Engine design A15MF

In 2002, the 16-valve A15MF was added to the Daewoo line of power units. The ancestor of this power plant was the 8 valve G15MF. Unlike its predecessor, the new unit boasted an electronic coil ignition system, a completely new cylinder head with 2 camshafts and 16 valves. The volume of the power plant remained the same - 1500 cc, power increased to 90 horsepower.

The A15MF engine is equipped with a 16-valve cylinder head and a metal intake manifold.

The engine is built on a cast iron block and an aluminum cylinder head. The design of the motor can be called long-stroke - the cylinder diameter is 76.5 mm, the piston stroke, in turn, is 81.5 mm. This CPG architecture allows for minimal fuel consumption and optimal traction from low revs. The cylinder head is designed using the DOHC system; hydraulic compensators are used in the design, which makes the engine very sensitive to the quality and oil change intervals.

The power ratings of the power plant are low. A power of 90 horsepower will not surprise anyone. It is worth noting that for comfortable movement around the city and on the highway, a torque of 137 Hm is quite enough. The motor has no pretensions to sport. Its purpose is to move the car from point A to point B, and it copes with the task assigned to it perfectly.

The compact engine allows it to be used even in small cars.

The A15MF is considered one of the most reliable engines. The power unit is capable of driving up to 700 thousand km. without major repairs. “Nexias” are used in the most difficult conditions and have already proven their endurance and unpretentiousness to everyone. The engine is not afraid of minor overheating, tolerates a lack of oil and practically does not bother its owners with malfunctions.

Features of the A15MF engine:

- distributed fuel injection;

- due to the cast iron block, the power plant turned out to be heavy;

- timing belt drive; if the belt breaks, the motor bends the valve;

- low fuel consumption and excellent traction in any speed range;

- coil ignition system;

- 16-valve DOHC cylinder head;

- use of hydraulic compensators;

- long-stroke CPG architecture.

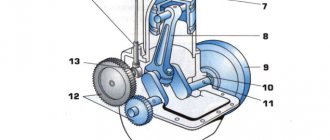

Engine diagram

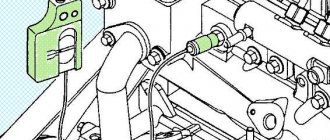

Description of replacing the timing belt on a Daewoo Nexia car, with a Sons 8-valve engine, with photographs and videos

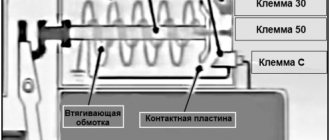

Elements of the F16D3 electronic engine control system:

This memory is volatile, i.e. When the electrical power is interrupted (the battery is disconnected or the wiring harness block is disconnected from the ECU), its contents are erased. The PROM stores the engine control program, which contains a sequence of operating commands (algorithms) and calibration data - settings. The PROM is non-volatile, i.e. The contents of the memory do not change when the power is turned off.

The ECU receives information from system sensors and controls actuators such as the fuel pump and injectors, ignition coil, idle speed control, oxygen concentration sensor heating element, canister purge valve, exhaust gas recirculation valve, intake tract length variable valve (on the F16D3 engine ), air conditioning compressor clutch, cooling fan.

Service Schedule A15MF

The A15MF engine is one of the most reliable engines in the line of budget power plants. In order to preserve its resource, it is necessary to carry out timely maintenance and use only high-quality spare parts and consumables. If these conditions are met, you can increase the resource declared by the manufacturer.

One of the most important consumables is motor oil. Since the design of the power plant involves hydraulic compensators, you should carefully select the oil. The optimal solution is oils with viscosity 5w30, 10w40.

The manufacturer recommends servicing the A15MF engine according to the following schedule:

- It is recommended to check the condition of drive belts every 20 thousand kilometers. Belts need to be replaced after 4 years of vehicle operation, since during this time the rubber will simply “stuff.” A broken belt will leave you without a power steering or generator;

- It is also recommended to inspect the timing belt during maintenance; it must be replaced after 100 thousand km. mileage, but for your own peace of mind it is better to install a new one at a mileage of 60 thousand kilometers. It is worth noting that the A15MF bends the valve, and if the timing belt breaks, then an expensive engine overhaul will be required;

Timing drive diagram for engine A15MF.

