The Ural 375 is an all-wheel drive cargo transport, characterized by increased cross-country ability. Production of the model was established at the facilities of the automobile plant in Miass. The peak of the car's popularity occurred in the early 1970s of the last century, so at present it is practically not used.

The Ural 375 found wide application in the army and was used as a chassis for various strike weapons (rocket launchers, multiple launch rocket systems and other devices). Some specimens were used in agriculture, construction and other fields.

After the appearance of a more modern competitor (Ural 4320), the model quickly began to lose popularity. However, its production was carried out before the collapse of the USSR.

Vehicle design features

In 1961, the first Ural-375 car rolled off the UralAZ assembly line.

This machine was designed primarily for military use. The main emphasis was on the vehicle's cross-country ability. Its wheel formula was 6x6.

Two driven rear axles, together with a forced-engaged front axle and a ground clearance of 400 mm, provided the car with the ability to overcome difficult obstacles and off-road conditions.

A special feature of the 375 model was a cabin with a soft canvas top, which was removable and mounted on arches. The windshield was straight, mounted in a rigid frame that could be lowered onto the hood.

A wooden platform was installed on the chassis for transporting people and goods. This platform had three lowering sides and reclining seats for people.

Geometric dimensions of the “375” model: 7,350x2,690x2,680 mm. The track of the front and rear wheels is 2,000 mm. With these parameters, the vehicle turned around with a radius of 10.8 meters, which indicates good indicators of its maneuverability.

The carrying capacity of the 375 model was 4 tons, and it could tow a trailer weighing from five to ten tons.

A serious drawback of the car was its high fuel consumption, which is why it was popularly called a “glutton.”

Although the claimed consumption was 48 liters per 100 kilometers, in reality it reached 70 liters. The main reason is the ZIL-6E129 carburetor gasoline engine. It was not only uneconomical, but also had a short TBO.

"Ural" in this configuration was produced until 1964.

Did you know that the technical characteristics of the GAZ-33081 “Sadko” make this truck universal, allowing you to install various add-ons on the base chassis?

This article provides a description of the 31st series of the Ural-4320 car.

This is interesting: UAZ Hunter technical characteristics: chassis, interior

Design features of the Ural-375 truck

The first production car, the Ural-375, was produced in 1961. This truck was designed for use in the army, but it was perfect for use in hard-to-reach areas of the USSR. Despite the heavy weight of the vehicle, the maneuverability of the Ural-375 was simply phenomenal. This was facilitated by the 6x6 wheel arrangement and the Ural-375 axle design. Two rear drive axles and a Ural-375 front axle that can be connected if necessary, combined with a ground clearance of 400 mm, made this vehicle a real army off-road truck.

Since the main model "Ural-375" was intended for the needs of the army, it had the following features:

- The car's cabin had a soft canvas top, which was attached to arches and easily removed;

- The windshield was straight, since it was possible to lower it along with the frame (in which it was attached) onto the hood;

- The chassis of the first Ural-375 model was equipped with a wooden body in which it was possible to transport both cargo and people. To do this, three sides in the body could be opened, and special folding benches were used to transport people.

As for the main technical characteristics of the Ural-375, they were as follows:

- The length of the car was 7,350 mm;

- Width – 2,690 mm;

- Cabin height – 2,680 mm. If the car was operated with an awning, then its height was 2,980 mm along the awning;

- It could carry cargo weighing up to 4 tons. This is not much for such a vehicle, but the weight of the towed trailer could reach 10 tons;

- As for fuel consumption, it far exceeded the declared 48 liters per 100 km and could reach up to 70 liters. Such fuel consumption was the norm for the old ZIL-6E129 engine, which, although it worked well in conjunction with the Ural-375 gearbox, also had an extremely short resource. After a new engine was installed on the Ural (since 1964), fuel consumption was reduced.

What models were produced

The first copies of the powerful all-terrain vehicle appeared on the roads in 1961. The cabin was made with a removable fabric roof. They installed a flat windshield, which was raised when necessary. The model was produced for only three years. This version of the Ural 375 had not the worst characteristics, but not the best either.

