Front-wheel drive VAZ cars of the tenth family (VAZ-2110 sedan, VAZ-2111 station wagon and VAZ-2112 hatchback) were equipped with various engines. Among them were carburetor and injection, 8 and 16 valves.

Ignition was also used in two types: from a central distribution module or using independent ignition coils. We present to the reader's attention one of these engines: the VAZ 2112 engine, production began in 1997.

Passport details

Initially, the 12th was produced in 2 versions: 21120 and 21124. The characteristics of the 16-valve VAZ 2112 engine of these modifications are given in the following table.

| Engine model | 21120 | 21124 |

| Type | Gasoline 4-stroke | |

| Configuration | Inline 4-cylinder | |

| Nutrition method | Injection distributed injection | |

| Number of valves | 16 | |

| Working volume, l | 1,488 | 1,596 |

| Productivity, l. With. | 93 | 89 |

| Geometric dimensions Ø × L of the piston, mm | 82×71 | 82×75,6 |

| Compression | 10,5 | 10,3 |

| Maximum torsion moment Mkr, Nm | 140/3800 min-1 | 131/3700 min-1 |

| Toxicity standards | Euro-3 (on later engines - Euro-4) | |

It follows from the table that the technical characteristics of the two versions are quite similar, with the exception of the higher torque of the 120th engine.

Engine VAZ 21127 (21129)

The base engine for new Lada products is Lada Vesta and Lada X-Ray. The VAZ 21127 engine has received virtually no significant changes in terms of its “steel” filling. The main changes affected the intake system and engine management system. Unlike the VAZ 21126, the new engine received an intake receiver with variable geometry, which made it possible to improve the engine’s power parameters due to more efficient air supply: at low speeds, air flows through long channels, and after reaching the bar of 4000 rpm, a short intake tract opens. This made it possible to obtain an increase in torque not only at low speeds, but also to maintain them at high speeds. Stable air intake at idle also had a qualitative effect on the noise level of the new engine, which decreased significantly.

Also, for the first time in mass-produced Lada engine models, the control program is focused not on the mass air flow sensor, but on the absolute pressure sensor. This made it possible to increase reliability, since the mass air flow sensor often failed due to dust falling into its operating area.

These seemingly insignificant changes made it possible to add an additional 8 hp. and 5N/m of torque to the indicator of its predecessor and reach a maximum output power of 106 hp. and 150N/m of torque.

This engine also has the VAZ 21129 index, it has exactly the same technical parameters, the difference is the engine mounting points in the engine compartment. The changes were made to install the engine on the Lada Vesta and Lada X-Ray models.

Power core

The VAZ 2112 engine was not created from scratch. Its design with a 16-valve gas distribution mechanism (GRM) repeats the model 2110, and the cylinder block (BC) is a copy of the “eight” (21083). This can be verified by comparing their geometric parameters: bore diameter and center distances.

True, the blocks are not interchangeable, since they differ in the diameter of the cylinder head (cylinder head) mounting screws. Unlike parts 21083 and 2110, the BC has additional oil channels in the main bearings to supply oil to the lubricating nozzles. Through these devices, additional lubrication of the lower part of the cylinder surfaces is carried out, as well as cooling of the piston bottoms.

Now a little about how the 120th and 124th engines differ from each other. VAZ 21120 contains BC 2112 with a height of 194.8 mm, and 21124 contains BC 11193. The height parameter of the latter is 197.1 mm (the so-called “high” block). The 124th crankshaft has a longer stroke compared to the 12th. For motor 2112, the elbow has a size of 35.5 mm (stroke 71), and for motor 21124 it has a size of 37.8 mm (stroke 75.6). As a result, the working volume of the 124th version is 1.6 liters, versus 1.5 for the 120th.

The pistons also differ from each other. Both have counterbores to ensure the exit of the valve plate. However, on the 120 engine their depth is deceptive. It is designed only for the normal functioning of the timing belt, and in the event of a toothed belt break, the “meeting” of the valves with the pistons becomes inevitable. The 124th drive has everything in order; eliminating the incident will only require replacing the belt without disassembling the power unit.