- It is recommended to change the coolant every 4 years, and you should also monitor the condition of the cooling system pipes. The service life of the pump is on average 60,000 km; during scheduled maintenance, it is advisable to check the pump for play and inspect it for leaks;

- It is recommended to change spark plugs every 50 thousand kilometers, given the quality of Russian fuel, it is better to monitor the condition of the spark plugs every six months. If you neglect to replace spark plugs, ignition breakdowns may occur, and poor starting will also occur in the cold season. An increased gap on the spark plugs can damage the ignition coils;

- It is recommended to change all filter elements once a year. This rule will help keep the fuel system clean. If you do not replace the air filter on time, it will begin to let in dust, which will lead to increased wear of the CPG;

- An oil change should be done every 10,000 kilometers. Neglecting this rule will cause the formation of oil deposits on the engine walls. Violation of oil change intervals can also lead to blockage of oil channels, and this in turn will lead to immediate engine wear.

Hydraulic compensators allow you to forget about adjusting the valves; the main thing is to keep them in good condition.

Power plant oil

Changing the oil is an important procedure, especially when it is necessary to preserve engine life as much as possible; it is important to know all the nuances and requirements for its implementation.

There are no special requirements for oil for brand engines. The main thing is that the oil you pour is of high quality, does not burn, does not form soot, and has good additives. It is advisable to use synthetic or semi-synthetic oil.

If the engine is planned to be operated at low temperatures, it is necessary to use low viscosity oil. These are 5W30, 0W30, 5W40, 0W40 oils. If you use thick oil in cold weather, severe wear of parts in the engine occurs, therefore, it should not be used.

The most commonly used oils are from the following manufacturers: Castrol, Mobil, Chevron, ELF.

Source

Review of faults and methods for repairing them

The power unit has a high level of reliability. Yes, every engine has its own shortcomings and weak points, and the A15MF is no exception. With careless operation, oil consumption often occurs and problems arise with hydraulic pushers. If you monitor the engine and carry out all technical work on time, you can avoid most problems.

Below are the most typical breakdowns and “weak points”:

- Oil burning occurs after 100 thousand kilometers, first a smell appears from the exhaust pipe, then bluish smoke. The problem is often the valve stem seals. If replacing them does not help, then there is only one way out - engine overhaul.

- A knocking sound in the cylinder head area can be caused by faulty hydraulic compensators. Most often, hydraulic tappets fail due to bad oil. There are several options for solving the problem: flushing or replacing faulty elements. To prevent breakdowns, it is recommended to observe oil change intervals and fill only high-quality lubricant.

- If you do not monitor the condition of the spark plugs, the engine begins to run unevenly, vibrations and other delights appear.

- The power unit is very picky about fuel quality. Poor quality gasoline causes contamination of the EGR valve. Car owners most often simply turn it off. The valve itself is designed to reduce the toxicity of exhaust gases.

The cast iron cylinder block withstands overheating and is difficult to “kill”.

Engine Daewoo Nexia 1.6

Since 2008, the Daewoo Nexia has been equipped with a new 16-valve F16D3 engine that meets Euro 3 and 4 environmental requirements; this engine first appeared on the Chevrolet Lacetti. The Chevrolet Cruze model was also equipped with the F16D3 engine; the prototype of the engine was the Opel X14XE power unit. Although the volumes of these engines are different, structurally and externally they are very similar to each other. Both engines have:

The F16D3 gasoline engine has the following technical characteristics:

To reduce the toxicity of exhaust gases, an EGR valve is installed on this engine, but the recirculation system often becomes coked from Russian gasoline, and many car owners turn off this valve. The F16D3 engine is not only similar to the X14XE, it also adopted all the diseases from the Opel power unit:

The leak would not cause much trouble if the oil did not flow into the spark plug wells. Penetrating into the well, the oil hits the electrodes of the spark plug, and the internal combustion engine begins to throttle. But the Daewoo Nexia 1.6 engine rarely consumes oil through the piston rings; in this regard, the engine is reliable.

Tuning options for the A15MF engine

The power unit is very popular. Thanks to this, you can find almost any tuning for it. From a wide variety of camshafts to turbos and multi-throttle units. There are two options for tuning the power unit - “a.

To build an “evil” atmospheric motor you need:

- make porting of the cylinder head to improve purging;

- mill the head to increase the compression ratio;

- install “evil” camshafts;

- replace the valves with larger ones;

- implement 4-throttle intake;

- build a direct-flow exhaust system;

- replace the ECU with “January” - required for flexible and convenient engine tuning;

This tuning option will allow you to add 30-40 horsepower to the engine, but it should be taken into account that boosting will have a negative impact on the resource of the power plant.

