The Gazelle car first appeared in 1994 and was produced by the Gorky Automobile Plant. The car showed itself well. It was just repaired and turned out to be very reliable. Its only drawback is the engine. Although at the time of release it was still quite competitive, after a few years the question of finding an alternative became serious. In particular, this is confirmed by consumer reviews. The Chrysler engine has been installed in the Gazelle since 2006 and has been very successful.

Technical characteristics of the Chrysler ICE 2.4 liters

A contract was signed with the American one in 2006, which provided for the installation of 2.4-liter engines on cars such as Gazelle, Sobol and Volga 31105. The power of such internal combustion engines was about 137 horsepower, but there were variations of 152 horsepower. With. It became an excellent replacement for the ZMZ-402, which is already obsolete. At the same time, the dimensions of the Chrysler engine were no larger than the 402, and the technical characteristics were an order of magnitude higher. And this despite the fact that Chrysler’s internal combustion engine was also not new. But during operation, it has proven itself to be a reliable motor that can run for quite a long time, subject to proper operation and maintenance.

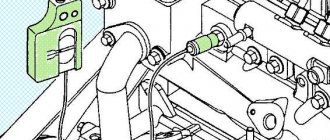

This engine had an injection system and an electronic ignition system. The camshafts were located on top, which greatly simplified maintenance and repair. Among the disadvantages, it is worth highlighting the cylinder head made of aluminum. This metal really does not like overheating, so special attention was paid to cooling the motor.

Chrysler engine

In two thousand and six, a contract was signed with Chrysler at the Gorky Automobile Plant, and American engines with a volume of 2429 cm3 and a capacity of 137 horsepower began to be installed on cars produced by GAZ (Volga 31105, Gazelle, Sobol). This engine was an excellent replacement for the obsolete ZMZ-402 carburetor engine - the American power unit has almost the same dimensions as the Trans-Volga engine. Although by American standards Chrysler is also not new, it is time-tested and has good technical data.

The Chrysler 2.4 L engine diagram is completely simple, the engine has:

- top valve arrangement;

- overhead camshafts;

- timing belt drive;

- liquid cooling (with antifreeze or antifreeze in the radiator);

- electronic ignition system with engine control unit;

- four valves per cylinder (DOHC);

- aluminum cylinder head;

- cast iron cylinder block;

- balancer shafts (2 shafts in one housing), they are driven by a chain drive from the crankshaft;

- distributed injection (fuel injection system).

American engines of 2006-08, installed on the Gazelle, complied with Euro-2 environmental standards, engines of the 2008-2010 model were modified and began to comply with Euro-3 international standards.

Chrysler engine on Gazelle: reviews from owners

The installed power units complied with Euro-2 environmental standards, and were later slightly redesigned for Euro-3. Despite the fact that the engine was not any innovation, it was widely used in cars such as the Gazelle. In particular, reviews indicate the following advantages:

- high reliability of the motor;

- positive dynamics compared to the 402nd internal combustion engine;

- low oil consumption (1.0 liter per 10,000 kilometers);

- The simple design allows for easy maintenance.

In general, the Gazelle with the Chrysler engine has changed somewhat. This primarily concerns dynamics, which have increased significantly. The motor quite adequately accepts the 92nd beznin, which is also a plus. In general, an excellent internal combustion engine, but it also had its problems, which we will talk about a little below.

Oil leak at pressure sensor

Often on this engine it is necessary to replace the oil pressure sensor, which begins to leak. It is located directly under the exhaust manifold, so you can tell that it has started to leak if there is a small puddle of oil under the car. But if you ignore this problem, the oil begins to ooze abundantly, and consumption increases to 1 liter per thousand km. Sometimes a leaking sensor is indicated by a “red oil can” that flashes on the panel for just a couple of seconds. It was experimentally established that the sensors installed on the 1.6 internal combustion engine, which were equipped with the first generation Minis, have an impressive service life and resistance to wear.

Where can I get spare parts?

As noted above, the Gazelle and Chrysler 2.4 engines are very reliable and break down extremely rarely. He really doesn't like overheating, but otherwise everything is fine. But in any case, breakdowns occur. They are associated both with normal wear of the cylinder-piston group and with unexpected malfunctions. It is clear that in such cases it is necessary to repair the engine. Many specialists at that time had already encountered such power units, and were able to carry out repairs efficiently and quickly, but that was not the problem.

