Home » Diesel » Diesel engine operating temperature - monitoring and warming up 933

Hello dear friends, nowadays modern diesel engines with rapid warming up to operating temperature are gaining more and more popularity.

Before you begin to consider any specific parameters, you need to have an idea of what a diesel engine actually is. In 1824, the theory was first put forward that a body could be heated to the desired temperature if it was subjected to a change in volume. In other words, apply rapid compression.

This was not put into practice until several decades later. The first diesel engine unit was released in 1897. It was developed by German engineer Rudolf Diesel. The operation of such an engine is based on the fact that atomized fuel, interacting with air (heated as a result of compression), self-ignites. Today, diesel engines are used only in cars and agricultural equipment; they have also found their place in tanks and ships.

Diesel engine features

This type of engine was invented back in 1824 by a French physicist who put forward the theory that by changing the volume of a body, it can be heated, that is, it can be rapidly compressed.

This hypothesis found practical application only 70 years later. It was then that the first diesel engine was released. Its operating principle is as follows: self-ignition of the injected fuel occurs, which interacts with air during the compression process.

The diesel engine has a wide range of applications, from passenger cars, agricultural equipment to military equipment (tanks, sea vessels).

Diesel engine operating temperature - monitoring and warming up

Hello dear friends, nowadays modern diesel engines with rapid warming up to operating temperature are gaining more and more popularity.

Before you begin to consider any specific parameters, you need to have an idea of what a diesel engine actually is. In 1824, the theory was first put forward that a body could be heated to the desired temperature if it was subjected to a change in volume. In other words, apply rapid compression.

Advantages and disadvantages of a diesel engine

Like all other engines, diesel has a number of both positive and negative aspects. Main advantages:

- Firstly, diesel engines can consume any fuel, so there are no serious requirements for it.

- Secondly, the greater the mass and concentration of carbon atoms, the greater the calorific value of the engine and its efficiency.

- Thirdly, vehicles with diesel engines are more responsive due to the high torque at low speeds. Therefore, owners of fast sports cars prefer the diesel engine option.

- Fourthly, the carbon dioxide content in the exhaust is an order of magnitude lower than that of similar gasoline engines.

- Fifthly, the diesel engine is more economical, since the cost of diesel fuel is less than the cost of gasoline.

Despite such an impressive list of advantages, the diesel engine also has a number of disadvantages:

- Firstly, the cost of a diesel engine is higher than the cost of a gasoline engine, since due to the high mechanical stress that occurs during operation, the parts must be of high quality and durable.

- Secondly, the power of gasoline engines exceeds the power of diesel engines.

- Thirdly, in winter, diesel fuel is more likely to solidify than gasoline.

- Fourthly, the operation of a diesel engine must be extremely careful and careful, since if you do not take care of it, you will have to carry out repair work, which will cost a lot of money.

Combustion chambers of diesel engines and operating features of such an internal combustion engine

Let's start with the fact that the combustion chambers of diesel engines are somewhat different from gasoline engines. There are two main types of cameras:

- undivided combustion chamber of a diesel engine;

- divided combustion chamber of a diesel internal combustion engine;

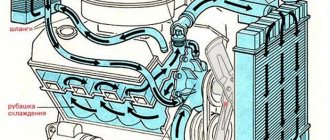

The undivided type is a single-volume chamber, usually of a simple shape, which is coordinated with the location of the nozzles. Such chambers are usually made in the piston bottom; they can also be made partly in the bottom and partly in the cylinder head, rarely only in the cylinder head.

The divided type of combustion chamber involves two volumes separate from each other, which are connected through special channels. There can be one or more such channels.

If we talk about the pros and cons, the first type allows the engine to provide better efficiency, but the temperatures in such a combustion chamber are higher. Shock loads are also increasing. As for separated combustion chambers, the efficiency is lower, but it is possible to achieve more complete combustion of fuel; such a diesel engine cokes less, smokes less, etc.

Combustion phases

The engine's operating process is divided into four parts. The first is the injection of a combustible mixture into the combustion chamber, in which there is high pressure.

