What you need for work

You can tune the wheels on your car yourself if you follow the rules. To work, you will need the selected paint material and the necessary tools.

| Tools, materials | Description |

| Sandpaper | Required for the disc cleaning stage, and will also be needed after priming and polishing |

| Respirator, gloves, tape | Protective suit for face and hands, as well as tape or film to cover tires |

| Construction hair dryer | Necessary at the drying stage, can be replaced with a warm gun |

| Sander | Necessary for the cleaning stage, helps remove traces of rust and corrosion |

| Spray gun | A spray gun will be needed when using liquid nitro enamel |

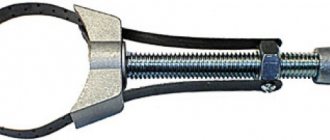

If you choose the method of powder coating of paint, then for the work you need a baking oven, as well as a special gun with which to apply the powder. Devices for powdering can be made with your own hands from available materials.

Step-by-step algorithm for painting at home

The process of painting discs consists of several stages. Each of them has features. Car painters claim that the most significant process remains the preparation stage. It involves sequential steps of stripping, removing old coating and creating a suitable surface for the finish coat. Preparatory work takes from 2 to 4 days. Painting takes 1 day. Drying lasts up to 4 days.

See also

Types of stained glass paints for painting on glass, how long they take to dry and application

Preparatory work

The purpose of preparation is to strip the old coating and create a surface on which the selected paint and varnish material will lie in an even layer. To remove traces of corrosion or remove old coating, use a grinding machine. It can be replaced with an electric drill. The purpose of the equipment is to create a chip by which you can pick up the coating and remove it.

Expert opinion

Zakharova Irina Yurievna

Cleaning professional with 15 years of experience. Our best expert.

Ask a Question

Attention! After removing the coating, minor errors are thoroughly cleaned with sandpaper.

An important step in preparing discs is degreasing the surface. Treatment with a degreaser allows you to get a clean, flat surface on which any primer fits well. The degreaser is applied with a sponge, then the traces of treatment are erased with a dry, clean cloth. Degreasers can be purchased at stores that sell automotive parts. The market offers water-alcohol-based products or compositions made from organic solvents.

The next stage is priming. Priming is carried out only when the discs are scratched, chips or cracks are visible on them. If painting is carried out on a new casting for the purpose of color tuning, then priming can be avoided. The primer layer must be completely dry before further work, then it must be treated to remove roughness using sandpaper.

Actually painting

The painting process algorithm depends on the type of paint chosen. They prefer to process car wheels using aerosol cans. All compositions intended for repair are produced in cylinders of different sizes.

Before you start spraying paint, protect the tires with film and tape, covering the entire surface from different sides. Painting rules:

- each subsequent coating is applied after the layer has completely dried, this takes from 20 to 60 minutes;

- to cover the rims on both sides, it is recommended to use the technique of hanging tires from a support;

- the process is interrupted to dry each layer;

- After drying the final layer, polishing varnish is applied.

Drying

A stage that is artificially shortened by influencing the processed part. After applying the next layer, install a heat gun opposite the disc or blow the surface with a construction hairdryer.

Information! Final drying after polishing takes two days.

See also

Types and technical characteristics of VD AK paints, top 7 brands and how to choose

Paint for car wheels: which one is better to choose?

Many novice car enthusiasts often wonder what to paint their rims with. Today, stores of goods and spare parts for cars are replete with various types of paints, which are divided into three main types:

Painted car wheels

- paint for wheel rims in powder form;

- rubber;

- acrylic.

Before giving preference to one or another type of this product, you should familiarize yourself with the features of each of them. As for powder paint, it is recommended to paint alloy wheels with it, since it helps create a durable and hard coating on the surface of the part. Such enamel is not susceptible to mechanical damage, and it can be applied to any type of metal.

Note!

Before applying powder paint, you need to acquire special equipment. Enamel should only be stored indoors, and wheels should be painted in a closed box.

It is worth noting that processing car wheels using powder material is an expensive procedure, the cost of which on average is 5,000 rubles. This fact can be explained by the fact that before applying the enamel, the master treats the surface using a sandblaster, after which he degreases it and coats it with a primer. The final step is to apply paint, which is pre-melted at a temperature of at least 200 degrees so that the material adheres well to the metal coating of the car disk.

To sell acrylic-based paint, spray cans are used in most cases, and it is divided into two types: matte and glossy. The cost of one can, which contains about 0.5 liters of enamel, ranges around 300 rubles, but to paint 4 discs you may need 2-3 of these bottles. The advantages of the product include the fact that it is not exposed to snow, rain and sunlight, but for maximum adhesion, the surface of the parts must be well prepared for applying acrylic paint.

