Design features and scope of application

The KamAZ-53212 onboard tractor is intended for transporting a variety of cargo, including as part of a road train (with a trailer) on roads designed to accommodate vehicles with an axle load of up to 10 t. Most often, these machines work with trailers GKB-8350, GKB-8352 and GKB-8355, which have the same standard size as the truck body.

The KamAZ-53212 body is a metal platform with a wooden floor; with folding side and rear sides. The installation of an awning is provided, which turns the flatbed truck into a wagon, into that very long-range “tramp”.

The main distinctive feature of the KamAZ-53212 is its extended wheelbase, which significantly increases the model’s application possibilities. From the factory, KamAZ-53212 trucks were equipped with a metal platform that could hold up to 34 cubic meters of cargo, and when coupled with a trailer, the total volume is 64 cubic meters. The car steadily and confidently endures merciless operation in the widest temperature ranges - from -35 to +40 degrees Celsius; at an altitude of several thousand meters above sea level.

Vehicle plate

The vehicle manufacturer's plate is installed in the right door opening.

The plate contains:

- name of the manufacturer;

- identification number, including: XTC - manufacturer code;

- a - conventional car model code, consisting of six characters;

- b — year of manufacture code (1 character);

- с — serial production number of the vehicle (7 characters);

If the technically permissible maximum mass exceeds the corresponding permissible maximum mass, the mass values are indicated in two columns.

Technically permissible maximum weights:

- m* — technically permissible maximum weight of the vehicle;

- m1* — technically permissible maximum weight of a road train (for tractors);

- P1* - technically permissible maximum weight on the front axle;

- P2* - technically permissible maximum weight on the second axle;

- P3* - technically permissible maximum weight on the third axle;

- P4* - technically permissible maximum weight per fourth axle.

- Permitted maximum weights:

- m is the permissible maximum weight of the vehicle;

- m1 — permissible maximum weight of the road train (for tractors);

- P1 - permitted maximum weight on the front axle;

- P2 - permitted maximum weight on the second axle;

- P3 - permitted maximum weight on the third axle;

- P4 - permitted maximum weight per fourth axle.

Technical characteristics of the KamAZ-53212 vehicle

Weight and dimensions parameters

- Length – 8,530 m; Width – 2500 mm; Height – 3,800 m.

- Platform length – 6,090 m;

- The internal width of the platform is 2,420 m;

- Ground clearance – 280 mm;

- Rear track – 1.855 m; front track - 2.026 m;

- The angle of the climb to be overcome is at least 30 percent (18 degrees);

- Outer turning radius - on the outer wheel: 9 m, overall: 9.8 m;

- Curb weight of the vehicle – 8.2 tons;

- Front axle load – 3525 kgf;

- The load on the rear bogie is 4475 kgf.

- Load capacity – 10 tons;

- Gross weight – 18.225 tons;

- Load on the front axle - 4290 kgf;

- The load on the rear bogie is −13935 kgf.

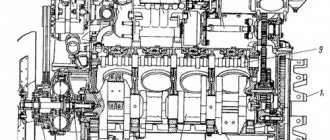

Engine KamAZ-53212

The vehicle is equipped with a KAMAZ-740.10 diesel engine. (later versions were equipped with its modernized and optimized version - KamAZ-740.11). This is a V-shaped eight-cylinder liquid-cooled engine with a 16-valve “OHV” mechanism. The KAMAZ-740.10 engine is equipped with a turbocharging system.

- Working volume – 10.85 liters.

- Power – 154 kW (or 210 horsepower), ranging from 2600 rpm.

- Cylinder diameter – 120 mm. Piston stroke – 120 mm.

- Torque – 657 Nm (65 kgf-m), in the range from 1500 to 1800 rpm.

- Compression ratio – 17.

- The operating order of the cylinders is: 1-5-4-2-6-3-7-8.

The injectors are of a closed type, the high-pressure fuel pump is 8-section, spool-type, with a low-pressure fuel priming pump, a fuel injection advance clutch and an all-mode speed controller.