Replacing the pistons on the 21120 engine with 124s will allow you to avoid the troubles associated with a broken belt. True, the power of the VAZ 2112 engine will be somewhat less.

Engine VAZ 2110, VAZ 2111, VAZ 2112 (Injection)

Longitudinal section of the engine mod. 2110

Cross section of engine mod. 2110

Cross section of engine mod. 2111

Longitudinal section of the engine mod. 2112

Cross section of engine mod. 2112

Above are longitudinal and transverse sections of all engines used on the VAZ-2110. The VAZ-2110 can be equipped with both the 2110 engine and the 2112 engine (16 valves), created on the basis of the VAZ 211083 engines. On some older models, it is possible to install 21083 engines. All these engines run on AI-92 gasoline (16 valves). class on AI-95), according to a four-stroke circuit, in-line, four-cylinder. Engines 2111 and 2112 are injection - with a fuel injection system.

The cylinder block material is high-strength cast iron, very hard.

The cooling is made uniform throughout the entire unit, eliminating uneven heating. The cooling jacket is open at the top towards the block head. At the bottom of the block there are five crankshaft bearing supports, their covers are secured with bolts. The crankshaft is also made of special high-strength cast iron. The connecting rod bearings are lubricated through oil valves that are drilled into the crankshaft. There is a vibration reduction system consisting of eight counterweights located on the crankshaft. In front of the crankshaft there is an oil pump and a timing belt pulley. A cast iron flywheel is installed behind the crankshaft.

Forged steel connecting rods with caps on the lower heads. Thin-walled liners are installed in the lower head of the connecting rod, and a steel-bronze bushing is pressed into the upper head.

The pistons have three rings: 2 for compression and 1 for oil control. Piston material is aluminum alloy. On the piston bottoms there is a recess for the combustion chamber and in the case of the VAZ 2112 engine there are 4 (2 on 2110) recesses for the valves. On a 16-valve engine, the pistons are cooled with oil. There are 4 injectors installed on a special fuel rail, which are small tubes with spring-loaded balls in them. The oil sump is made of steel, stamped, and is attached from below to the cylinder block.

A cylinder head cast from aluminum alloy is installed on top of the cylinder block. At the bottom of the head, channels are cast through which liquid circulates, cooling the combustion chambers. A camshaft is installed in the upper part of the head (engines mod. 2112 have two camshafts: one for the intake valves, the second for the exhaust valves). For 8-valve engines, the camshaft rotates in supports, in the upper part of the cylinder head and in two bearing housings secured with nuts on studs screwed into the cylinder head. For a 16-valve engine, the camshafts are installed in supports, which are made in the upper part of the cylinder head, and in a common bearing housing. The camshafts are cast from cast iron. To reduce their wear, the working surfaces of the cams and the surfaces under the oil seal and eccentric of the fuel pump drive are subjected to heat treatment. Cams The shafts operate the valves through pushers. The engine has mod. 2112 are equipped with hydraulic valve lifters, which do not require adjustment, unlike 8-valve engines.

On 8-valve engines (2110, 2111) there are two valves per cylinder: inlet and exhaust, on 16-valve engines (2112) there are four valves - 2 inlet and 2 exhaust. The guide bushings and valve seats are pressed into the block head.

On 8-valve engines (2110, 2111), two springs are installed on each valve, and on 16-valve engines (2112) - 1. The camshafts are driven by a toothed belt from the crankshaft.

Combined lubrication system: splash and pressure. Main and connecting rod bearings and camshaft bearings are lubricated under pressure. The system consists of an oil sump, gear oil pump with oil receiver, full flow oil filter, oil pressure sensor and oil valves.

The engine cooling system is passive and active. There is a powerful electric fan that turns on at 115 degrees and turns off at 95.

The power system consists of the following components:

- air filter;

- fuel tank;

- fuel pump;

- fuel line;

- 2110 - carburetor and 2112 - fuel rail with injectors and fuel pressure regulator;

- Various sensors on 2112.

