What is engine compression ratio

Conventionally, the amount of compression is also represented as the ratio of pressures in the device during the supply of fuel and the explosion of the mixture. This particular degree is determined by the design of the car engine, and can be high or low.

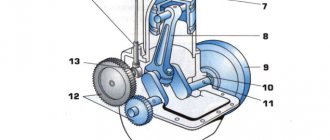

Before the actual process of ignition of the combustible mixture, the pistons compress the fuel to a certain volume. Engineers are able to vary this indicator, calculating it at the design stage. Having learned the quantitative ratio of this value to the volume of the combustion chamber, one can draw various conclusions.

On gasoline power plants, the compression ratio reaches a maximum of 12 units. The higher the engine compression ratio or SSD here, the greater the specific power of the engine. However, with a strong increase in this indicator, the resource of the unit decreases, especially when refueling with low-grade gasoline. On diesel engines, due to their technical differences, it can vary from 14 to 18 units.

In gasoline engines with a compression ratio increased to 12 units, nothing other than AI-98 Premium can be poured. Obviously, this will significantly increase fuel costs.

So compression ratio and compression are the same thing?

As you understand, of course not! The degree of compression is a coefficient that is calculated using volumes, but compression is trivially measured with special pressure gauges (compressometers).

In practical terms, the compression will be slightly greater than the compression ratio (st). For example, with a compression ratio of 9.5, the compression is often from 11 to 12!

Why does this happen? Yes, because when measuring compression, the air-fuel mixture heats up from pressure, causing an increase in temperature.

These indicators could be equal if the process were isothermal (that is, excluding the influence of temperature, both from the outside and from the inside) in a closed, hermetically sealed housing. But since this is not possible in practice, the values will differ.

Now the video version of the article, watch it

This is where I end, I think my article was useful to you, read our AUTOBLOG.

(

19 votes, average: 4.47 out of 5)

Similar news

How to unscrew the oil filter (without using a wrench). What should the EU do?

Boring the cylinder block. Why does the engine need it and can it be done?

To turn over or not to turn over the engine until the cut-off? Is it necessary to do this

Source

What does it affect?

SSD directly determines the amount of work produced by the internal combustion engine. The higher the compression ratio is initially calculated, the more productive the ignition will be. The output of the motor will increase proportionally. Let us remember how developers in the 90s tried to increase this figure without completely modernizing the engine. In this way, they competed with each other, making the units more powerful without spending a lot of money. But what’s most interesting is that the engines in this case did not consume more fuel, and even became more economical.

However, there is a limit to everything, and as mentioned above, too high a coefficient leads to a decrease in the life of the internal combustion engine. Why is this happening? The fact is that with significant compression, the fuel mixture begins to spontaneously detonate and explode. This especially affects gasoline-powered units, so here this coefficient has a strict limitation.

Remember that the use of low-octane fuel causes detonation on units with increased SSD. Conversely, high-octane fuel may not allow the engine to fully open if used in units with a low compression ratio. For this reason, both parameters must match. More details in the table below.

Is it possible to increase the compression ratio?

This procedure is used when tuning a car engine. Boosting is achieved by changing the volume of the incoming portion of fuel. Before carrying out this modernization, it should be taken into account that with an increase in the power of the unit, the load on the parts not only of the internal combustion engine itself, but also of other systems, for example, the transmission and chassis, will increase.

It is worth considering that the procedure is expensive, and in the case of reworking already quite powerful units, the increase in horsepower may be insignificant. Below are several ways to increase the compression ratio in the cylinders.

Cylinder boring

A more favorable time to carry out this procedure is a major overhaul of the engine. The cylinder block will still need to be disassembled, so it will be cheaper to do these two tasks at the same time.

When boring the cylinders, the engine volume will increase, and this will also require the installation of pistons and rings of larger diameter. Some choose repair pistons or rings, but for boosting it is better to use analogues for units with a large volume set at the factory.

Boring must be carried out by a specialist using special equipment. Only in this case is it possible to achieve perfectly identical cylinder sizes.

Refinement of the cylinder head

The second way to increase the compression ratio is to machine the bottom of the cylinder head with a router. In this case, the volume of the cylinders remains the same, but the space above the piston changes. The edge is removed within the limits permitted by the motor design. This procedure should also be performed by a specialist who is already involved in this kind of modification of motors.

In this case, you need to accurately calculate the amount of edge removed, because if you remove too much, the piston will touch the open valve. This, in turn, will negatively affect the operation of the motor, and in some cases, make it completely unusable, which is why you will have to look for a new head.

After modifying the cylinder head, it will be necessary to adjust the operation of the gas distribution mechanism so that it correctly distributes the valve opening phases.

Combustion chamber volume measurement

Before you start boosting the engine using the methods listed above, you need to know exactly what the volume of the combustion chamber is (the space above the piston when the piston has reached top dead center).