The air filter is dry, with a replaceable cardboard filter element and a clogging indicator. The engine is equipped with an electric torch device (EFD) and, as an option, a PZD-30 pre-heater.

For 100 kilometers of travel, KamAZ-53212 on average consumes, according to manufacturers, approximately 25 liters of diesel fuel (consumption may vary depending on the fuel injection pump settings). The car's fuel tank holds 250 liters.

Additionally, the diesel fuel supply can be increased to five hundred liters. The driving range for this model is approximately 500-750 km as part of a road train, and 700-1000 km for an on-board vehicle.

Gearbox and clutch

The engine works in conjunction with a 5-speed manual transmission (+ 2-speed divider). The total number of “speeds” is ten forward and two backward. Gear ratios: “I-7.82 and 6.38; II-4.03 and 3.29; III-2.5 and 2.04; IV-1.53 and 1.25; V-1.0 and 0.815; ZX-7.38 and 6.02". II, III, IV and V gears are equipped with synchronizers.

The divider is also equipped with a synchronizer. The divider control is pneumomechanical type, pre-selector. Cardan transmission - two cardan shafts.

The main gear is double (bevel and cylindrical), its gear ratio is 6.53 (on request - 7.22; 5.94; 5.43); The middle axle is a straight axle, with a center differential locked using an electro-pneumatic or pneumatic drive.

The clutch on the KamAZ-53212 truck is a friction system, dry, double-disc; its drive is hydraulic, with a pneumatic booster. KamAZ-53212 is also equipped with an all-wheel drive system, with the ability to lock the center differential.

Steering and brake control

The steering mechanism consists of a screw with a ball nut and a piston-rack that engages with the toothed sector of the bipod shaft. Gear ratio – 20. Hydraulic booster – built-in, oil pressure in the booster – 80-90 kgf/cm2.

The service brake system is with drum mechanisms (diameter 400 mm, lining width 140 mm, cam release), with a dual-circuit pneumatic drive. Brake chambers: front - type 24, bogies - 20/20, with spring energy accumulators.

Parking brake - trolley brakes from spring energy accumulators, pneumatic drive. The spare brake is combined with the parking brake. The auxiliary brake is a motor retarder with a pneumatic drive.

The trailer brake drive is combined (two- and single-drive). There is an alcohol fuse against condensate freezing. Vehicle safety in motion and in parking is guaranteed by four systems:

- working, which contains separate dual-circuit pneumatics for the rear and front bogies, and drum drive mechanisms;

- parking, which is brought into working condition by means of spring batteries;

- auxiliary, with special dampers in the exhaust system;

- spare, represented by an additional parking brake (activated together with the main one). Its presence guarantees braking of the car in the event of an accident of the main systems.

Suspension and chassis; electrical equipment

The car frame is made on the basis of a system of side members made of special high-strength steel. In this design, the floor and base of the platform also received additional reinforcement.

The model has a dependent suspension, which is mounted on semi-elliptic springs, with a standard difference between the rear and front, with reaction bars and telescopic shock absorbers.

The rear part of the car is built on a balanced dependent suspension. There are the same springs, and the shock absorbers differ in the reaction rods. The springs of the rear bogie of the tractor are further strengthened. The beams on the drive axles are also reinforced.

KamAZ-53212 vehicles are equipped with discless wheels and pneumatic tube tires. The tire size is as follows: 9.00R20 (260R508). The truck is equipped with two 12 Volt / 190 Amp-hour batteries; generator 28 Volt / 1000 Watt. The voltage in the electrical network is 24 Volts.

"KAMAZ-65111"

The dump truck, whose name is “KAMAZ-65111”, is a vehicle capable of transporting loads up to 14 thousand kilograms. Its feature is a one-piece platform. Another fact also deserves attention - the ability to protect cargo from hypothermia in winter. Especially the last nuance becomes convenient when transporting liquid materials.

