WOULDN'T WE SPOILE GASOLINE?

Before starting the tests, we decided to make sure that introducing additional additives into high-quality gasoline would not lead to its spoilage. To do this, we prepared control samples by adding drugs to gasoline according to the manufacturers’ recommendations and took them to a certified laboratory to find out whether the purifiers contained anything prohibited by the Technical Regulations of the Customs Union. In addition, we checked how the addition of a purifier affects the octane number of gasoline.

The results are in the table. They turned out to be quite positive. Only the Hi-Gear cleaner excels: after adding it, a small amount of resin appears in gasoline. Presumably, this is a lubricating additive: the description of the drug claims to improve this ability of gasoline. By the way, there is no such parameter in the regulatory documents for gasoline - it is important only for diesel fuel.

All drugs increased the content of bound oxygen in gasoline, but it was still very far from reaching the maximum norm (2.7%). An increase in oxygen content indicates the presence of additional oxygenates in the purifiers, intended to improve fuel combustion. And this is a necessary condition for high-temperature cleaning of engine parts. This feature was manifested to a slightly greater extent in the Suprotek cleaner. It is important not to overdo this parameter: an excess of bound oxygen in the fuel can confuse the engine management system.

Special solvents combat deposits in the “cold” part of the engine. Indeed, after adding additives, the pH level in gasoline increased noticeably. The leader here is the Hi-Gear cleaner; it’s not called “fast” for nothing. But an increase in acidity can affect the life of seals in the fuel system. Therefore, its moderate increase in Liqui Moly and Suprotek cleaners is apparently more justified. The main thing: the experimental drugs do not contain anything prohibited - no methanol, no metals, no benzene; the change in octane number does not exceed the measurement error.

Motor tests showed that all tested drugs work. The mass of deposits on parts formed during standard contamination has decreased significantly. It might have taken longer to clean completely. Since normal engine operating conditions are more severe than laboratory ones, the real efficiency of the cleaner should be higher. But we deliberately did not go to extreme conditions: we need to analyze the effectiveness of the drugs themselves, eliminating the factor of temperature self-cleaning, which works independently.

The leaders were Liqui Moly and our “import substitution” - the Suprotek cleaner. In load modes, cleaning with these preparations reduced fuel consumption by an average of 3.5–4%, and in idle modes the effect increased to 7–8%. The content of residual hydrocarbons in the exhaust gases has noticeably decreased, and this is one of the important indicators of the degree of engine contamination.

What did the gasoline show? Long-term tests on regular gasoline without any purifiers did not reveal any pronounced trend. But with Lukoil Ecto gasoline, combustion quality began to improve: fuel consumption and CH content at control points decreased. Therefore, he still washes. However, improvement occurs only after a certain point. At the beginning of the test cycle, we experienced a general deterioration in engine performance: deposits began to be actively washed out of the fuel system, which spoiled the mixture formation process. But then positive dynamics clearly emerged, and by the end of the tests the indicators stabilized at a significantly better level than before the start of testing the contaminated engine.

Lukoil Ecto gasoline works much like additives, but much softer. It seems that the principle of action of the cleaners is the same as that of commercial gasoline detergent additives, but the effect is enhanced by a higher concentration.

Weight analysis of the parts confirms these conclusions: the cleaners provided a more noticeable reduction in the mass of deposits than Lukoil Ecto gasoline. Most of the deposits went into the exhaust pipe during the tests, and the best results were shown by the leaders in motor performance - Liqui Moly and Suprotek.

Do-it-yourself flushing of the diesel fuel system

The appearance of the first symptoms of injector contamination requires the car owner not only to diagnose the malfunction, but also to carry out a set of measures to flush the fuel system.

The future expenses of the car owner depend on the timeliness of this work. Chronic contamination leads to breakdown of expensive parts and the need to replace them.

Self-cleaning of the fuel system of a diesel engine is most often done using special additives that are added to the fuel tank, mixed with fuel and provide high-quality cleaning of various “garbage”.

After using the additive, you can use the car as usual, being confident in the effective operation of the product.

The flushing composition is mixed with fuel, passes all the way through the diesel fuel system, is supplied to the injectors and cylinders, where it burns under pressure.

To get results, it is advisable to give preference to products from well-known brands.

Saving in this matter can lead to a lack of results or even greater contamination of the system.

Experts note that this method is ineffective, because it will not be possible to remove 100% of the contaminants.

But the additive copes with a certain percentage of “garbage”, eliminating the main signs of a malfunction - increased fuel consumption, decreased dynamics and a drop in engine power.

