When servicing brake calipers or completely replacing them, it is recommended to lubricate their rubbing surfaces: guides (pins), working cylinder piston, clamping brackets. This is written in the manual of any car. But if you do this incorrectly and with unsuitable lubricants, you can render most of the components of the caliper unusable.

To understand how to properly lubricate all elements of the caliper, and how such maintenance can be carried out, you should initially understand the following questions:

- Under what conditions does this disc brake element have to work?

- What requirements must the lubricant chosen for it meet?

To each his own: requirements for lubrication of guide supports

For the closed design of the caliper guide pins, and only closed pins can be lubricated, not every composition is suitable. For example, lubricants with a wide range of applications, such as Solidol or Litol-24, are inappropriate here. Knowing the requirements for brake chemistry, comments are unnecessary here:

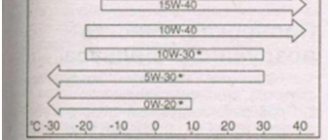

- Heat resistance. When braking, parts heat up profusely, including the caliper body. The lubricant must maintain its operating properties at a temperature of +200°C.

- Water-repellent effect. Brake calipers are not protected from water, so the lubricant should not be washed away by the liquid.

- Neutral to brake fluid.

- Frost resistance. At subzero temperatures, the unit must remain mobile.

- Neutral to rubber and plastics. In a closed structure, the presence of anthers and covers is inevitable. The lubricant should not destroy them or increase their size.

High Temperature Copper Greases

These products contain three main components:

- finely dispersed copper in the form of small particles;

- synthetic and mineral oil;

- anti-corrosion additives.

These products are sold in the form of a spray or paste. Due to their high viscosity, they get into all the gaps and are not washed out from there. Copper lubricants operate over an impressive temperature range, do not evaporate, and minimize the impact of frictional forces.

But you need to apply copper grease correctly:

- Carefully prepare the working surface of the element by cleaning it.

- Apply the product carefully to the surface, preventing dirt from entering.

- Do not remove excess product from the part.

Carefully! If your car has aluminum calipers, the use of copper lubricants is prohibited, as this will lead to contact corrosion of the aluminum.

Basic basis of lubricant composition

Strictly speaking, only chemistry based on synthetic oils meets the presented criteria. And do not follow the lead of incompetent sellers who advise using anti-squeak paste intended for application to the non-working sides of the pads. This is one method of dealing with squeaking brakes , a problem for which we have already discussed solutions.

Mineral-based compounds, as well as anti-squeak products based on copper or ceramics, lead to swelling of the boots and coking of the fingers, resulting in brake wedging. Synthetic analogues are neutral to rubber, evaporate poorly and contain a thickener. It is thanks to him that the lubricant remains plastic and does not drain at high temperatures.

Copper high temperature grease

This lubricant is also used for calipers and guides due to its ability to withstand high temperatures.

The composition of copper caliper lubricant includes: fine copper, mineral and synthetic oil and anti-corrosion substances.

Available in paste and spray form. The consistency is thicker than the other lubricants discussed above.

IMPORTANT! Car calipers are also made of aluminum. If the caliper is aluminum, then copper grease cannot be used!

Working in pairs, aluminum and copper, oxidation and subsequent corrosion occur.

Lubricant for slide guides: specific examples

Highly specialized chemistry is not always distinguished by thematic inscriptions. To make sure that you have exactly what you need in your hands, in most cases you will have to read the back of the package, delving into the fine print. It’s another matter to go to the store, being savvy about the name of a specific composition. There are not so many of them for “directions”:

- TRW PFG110

- Permatex Ultra Disc Brake Caliper Lube

- Liqui Moly art. 7656

- Slipkote 220-R DBC

In continuation of the above, it is appropriate to talk about the representative of Liqui Moly. In the line of this manufacturer there are two similar in appearance, but completely different in scope of application. You can easily get confused - the packaging is the same, only the article number and part of the inscription, upon careful inspection, will prevent confusion:

- Liqiu Moly Bremsen Anti Quietsch Paste (item 7585). It has a gray-blue color, the base is synthetic, the filler is microceramics. Despite the high heat resistance, lubrication of guide supports with this composition is prohibited. The product is recommended for lubricating the guide pads, the interface between the caliper and the pads. This product is positioned as anti-squeak only.

- Liqui Moly Anti Quietsch Paste (item 7656). Rich in red pigment. Does not lose viscosity up to +250°C. Designed for lubrication of caliper guides and insertion into brake boots.

