Restoring automobile alloy wheels by applying powder coating to their surface falls into the category of repair work that is carried out only in the presence of minor damage. At the same time, going to a service station is not very profitable for most motorists, since it is associated with significant financial costs.

That is why powder coating of discs with your own hands is the only acceptable option for users who expect to save on repairs and independently control the entire technological process.

- Powder painting at home. Video:

The essence of this technique is that first a polymer powder dye is applied to a previously prepared metal surface in a special way.

Immediately after this, the painted product is subjected to a special heat treatment, as a result of which the powder melts, forming a continuous and evenly distributed film.

There is a similar article on this topic - Do-it-yourself airbrush on a car.

The coating obtained in this way has the following remarkable properties:

- high degree of protection against corrosion;

- good adhesion (adhesion) to the previously prepared base;

- climatic and chemical resistance;

- impact strength;

- decorative appeal and durability.

The advantages of this technology include:

- Possibility of forming a single-layer coating, which is impossible when using liquid paints and varnishes.

- There is no need to use a solvent or control the viscosity of the applied composition.

- Economical consumption of dye, explained by the possibility of reusing the sprayed powder, which does not leave the paint booth.

- The procedure for forming a powder layer does not take much time, which during conventional painting is spent on drying the product. This saving is explained by the fact that immediately after application the coating is subjected to heat treatment (polymerization).

- Environmental safety of the dye used, which does not contain toxic compounds. In this regard, during the spraying process there is no need to use powerful ventilation equipment.

Conditions for independent work

Despite the fact that the powder coating technique is quite complex, almost anyone with the appropriate technical skills can handle this class of work. However, their independent implementation is possible only if the following conditions are met:

- the presence of a room suitable for these purposes in which painting and drying areas can be arranged;

- purchase or rental of special equipment for powder painting (spray gun, spray gun, etc.);

- competent choice of the type of special dye used for the protective treatment of metal surfaces.

We also note that all of the above requirements must be met at the stage of preparation for the main work operations (that is, before directly painting the wheels).

In the following sections of the article, each of the components of the preparatory process will be discussed in more detail.

Painting wheels. Useful tips. Video:

Selecting a room

There are two approaches to choosing a closed area suitable for arranging a paint booth.

- The first of them is optimally suited for country houses (dachas, for example) and involves the use of any utility room for these purposes.

- As a second option, you can consider an existing garage building on your property, converted for powder coating of wheels.

Additional information: In the first of these approaches, the required function can be performed by a repair shop or a heated extension to the house.

Before choosing a room convenient for carrying out work, first of all, you need to have an idea of the size of the area sufficient to organize painting and thermal drying of discs. That is why you should first decide on the dimensions and number of disks to be simultaneously placed in the processing area.

In a situation where you intend to work with small-sized piece products, an area of 3 by 3 meters within the confines of an outbuilding converted for painting should be sufficient with a margin.

If there is a significant number of products being processed, you will need a larger room with dimensions sufficient for comfortable work. In addition, powder painting technology assumes the presence of forced ventilation, which ensures that microparticles of dye and dust hazardous to human health are removed from the working area.

Important! To comply with the requirements of the technological process (in terms of high-temperature drying with the possibility of polymerization of the protective layer), the room you choose must be equipped with a heating system or a special thermal oven.

It is also necessary to take care of high-quality lighting in the processing area, sufficient for full visual control of all stages of the painting process.

Industrial fluorescent lamps can be considered as one of the effective lighting options.

Preparing the premises and equipment

A garage is quite suitable for work if there is little dust, normal temperature and enough space. It is necessary to take care of the quality of lighting - it should allow full visual control over the process. Fluorescent lamps are well suited for this purpose. A well-organized ventilation system is also a prerequisite - otherwise you risk compromising your health.

Next, you need to equip a special box where painting will be carried out. It should have a roasting oven - you can easily adapt an oven for this purpose.

Wheels look attractive after painting

For painting you will need a spray gun with the ability to connect compressed air. You can also use a compressor. It must have a high pressure filter included.

To collect unused paint, you will need a recuperator - it can be replaced with a cyclonic vacuum cleaner if desired.

The electrical network in the room must be able to withstand the given load, and also have proper grounding.

Preparation of main and auxiliary equipment

It is advisable to use industrial-grade devices (powder painting gun plus compressor unit) as a mechanism for supplying the dye to the processing site and distributing it evenly over the surface of the disks. At home, it is most convenient to rent expensive painting units for the duration of the main work.

In addition, in order to supply power to the main and auxiliary equipment (thermal furnace, compressor, heating and lighting systems), powerful electrical wiring must be connected to the selected room.

If the specified conditions are met, known methods of drying and polymerization of painted surfaces can be implemented in the following ways:

- in the simplest case - through the use of a system of electric heaters of sufficiently high power;

- with a more professional approach - using a special oven for powder coating of processed products.

It is clear that the implementation of the second option is associated with large material and labor costs, even if you rent furnace equipment for the duration of complex work.

At the same time, painting the wheels yourself will still cost you less than if you contact a car repair shop.

