Technical specifications in numbers

- Number and arrangement of cylinders: 8, V-shaped.

- Working volume: 4.254 liters.

- Cylinder diameter: 92 mm, piston stroke: 80 mm.

- Compression ratio: 7.6.

- Number of valves per cylinder: 2 (1-inlet; 1-exhaust).

- The operating order of the cylinders is: 1-5-4-2-6-3-7-8.

- Rated engine power: 92 kW, or 125 hp. – at 3400 rpm.

- Maximum torque: 294 N.m, or 30 kgf.m, at a rotation speed of 2-2.5 thousand rpm.

- Minimum specific fuel consumption: 286 g/kWh, or 210 g/l S.h.

- Oil consumption for waste: 0.4% of gasoline consumption.

The engine of the GAZ-3307 and GAZ-53 car and its main parts.

The GAZ-3307 and GAZ-53 are equipped with a ZMZ-53 engine and modifications from the Zavolzhsky Motor Plant. The GAZ-3307 and GAZ-53 engines are V-shaped, eight-cylinder, carburetor, four-stroke. The engine cylinder displacement is 4.25 liters, with a cylinder diameter of 92 mm and a piston stroke of 80 mm. The need to repair the GAZ-3307 and GAZ-53 engine is caused by wear of parts and is determined by checking its technical condition. In some cases, premature repairs may be caused by the breakdown of individual parts due to improper operation or a hidden defect.

The first 2.5 - 5.0 thousand km run-in of engine parts occurs. Further (up to 150-175 thousand km) the wear rate decreases. This is the period of normal operation. Then the wear rate increases again and by about 200 thousand km the gaps between the rubbing parts increase so much that repairs become necessary.

The maximum clearances in the GAZ-3307 and GAZ-53 engines between the main rubbing pairs due to wear are approximately, mm:

- Piston skirt - cylinder liner - 0.250-0.300

- Piston ring - grooves in the piston its height - 0.150

- Piston ring lock - 2,500

- Connecting rod upper head - piston pin - 0.030

- Connecting rod and main bearings - 0.150

- Valve stem - guide - 0.250

- Camshaft journal - bushing in block - 0.150

- Axial play of camshaft and crankshaft - 0.250

Engine parameters of the GAZ-3307 truck.

- Model - ZMZ-511.

- Type - Gasoline, 4-stroke, carburetor, liquid cooling

- Number and arrangement of cylinders - 8, V-shaped

- The operating order of the cylinders is 1-5-4-2-6-3-7-8

- Direction of rotation of the crankshaft - Right

- Cylinder diameter and piston stroke, mm - 92x88

- Working volume, l - 4.67

- Compression ratio - 7.6

- Rated net power, kW (hp), not less than — 87.5(119)

- Maximum net torque, Nm (kg/cm) - 413(42)

- Ventilation system - Closed

Cylinder block and head of the ZMZ engine.

The cylinder block of the ZMZ engine is cast from an aluminum alloy and subjected to heat treatment and impregnation with a special artificial resin, which ensures the tightness of the casting; is a monoblock V-shaped design. The camber angle of the cylindrical part of the block is 90°. The walls of the ZMZ cylinder block form a cylinder water jacket, in the lower part of which there are slots for installing cylinder liners.

Along the contour of the water jacket, the cylinder head mounting studs are screwed into special bosses. To increase the rigidity of the block, its lower plane is located 75 mm below the axis of the crankshaft. In the end walls and three internal partitions of the ZMZ engine cylinder block there are sockets for the main bearings of the crankshaft and camshaft bearings. The lower half of the main bearing housing is made of ductile iron. In addition to the rear main bearing cover, there is an oil seal holder on the rear wall of the block.

The main bearing caps and oil seal holder are bored together with the block, so they are not interchangeable and must be reinstalled after disassembly. Four covers, except for the front one, are identical, so the serial numbers 2, 3 and 4 are printed on the covers. The fifth cover is not numbered. The clutch housing is attached to the rear end of the cylinder block. Precise positioning of the crankcase on the block is ensured by two locating pins. The installation hole and the mating plane on the clutch housing for fastening the gearbox are processed together with the cylinder block when boring the main bearing beds, so moving the crankcases from block to block without special adjustment is unacceptable.

Liners and cylinder head for GAZ-3307 and GAZ-53.

ZMZ cylinder block liners are made of special wear-resistant cast iron. In the upper part of the liner there is a flange for sealing with a head gasket, in the lower part there is a ground belt and a collar for fixation in the cylinder block and sealing. In the lower part the liner is sealed with a copper ring, in the upper part - with a cylinder head gasket. The reliability of this seal depends on the protrusion of the upper flange of the liner above the surface of the cylinder block within 0.02 - 0.30 mm, which is ensured by the precision of manufacturing the block and the liner itself.