The fuel pump for the 2110 engine is located on the cylinder head and is driven by an eccentric on the camshaft through a pusher. 16th grade engines, the fuel pump is electric, immersed in the tank and combined with a fuel level sensor.

The entire electronic system of 8 and 16 valve engines is controlled by a controller (ECU), which also controls the entire engine power system.

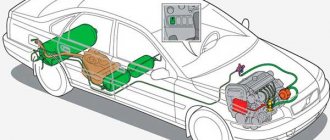

Transmission VAZ 2110, 21102, 2112

Malfunctions of the ignition system of the VAZ 2110. Causes and methods of eliminating them.

We recommend watching:

- General information on engines 2110, 2111 and 2112

- Features of engine assembly VAZ 2112, 21124, 21126

- Features of engine disassembly VAZ 2112, 21124,…

- Troubleshooting the VAZ 2110 engine. Tolerance table

- Repair of cylinder head VAZ-2110, 21102, 21103, 21104

- The procedure for assembling the VAZ 2111 engine

- Installation of fog lights on Lada Vesta

- Malfunctions of engines 2110, 2111 and 2112 and methods...

Other differences

The engines also differ in their “inhalation” design. The 120th intake consists of two aluminum parts: a manifold (“horn”) and a receiver, connected to each other by rubber corrugations. Unit 21124 is “decorated” by an intake system made of plastic and consisting of a single part.

The ignition system is designed differently. The VAZ 2112 is equipped with an ignition distributor module, and on the 21124, individual coils are installed for each cylinder. Due to differences in intake and ignition systems, valve covers also differ.

The 1.6-liter unit has some other differences from its brother: the pressure regulator has been moved from the fuel rail to the pump, the catalyst is located directly at the cylinder head, there are 2 oxygen sensors (Euro-3) instead of one (Euro-2) for the 1.5 liter. The split timing case design makes it easy to replace the timing belt.

People often ask: where is the serial number of the engine on the VAZ 2112? Indeed, the number located under the air filter is quite difficult to detect. It is located at the rear end of the BC, under the thermostat housing. To find the required numbers, you need to release the air filter mount and tilt it slightly to the side.

If corrosion makes it difficult to read the serial designation, you should use fine abrasive sandpaper and then wash the area with WD-40.

History of production of the VAZ 21128 power unit

The production of the domestic VAZ 21128 engine with a volume of 1.8 liters has been carried out by the closed JSC Super-Auto since 2003. This is a small-scale automobile production. Every month, up to 500 brand new cars with a 1.8 liter engine roll off the production lines of the enterprise. Moreover, the joint-stock company is not engaged in the full production process. Cars come from AvtoVAZ. The engine is removed from them, it is disassembled and reassembled with original parts. The ShPG and crankshaft must be replaced. Despite small-scale production, the closed society constantly maintains a tight connection with leading AvtoVAZ engineers. Super-Auto maintains all the quality standards of the German concern Renault-Nissan, which are observed at AvtoVAZ.

The entire automotive production of the company can be divided into two parts. At the beginning of the two thousandth, the reliable VAZ 21124 power unit was taken as the basis for the new engine. To obtain a volume of 1.8 liters, the following were subject to modernization: the ShPG, crankshaft, and cylinder block. The first 21128 engines were installed on VAZ cars of the tenth family. The power of the new power unit exceeded its prototype 124 engine by more than 15 hp, and torque also increased, especially at low speeds. The advantages of the new engine were obvious. But there were also important shortcomings. Model 128 car engines, based on the VAZ 21124, had a short working life. They didn’t even live to see 100 thousand kilometers.

In 2014, engine 21128 underwent global changes. Super-Auto engineers decided to take the VAZ 21126 as a basis. The main concept of the new engine was, as on the 126 model, the use of imported components. According to the old habit, Federal Mogul was tasked with manufacturing pistons for the new model; the crankshafts and connecting rods were supplied by the Italians. The cylinders of the new engine were not bored; to obtain a larger volume, they limited themselves to increasing the piston stroke. The engine capacity has become smaller, but not significantly. But lightweight ShPG parts and a new crankshaft with larger cranks did their job. The engine has become even more powerful, and torque has increased significantly at low speeds. The engine turned out to be fast, agile, and picked up speed with lightning speed. He could reach a hundred kilometers in 10 seconds. The disadvantage of the engine was all the diseases inherent in the 126 engine.