Reviews

Now let’s turn to the comments of motorists who have already used Liqui Moly lubricant. After all, no beautiful product descriptions provided by the manufacturer can be compared with real consumer reviews.

| Positive | Negative |

| Good day to all! I decided to write my comment about the use of Liqui Moly lubricant for guide calipers. The car is a 2003 Daewoo Nexia. About six months ago, while driving, I noticed that some kind of extraneous sound began to appear. At first it was a small squeak, with which I drove for almost two months. But over time, this sound began to develop into noise and began to really infuriate me. So, I went to the service station, where the guy listened to me, quickly unscrewed the wheel and said that the car’s guides needed to be lubricated. He says that the old grease is no longer on them, which is where the noise comes from. And he advised me to immediately buy Liqui Moly. At that time (three or four months ago) it cost about 200 rubles (60-70 hryvnia) and was one of the most expensive in the store. But the noise problem immediately disappeared! | In general, there was this problem: when I hit a hole while moving, some kind of noise began to be heard. At first I didn't think much of it because the sound only appeared occasionally. But when the creaking began to appear in every pit, I decided to address this issue. I removed the right wheel because the noise was coming from the right side. Everything seemed to be fine with the brake pads. I read reviews from motorists on the Internet and concluded that the guides needed to be lubricated, especially since when I paid attention to them, I realized that there was something wrong with the lubricant. I purchased the most expensive Liqui Moly Kupfer-Paste lubricant, which at that time cost about 500 rubles, but, unfortunately, it did not help. Although I lubricated everything correctly - all the rubbing elements. So trust other reviews after this - there is only deception around. |

| Standard substances such as graphite lubricant or Litol-24 are no longer relevant for a long time! Firstly, they cannot function properly at high temperatures (and their operating temperatures range from 65 to 100 degrees). And while driving, the temperature in the guides can reach 300 degrees or more! Secondly, their service life is significantly lower compared to Liqui Moly! Liqui Moly is still a foreign quality that you can’t argue with! Moreover, this lubricant, unlike graphite, was developed and created specifically for guides, so draw your conclusions! | I read a lot about Liqui Moly lubricant on the Internet. I decided to use this substance when replacing the guides. The time to change the calipers has come, since the rubber bands on them are cracked and I decided not to delay the replacement (VAZ 2109 car). I lubricated everything properly. About six months passed, and the left caliper simply cracked. Fortunately, I managed to see it in time. The condition of the right caliper was also assessed as unsatisfactory. Would you say the parts are of poor quality? I don’t think so, because I bought original calipers and I’m confident in their quality. Apparently, Liqui Moly is not such a quality product as it is described. |

| I would like to note that for a long time I did not use lubricant at all. Or rather, when I changed the guides on the wheels (about three years ago), they lubricated them with something and, apparently, a good substance, since for three years I had practically no problems with third-party sounds. Then the noises appeared. Naturally, first of all, I checked the brake discs and pads, but they were in good condition and could last at least 10 thousand kilometers. So I removed the wheels, cleaned them of old grease, degreased them and re-lubricated them. To my surprise, the noise disappeared, thanks to Liqui Moly. | I want to say right away - Liqui Moly lubricant sucks! On my wife's car (Hyundai Elantra), it was necessary to lubricate the guides because a squeak appeared. I lubricated it and it lasted about two weeks. After that, the lubricant seemed to have disappeared somewhere. Most likely, it was washed away with water or a brake fluid. I used Litol-24 - my wife has been driving for six months without complaining. Same thing with my Renault Sandero. I replaced the guides and decided to lubricate them, but literally a week later a squeak appeared. I replaced Liqui Moly with Litol, and everything went away. So does it make sense to overpay? |

| I'll tell you this: it's better to overpay a little once and buy good lubricant than to drive around and constantly hear squeaking. My neighbor had the same problem, but he gave up on it and as a result, after about six months, his guides rusted and his right wheel almost fell off while driving! As it turned out later, he never lubricated the calipers at all and almost killed himself and his little child! And all because, you see, he got used to the creaking and decided not to deal with this issue. | I also used Liqui Moly once. At first everything was fine, the lubricant paid off, but then either its quality deteriorated, or I fell for a fake. In general, it doesn't help. Although, using cheaper analogues, you can achieve a better effect! |

Guide lubricant Kupfer-Paste original copper color

We recommend: Why you shouldn’t buy fake car parts

As you understand, motorists have divided opinions about the lubricant. Some consider Liqui Moly to be a high-quality lubricant for guide calipers, while others find shortcomings in its operation. One way or another, lubricant cannot guarantee eternal operation of calipers, however, a high-quality substance may well increase the service life of brake system elements. Of course, when applying material to the guides, it is necessary to completely eliminate dust, dirt and moisture that may accumulate on the calipers.