The engine is diesel type and has turbines. Its power is 260 “horses”. The cylinders are in the shape of the Latin letter “V”, and there are eight of them in total. The gearbox is a mechanical design with 10 steps. Engine displacement is 11 liters. There is no sleeping space in the cabin. The car has a high roof level.

Repairing KamAZ vehicles is a rather labor-intensive process that requires maximum professionalism and concentration. It should be noted that it should only be carried out at service stations or service centers. If this is not possible, then the maintenance may well be carried out by a company mechanic, but he must have sufficient experience working with similar vehicles.

Cabin "KAMAZ-53212"

The cabin in KamAZ-53212 vehicles is three-seater, tilting forward, with noise and thermal insulation; equipped with places for fastening seat belts, with a berth.

The driver's seat is sprung and adjustable in two directions: posture and height. Also, the driver of KamAZ-53212 has the ability to adjust the static deflection of the seat.

True, drivers of KamAZ-53212 categorically do not recommend getting carried away with changes in seat adjustments too often. Because in these cases quite noticeable vibrations begin to appear, which turn out to be quite difficult to eliminate. The height of the cabin allows you to stand in it, feeling quite comfortable.

The KamAZ-53212 cabin has decent thermal and sound insulation characteristics. To minimize distortions and vibrations inevitably caused by wind loads and pressure from the oncoming flow, the cabin is attached to the frame through an elastic suspension.

It can be said without exaggeration that for the eighties of the twentieth century, KamAZ-53212 had one of the best cabin interiors in the Soviet Union (not only among trucks, but also among passenger cars). The instrument panel, which has a progressive design for that era, contains only dials - dial indicators, without any electronics. They are read equally well and accurately under any conditions.

"KAMAZ-5460"

This model is a tractor. It is equipped with rear wheel drive. The cabin received a good height due to the raising of the roof, and two additional berths were installed. This KamAZ vehicle, the technical characteristics of which will be described below, differs from other models in this line in that it significantly saves fuel.

Its engine works with a 12-speed automatic transmission. The maximum speed that the car can reach is 110 km/h. The car “eats” approximately 36 liters of fuel per 100 km.

Reviews from experienced drivers and owners of KamAZ-53212

First, about the advantages of this model.

Reliability, endurance, unpretentiousness, ease of operation, scheduled maintenance and repair.

While the cars were operated according to the planned program adopted in the USSR (maximum 10 years of work - and before being written off), the car was considered reliable, and quite rightly so. But, starting from the mid-nineties, when many of these KamaAZs ended up in private hands, stories began full of resentment to the poor quality and insufficient reliability of these trucks.

It is hardly possible to take seriously the opinions of people who received 10-15-20 year old trucks and immediately began to operate them in a horrific manner. (From road tales about overloads of KamAZ trucks of this brand and related incidents, you can assemble a book of decent volume and very entertaining content).

Especially in those hard years, drivers and traders from Dagestan and other regions of the Caucasus were zealous, overloading their KamAZ trucks. (As you know, a significant part of the male population of these regions traditionally earns their living as long-distance drivers).

A car that has traveled hundreds of thousands of kilometers and lived for a couple of decades can no longer be reliable. Even the simple aging of materials must be taken into account here, because only cognac becomes better over the years. But not a car.

The undoubted advantage of this KamAZ, which many people note, is its excellent stove, which is capable of quickly and efficiently heating the interior in any frost, even if the engine is idling.

The excellent visibility from the driver's seat deserves kind words; the ability of the car to clearly hold the road in difficult weather conditions, thanks to the locking of the center differential.

The cross-country ability of KamAZ-53212 is very decent for a vehicle of this class. Valiant melon growers in the 90s looked with amazement at the ordeal of used European and American-made trucks, which, out of inexperience, stuck on the sandy soil of melon fields to load watermelons.