Good results are achieved by regular use of additives that perform a preventive function. As a result, the fuel system remains clean for a long time, and there is no need to flush it at a service station.

If the car owner has not maintained the system for a long time, it is unlikely that it will be possible to remove stubborn dirt. In such a situation, it is better to contact a service where cleaning is carried out using special equipment.

It should be noted that there are a number of other methods for cleaning diesel injectors. One of them is the dismantling of products for direct cleaning by simulating work.

This option is suitable for old-style engines, but in the case of new diesel engines it is dangerous. The main risk is the difficulty of dismantling the nozzle. Even if the latter can be removed, there remains a high risk of damage to the device.

As a result, you will have to buy a new part, the cost of which will cover the savings of replacing it yourself several times.

There is another cleaning option - using washing liquid.

Below we will consider the principle of performing the work using the example of a composition from the manufacturer Wynns.

- Take a pair of gasoline-resistant hoses with a length of 70-80 cm. The diameter of one tube should be 0.8 cm, and the second - 1.0 cm.

- Remove the original tubes from the injection pump and put the purchased products in their place. Place the second edges of the hoses in a container with the product poured into it.

- Place a standard Zhiguli filter on the thicker tube that supplies fluid to the injection pump. Be careful when doing this - the hose must reach the bottom of the container to prevent air entrapment. In this case, the bottle itself must be secured under the hood.

- Start the engine and leave it running for 15 minutes at idle. After this, press the accelerator pedal several times, wait another 3-4 minutes and turn off the engine.

- Wait 15-20 minutes until the liquid has completely cooled and the deposits have left the surface.

- Carry out the procedures discussed above until the rinsing composition runs out.

Monitor the mixture carefully. You cannot allow a diesel engine to stall due to lack of fluid. On many modern cars, fuel-cooled electronics are installed in the internal part of the fuel injection pump.

If there is a shortage of flushing fluid or fuel, it may suffer. To optimize flushing, you can make a special coil and lower it into a bucket to ensure high-quality cooling of the liquid.

After the composition has been developed, return the fuel pipes to their original places and start the engine. As soon as the diesel engine's operation returns to normal, turn it off.

The work of self-flushing the fuel system is completed, and the car is ready for use.

Be careful and remember the dangers of the working fluid. It helps to wash your hands, but after using it, it is advisable to rinse your skin with clean water and lubricate it with cream.

If the fuel injection pump of the car is very dirty, it is recommended to take two cans of liquid and then proceed according to the algorithm described above. Empty the contents of the can to the end so that the engine does not stall.

After this, turn off the diesel engine, and the next day perform the same manipulation, but using the second can.

Upon completion of the work, all that remains is to return everything to its place.

TO POUR OR NOT TO POUR CLEANERS INTO A PETROL ENGINE?

Conclusion: the drugs really work , they can be used. But there is still a wormhole of doubt: won’t these products somehow harm the engine?

Let's think. Introducing drugs into fuel increases the content of bound oxygen. The bulk of commercial gasoline has a large reserve of this parameter, so problems should not arise. But here we often find natural fuel with tens of percent methanol. That's where oxygen is either at its limit or even going off scale. In this case, adding additional oxygenates is not advisable. Therefore, principle one: use cleaners only in combination with high-quality gasoline .

WHERE DOES THE MUD COME FROM AND HOW TO DEAL WITH IT?

The engine itself is dirty. Deposits in the combustion chamber are a consequence of incomplete combustion of fuel and oil; they disrupt the thermal state, change the compression ratio, reducing the volume of the combustion chamber. So it's not far from detonation. In the intake system, dirt forms on the inside of the valve plates and on the walls of the intake ports. They interfere with the filling of the cylinders and thereby steal some of the power. Deposits in the fuel system, especially in injectors, disrupt the mixture formation processes.

Problems in different areas of the engine have different natures. In the combustion chamber and on the valves we will find predominantly solid particles (such as coke), glued together with organic matter and forming a black “fur coat”. In a fuel system where operating temperatures are low, there is nowhere for cokes to come from, and deposits form there in the form of varnish films of varying thicknesses.

Hence there are two different principles for removing deposits. In the fuel system, the varnish must be dissolved, and in the combustion chamber, the coke is removed by burning off the organic binder, which holds the carbon deposits on the surface. To do this, you need to use a fuel additive that will briefly increase the combustion temperature. Or go out of town and drive a hundred kilometers at good speed - high-temperature cleaning is guaranteed.