Possible faults

With proper care, the engine unit of the 12th family works flawlessly, because the basic design was created in collaboration with the German company Porsche, an authority in the field of engine building. The only “jamb” is the use of a belt drive. D

The problem is not even in her, but in the fact that the VAZ people stubbornly refuse to take into account Russian realities. The use of a timing belt requires high-quality spare parts, which, unfortunately, we can only dream of. And not everyone carries out regulated maintenance, relying on the well-known Russian “maybe”.

After all, in the 124th engine they made normal counterbores on the piston heads, and there is no problem, while the 2112 engine, like some other VAZ engines, suffers from a congenital disease called “valve bending”. The remaining faults are typical for many internal combustion engines, including VAZ engines:

- The 2112 engine is being tuned. The fault should be looked for in the distribution module, high-voltage wires, spark plugs.

- Unstable idle operation (XX). In this case, check the control device, crankshaft and throttle plate position sensors. The latter needs to be cleaned. If the search does not produce results, most likely the mass air flow sensor has failed.

- The drive stalls at idle or while moving (during gear shifting). This may be a consequence of contamination of the throttle mechanism, its sensor (TSP) or IAC.

- When starting, the motor does not “catch”. If it is not the starter or the battery that is at fault, the fault should be looked for in the ignition or power system.

- The hydraulic compensators or, what is much more dangerous, the main or connecting rod bearings are knocking. This is usually caused by a decrease in engine oil pressure.

- The engine unit warms up slowly. It is necessary to check the condition of the coolant and the operation of the thermostat.

- The motor pulls poorly and the work process is accompanied by vibrations. It is advisable to diagnose the power unit.

- Insufficient oil pressure - there may be several reasons. One of them is untimely oil change in the VAZ engine. With prolonged use, the oil pump may fail.

If the indicator is on, there is no oil pressure, you should stop driving until the problem is clarified, and if necessary, resort to the services of a tow truck.

Engine VAZ 21128 characteristics

Years of manufacture - (2003 - present day) Cylinder block material - cast iron Power system - injector Type - in-line Number of cylinders - 4 Valves per cylinder - 4 Piston stroke - 84 mm Cylinder diameter - 82.5 mm (82 mm since 2014) Grade compression - 10.5 Engine capacity 128 - 1796 cm3 (1774 cm3 since 2014) Engine power 21128 - 98 hp /5200 rpm (123 hp / 5500 rpm) Torque - 162 Nm / 3200 rpm (165 Nm / 4000 rpm) Fuel - AI95 Fuel consumption - city 9.8 l. | track 5.4 l. | mixed 7.5 l/100 km Oil consumption in the 21128 engine - about 300 g/1000 km Weight of the VAZ 21128 engine - 117 kg Geometric dimensions of the engine (LxWxH), mm - Oil in the VAZ 21128 engine: 5W-30 5W-40 10W-40 15W40 How much oil is in engine 21128: 3.5 l. When replacing, fill in about 3.2 liters.

Repair and maintenance of the power unit

A specific case of repair work is given as an example. Repair of the VAZ 2112 engine was required for several reasons: you have to constantly add antifreeze, the lubrication indicator blinks, and the hydraulic compensators click. We preliminarily carried out a compression measurement, which showed a difference in the cylinders of up to two atmospheres.

During the disassembly process, the causes of the malfunction were identified:

- burnout of the cylinder head gasket, as a result of which antifreeze went into one of the cylinders;

- corrosion of the cylinder head mating plane;

- wear of the crankshaft main journal liners;

- wear of exhaust valve guides;

- sintering of the insides of the catalytic collector.