Acrylic paint for rims

Rubber enamel appeared on the market not so long ago, and it is also sold in cans, which greatly facilitates the work of the master, since there is no need to use additional painting equipment. One of the main advantages of enamel is that almost no effort is required to remove it. Such paint and varnish products can be glossy, matte, fluorescent or metallic.

You might be interested in this About the manufacturer of alloy wheels iFree (Ifri)

Rubber paint resists ultraviolet rays and various precipitation.

Due to its rapid hardening and formation of an even hard layer, this is the product preferred by most motorists.

Features of painting stamped discs with your own hands

Stamped wheels differ from cast wheels in their unpresentable appearance. Stamped parts are repainted independently to highlight the car and make the coating more attractive in appearance. Stamped discs are susceptible to rust, so it is recommended to coat them with compounds with high anti-corrosion properties.

Experienced motorists recommend chrome plating on stamped wheels. This is a way to give disks a presentable appearance using various types of aerosol paints. To do this, apply an aerosol with a “chrome effect” to a layer of black primer. The creation of the final coating is completed by varnishing.

How to properly paint alloy wheels for a car using a spray can

Alloy wheels are spray painted in any chosen color. The effect of painting depends on how well the surface was prepared. Old castings that are covered with rust stains are recommended to be painted metallic. This is a modern tuning option suitable for any car.

Apply several layers from the can onto the primed surface of the disc, then leave until completely dry. A special feature of painting from cylinders is the precise adherence to the distance. The balloon is moved away from the part by 30-40 centimeters at an angle of 45 degrees.

The casting is painted in two colors. This method requires patience. Each layer of paint is dried, then construction tape is glued to the treated area, and another selected color is applied from a can or with a brush.

What paint is better to paint rims?

Based on feedback from car enthusiasts, experts have concluded that today there are several popular manufacturers of paints and varnishes on the market that are popular. Such brands are represented by the brands Motip, Kudo, Body and Chameleon, but before you give preference to one or another enamel, you should familiarize yourself with the pros and cons of each of them.

KUDO car paint has a unique composition, which includes components that help eliminate small chips, scratches and other damage to car wheels or car components.

On a note.

Thanks to such unique components and chemicals, wheel rims are not afraid of corrosion and any mechanical stress.

The advantages of Kudo enamel are represented by impeccable gloss and long lasting results. Disadvantages include low resistance to dust settling and high consumption of material when painting. Car owners say that the paint dries quickly, and the color after painting is rich and bright.

You might be interested in this: Wheel rims R16

Enamel for KUDO wheels

Important!

Kudo paint material is incompatible with many other paints, and minor abrasions are noticeable after its application. After driving on country roads, dust sometimes remains on the vehicle.

Another high-quality product is Motip brand wheel paint, which can be applied not only to wheels, but also to the body of trucks. The advantages of such enamel include the following:

- excellent adhesion to the coating of parts, durability of the result and resistance to weather conditions;

- a varied palette of shades and colors;

- After painting, the remaining paintwork in the can can be saved to be used later for subsequent paintings.

Motip paint should be applied in several layers, since it is unable to completely cover the surface the first time. As for the unpleasant odor of the solvent, it quickly disappears after the painting procedure.

The composition of Greek-made car paint Body can withstand maximum temperatures.

As a result of the tests, it was found that the “Body” paint for wheels does not peel off even when the temperature reaches 600 degrees. The advantages of the material are represented by a rich gloss color, impeccable adhesion to the coating and resistance to changes in temperature. A minor drawback is that the paintwork material must be applied in several layers.

The composition of the Chameleon paint coating is distinguished by the content of artificial pigments, which refract and reflect the sun's rays falling on the surface of the car wheels. This, in turn, contributes to the formation of waves of different lengths, which are perceived by the human eye as iridescent shades of colors. The first layer of luminous paint on the wheels consists of aluminum and chrome, followed by two transparent layers, which are located on the sides of the central one. Two translucent layers are applied to the outer part of the coating.

It is translucent and transparent coatings that help create a mirror effect on vehicle rims. As stated above, Chameleon paint reflects the sun's rays from different angles, but it all depends on the position of the particles in the pigment, as well as on the viewing angle of the human eye. Depending on the thickness of the layer, the wavelength is automatically determined based on the metal oxide.

Enamel for discs “Chameleon”

The wavelength of the blue, red, or yellow wavelength determines the suppression and reflection of color, as well as the resulting visual hue. This fact indicates that when a driver looks at a car disc coated with Chameleon paint, he sees different surface colors from different angles.