Flushing the diesel fuel system at a service station

As noted above, severe contamination requires the use of special equipment, which is available only at specialized service stations.

Today, two types of injector cleaning are most in demand:

- Ultrasound. In this case, the capabilities of ultrasonic waves are used. Before starting work, the injectors are removed from the engine and then placed in a special compound. Thanks to the use of a special liquid, it is possible to optimize the process of propagation of ultrasonic waves and improve the results. The principle of operation is the action of vibrations that propagate in the solution and cause deposits to “unstick” from the walls, simultaneously destroying them. The advantage of this method is that the integrity of the fuel atomization and supply system remains intact. The action of ultrasound gradually promotes peeling of dirt and its dissolution. For greater effectiveness, the procedure should be repeated every three years.

- Washing on the stand. An equally effective method is the use of flushing equipment, which allows you to clean the injectors without removing them from the car. The advantages of this option are high speed, convenience and safety for the engine. When work is completed, the diesel fuel system is disconnected from the engine, and a unit with a cleaning compound is connected to the freed pipes. After connection, the engine starts, and the flushing fluid begins to circulate through the system, removing accumulated deposits and dirt. The entire procedure for flushing the fuel system takes no more than half an hour. If the diesel engine has not been cleaned for a long time, it is advisable to repeat the procedure twice. This method is recommended for use in cases of serious contamination, when cleaning with your own hands no longer gives the expected result.

Stand 3 (1)

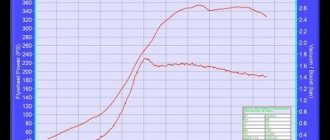

We took as a basis the methodology developed for assessing the performance quality of “improved” gasolines. The test engines were provided with so-called reference pollution. In the original engine, with new injectors and spark plugs, a cleaned combustion chamber and clean valves, several tens of liters of a mixture of gasoline, diesel fuel and mineral motor oil were burned in specially selected modes that ensure an increased rate of deposit formation. After this, such a parameter as the residue in the flask, which characterizes the tendency to form deposits, increased from the initial 1–2 to 7%, and the tar content increased from almost zero to 12 mg per 100 cm³ of gasoline (at a rate of 5 mg/100 cm³ maintained in ancient GOST).

After the tests, the engine was partially disassembled, the injectors, intake valves, and spark plugs were weighed. Then - assembly and characterization in several modes. In this case, idle speed and light loads were used to avoid thermal self-cleaning of the engine. Pollution has led to an increase in fuel consumption and toxicity, most of all in idling mode. When testing the cleaning properties in strictly fixed modes, 80 liters of fuel containing the tested preparations were produced. In addition, a similar test cycle was carried out for the “regular” base fuel Lukoil A95-K5 and the “improved” Lukoil Ecto gasoline. The control characteristics of the engine were periodically taken to track the dynamics of the drugs. The engine was then disassembled, the parts were weighed and photographed. Comparison with the original data made it possible to judge the presence or absence of a washing effect. Next, the engine was reassembled and its characteristics were measured when running on pure gasoline, without any additional additives.

How to flush the diesel engine power system: methods and means for flushing

- 1 When to clean diesel injectors: main signs

- 2 How to flush the fuel system of a diesel engine yourself

- 3 Other available methods for flushing the injector and engine power system

- 4 What's the result?

It is well known that the fuel system of an engine, both gasoline and diesel, requires periodic flushing. At the same time, diesel fuel equipment is much more sensitive to fuel quality, and the slightest deviations from the norm immediately affect the operation of the entire power unit.

For this reason, the need to rinse and clean the injectors on a diesel engine is a very pressing issue. This procedure should be performed both when the first signs of contamination appear, and for preventive purposes, when no symptoms of contamination of the power system are detected.

Next, we will talk about how to flush the fuel system of a diesel engine, what signs indicate the need to clean the injection, and also how to flush the injection nozzles of a diesel internal combustion engine.

Easy flushing method

Many car owners are wondering how to flush the fuel system of a diesel engine in a simplified manner. In modern conditions, even the most complex work can be completed. Therefore, experts talk about three ways to flush the fuel system. Each process has different efficiencies. Therefore, everything depends on the wishes of car owners.

The simplest and most accessible method is considered to be combating pollution independently. To do this, you will need to use a special liquid, which is created for both old and new units. After adding the mixture to the fuel tank, the system will be completely cleared of various deposits that damage the injectors.

Experts recommend that car owners purchase a mixture from a well-known manufacturer. In this way, you can achieve the desired results.