Steep (on asphalt) and powerful cars turned out to be completely helpless on slightly loose soil, where KamAZ trucks drove completely calmly. These same unsightly, in comparison, KamAZ trucks, by the way, pulled the “urban and intelligent” foreign trucks out of unexpected sandy captivity.

Now about the disadvantages, of which there are also many.

Firstly, in KamAZ-53212, both the engine and everything else “snot” with oil. After parking any KamAZ of those years (not only the 53212 model), an indispensable attribute is stains on the asphalt or ground - from oil or diesel fuel. It gradually leaks from it, like from a wild boar wounded during a hunt, and it is almost useless to fight these small but annoying leaks.

Tie wire and a piece of oxygen hose should always be in stock, pneumatics do not stand up to criticism. Main pipes are constantly damaged due to rubbing or simply breaking. The tubes themselves are located in the frame, in rather hard-to-reach places.

Pneumatic cranes also often cannot withstand loads. As a rule, the crane responsible for the axle load fails first, then the triple protection, etc. and so on. In most cases, there is only one reason: oil enters the air from the compressor, which cannot be restored to its ideal form. Oil destroys rubber parts in the system.

Drivers and owners of used KamAZ-53212 are unanimous in the opinion that it is impossible to work simply as a driver on this truck, you need to be (or become) also a mechanic, qualified, self-confident and ready for anything.

Types of KamAZ vehicles - model range and classification

KamAZ 4208 (in various modifications)

The average price is about 3.5 million rubles.

- engine type – diesel;

- maximum power – 240 hp;

- The volume of the motor used is 10850 cm3.

The estimated cost of the Kamaz shown in the photo is 3.6 million rubles.

- engine type – diesel;

- maximum power – 240 hp;

- The volume of the motor used is 10850 cm3.

The average price is about 2-2.5 million rubles.

- engine type – diesel;

- maximum power – 178 hp;

- The volume of the engine used is 5900 cm3.

Read more about model 4308 in this article.

The average price of the Kamaz-4310 model reaches two million rubles.

- engine type – diesel;

- weight – 8.41 tons;

- maximum speed – 85 km/h;

- Fuel tank volume – 2X125 l.

The estimated cost may be 2.2 million rubles or more.

- engine type – diesel;

- maximum power – 240 hp;

- The volume of the motor used is 10850 cm3.

43118

The estimated price for the truck is just over 2.5 million rubles.

- engine type – diesel;

- maximum power – 260 hp;

- The volume of the motor used is 10850 cm3.

- engine type – diesel;

- maximum power – 178 hp;

- The volume of the engine used is 5900 cm3.

The estimated cost of this truck is about 2.3 million rubles.

- engine type – diesel;

- maximum power – 240 hp;

- The volume of the motor used is 10850 cm3.

The estimated price for such a car can reach up to 2.8 million rubles.

- engine type – diesel;

- maximum power – 240 hp;

- The volume of the motor used is 10850 cm3.

The estimated cost for such equipment is about 850-900 thousand rubles.

- engine type – diesel;

- maximum power – 260 hp;

- The volume of the motor used is 10850 cm3.

The price for such a truck can reach 2.3 million rubles.

- engine type – diesel;

- maximum power – 240 hp;

- The volume of the motor used is 10850 cm3.

The price for such a truck can reach 2.6-2.7 million rubles.

- engine type – diesel;

- maximum power – 240 hp;

- The volume of the motor used is 10850 cm3.

The estimated price for such a truck is about 1.8 million rubles.

- engine type – diesel;

- maximum power – 240 hp;

- The volume of the motor used is 10850 cm3.

The estimated cost of such equipment is about 1.7 million rubles.

- engine type – diesel;

- maximum power – 260 hp;

- The volume of the motor used is 10850 cm3.

The average price for such a truck can reach 9-10 million rubles.

- engine type – diesel;

- maximum power – 730 hp;

- the volume of the motor used is 17240 cm3;

- weight – 12 tons;

- maximum speed – 240 km/h.

4326-9 – participant of the Dakar rally

The estimated cost is about seven million rubles.