According to the diameter of the cylinder, liners are divided into five size groups. The marking is made on the ground belt of the cylinder block liner. Symbol for size groups A, B, C, D and D. The cylinder head of the GAZ-3307 and GAZ-53 engines is cast from aluminum alloy, common to four cylinders of the same row. The valve seats are plug-in, made of special heat-resistant cast iron. The valve guides are made of copper-graphite cermet. Each of the heads is attached to the block with studs, and is fixed with two dowel pins-bushings pressed into the cylinder block.

Flat steel washers are installed under the stud nuts. Between the cylinder heads and the block, the GAZ-3307 and GAZ-53 engines are installed on gaskets made of asbestos cardboard, reinforced with a steel frame and impregnated with graphite. Periodically check the attachment of the cylinder heads to the block and clean the piston bottoms and the surfaces of the combustion chambers from carbon deposits. Tighten the nuts securing the cylinder heads of the GAZ-3307 and GAZ-53 engines.

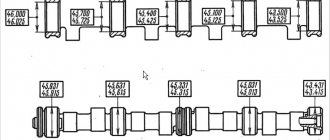

Before doing this, drain the coolant from the cooling system. Then, to eliminate the mutual influence of tightening one head on the other, loosen the fastening of the intake pipe to the cylinder heads. After this, tighten the nuts securing the head to the block with a torque wrench to a torque of 73 - 78 Nm in the sequence shown in Fig. 1.

Fig.1.

The procedure for tightening the nuts securing the cylinder head of the GAZ-3307 and GAZ-53 engines.

It is recommended to perform this operation during the first three technical services; subsequently, the heads should be tightened after each maintenance-2. When using the recommended gasoline and oils and observing the temperature conditions of the engine (the coolant temperature should be maintained within 80 - 90 ° C), carbon deposits are insignificant and do not affect engine operation. If these conditions are violated, a layer of soot may form in the ZMZ engine, causing detonation, a drop in power and an increase in fuel consumption.

Check the working surface of the cylinder block liner, which, as a result of natural wear, acquires a cone shape along its length and an oval shape along its circumference. The wear reaches its greatest value in the upper part of the liner against the upper compression ring, and the smallest in the lower part against the oil scraper ring. Cylinder liner wear of 0.3 mm is the maximum allowable. With heavy wear, the engine smokes, consumes a lot of oil and loses power, and the wear of the crankshaft journals progressively increases.

ZMZ cylinder block liners have the following repair dimensions with a repair interval of 0.5 mm: 92.5 - I; 93.0 - II; 93.5 - III. After repair size III, the sleeve is replaced with a new one. The pusher guides and the need to change them are caused mainly by an increase in the gaps between the pusher and the guide in the block as a result of wear, which leads to a day in this connection. The permissible maximum size of the guides should not exceed a diameter of 25.05 mm. For the GAZ-3307 and GAZ-53 engines, only standard-sized pushers are produced as spare parts, so when the guides wear out, repair bushings are installed in the cylinder block.

Repair bushings are made of aluminum alloy or bronze. Dimensions of the bushings: outer diameter 30 mm, inner diameter (with allowance for reaming after pressing into the block) 24.5+0.1 mm; sleeve length 41 mm. The hole in the ZMZ block for pressing in the bushing is countersunk and then expanded to a diameter of 30+0'03 mm. Before pressing the bushings, the block is heated to a temperature of 90 - 100 °C. After pressing, the bushings are expanded to a diameter of 25+0.023 mm, surface roughness class 8.

Add a comment

Engine ZMZ 5231 10

Modern trucks of the GAZ 3307 brand use a gasoline, or scientifically, carburetor engine. This engine is called ZMZ-5231.10.

The most important difference of this modification is the increase in engine capacity to 4.67 liters. The volume increased due to an increase in the piston stroke from 80 to 88 mm.

The cylinder diameter remained unchanged (92 mm), but a different crankshaft and pistons were installed.

Return to contents

Engine production and application

The plant produced the first gasoline engine, model ZMZ-511, in 1959. The new power unit was supposed to replace the outdated GAZ-51 engine, and at the initial stage of production it was intended to equip the GAZ-53 medium-duty truck, which was produced from 1961 to 1993.

Due to its simple design and high-quality technical parameters, the ZMZ-511 turned out to be a very successful engine and has proven itself well in the installed vehicle. Therefore, the company has prepared several modifications of the engine to equip other vehicles, namely:

- off-road truck GAZ-66;

- small class buses "PAZ";

- SAZ dump trucks;

- middle class buses "KaVZ";

- truck GAZ-3307, which replaced the GAZ-53 model.

The plant is currently producing a modernized version of the engine under the designation ZMZ-511.10.