What is this

Water injection into internal combustion engines is an idea that came to the automotive industry from the aircraft industry. Back during World War II, American and German engineers used the injection of a mixture of water and methanol into fighter engines. This increases the power of the engines in afterburner mode. The development of this idea was buried after the advent of the turbojet era.

In the 80s of the 20th century, technology returned, but in motorsport. Water injection began to be used to improve engine performance in Formula 1 racing cars, and later in the Le Mans endurance race and rally series. However, the design was invariably prohibited by the championship organizers. The idea of injecting water into the engine reached its maximum popularity in the world of drag racing, where there was no serious control on the part of the race organizers.

From that moment on, water injection into the cylinders of piston internal combustion engines became one of the elements of auto tuning. This situation has not been changed even by the advent of intercoolers, which are more efficient than water injection systems into the engine. The latter are still popular because of their low cost, unpretentiousness and ease of installation. However, they are used, as a rule, on highly accelerated engines, especially those equipped with a turbine.

avtoexperts.ru

Sooner or later, in any automotive community, the topic of water injection into the engine usually arises, they say, someone somewhere heard that it increases power and reduces fuel consumption. The topic attracts many, because it seems like manna from heaven - you don’t have to fence the turbines, don’t install nitrogen, but simply inject free water into the engine and it will immediately be transformed. It seems too incredible to be true. But in fact, the “water” issue is still more interesting than it seems at first glance - there is a benefit from injecting water into the engine, but there is no point in installing it. Confused? Let's figure it out.

Water injection into the engine

The fact that adding water to the engine could be a good idea was thought about more than 100 years ago, and not by some garage tuners, but by quite decent factory engineers. True, at first the technology was used by the aircraft engine industry, but the automotive industry also looked at the idea. In the post-war years, there was even a production car in which water injection was implemented at the factory - the Oldsmobile F-85 Jetfire.

1962 Oldsmobile F-85 Jetfire

GM used water to combat detonation. Then Saab worked with this topic for a long time, and not several models at once.

1967 Saab 99 Turbo

Even today, the BMW M4 is produced, in which one of the engines also uses this technology. What can I say, even in Formula 1 in the early 80s, before the introduction of a direct ban, some teams installed similar systems and received an increase in power. If so many smart engineers worked on this topic, does it mean that water injection makes sense?

BMW M4 Coupe with water injection system into the engine

Why does it help?

Yes, it makes sense. This may be difficult for a person far from physics to understand. How is it that the engine runs on gasoline, why does adding water somehow improve its performance? But in fact, everything is logical - water allows you to cool the fuel-air mixture, which in itself is not bad (to compress the cooled mixture you need to spend less energy, which means the engine will transfer more power to the wheels), and when it gets into the cylinder, it also evaporates and slightly increases the compression ratio, which is precisely what gives an increase in power. In addition, water increases the combustion rate, which can significantly reduce detonation. Over the years, engineers have solved different problems using water injection. Before the advent of intercoolers - cooling the mixture, after their appearance - a short-term increase in power, in everyday life - a decrease in the octane number of the fuel.

Oldsmobile F-85 Jetfire engine diagram

The technical implementation of injection can be different, but in the most primitive versions it is very cheap. Any container, a hose from a dropper, a windshield washer motor, a nozzle for spraying into the intake manifold, a simple electrical circuit. But this, of course, is unreliable and risky - a little too much with the water supply and hello, water hammer. Today, injection systems with computer control based on data from a sensor have already been invented; this allows the system to operate stably, but also, of course, increases the cost of installation. Now many companies have started selling ready-made kits - but they cost $800-1000.

Water injection kit for AQUABAST WI-2.0 engine

Why shouldn't you put

After reading the last section, many readers probably had an idea why the water injection system is still not installed on all cars in the world, if it is relatively simple to implement and improves engine performance. And of course there are reasons for this.

Firstly, the presence of water in the mixture worsens emissions, and environmental standards are becoming stricter and stricter; automakers do not want to deal with this problem at all.

Engine water injection system

Secondly, setting up water injection so that it works stably is not an easy task, especially when it comes to injection into the intake manifold. No matter how you position the injector, the filling of different cylinders with water will still be different, and this almost guarantees unstable operation at full power and at low speeds under load. The technology of distributed water injection could theoretically solve this problem, but the cost of the issue is already beginning to affect it - today, for budget cars, even distributed injection of gasoline is too expensive and complicated, let alone water.

Installed system

Thirdly, water for the end consumer is not free. Tap water should not be used for injection into the engine. Or rather, of course, it is possible, but due to salts and additives, the walls of the engine cylinders will be covered with deposits within a couple of thousand kilometers (remember kitchen kettles!), and then there will be trouble with the engine. So, at a minimum, you need distilled water. But in a good way, you need to add methanol to it so that it can be used in winter and the engine runs smoother. That is, in addition to the cost of gasoline, the car owner has a need to buy (well, or make it himself) injection fluid. And this is unlikely to reduce operating costs.