The fact is that it was not so easy to find spare parts for this engine. Basically everything was ordered directly from the USA. But in this case, delivery times were significant. Often they ranged from one to 3 months of waiting. Of course, over time the situation became simpler, especially with the advent of such a car as the Volga Cyber, which was also equipped with an American internal combustion engine. Now almost all spare parts are in stock and there is no need to wait for months. The shortage of parts for the motor, as you may have guessed, is the main problem during operation.

Specifications

The Chrysler ICE model EDZ 2.4 was installed on American cars PT Cruiser, Sebring, Dodge Stratus/ Caravan, Jeep Wrangler/ Cherokee, and on a number of other American car models. Chrysler 2.4L internal combustion engine - 16-valve, 4-cylinder, in-line, with a thin-walled cast-iron block, with a dual-mass (damper) flywheel.

The internal combustion engine has the following technical characteristics:

- cylinder volume – 2429 cm?;

- power - 101 kilowatts (137 hp);

- diameter of standard pistons – 87.5 mm;

- location in the engine compartment – longitudinal;

- piston stroke – 101 mm;

- engine type – petrol;

- compression ratio - 9.48;

- weight – 179 kg.

Due to the existing balancer shafts, the engine operates stably at idle, with virtually no vibration. The valve covers are made of plastic, and sixteen hydraulic compensators are installed in the cylinder head. On average, before a major overhaul, a Chrysler 2.4 power unit lasts 300-350 thousand km, but subject to careful operation and timely maintenance.

Briefly about other shortcomings

Nevertheless, installing a Chrysler engine on a Gazelle entailed a large number of alterations. This applies to both the gearbox and hydraulics. But this is only if an American internal combustion engine was installed instead of the ZMZ-402. Chrysler engines were standard on the conveyors. Many owners still noted the high cost of repairs. This is not surprising, because the engine is still imported, although it has been known to everyone for a long time. But here the cost of spare parts had a greater impact than the cost of work at the service station.

High fuel consumption was also noted. But if we compare with the 402, then the appetite can be considered quite moderate for such a working volume. The main problems arose with the clutch, which often broke. It was too weak for a high-speed American engine. We had to change the spark plugs often; this was done approximately once every 30-40 thousand kilometers. Although such an interval can be called quite normal during intensive use. Otherwise, the Chrysler engine on the Gazelle, a photo of which you can see in this article, is used very successfully today.

Chrysler powertrain naming system

Names of Chrysler gasoline engines:

- EZB, EZH;

- E.E.R., E.G.W.;

- EBD, ECB;

- ERB;

- EGA, EGH;

- ECN, ED3.

Names of diesel engines:

- ECD;

- EDJ, EXL.

Engine names begin with the letter E. It is an abbreviation for the English engine - motor. The second letter means family. For single-series engines it will always be the same. The third letter denotes the line of power units in the order in which they arrived on the conveyor.

Similar article Installation of ignition and distributor drive on a 402 UAZ ZMZ engine

2.4 DOCH engine maintenance

The American motor has a very simple design and is not particularly demanding. It was installed on many US cars. For example, Dodge Stratus, Chrysler Sebring, Jeep Wrangel and others. In order for the power unit to run as long as possible, the following requirements must be met:

- change engine oil on time;

- carry out timely replacement of the timing system;

- eliminate possible leaks from under the valve cover;

- monitor the cooling system.

In principle, these measures apply to any existing internal combustion engine. As for changing engine oil, it needs to be changed every 6-10 thousand kilometers, depending on operating conditions. It is not recommended to tighten it, as this significantly reduces the service life of the power unit. It is recommended to replace gas distribution mechanism elements every 100-120 thousand kilometers. Due to the fact that operating conditions in Russia are more severe, it is recommended to reduce the period to 70-80 thousand kilometers, as evidenced by expert reviews. The Chrysler engine on the Gazelle is equipped with a belt drive, so the condition of the timing belt can often be determined visually.

Wear of crankshaft bearings and journals

The Chrysler engine installed in American cars works together with an automatic transmission, but Volga and Gazelle engineers were able to “make friends” with a manual one. And in the first years, they quickly discovered a problem: at about 10 thousand mileage, axial play of the crankshaft appeared, which was accompanied by copious oil drips.