This is truly the best method for removing stains on your own without unnecessary hassle. Many mothers use the product for preventive purposes. According to experts, it is necessary to pay attention to the fuel system in time. If you do not carry out the appropriate procedures, then in the future problems may arise with the fuel pump grid, fuel filter and, of course, with the injectors.

Basically, complete and thorough washing is carried out at intervals of no more than ten kilometers. The cost of cleaning the fuel system is not high. Therefore, you can regularly buy liquid and follow the appropriate procedures. Basically the process is quite easy. If desired, each person can perform this action.

Some car owners use maintenance services. To connect the fuel rail, craftsmen use a special installation. Thanks to the latest innovations, the cleaning solvent is supplied.

But first, the power system from the fuel tank must be disconnected. The ramp immediately performs its function and completely flushes the fuel system. It is worth noting that there are single and double circuit installations.

According to professionals, it is much preferable to use a dual-circuit installation, which has a number of advantages. The solvent can also be used independently. Flushing with this device does not require any special skills. To carry out the work yourself, you will need to purchase a new fuel filter, fuel hoses and flushing fluid.

In order not to spend extra money on purchasing a pump, you can use a supercharger. Flushing the fuel system of a diesel engine is not that difficult. Anyone can perform the procedure without unnecessary hassle at home.

At the same time, you can save money and not seek help from a car service. If you clean the device twice a year, you can maintain the integrity of the fuel system.

Source

When to clean diesel injectors: main signs

So, as already mentioned, during the operation of a vehicle, contamination of injectors and other elements of the power system is almost inevitable, especially in the CIS.

Moreover, even if the owner fills the tank with the highest quality and most expensive diesel fuel at a gas station, and also changes all the filters in a timely manner, this will only increase the service intervals for cleaning the injectors, but does not in any way eliminate this need.

Moreover, a simple car owner often does not have the opportunity to determine the quality of fuel. This is often taken advantage of by unscrupulous gas station owners who sell fuel of very mediocre quality in their networks, passing it off as the most “elite” expensive diesel fuel.

It becomes clear that fuel is often the main culprit for injector contamination. In the case of diesel, the need to use “winter” and “summer” diesel fuel, as well as to use all kinds of additives and antigels, means the presence of additional impurities in the fuel.

But that's not all. The power supply system of diesel engines works with fuel, which itself initially has many “heavy” fractions. In this case, the most active accumulation of deposits occurs at the moment when the heated engine is already turned off.

The fact is that diesel injectors not only pass diesel fuel under high pressure, but are also subject to strong heating. Under such conditions, both the production of mechanical parts and the contamination of diesel injectors occur.

After stopping, the engine is hot, the cooling system does not work, but the fuel remaining in the injectors literally “burns”, leaving a characteristic coating in the form of varnish deposits on the injector surfaces.

The specified layer of varnish coating reduces the cross-section of the passage channel, actually reducing the ability of the nozzle to supply diesel fuel to the combustion chamber in the required volume. For example, a layer that is just over 4 microns thick can already reduce injector performance by 20% or more. As a result, the diesel engine does not perform well, loses power, fuel consumption increases, etc.

You can determine that diesel injectors need to be cleaned by the following signs:

- the engine does not start well;

- idle speed fluctuates;

- diesel troit;

- acceleration dynamics have worsened;

- dips appeared when pressing the gas pedal;

- increased diesel fuel consumption;

- the engine produces gray or black smoke;

Let us add that usually the combination of the listed symptoms more often annoys the driver with the onset of cold weather. The reason is a decrease in the ability of the fuel-air mixture to evaporate under conditions of low outside temperature.

It is important to understand that any malfunctions in the diesel engine cannot be ignored. For example, if you do not clean the injectors in a timely manner, then in the future there will be severe coking of the nozzle, as well as the internal channels, and the rate of wear of the shut-off needle will increase. Then the nozzle becomes deformed, etc.

Please note that even if you then clean it, no amount of washing will cope with such damage. In other words, if you start the process, then the diesel injectors will need to be either repaired or completely replaced with new elements.

Flushing the fuel system of a diesel engine: description of the main methods

Each diesel and gasoline unit, when operating a vehicle, needs thorough cleaning.

Over time, the fuel system fails and causes a lot of trouble for car owners. This factor may be caused by the accumulation of various resinous and varnish deposits. Problems can be solved in various ways. Therefore, to begin with, we suggest that you carefully read the article and familiarize yourself with the basic advice of experts. To remove certain contaminants, it is necessary to thoroughly flush the device. After all, the fuel system requires regular careful maintenance. First of all, you should take into account the time intervals for the procedures.