Real example

The economic dubiousness of using water in the mass automotive industry can be seen precisely in the example of BMW. Engineers report that using water, it was possible to increase engine power by 14 hp, while fuel consumption decreased by 8%. The system consumes 1.5 liters of water-methanol mixture per 100 kilometers. The water tank is 7 liters, which means you need to fill it up every 500 kilometers, about the same as gasoline. Yes, the car will work normally without water, but without any increase in power or economy. So we think that the benefit on gasoline is not that big, there is an increase in horsepower, but it’s also not global, and there are a lot of hassles with the system. For a regular car it won't pay off.

Under the hood of the BMW M4 Safety Car with water injection system

But in racing, where “we don’t stand behind the price,” the water injection system is very justified, especially in drag (although there you have to compete with nitrogen), where the resource is not important, the cost of operation is also, and every tenth of a second removed from the result increases the chances to win. However, the same problems that can be solved with the help of water can be solved in other ways, so this is also an optional question.

So it turns out to be a paradox: injecting water into the engine actually improves its performance, but due to a combination of factors, such systems almost never justify themselves, no matter how much some dreamers would like to refuel from the water supply and drive at full power.

Principle of operation

The operating principle of engine injection is based on the operation of a separate nozzle through which water is injected into the engine intake manifold. As a result, the fuel-air mixture (FA) consists not only of gasoline and air, but also water. Since it has a greater heat capacity, the temperature in the engine cylinders decreases, and the temperature of the suspension increases. This mixture has greater density and weight, which allows you to spend less resources on compression.

As a result, the efficiency and output of the engine increases: power increases (up to 20%), torque increases, and detonation decreases. At the same time, due to the use of water, the concentration of harmful substances in the vehicle exhaust is reduced.

The water injection system into fuel also has its disadvantages.

- Almost no engine water injection system allows for uniform distribution of fluid. One or more cylinders receive less water, resulting in a lean mixture. As a result, instability of the engine and a decrease in acceleration speed may be observed when the throttle is fully open. This problem can be solved by using an individual injector for each engine cylinder. However, such a system turns out to be too expensive.

- Only distilled water is suitable for use - ordinary tap water is not suitable. Using ordinary water leads to the formation of salt deposits, which reduces the efficiency of the engine and can contribute to its breakdown.

- Another drawback of the system is the difficulty of using it in Russian conditions. Water simply freezes at subzero temperatures. Therefore, in domestic conditions, water is more often used in combination with alcohol additives, but at low negative temperatures they do not help either. In this case, you have to remove the system from the car.

Why is water injection into the engine needed and how does it work: pros and cons

First, a little history. The very idea of injecting water into a motor is over a hundred years old. This system has found its greatest practical application in aviation in relation to piston aircraft engines.

In the 1940s, German and American pilots, as well as pilots from other countries, actively used water injection to increase the power of their aircraft engines. More precisely, a mixture of water and methanol was injected into the power units.

At the same time, the combustion rate of the mixture itself will slow down, that is, the engine is not at risk of fuel detonation. The temperature in the combustion chamber also decreases. These are the main advantages of the system if it was decided to install water injection into a diesel engine, naturally aspirated gasoline or turbo unit, etc.

The list of minuses also notes the fact that in cold weather it is quite difficult to use this injection system, since the water simply freezes. The use of alcohol additives can solve the problem only with a slight cold snap. With the onset of severe frosts, the entire system must be removed or drained and then turned off.

How to make it yourself

Ready-made installation kits for water injection into the engine are available for sale. However, their cost can be several hundred thousand rubles. Therefore, many car owners prefer to assemble and install homemade systems.

To make water injection into the engine, the car owner will need:

- 12 V electric pump;

- nozzle (jet) for spraying;

- water storage container - a standard washer fluid tank will do;

- salt filter installed on the tank;

- water movement lines - ordinary medical tubes from an IV, for blood transfusion, etc. are suitable.

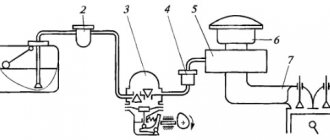

The installation diagram of the water injection system is as follows.

- The tank is installed in the engine compartment in any free space that is suitable in size. A salt filter is installed at the outlet of the tank, which will prevent salt deposits from contaminating the engine.

- A 12-volt electric pump is located inside the car, which will ensure continuous operation of the water supply system.

- The nozzle is installed in the intake manifold behind the injector. The water supply tube is selected according to the size of the nozzle.

- The system is connected to the intake manifold. Holes are made in it, which then need to be sealed.

For factory water supply systems, the electronic control unit is responsible for the volume of incoming liquid. In homemade devices, you have to experiment to achieve the required dosage. The volume of incoming water is regulated by a tube and a nozzle - the doses of water entering the cylinders depend on their sizes. Therefore, tubes and nozzles are selected experimentally.

Ideally, the ratio of water and gasoline should be 1 to 10 - it is with this ratio that the greatest efficiency of the system is achieved. If the dose of water is exceeded, you can experience water hammer in the engine cylinders. Therefore, when setting up the system, you need to start with the minimum possible volumes of water, gradually increasing the dosage. As already mentioned, volume control is achieved by increasing the size of the nozzle and water supply lines.