Starting in 1964, a truck with the letter D was produced. It was equipped with a metal platform and a driver’s cab. For the convenience of passengers and loaders, a folding tailgate was installed. Benches and a driver signal button were placed in the back.

The first Ural 375 trucks had not very good fuel consumption characteristics. 70 liters of A-92 fuel were required for every 100 km. After modernization, consumption dropped to 50 liters per 100 km. On difficult terrain, in harsh winter engine operating conditions, gasoline consumption increased by another 20-30 liters.

Modification A was produced with longer spars. An army kung was installed on the model. The tank was moved down, the gas exhaust pipe system was installed in another place. A spare tire was hung on the rear overhang of the frame. The Ural-375T was created as a prototype for the next model with the letter N, and therefore was not mass-produced.

The model with the letter E was developed for the army; weapons and military equipment for various purposes were installed in the body. These were cars with:

- tank;

— generators;

- crane;

- rockets.

Radar stations were also installed in the body.

Many people know the military Ural-375SK1 and the civilian model SN. They were widely used throughout the country. In the army, the vehicle was also needed to transport missile systems. For operation in the coldest conditions, a model with the letter K was developed. It was equipped with low-temperature resistant rubber products, an additional radiator grille, and an insulated cabin.

The civilian model Ural-375N was also produced with a wooden platform, but with all folding sides. The truck did not have shielded electrical equipment or an air intake. The joints of the transmission elements were not sealed, and the tire pressure was not regulated.

Main modifications of the Ural-375

Modifications Ural -375

| UralZiS-NAMI 375 | Prototypes that were produced at KEO UralAZ. They came with a ZIL-130 cab. | |

| Ural-375 | The main modification of the truck is flatbed, the cabin has a soft top. Purpose: to transport various loads on all types of roads, and to tow trailers weighing up to 5 tons. Wheel formula 6x6. It came with a ZIL-375 carburetor engine. Years of production: 1960-1964. | |

| Ural-375S | Truck tractor on the Ural-375 platform with a frame reduced by 135 mm. The truck was used to tow semi-trailers weighing up to 12 tons on all types of roads. | |

| Ural-375D | Since 1964, after improvements, the machine began to be created under the symbol Ural-375D. It differed from the debut configuration in the absence of a front axle disconnect mechanism and a solid metal cabin, which was developed for the Ural-377. | |

| Ural-375SK1 | An improved version of the Ural-375S truck tractor. Years of production: 1964-1982. | |

| Ural-375K | The modification was intended for operation at low temperature conditions: down to -60 C. The cabin came with auxiliary thermal insulation and double glass, and also installed a pre-heater of increased performance, electrical equipment had frost-resistant insulation, and frost-resistant rubber was used. | |

| Ural-375N | In this model, the truck was equipped with ZIL-375YA4 power units instead of the ZIL-375 engine, wide-profile tires, units in the usual non-sealed design, and unshielded electrical equipment. There is no system for sealing and adjusting air pressure in the wheels. | |

| Ural-375SN | A truck tractor on a 375N platform with a rear frame overhang reduced by 135 mm. The vehicle was intended for towing semi-trailers weighing up to 18.5 tons on hard surfaces and on the ground - up to 12.5 tons. Following the updates in 1982, it acquired the index 375СНМ. | |

| Ural-375Yu | The Ural-375Yu is a variation of the basic truck for hot climates. Operation is envisaged at temperatures from -20 to +50. The truck differed from the main vehicle in insulation of electric drives, fittings, as well as metal-free products made from materials resistant to high temperatures. The export version acquired the name Ural-375ДУ (Ural-375ДМУ since 1982). |

Modifications

In 1964, the developers of the automobile plant made serious changes to the design of the Ural, and the 375D model was launched into mass production.

The main features of this machine were:

- all- metal cabin with two doors, without a sleeping bag, which can accommodate three people;

- to install a van-type body, the length of the frame was increased by more than 300 mm;

- the front axle became non-disconnectable , the transfer case changed;

- ZIL-375 engine on the car .

"375D" was the base model of the new "Ural". In subsequent years, new modifications of this vehicle in a wide variety of configurations began to be produced on its chassis.

For military needs, the BM-21 Grad launcher, AC tank trucks, ATMZ fuel tankers, 8T and 9T truck cranes, as well as the P 18 radar were produced on the 375D base.