According to experts, domestically produced fuel contains low-quality impurities. For example, in European developed countries, the predominance of sulfur and other impurities in excess quantities is unacceptable. After all, these components contribute to contamination of the fuel system.

The combustion of such petroleum products leads to severe environmental pollution. Thus, the human body is susceptible to negative environmental factors. Accordingly, at first, great importance should be given to the use of high-quality fuel.

Deposits that accumulate in diesel and gasoline units have a negative impact on the injectors. These parts wear out over time. It is worth noting that high temperatures, which reach up to one hundred twenty degrees and pressure up to five bars, contribute to the hardening of deposits, as well as the transformation into certain growths.

As a result, the fuel is unable to dissolve such compounds. Naturally, the injectors stop working normally. Due to these unfavorable factors, the following occurs:

- reduction of their capacity;

- changing the direction and shape of the spray torch;

- injectors stop functioning

In some cases, the injectors become clogged in the fuel system or are open. Unfortunately, a failure occurs in the diesel engine and, accordingly, fuel flows into the cylinders. Such breakdowns and defects are not particularly relevant to the type of unit. After all, any injector can rearrange itself and stop normal functioning.

Today there is a Common Rail system that operates under high pressure. As soon as the injectors fail, the damage is immediately displayed on the unit.

Fuel flows into the cylinders unevenly. That is, the device does not accept the mixture. As a result, damage may occur. Over time, the engine power also deteriorates. For example, during the cold season, car owners find it difficult to start their cars. The engine stalls and a lot of additional problems arise. In this case, fuel is consumed several times more.

How to flush the fuel system of a diesel engine yourself

As you can see, a number of factors lead to the formation of a layer of deposits and carbon deposits on the working surfaces of the injectors. If you do not clean it, then sooner or later the engine will begin to malfunction. In this case, washing must be done in a timely manner.

The main task is to remove minor deposits and carbon deposits from working surfaces, which will help avoid more serious consequences. To do this, you can visit a service station and use the injector washing service at a special stand.

You can also do the procedure for cleaning diesel engine injectors yourself at home. To do this, you need to have injector flushing fluid. As a rule, such liquids are available for sale. Many car enthusiasts successfully use one of the simplest and most affordable solutions called Solvent.

You can wash the injector with Solvent on both gasoline and diesel engines. Such a cleaner can be from different manufacturers; WYNNS is a proven solution, but there are other high-quality analogues.

Now let's look at cleaning in practice:

- At the very beginning, a Solvent jar from a suitable manufacturer is purchased.

- Then you need to prepare a pair of gas-resistant hoses (length about 80 cm). The diameter of the hoses must be suitable for fitting onto the injection pump fittings.

- Next, the standard hoses are removed from the high-pressure fuel pump and pre-prepared ones are put on.

- The free ends of the hoses are inserted into a container (a plastic container, bottle, etc. will do) into which Solvent Vince or another similar cleaner is pre-filled.

- Let us add that you need to additionally install a simple fuel filter on the hose through which fuel is supplied to the injection pump. This will prevent possible dirt from getting out of the plastic container.

- The fuel supply hose itself must also be placed in a container so that the end is lowered to the very bottom, since air cannot be allowed to enter the injection pump.

- Then the container with the inserted hoses must be securely secured in the engine compartment;

- Now the engine can be started, after which in idling mode you should “accelerate”, raising the speed to medium and higher. After applying the gas, you need to let the engine idle for about 2-3 minutes and turn off the engine.

- After this there is a pause. After 20-25 minutes, the deposits should soften (acidify), after which the procedure must be repeated.

- The end can be considered the moment when the solvent in the container is almost finished. At the same time, it is important to prevent the engine from stalling because the flushing liquid in the container runs out.

Regarding the last point, you need to understand that many fuel injection pumps on diesel engines have elements inside that require active cooling by fuel during pump operation. During cleaning, diesel fuel is replaced with flushing liquid, but the cooling principle does not change.

Taking into account this feature, you can additionally use a long “supply” hose of the cleaner, making sure that the part of the hose through which the solvent goes to the pump is also immersed in a second container. This container should be filled with cold water, and the purifier itself will not overheat.

The final stage can be considered assembling in the reverse order, connecting standard hoses and test running the internal combustion engine. After the engine begins to operate steadily at idle and other speeds, you can begin to operate the car.