If you wanted to assemble a turbo engine, you will need:

- make porting of the cylinder head to improve purging;

- lower the compression ratio by installing a thick cylinder head gasket, or you can install turbo pistons;

- choose a turbine for the engine, for example IHI VF14;

- implement mounting of the turbine to the exhaust manifold;

- arrange lubrication and cooling of the supercharger;

- place and secure an intercooler, pipes, and bluffs under the hood;

- replace the ECU with “January”;

- select fuel injectors and pump;

- correctly configure the engine on the assembled configuration.

Turbo tuning will allow you to add about 90 horsepower to the engine.

List of internal combustion engine modifications

The power plant had only 1 modification - A15MF.

The G15MF is equipped with distributed injection and a distributor ignition system.

G15MF - 8-valve power unit, its power is only 75 horsepower, engine production lasted until 2002.

A15MF is a 16-valve version of the G15MF; in fact, the engines differed only in the cylinder head and attachments. The crankshaft and all elements of the CPG are absolutely identical. The new cylinder head made it possible to achieve a power of 90 horsepower. Production of the power unit began in 2002 and lasted 6 years.

Specifications A15MF

| Manufacturer | Daewoo |

| Engine brand | A15MF |

| Years of production | 2002-2008 |

| Volume | 1498 cm3 (1.5 l) |

| Power | 85-90 |

| Torque moment | 130 (13) / 3800 130 (13) / 4400 137 (14) / 3600 |

| Weight | 117 kg |

| Compression ratio | 8.3 — 10.3 |

| Nutrition | injector |

| Motor type | in-line petrol |

| Ignition | coils |

| Number of cylinders | 4, bored inside the block without sleeves |

| Location of the first cylinder | TVE |

| Number of valves on each cylinder | 4 |

| Cylinder head material | aluminum alloy |

| Intake manifold | duralumin |

| An exhaust manifold | cast iron |

| Camshaft | 5 supports, casting, cast iron |

| Cylinder block material | cast iron |

| Cylinder diameter | 76.5 mm |

| Pistons | alloy, the pin hole is shifted by 0.7 mm to the rear wall |

| Crankshaft | cast iron, 8 counterweights, 5 supports |

| Piston stroke | 81.5 mm |

| Fuel | AI-92 |

| Environmental standards | Euro-3 |

| Fuel consumption | highway – 5.4 l/100 km mixed cycle 7.6 l/100 km city – 9.8 l/100 km |

| Oil consumption | maximum 0.5 l/1000 km |

| What kind of oil to pour into the engine by viscosity | 5W30, 5W40, 0W30, 0W40 |

| Which engine oil is best by manufacturer | Liqui Moly, LukOil, Rosneft |

| Oil for A15SMS by composition | synthetics, semi-synthetics |

| Engine oil volume | 4.5 l |

| Operating temperature | 95° |

| ICE resource | declared 250,000 km actual 350,000 km |

| Adjustment of valves | hydraulic compensators |

| Cooling system | forced, antifreeze |

| Coolant volume | 10.7 l |

| water pump | with plastic impeller |

| Spark plugs for A15SMS | BCPR6ES from NGK or domestic AU17DVRM |

| Spark plug gap | 1.1 mm |

| Timing belt | Gates, width 22 mm, service life 100,000 km |

| Cylinder operating order | 1-3-4-2 |

| Air filter | Nitto, Knecht, Fram, WIX, Hengst |

| Oil filter | with check valve |

| Flywheel | with clutch landing diameter 200 mm or 215 mm |

| Flywheel mounting bolts | M12x1.25 mm, length 26 mm |

| Valve stem seals | manufacturer Goetze |

| Compression | from 11 bar, difference in adjacent cylinders maximum 1 bar |

| XX speed | 750 – 800 min-1 |

| Tightening force of threaded connections | spark plug – 31 – 39 Nm flywheel – 62 – 87 Nm clutch bolt – 19 – 30 Nm bearing cap – 68 – 84 Nm (main) and 43 – 53 (connecting rod) cylinder head – three stages 20 Nm, 69 – 85 Nm + 90 ° + 90° |

If you have any questions, leave them in the comments below the article. We or our visitors will be happy to answer them