As one of the options for a professional approach to arranging a furnace that ensures high-quality polymerization of the dye, the case of making it yourself can be considered. You can familiarize yourself with the procedure for assembling it and connecting it to the network in our future articles.

For those who have decided to do powder painting at home and do without a special oven design, we advise you to pay attention to the possibility of using conventional electric heaters.

When choosing this option, we should not forget that violation of the rules for operating electrical appliances can lead to a short circuit in the wiring and its fire.

That is why, even at the preparatory stage, you should worry about the quality of electrically conductive cables and carefully check the operating modes of all devices connected to them.

Please note: To the listed equipment you should add a powerful vacuum cleaner with a cyclone nozzle, with which you can ensure maximum air purity in the painting area. The need for this household device, as a rule, arises in cases where the painting booth is not equipped with adequate ventilation.

Powder painting at home. Video:

Equipment for work

Car repair shops use special equipment to spray paint on rims; at home, the work can be done with a minimal set of equipment:

- sandpaper grit 200-600;

- rags for removing dust;

- metal brushes;

- spray gun or spray gun.

In addition, you may need a sandblaster if it turns out that rust is corroding the metal. Instead of sandblasting equipment, you can use an electric drill with various attachments.

When painting rims yourself, it is advisable to have a separate room for the baking chamber, where powerful electric heaters should be placed. In addition, it is recommended to install a hanging system - attach a long wire to a beam in the garage, on which the disc for painting will be suspended.

Please note: High-quality painting of heating radiators with powder paint with hot polymerization

Good lighting should also be provided - the quality of painting will also depend on visual control of the process. Experienced car enthusiasts advise installing fluorescent lamps. Their bright but cool light will allow you to see the painted surface of the discs as it appears in daylight.

In all videos, for high-quality and effective painting of wheels with your own hands, it is recommended to buy or rent a good paint gun.

In addition to lighting and heating devices, according to safety regulations, the garage must have a good ventilation system so that after removing the old coating from the wheels and applying new paint, the smell will disappear faster.

According to safety regulations, the electrical network must withstand heavy loads and have reliable grounding.

Dye selection

In this section, we move on to describe the most critical part of the preparatory activities, which is choosing the appropriate powder coating. In it we will try to answer the following questions that interest every car enthusiast:

- How to paint car rims yourself (i.e., with your own hands)?

- What are the features of choosing a powder dye suitable for these products?

When studying these issues, first of all, let us draw your attention to the fact that the domestic market offers a large number of types, brands and colors of dyes of this class. That’s why, before you paint your car’s rims yourself, you need to decide on the choice of powder material suitable for your conditions.

It should be assumed that the following types of polymer coatings can be used to paint discs with your own hands:

- epoxy paints;

- polyester and polyurethane compounds;

- silicone dyes.

Each of the powder coating materials listed above has special, inherent qualities that determine the degree of security of the processed product. Thus, epoxy compositions are characterized by increased resistance to alkaline and acidic environments, and polyester paints have excellent anti-corrosion properties.

The advantages of polyurethane coatings include increased resistance to solvents and abrasives.

Silicone dyes differ from others in that they can withstand significant temperatures.

Important! You can choose a specific type of dye only after familiarizing yourself with the features of each sample, which determine the possibility of using it for self-application at home.

The most common and well-known names of powder protective coatings include such well-known domestic and foreign samples as “Pulverit”, P-EP 45, “Infralit”, “Bichon”, “Beckers”, “Radar”, “Inver”, TFC and Flycoat.

Using products from these manufacturers, every car enthusiast can easily cope with all the tasks assigned to him, including selecting the appropriate color scheme (in the RAL standard) and the surface texture of the wheels.

Using some of these dyes, you can change the structure of the coating, which is represented by a number of popular types (shagreen, antique, moire and the like).

Additional information: powder coating of wheels requires the mandatory use of special work clothing and respiratory protection.

As such, in domestic conditions, a regular respirator, safety glasses and thick cotton gloves are most often used.

Do-it-yourself powder coating of wheels: technology

Hello! Nice to see you again! We continue to delight you with new, interesting and, we hope, useful materials. Our hero today is powder coating of wheels.

If you need to restore car wheels, especially alloy wheels, then applying a powder composition is considered the most reliable way. It is the most technologically complex, and the price is fair, but high.

I will say right away that the option of doing it yourself looks doubtful, since applying powder paint has a special technology. Without certain components, you simply won't be able to get the job done right. But let's talk about everything sequentially.

Powder coating of wheels

Once all the conditions for independent restoration work have been met, you can proceed to direct processing of the disks, carried out in accordance with the requirements of current regulations.

Before you paint car rims with your own hands, you need to carefully familiarize yourself with the technological features of these procedures. According to accepted standards, the order of their implementation is as follows:

1. Before starting painting work, the surfaces of the disks are thoroughly cleaned of corrosion, old paint residues, as well as traces of dirt and oil stains using a metal brush, sandpaper and solvent (abrasive and chemical treatment, including degreasing).