- engine type – diesel;

- maximum power – 850 hp;

- total number of cylinders – 8;

- weight – 9.5 tons;

- length – 722 cm;

- height – 318 cm.

Read the article about the hooded Kamaz based on 4326.

The price for such a truck is about 3.1 million rubles.

- engine type – diesel;

- maximum power – 300 hp;

- The volume of the engine used is 6700 cm3.

53212

Prices for such a truck do not exceed one million rubles.

- engine type – diesel;

- maximum power – 210 hp;

- weight – 18225 kg;

- maximum speed – 80 km/h.

The estimated cost of such a model is about one million rubles.

- engine type – diesel;

- maximum power – 240 hp;

- The volume of the motor used is 10850 cm3.

The estimated cost of such a model is about 2.6 million rubles.

- engine type – diesel;

- maximum power – 260 hp;

- The volume of the motor used is 10850 cm3.

The estimated cost for such a model ranges from two to three million rubles.

- engine type – diesel;

- maximum power – 260 hp;

- The volume of the motor used is 10850 cm3.

The price for such a model is about 600 thousand rubles.

- engine type – diesel;

- maximum power – 240 hp;

- The volume of the motor used is 10850 cm3.

The price for such models can reach two million rubles.

- engine type – diesel;

- maximum power – 360 hp;

- The volume of the motor used is 10850 cm3.

The price for such a model is about 900 thousand rubles.

engine type – diesel;

- maximum power – 260 hp;

- The volume of the motor used is 10850 cm3.

The estimated cost of such a model is about 1.2 million rubles.

- engine type – diesel;

- maximum power – 260 hp;

- The volume of the motor used is 10850 cm3.

The price for such a model can reach two million rubles.

- engine type – diesel;

- maximum power – 360 hp;

- The volume of the motor used is 11760 cm3.

Take a closer look at this model.

Prices for such cars range from 4 to 4.3 million rubles.

- engine type – diesel;

- maximum power – 320 hp;

- The volume of the motor used is 11760 cm3.

Dump truck 65222

The price for such a dump truck can reach five million rubles.

- engine type – diesel;

- maximum power – 360 hp;

- The volume of the motor used is 10850 cm3.

Engine type 6540

A representative of the KamAZ dump truck model range, the estimated cost of this model is about three million rubles.

- engine type – diesel;

- maximum power – 260 hp;

- The volume of the motor used is 10850 cm3.

Model 6560

The estimated cost of such a model is about 7.3 million rubles.

- engine type – diesel;

- maximum power – 400 hp;

- The volume of the motor used is 11760 cm3.

Truck brand ATZ 56132

The cost of this model is about 2.7 million rubles.

- engine type – diesel;

- maximum power – 280 hp;

- The volume of the motor used is 11760 cm3.

Technical characteristics of the SZAP-3517 machine

The price for such a model can reach 3.7 million rubles.

- engine type – diesel;

- maximum power – 240 hp;

- The volume of the motor used is 10850 cm3.

Cost of KamAZ-53212

The KamAZ-53212 truck model, as already noted, is distinguished by its endurance and long service life. That’s why today many of these trucks, which have not been produced since 2000, are successfully used in various fields of industry, construction and agriculture.

Perhaps, at the end of the 2010s, it makes sense for only a truly experienced driver and a car mechanic “all in one” to decide to buy this used car.

For a minimal cost it is possible to purchase a used chassis. In this case, the price tag for a car in working condition starts at 120,000 rubles (early 90s). For KamAZ-53212 from the late 90s they will cost from 300,000 to 450,000 rubles.

But modifications with special equipment installed on the chassis are offered much more expensive. For example, KamAZ-53212 trucks with loader cranes are offered at prices ranging from 700,000 to 1,000,000 rubles.

Overall, this is a good car - KamAZ-53212! Especially for the 80s of the twentieth century. Many men in the CIS remember with sincere gratitude not just a car, but also a friend - KamAZ-53212! For the 21st century, this is, naturally, an already outdated car. But still left a noticeable mark on the history of our country.