Description of engine restoration procedures:

- milling the head plane and the mating plane of the block;

- repressing exhaust valve guides;

- mechanical processing (without lapping) of valve seats;

Installation of new parts:

- pistons of size group C (instead of the original B);

- piston rings;

- crankshaft bearings and thrust half-rings;

- oil seals and gaskets;

- cooling pump;

- valve stem seals;

- metal cylinder head gasket from Priora;

- toothed belt complete with tension roller from Power Grip;

- INA hydraulic pushers;

- NGK spark plugs;

- “spider” 4-1 made of stainless steel;

People often ask: what kind of oil to pour into a VAZ 2112? In the described case, after assembly, Lukoil Lux 10W40 engine oil was filled in.

Changing the oil on a VAZ 2112 requires 3.3 liters of fluid, and with a concomitant filter change - 3.4, although the total volume of the lubrication system is 3.6 liters.

Engine lubrication system 126

The 16 valve VAZ 126 engine, the characteristics of which are presented above, has a mixed-type lubrication system. Parts subject to high loads are lubricated with oil supplied under high pressure. Oil pressure is supplied by a gear-type pump.

Components not subject to high loads are lubricated by spraying oil. The parts of the gas distribution mechanism are lubricated by splashing. After splashing, the lubricant flows into the oil pan.

To increase the service life of components, the lubrication system is equipped with a two-stage oil purification system. For rough cleaning, a metal mesh oil receiver installed in the crankcase of the power unit is provided. It cleans the system of metal shavings and large contaminants. Fine cleaning of the lubricant is carried out with a replaceable filter element. It cleans the lubricant of metal shavings and fine contaminants.

Tuning options

Those who like to “grab” are interested in the question: how much additional horsepower can a tuning engine get? Tuning a 2112 engine is performed in different ways:

- Replacing the cam shafts with tuning ones (STI-1, STI-2, STI-3.1, Stolnikov 8.9) coupled with the installation of a lightweight ShPG, enlarged throttle valves and 4-2-1 “pants” will allow boosting the 120th engine to 120 hp. With;

- if you modify the cylinder head and install wide-phase camshafts, the increase will be 130 - 140 hp. With;

- installing a crankshaft with a long crank (37.8 mm), modifying the combustion chamber in the cylinder head and using T-shaped valves will increase the power to 150 hp. With.

Fans of “classic” Lada cars install the VAZ 2112 engine on rear-wheel drive cars: VAZ-2105, -2107. So that the unit can be located under the hood, even part of the engine compartment partition is cut out.

The generation of 12 engines turned out to be “long-lasting”. In addition to the brands described above, others were later developed: VAZ-21126, −127, −129. They are still installed today on LADA Priora, LADA Kalina, LADA Granta cars.

Known disadvantages and criticism of changing the stroke length of the piston

It would seem that it couldn’t be simpler - just take another ShPG, a longer stroke one, and now we have an engine with an increased displacement. It’s even surprising why they didn’t do this earlier (several years ago, when the 21126 motor first appeared). Experts say that in reality everything is somewhat more complicated than inexperienced owners think. The arguments that are given below are relevant both to the 21128 engine and to the internal combustion engine in general.

The general rule is that an engine with a longer stroke produces more torque at low rpm. If we compare engines with equal displacement and different piston strokes, it is the engine with the long-stroke SHPG that will be more “high-torque”. This is what the test results of the updated VAZ-21128 engine demonstrate (145 N*m can be removed from the shaft already at 2300-2400 rpm). The disadvantages associated with increasing the piston stroke are due to one factor - a longer elbow has a high moment of inertia. In addition, by increasing the angle of operation of the connecting rod, there is no need to wait for the load on the cylinder walls to decrease. All this, as you can understand, does not at all contribute to the increase in the durability of the internal combustion engine.

What is the actual service life of the 21128 engine? This is the most interesting and pressing question today. As representatives of the manufacturer assure, the durability of the internal combustion engine in question remains on par with the VAZ-21126 engine. As a result, it can be argued that VAZ power units do not require major repairs within the following period:

- 21116 (8 valves) – 200,000 km;

- 21126 – 160,000 km;

- 21128 – less than 160,000 km, but not by much (not by an order of magnitude).

This is interesting: Catalysts