This was due to the fact that the clutch basket exerted excessive axial pressure on the crankshaft, and the American half rings were not designed for this. And the play appeared due to colossal wear. This problem is relevant for domestic cars produced before mid-2007. After which a solution to the problem was found, in particular, the yoke plate was removed from the engines and improved half rings were installed.

Did you need to replace the engine on a Chrysler Neon, Chrysler RT Cruiser, Chrysler Voyager, Dodge Caliber? You can easily find the model you need in our catalog.

And by following these links, you can see which Dodge and Chrysler models are available at our auto dismantling site. You can also order parts from them.

What to do during maintenance

In addition to timely replacement of engine oil, it is strongly recommended to inspect the condition of the air filter every 15,000 kilometers. It would be a good idea to check the compression in the cylinders, as well as conduct computer diagnostics. This will allow you to find errors in electronic systems, if any. You can also use the scanner to look at other characteristics: injector efficiency, ignition timing, etc.

Quite often, oil pressure sensors fail on American-made engines. They may work, but they leak. This, in turn, leads to significant consumption of lubricant, which can result in oil starvation. If this happens and is not noticed in time, the engine may seize, and this is already a full-fledged overhaul. It is also noteworthy that if the timing belt breaks, the valve does not bend, but it is not recommended to check this.

Chrysler engine maintenance

The Chrysler engine is not capricious and is quite easy to maintain; maintenance should be carried out every ten thousand kilometers:

- change engine oil and oil filter;

- carry out an external inspection of the engine compartment for oil leaks on the engine, as well as coolant from the pipes and radiator;

- check the condition of timing parts;

- determine the presence of possible knocks.

According to the manufacturer’s recommendations, replacement of timing parts (belt and tension rollers) should be performed every 70-75 thousand km, but such regulations were established by the Gorky Automobile Plant. In America, it is recommended to replace the timing belt after 120-130 thousand km, and perhaps in Russia a shorter service life is declared due to the more severe operating conditions of Russian cars.

It is recommended to replace the internal combustion engine air filter after 15 thousand km; also during maintenance, compression in the cylinders is measured, and computer diagnostics of the electronic internal combustion engine control system is performed:

- errors are detected if they are present in the electronics;

- parameters are checked - operating coolant temperature, ignition timing, injector performance.

If the engine sensors are faulty, the diagnostic tool (auto scanner, computer device) generates an error, which is determined by the code. If the oil pressure indicator light on the Gazelle instrument cluster lights up while the engine is running, it is necessary to carry out a control pressure measurement with a mechanical pressure gauge.

About the features of operation

They installed the Chrysler engine in the Gazelle from 2006 to 2010. During this period of operation, many motorists and experts gained certain knowledge about the features of the engine. In general, there is nothing new here, since an engine of this type is practically no different from similar ones. The most dangerous thing for a Chrysler engine is overheating. To do this, it is advisable to change the antifreeze in a timely manner. It is recommended to do this every 2 years. The total volume of the system is 10 liters. It is necessary to regularly check the condition of the pipes and thermostat housing for cracks.

Experts note that before each trip you need to look at the oil level on the dipstick and top up if necessary. For a complete replacement, approximately 4.7-4.8 liters are needed; if the crankcase is dry, then about 5.3 liters of lubricant are included. In this case, the quality of the oil is of great importance. It is advisable to pour what is prescribed by the manufacturer or an analogue with the appropriate tolerances. This applies not only to the brand, but also to the viscosity, usually a 5w30 synthetic base.

Features of operating a Gazelle with a Chrysler engine

Chrysler's internal combustion engine is generally no different from standard 4-cylinder gasoline engines installed in modern cars, so nothing new is written in the Gazelle's operating instructions for this engine. In order for Chrysler to work out its assigned resource, it is necessary:

- prevent overheating of the internal combustion engine;

- carry out maintenance in a timely manner;

- Every time before a trip, check the oil level in the oil sump;

- If various kinds of knocking noises appear, carry out engine diagnostics in a workshop and, if necessary, repair the power unit.

If the level of coolant in the expansion tank has decreased, it must be topped up. It is recommended to completely change the antifreeze once every two years or as it becomes dirty; the entire cooling system includes 10 liters of coolant.