Brief information about the KAMAZ automobile plant

This December will mark the half-century anniversary of the start of construction of the Kama Automobile Plant (KAMAZ) in Naberezhnye Chelny. The economic situation in the Soviet Union and the state housing construction program required a sharp increase in the fleet of heavy-duty trucks (from 8 to 20 tons).

After much comparison and comparison of more than 70 different options, Naberezhnye Chelny turned out to be the most suitable due to the fact that, in terms of geographical location, the town was located almost in the very center of the USSR. In addition, one of the largest construction companies, KamGESenergostroy, operated there. And this made it possible to build a dam and hydroelectric power station in the shortest possible time.

The plant, and with it residential buildings and all the necessary infrastructure for its future workers, was built at an accelerated pace, and already in 1974, trial production was launched, and in 1975, the first engine was assembled. On February 16, 1976, the first truck rolled off it - KAMAZ-5320.

The Kama Automobile Plant developed rapidly, and already in 1979, having produced 100 thousand vehicles, it became the world leader in terms of production of trucks. In the period from 1976 to 1978, three basic models were produced: KAMAZ-5320 with a lifting capacity of 8 tons, a modification on its basis of the KAMAZ-5511 construction dump truck with a capacity of 10 tons, and a KAMAZ-5410 truck tractor with a lifting capacity of 20 tons.

Then a ten-ton KAMAZ-53252 truck with an extended wheelbase, a dump truck for agricultural needs, and a KAMAZ-54112 truck tractor designed for road trains with a lifting capacity of 33 tons were developed.

In February 1980, the 150,000th KAMAZ was produced. And in 1981, the second stage of the plant was put into operation, after which the production of six-ton KAMAZ-4310 vehicles began. The basic model was prepared for military purposes, for which it was equipped with a winch. Based on the same model, the agricultural KAMAZ-43105 was created.

In addition to trucks and dump trucks, the plant produced automotive equipment for a wide range of applications: loaders, tractors, truck tractors, flatbed trucks and even buses. In the early 80s, each base model was equipped with modified engines producing 220 horsepower with a 10-speed gearbox. By the mid-80s, the plant gained good momentum, and in 1988 the millionth truck rolled off the factory assembly line.

The company continued to introduce new models. By this time, almost a third of the cargo fleet of our entire vast country consisted of vehicles from the Kama Automobile Plant, but they still could not withstand competition with foreign analogues. In this regard, a decision was made to develop and build a new generation of heavy-duty trucks.

In the 90s of the twentieth century, the country switched to market relations, and imported trucks began to appear on the roads. The plant experienced serious difficulties with sales, which led to a crisis and almost bankruptcy. But, as they say, trouble does not come alone - in the spring of 1993, an unprecedented fire occurred in Naberezhnye Chelny, destroying the engine plant, the main production building and almost all complex technological equipment.

It seemed that everything was lost: the symbol of freight transport of the USSR could no longer rise... However, at the end of the 90s, the KAMAZ plant, thanks to the invaluable help and support of the government of the Russian Federation and Tatarstan, again began producing trucks.

And in the early 2000s, the positive results of the enterprise allowed it to begin improving the model range of popular trucks. Thanks to foreign investments (10% of KAMAZ shares were sold to the German concern Daimler AG) and the creation of two joint ventures with it, a rapid renewal of the line of manufactured models began. Thus, in 2013, serial production of the new flagship KAMAZ-5490 tractor began, which served as the basis for a whole family of trucks.

On February 15, 2012, the Kama Automobile Plant produced the two millionth KamAZ. Currently, the plant produces more than 30 thousand trucks of various modifications per year, which allows it to operate stably.

All KamAZ models: Technical data

The Kama Automobile Plant as a whole, and individual KamAZ models, are certainly familiar to everyone.