If it is impossible to remove rust embedded in the metal, you will have to organize its etching, carried out using solutions of various acids (sulfuric, phosphoric, hydrochloric or nitric).

Please note: When performing these operations, special attention must be paid to observing safety precautions when handling chemicals.

2. At the next stage of surface preparation, it is treated with chromium, iron or manganese phosphate, which helps improve the adhesion of the metal to the protective primer. Upon completion of the phosphating process, the discs prepared for painting are thoroughly washed with warm water and then dried.

3. Next, they proceed to applying a special primer coating to the surface, which ensures improved anti-corrosion properties and adhesion to the sprayed dye. To protect cast wheels, epoxy (epoxy-zinc) primers are usually used.

4. Upon completion of the preparatory work, the discs are placed in a special painting area or box with limited scattering of microparticles sprayed by the gun (in this case, the body of the processed products is reliably grounded).

What is engine chip tuning, pros and cons. - there is more useful information here.

5. The powder mixture is applied to the surfaces to be treated using the electrostatic spraying method, according to which charged particles, when scattered, are attracted by a grounded metal disk.

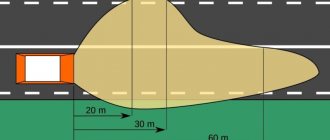

Important! When spraying powder dye, the spray gun or gun should be located at a distance of approximately 30-50 cm from the surface to be treated.

Upon completion of paint application, the discs are subjected to special heat treatment (so-called “polymerization”), which ensures the melting of the protective layer and its reliable adhesion to the previously prepared coating.

You might be interested in this article - Do-it-yourself airbrush on a car.

For this purpose, they are either placed in a home-made oven or subjected to high-temperature treatment using powerful electric heaters.

Features of painting car rims with powder paint: advantages and equipment

The technology of surface restoration using powder paints is quite popular. Experts explain this with a number of positive aspects from using this technique:

- Durability and resistance to mechanical stress and chemical reagents.

- Do-it -yourself powder coating of discs in the video is quite affordable and requires minimal consumption of materials.

- Possibility of creating paint of any shade.

However, the option is practically impossible to implement at home, because there is a technological need for special equipment:

- Spray booth.

- Electrostatic spray gun.

- Drying oven.

Accordingly, you will need a compressor and a reliable power source, preferably a three-phase type. However, there are craftsmen who were able to equip a workplace from improvised means, for example, they use household ovens as ovens. How justified this is for a single use, everyone can judge for himself, but it is quite obvious that the total cost of the event is too high.

This suggests a conclusion - restoring the appearance of wheels using an aerosol can is the best option. However, we will not talk about it; below we will consider what painting wheels with powder paint is and the main nuances of the method.

Equipment for work

The main disadvantage of the powder painting method is the rather complex technology and expensive equipment, although in certain cases the use of household appliances is allowed:

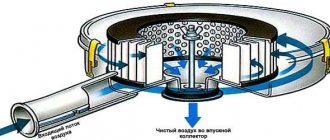

- A dry spray paint booth must be equipped with a recuperator that collects powder paint residues. They are subsequently reused. At home, our “homemade” ones have adapted to using a conventional cyclone-type vacuum cleaner.

- Sandblasting machine for cleaning surfaces with an abrasive-air mixture. It is possible to use homemade devices or, as a last resort, manual cleaning with sandpaper of the appropriate grain size.

- A compressor unit that is capable of providing a working pressure of up to 5 atmospheres to ensure the operation of a sandblaster and a paint gun. It is necessary to have an oil trap and a filter with a sorbent for preparing compressed air.

- Tribostatic or electrostatic paint spray gun. The first one is suitable for working only with epoxy stains, and the second one is suitable for working with all types of powder paints. There are homemade options, for example, made from a plastic bottle and a metal cap.

- Drying chamber with exhaust hood, providing a temperature of 200°C.

- Powerful electrical network with grounding.

In all videos, for high-quality and effective painting of wheels with your own hands, it is recommended to buy or rent a good paint gun. Without practice, it is not advisable to get involved with making a homemade device for the first time, since this process can take a lot of time, and its result does not guarantee one hundred percent implementation.

Base materials

When painting car wheels, the following types of powder paints are used:

- Polyester

coatings are resistant to corrosion and harsh atmospheric conditions. - Epoxy

- the layer of this paint is especially resistant to alkaline and acidic environments. - Polyurethane

- the coating retains its original appearance even after abrasive action, and is also resistant to oils and solvents. - Silicone

– especially resistant to high temperatures.

There are a large number of products on the market, with which it is easy to choose the desired color, texture (glossy or matte), as well as the structural type of polymer surface (shagreen, antique, etc.). The most popular brands of paints are:

The range of colors that is common in Russia is determined by the RAL standard, but manufacturers also offer a number of paints of other standards.

In the absence of sandblasting, you can use a drill with attachments, however, as when painting stamped car wheels ; In this case, sandpaper with different abrasive numbers (P200-P600) will also help. For degreasing you will need a solvent and special wipes.