Only in this way can the lubricant be truly effective. If you do not degrease the surface of the calipers, then there is a high probability that the substance will simply be washed away by water or brake fluid, which means that its operation will be useless.

In addition, do not forget that the lubricant must be of high quality and original production. The original is produced in Germany, but the company has representative offices in Russia and Ukraine, so the label in Ukrainian or Russian should not confuse you. The main thing is that the substance is made in Germany.

It is also worth adding that often a fake can be identified by a color that does not match the original. As stated above, the colors of the original Anti-Quietsch-Paste and Liqui Moly Kupfer-Paste are red and copper, respectively. If you purchased a lubricant of a different color, it is better to refrain from using it.

Which composition is better to buy

Disputes about the advantages and disadvantages of one or another model of lubricant composition are ongoing. There is no ideal option and it is unlikely to appear. Turning to statistical data, Liqui Moly Anti Quietsch Paste attracts the largest number of negative reviews.

TRW PFG110 and Slipkote 220-R DBC are widely popular. The only disadvantage of these two representatives is the price. Small tubes (85 g) will cost about 1000 rubles each. However, the lion's share of reviews are positive.

Why lubricate brakes?

Under normal driving conditions, the outer casing of the caliper heats up to +150-200°C, and if the driver likes to brake sharply and is a supporter of an aggressive driving style, then up to +300°C. Rubbing parts are heated to higher temperatures: pads - up to +600°C. The caliper is constantly in contact with dirt, water, and powders used to treat roads against ice. Wear of the piston rings leads to leakage of brake fluid, which is also not harmless to the components of the unit. Lubrication performs a protective function. It protects parts from harmful effects and extends their service life.

The design provides that the caliper must move along guides that resemble long bolts with a short thread section. Over time, under the influence of external factors, the lubricant on the fingers thickens and dries, significantly complicating the braking process and contributing to wear of parts. You need to know how often the caliper guides should be lubricated. A high-quality composition must be replaced along with caliper parts that have expired, for example brake pads. If the lubricant cokes earlier, then change it in a timely manner. The old composition is cleaned off and a new one is applied. The fact that the paste has become unusable is indicated by uneven and rapid wear of the pads, creaking, and knocking of the brakes. In the future, the situation worsens, up to the jamming of parts. It is necessary to lubricate not only the guides (fingers), but also other parts:

- cylinder walls;

- the inside of the boot;

- outer sides of the pads;

- clamping brackets.

And each element requires a composition with special properties. Not all guides need to be treated with lubricant. Manufacturers such as TEVES, LUCAS, ATE install a plastic bushing. By definition, it does not need to be lubricated. If it doesn't work properly, it is simply replaced. You can also polish the guides to improve their sliding properties if they become coked or corroded. However, it is useless to polish “fingers” that show signs of serious wear. Lubrication won't help either. Therefore, if they are knocking, they need to be replaced.

Brake caliper guide maintenance techniques

In order to get to the “guides”, you need to dismantle the caliper by performing a number of steps:

- Bend the locking plates of the guide bolts.

- Unscrew the bolts of each of the “guides” one by one, supporting it with a second key.

- Remove and hang the caliper.

- Remove the guides.

Next, you need to clean the seats and the fingers themselves from dirt. You can use a wire brush. Traces of rust should be cleaned with sandpaper. It would be a good idea to inspect the guides for wear. According to the unwritten rule, the fingers are changed after two or three pad changes.

It is necessary to lubricate the entire contact metal surface + the area under the rubber boot. Assembly is carried out in reverse order.

HOW ARE CAR CALIPERS LUBRICATED?

As a rule, work is carried out in conjunction with servicing the brake system: for example, replacing pads or brake discs. First, all parts are cleaned and checked for damage. Then all contact surfaces on the caliper are lubricated. The lubricant is applied in a thin layer: 2-3 grams per finger is enough. It is processed by itself, as well as the threaded connection. When learning how to lubricate a front or rear caliper, also pay attention to other components of the brake system: the piston of the brake cylinder, the caliper bracket at the T-shaped guides, etc.

If you have any questions regarding caliper lubricants or MSK products, our managers will be happy to answer them. Contact them to clarify the characteristics of lubricants and get a wholesale price list for our products!