But information about trucks that were once produced or are still being produced is scattered across the World Wide Web in such a way that it is quite difficult to get a complete picture. We took the trouble to sort and collect together data about all KamAZ vehicles and their characteristics, so that everyone could get the information they need in one place, without spending a long time searching. But first, some facts from the history of the plant. Birth of a Giant

The plant was launched in December 1969. The place for its construction was the city of Naberezhnye Chelny on the banks of the Kama River (then still the Tatar Autonomous Soviet Socialist Republic). KamAZ was an important government project - it was supposed to produce about 150 thousand cars and 250 thousand engines, as well as fill the severe shortage of special equipment with a carrying capacity of more than 8 tons.

The first KamAZ models, which by definition became trucks, tractors and dump trucks, durable and unpretentious (which is important for a country with such differences in climate), were based on a three-axle 6x4 diesel chassis with a “cab over engine” layout. The axle load of those vehicles is no more than 6 tons. A KamAZ-740 V8 four-stroke diesel engine (10.852 l) was developed especially for the new products. It was economical and produced 210 hp. However, from the very beginning the power was planned to vary from 180 to 360 “horses”. The gearbox was five-speed.

The first KamAZ models rolled off the assembly line right before the 25th Congress of the CPSU - February 16, 1976. Of all the models, 43% came with NefAZ (Neftekamsk Plant) bodies. Flatbed trucks and tractor-trailers accounted for 27% and 20%, respectively.

In 1981, the second stage of KamAZ was introduced and production of a new series of vehicles began - 4310 (6 tons, 6x6 all-wheel drive). Also in the early eighties, engines increased to 220 hp were installed on basic KamAZ models. power and ten-speed gearboxes.

High production rates had already been established by the mid-eighties, and October 1988 was marked by the production of the millionth KamAZ truck. But with the advent of perestroika and the appearance of imported trucks in our country, an urgent need arose to revise the strategy and produce a second generation of trucks, more competitive. The first KamAZ models began to lose popularity even in their homeland, not to mention the failed hopes for export.

After perestroika

The second generation KamAZ trucks received turbocharged engines, while imported components and power units were used. The cabins became more comfortable - 12 cm higher. In 1989, a two-axle 4x2 family, unified with three-axle models, went into production in small batches. Modified first-generation KamAZ models also came out - they received a gas-diesel engine with 210-220 hp. The plant became a joint stock company OJSC KAMAZ, and the most difficult time for it began.

April 1993 was a sad milestone in the history of the enterprise - after a severe fire, both the equipment and the main building were destroyed. Only by the end of the 90s, with the help of the authorities, production was completely restored and began to approach its previous level. In the summer of 1999, the milestone of 1 million 600 thousand diesel engines was reached.

In 1995, the third generation of KamAZ vehicles was launched into production. Modernized versions of the first 6x4 series were used as the basis. These KamAZ models were equipped with 240- and 260-horsepower turbocharged engines. The volume of the cabin has increased, and top and side fairings have appeared.

New millennium

The plant celebrated the two thousand years with the active development of trucks in accordance with European environmental standards. The first such engine came out in 2004. A little later, a joint production of parts for trucks began with the German manufacturer Zahnrad Fabrik. German influence became stronger in 2008, when Daimler AG bought 11% of KamAZ's authorized capital. By this time, more than 50 million rubles, after which the controlling stake was purchased by the Severstal-Auto holding.

The plant set a new production record, the first after the fire, in 2007 - 50 thousand trucks and more than 60 thousand engines per year.

KamAZ met 2010 in the world's leading positions in the production of diesel engines. Not only all kinds of KamAZ truck models have become popular, but also agricultural and road construction equipment produced under the CNH brand.

KamAZ celebrated its anniversary on February 15, 2012, having crossed the milestone of 2 million trucks produced. And today the plant continues to break records, annually bringing considerable profits to the country.

KamAZ models. Classification

The table below shows all KamAZ models produced during the existence of the plant, as well as their main technical characteristics. Trucks are sorted by type and arranged in ascending order of number in the model index.