Please note that during the cleaning process, you should avoid getting the washing liquid on your skin or eyes to avoid getting a chemical burn. It is also necessary to observe safety precautions, avoiding liquid spills in the engine compartment, etc. The composition is highly flammable and tends to evaporate, which can ultimately lead to a fire if careless.

By the way, if one can of solvent is not enough for cleaning (for example, the power system is too dirty), you need to have two cans of flushing. As the liquid in the main container decreases, you need to add cleaner from the second can.

Then you need to turn off the engine and leave the car for 12 hours. After this period has expired (heavy deposits will have time to completely acidify), the engine should again operate with the cleaner according to the scheme described above. For this, in fact, you need a second can of solvent.

Review of products for flushing the engine fuel system

As noted above, when performing work independently, special means are used to ensure rapid and effective breakdown of existing deposits.

The main thing is not to save on purchases and give preference to products from trusted brands.

Despite criticism from experts, this method has a right to exist.

The most popular products include:

Liqui Moly Systempflege Diesel.

A special additive that contains lubricants and other components.

The additive is intended for use in new diesel engines that use a common rail injection system and a pump injector.

In addition, it is possible to use Liqui Moly for low-sulfur fuels, which provides wear protection.

The advantages of the additive include excellent protective, dispersing and cleaning properties.

Regular use of the additive ensures reliable operation of injectors by improving fuel ignition during a cold start, as well as by reducing exhaust toxicity.

The main technical data of Liqui Moly Systempflege Diesel include yellow-brown color, freezing point of 36 degrees below zero and flash point of 62 degrees Celsius.

Used to solve the following problems:

Wynn Diesel System Purge.

A special flushing liquid that allows you to clean the fuel system yourself, without visiting a service station. The composition is sold in liter containers.

An additive designed to clean diesel engine injectors. It is easy to use, safe and highly effective.

To use the product, just pour it into a tank with a capacity of 50-55 liters. If the tank capacity is larger, then you need to use two bottles.

Regular use of the composition helps reduce engine smoke, reduce fuel consumption and prevent contamination of the fuel system.

Flushing using this product is recommended for cars with a mileage of more than 100,000 km, at intervals of at least once a year.

There is an alternative cleaner for the entire diesel engine fuel system.

Other available methods for flushing the injector and engine power system

As you can see, the solvent is an effective cleaner. However, there are other ways to flush injectors.

One such solution is flushing, which is poured directly into the fuel tank. The solution is controversial and is more suitable for new cars as a preventative measure.

If you pour such a flush into an old car, the risk that all deposits from the fuel system will clog the channels, dirt will get into the combustion chamber in the cylinders, etc., increases significantly. As a result, the injectors, pump and the engine itself will suffer.

- In practice, it is much preferable to clean the injectors by removing them. However, there is a minus here, since the remaining elements of the system are not washed. In other words, fuel rail (rail), pressure regulator, etc. are not cleaned. If the system is very dirty, then cleaning the injectors alone may not be enough.

- Comprehensive cleaning of the fuel system involves disassembling and removing all elements (pump, injectors, fuel tank, etc.). Then the injectors and injection pumps are checked on stands, cleaned, defective, repaired or replaced.

The remaining parts of the fuel system are thoroughly cleaned before installation. This method is the most effective and also guarantees that loose dirt will not get into the cylinders. At the same time, diagnostics allows you to accurately identify faulty injectors, and not just dirty ones.We also recommend reading the article on how to troubleshoot, flush, adjust and tune diesel injectors. From this article you will learn about the intricacies and nuances of this procedure, as well as what recommendations you should follow to get the best results.

For a collapsible nozzle, you can go by disassembling the element and washing it with cleaner. This method is common and often used when servicing a car yourself.

However, the result may still be worse compared to washing on a bench. You also need to be able to disassemble a diesel injector, and during reassembly, prevent even the slightest particles of dust or dirt from getting in. If this happens, there is a risk of rapid failure of the entire element.

How to clean the fuel system of a diesel engine?

We wrote above that regular cleaning of the fuel system is extremely important for extending the life of the engine. Before carrying out this activity, only an experienced TO center employee can decide whether the injectors need to be removed or not. Most often, the injectors are removed - in this case, cleaning is better and faster. In addition, removing the nozzles allows you to more accurately see the results of washing. Although this option also has its drawbacks. For example, this approach requires mandatory replacement of the sealing elements on the injectors. And sometimes - the fuel rail. This is not uncommon when it is necessary to purchase a new intake tract.