To fill a dry oil sump, 5.3 liters of engine oil are required; when changing the oil, 4.8 liters are included in the lubrication system. There are no recommendations on which brand of oil to fill, it is important to use products from well-known manufacturers; it is also necessary that the viscosity of the oil corresponds to the season. Some car owners even add mineral oil, but only change it more often.

Briefly about the renovation

Installing a Chrysler engine on a Gazelle is of course good, but it also needs to be repaired. With proper maintenance and gentle operating conditions, the engine runs about 350,000 kilometers. But if you change the oil at the wrong time, and don’t monitor the condition of the timing belt and cooling system, you will have to deal with capital issues much earlier.

However, there are a number of signs that indicate the need for repair work. Firstly, this is the appearance of various kinds of knocking noises during operation of the power unit. It is also worth paying attention to vibrations that can be caused by faulty ICE mounts or the engine itself.

If the engine has significantly lost its dynamics and is “eating” oil, then you should also prepare for repairs, most likely a major one. But all these signs are very indirect and cannot indicate with 100% probability that the problem is in the motor. Extraneous sounds often appear due to a malfunction of the timing elements, generator or air conditioner, as indicated by reviews. The Chrysler engine in the Gazelle has an extremely reliable crankshaft. The main cause of crankshaft failure is oil starvation and constant driving at high speeds. It has two repair sizes of inserts 0.25 and 0.5 mm. Then just replace it with a new one.

EGR valve

The Chrysler 2.4 engine is equipped with a USR valve, the rod of which is driven by a vacuum actuator. In general, the performance of the valve directly depends on the condition of the vacuum tubes and the membrane in the valve “mushroom”. After about 10-15 years, rubber begins to degrade, which affects the membrane as it loses its elasticity and begins to crack. All this leads to the fact that the valve simply does not open. True, most often the USR valve does not open due to soot deposits, which tightly clogs the valve. The electronic control unit sees that there is no gas flow in the intake manifold. If the flow of gases is constant and strong, but the engine begins to lose traction, noticeable vibrations appear, and in some cases the car refuses to start at all. To solve the problem associated with the EGR valve, it needs to be thoroughly cleaned.

Important Details

On American passenger cars, for which the engine was manufactured, automatic transmissions are mostly installed. The Gazelle has a manual transmission and, accordingly, a dual-mass flywheel. Because of this, the crankshaft half rings wear out greatly. In 80% of cases this was the reason for the failure of the American engine; reviews have repeatedly confirmed this. The Chrysler engine in the Gazelle has proven itself well from a technical point of view. It enjoys great popularity not only because of its unpretentiousness, but also because of its large resource.

Replacing the power unit

The Chrysler engine has a very good service life and is changed quite rarely, but it happens that it completely fails. On the first releases of Chrysler 2.4 2006-07, problems arose with the axial semi-rings of the crankshaft - they wore out intensively from the load. The thing is that this engine is designed to work with an automatic transmission, and on Gazelle with “mechanics” a dual-mass heavy flywheel is installed. When axial play of the crankshaft occurs in the seat of the axle washers, the cylinder block begins to wear out intensively, and it becomes unsuitable for further operation - engine replacement is required.

Subsequently, the problem with wear of the axial half rings was eliminated, and such a defect was encountered very rarely. In some cases, the engine is replaced because it is completely worn out, for example, the shaft is knocking, while the cylinder liners are also worn out. Often, instead of Chrysler, the ZMZ-405 internal combustion engine is installed - this engine is inexpensive and quite reliable, and it has a serious advantage over the American power unit - you can buy spare parts for the 405 in almost any specialized auto store, and their price does not bite.

Related articles:

- Fuel consumption on Gazelle cars On a Gazelle, fuel consumption per 100 kilometers, of course, depends on the type of internal combustion engine, but there are many other factors that affect fuel consumption. What determines fuel consumption, how is it [...]

- Which engine is better for a Gazelle? Gazelle cars have been produced by the Gorky Automobile Plant since 1994. GAZ began production of the second-generation Gazel Next LCV-class car in 2013; the main power unit on the car […]

- Dimensions of Gazelle car bodies Gazelle commercial vehicles at the Gorky Automobile Plant are produced in various bodies - there are flatbed trucks, all kinds of vans, minibuses, cars with standard and extended […]