Second, this mixture begins to ignite and burn. The third part is the formation of unspent mixture droplets, which then turn into soot. In phase 4, the combustion of fuel residues occurs in order to limit atmospheric pollution from them. Here a lack of oxygen is manifested, this is due to the burnt mass of fuel in the previous parts.

Phases of fuel combustion and the nature of exhaust gases

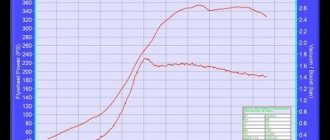

How is the combustion process of the fuel-air mixture carried out in diesel engines and what is the temperature in the chamber? So, the entire process of engine operation can be divided into four main stages. At the first stage, fuel is injected into the combustion chamber, which occurs under high pressure, which is the beginning of the whole process. Then the well-atomized mixture spontaneously ignites (second phase) and burns. True, the entire volume of fuel does not always mix well enough with air; there are also zones that have an uneven structure; they begin to burn with some delay. At this stage, a shock wave is likely to occur, but it is not dangerous, since it does not lead to detonation. The temperature prevailing in the combustion chamber reaches 1700 K.

During the third phase, droplets are formed from the unprocessed mixture; at elevated temperatures they turn into soot. This process, in turn, leads to a high degree of exhaust gas pollution. During this period, the temperature increases further by as much as 500 K and reaches a value of 2200 K, while the pressure, on the contrary, gradually decreases.

At the last stage, the remaining fuel mixture burns out so that it does not escape as part of the exhaust gases, significantly polluting the atmosphere and roads. This stage is characterized by a lack of oxygen, this is due to the fact that most of it has already been burned in the previous phases. If you calculate the entire amount of energy spent, it will be about 95%, while the remaining 5% is lost due to incomplete combustion of fuel.

By adjusting the compression ratio, or rather, bringing it to the maximum permissible value, you can slightly reduce fuel consumption. In this case, the temperature of the exhaust gases of a diesel engine will be in the range from 600 to 700 °C. But in similar carburetor engines its value can reach as much as 1100 °C. Therefore, it turns out that in the second case much more heat is lost, and there seems to be more exhaust gases.

Parameters of diesel engines

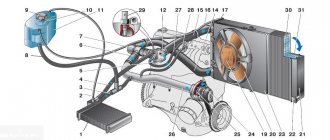

Many car owners ask the question what the operating temperature of a diesel engine should be. But to answer it, you should pay a little attention to the main parameters that affect the operation of the motor. The number of strokes is important in the operation of the motor, that is, there are two- and four-stroke.

The power of the unit also depends on the torque. The operating temperature of a diesel engine is determined by the degree of compression of the gas-fuel mixture, so the temperature is directly proportional to compression. Thus, as compression increases, the temperature will also increase, as a result of which the intensity of this process will increase, increasing the efficiency. It is worth remembering that the most efficient work is done when the fuel mixture burns evenly.

An important parameter to achieve the best possible performance is the operating temperature. The operating temperature of a diesel engine must be maintained based on the design and purpose of the engine. This fact determines whether the temperature is normal or not.

Compression ratio

The first condition that will determine whether the engine reaches the desired temperature is the compression ratio. This term is discussed in detail here . In short, it depends on how strongly the air in the cylinder is compressed whether the diesel fuel in the chamber will ignite or not. In a working unit, this parameter can reach 6-7 hundred degrees.

Unlike a gasoline unit, a diesel engine ensures fuel combustion by injecting a portion into hot air. The more the volume in the cylinder is compressed, the higher its temperature will be.

For this reason, the engine is tuned so that its compression ratio promotes uniform combustion of fuel, and not its sudden explosion as soon as it begins to atomize. If the permissible air compression is exceeded, the fuel-air mixture will not have time to form. This will lead to uncontrolled combustion of diesel fuel, negatively affecting the dynamic characteristics of the internal combustion engine.

Engines in which the working process is associated with the formation of an increased compression ratio are called hot. If this indicator exceeds the permissible standards, the unit will experience local thermal overloads. Plus, its operation may be accompanied by detonation.

Increased thermal and mechanical load leads to a reduction in the working life of the motor or some of its elements, for example, the crank mechanism. For the same reasons, the nozzle may fail.