There is a difference in approaches when installing the system on carburetor and injection cars. Installing the system on a car with carburetor injection is quite simple - you don’t need to use a nozzle. It is replaced by a needle from a regular medical syringe, installed in a tube leading from the electric pump. A needle makes a puncture in the ignition timing regulator tube, after which the needle is secured with sealant.

However, this scheme does not allow for efficient water injection - its dispersion qualities are not high enough, which reduces the efficiency of using the entire system. Therefore, many experts reject this method.

Soothe my sorrows: how water injection increases engine power

For more than a hundred years, automotive engineers have been working to improve engine performance. At first everything was simple: more displacement, more cylinders, more power! But it quickly became clear that replacement for displacement was still necessary: compressors, turbines, more complex timing with multi-valve designs and adjustable phases, distributed and direct injection, lightening the piston group were used... Now that the company is increasingly using internal combustion engines add electric motors, it seems that the limit of boosting a conventional motor has been reached. But no - you forgot about water injection! Let's figure out why this is done and why it is still not used in the mass automotive industry.

When you mention the water injection system into the cylinder, the average person will chuckle skeptically: if the car engine receives a water hammer, nothing good will come of it. But it’s one thing when, when driving through a deep puddle, a large amount of water enters the engine through the intake tract, which the piston tries to compress - this leads to the destruction of the connecting rod and piston group... It’s quite another thing to do a point injection of a special mixture into the combustion chamber.

How it works?

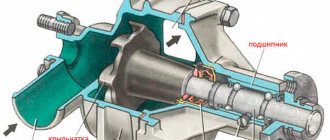

The water injection system is most often used on highly accelerated engines to improve their performance. Where does the extra power come from? There are several variations of the system, differing only in the installation points. To do this, a special nozzle is installed in the intake manifold, supplying a water-methanol mixture into the intake tract, which is mixed with the fuel mixture supplied to the combustion chamber.

Why a mixture of water and alcohol? Firstly, such a liquid freezes at lower temperatures, and secondly, water with alcohol has better dispersion, which is why a more uniform mixture is formed and the temperature in the intake manifold decreases. Due to finely dispersed droplets, the mixture is cooled, which makes it possible to increase the compression ratio and also reduce the combustion rate of the mixture in the cylinders, and this reduces the possibility of detonation. Also, reducing the combustion temperature of the fuel-water mixture affects the chemical processes in the combustion chamber, which reduces the concentration of harmful emissions of nitrogen and carbon dioxide.

Experiments by Russian designers on diesel engines with experimental systems have shown a reduction in nitrogen oxide emissions by three to four times, and CO2 emissions by 1.2 times.

It would seem that there are only advantages! But, like everything in the world, things are not perfect. The concentration of unburned hydrocarbons in the exhaust gases increases, which slightly increases the vehicle's fuel consumption. At low speed or wide open throttle, the engine may run rough.

Tips for use

Several recommendations can be made that, if followed, will improve the efficiency of using the water injection system into the engine.

- Using not just distilled water, but a mixture of it with alcohol in a ratio of 50 to 50 will help increase the efficiency of the system. Methanol burns more slowly than gasoline, which more smoothly increases the pressure in the engine cylinders. The result is a significant increase in torque.

- There is no particular point in installing the system on conventional naturally aspirated cars. Injecting water into the engine increases the efficiency of forced engines; the output is especially high on turbocharged engines. Installing a water injection system on a conventional naturally aspirated engine will only reduce detonation of the fuel-air mixture; in this case, there is no need to wait for a surge of power and torque.

- When installing the system, it is necessary to achieve the best atomization, since a finely dispersed mixture is most effective. Therefore, you need to use a powerful pump and a high-quality sprayer.

Making a water supply system for the engine is quite simple. It is much more difficult to adjust the volume of water so that it does not damage the motor and at the same time gives the desired effect. If there are doubts that it will be possible to accurately adjust the doses of water entering the cylinders, then it is better to purchase a factory kit with a built-in control unit.

Injecting water into the engine: how to do it yourself

The water injection system into the engine is one of the available methods of tuning the power unit. This solution allows you to increase the power, torque and efficiency of the internal combustion engine, increase knock resistance and improve a number of other engine characteristics.

Moreover, such tuning does not imply any major modifications to the power unit in terms of hardware, that is, water injection into an injection engine or carburetor engine can be installed with minimal intervention in the design.

Water injection system

Under such conditions, water is distributed unevenly among the cylinders, which prevents it from working properly;

And a special note about homemade products: water should be supplied to the fuel in a precisely dosed manner. However, it is difficult to manually adjust the desired proportion. And when there is an overflow, the probability of water hammer is quite high. By the way, this is why, immediately after the war, aviators refused to use the idea - the engines flew too often. They returned to it only with the advent of electronics.

Methods for constructing an injection system

Craftsmen have developed two injection methods:

In general, injecting water into an engine with your own hands is relatively easy. The main thing is to calculate the volume of water supplied.