In addition, staff KUNGs and vans with mobile repair shops were installed.

“375A” is a configuration with a KUNG K-375 body and a longer frame , the geometric dimensions of this variety are 8,000x2,500x2,680 mm. The 375E chassis was developed for various tanks, cranes and other special equipment.

For the purpose of transporting semi-trailers and using them as timber carriers, the 375S truck tractor and its modernized version 375SK1 were produced.

The 375K tractor was produced especially for the needs of the Far North and other places with difficult climatic conditions.

A cabin with double glass and improved thermal insulation, a reinforced heater for pre-launch preparation and special frost-resistant insulation of the electrical wiring made it possible to operate this machine at temperatures of minus sixty degrees Celsius.

With this configuration, special frost-resistant tires were also installed.

For use in the national economy, the “375N” model was produced.

The electrical wiring on this machine was not shielded, there was no automatic tire inflation, and the design of the units was not airtight. Another engine was installed on the car - ZIL-375YA4.

To tow heavy trailers up to 18.5 tons on paved roads, the Ural plant began producing the 375SN truck tractor with a shortened rear overhang. In the modernized version it was “375СНМ”.

A version of the machine for working in hot climates, “375Yu,” was provided. It was assumed that it would be able to operate uninterruptedly at temperatures from minus twenty to plus fifty degrees.

All major units - both power and electrical - had special additional insulation, and many metal parts were replaced with elements from non-metallic components.

Machines for export needs were marked “375ДУ” and “375ДМУ”.

According to its technical characteristics, the Bobcat S175 is a mini loader capable of working in difficult conditions in farming, public utilities and construction.

Studying this review will allow you to compare and note the advantages of various modifications of the Hyundai Porter.

"375D"

The technical characteristics of the Ural-375D are as follows:

- car dimensions in terms of dimensions - 7,350x2,690x2,680 mm, vehicle height along the awning - 2,980 mm;

- in the base car the body is in the form of a metal platform with lowering sides , it has folding seats for people.

The sides can be added with lattice structures. To protect passengers from wind and rain, an awning is used, installed on special arches, platform size 3,900x2,430x872 mm; - the track of the front and rear wheels is the same - 2,000 mm, ground clearance - 400 mm;

- the machine could make a turn with a radius of 10.5 m ;

- the cabin is completely made of metal, the front windshield does not roll down , it is divided in the middle by a metal insert for greater rigidity, the side windows in the doors are lowered, there are rotating windows;

- maximum travel speed - 75 km/h;

- the angle of the obstacle to be overcome is 40 degrees;

- the distance covered when braking from a speed of 40 km/h is 15 meters;

- the maximum possible distance covered without refueling while maintaining the control fuel consumption is 750 km;

- transmission - double-disc dry clutch with lever drive, 5-speed manual transmission with YaMZ-204U synchronizers, mechanical transfer case with center differential, which distributes torque between the front axle and the rear double-axle bogie, forces are transmitted using four cardan shafts;

- suspension front and rear spring with shock absorbers;

- brakes with pads and dual-circuit pneumohydraulic drive;

- steering mechanism with gear sector and hydraulic booster;

- the wheels are made according to a special design, have split rims, conical shelves and spacer rings;

- tires - OI-25 14.00-20, with automatic air pumping.

Engine of the model produced from 1964 to 1992

The Urals of the 375D model were equipped with a gasoline engine of the ZIL-375 design.

ZIL-375 has the following features and technical characteristics:

- gasoline four-stroke V8 design , that is, the engine has eight cylinders installed in a row, the pistons of which rotate one crankshaft.

This design is more stable than six-cylinder engines, it is fully balanced, operates stably under heavy loads and at low speeds; - with a volume of 7.0 liters, the engine develops a power of 180 hp. With. with a maximum torque of 465 Nm at 1,800 rpm;

- the power system uses a two-chamber carburetor , the fuel used is AI-92 gasoline, but AI-72 can be used for short periods of time;

- The cylinder block is made of cast iron, while the cylinder head is made of aluminum alloy , which provides the necessary strength and at the same time facilitates the design of the internal combustion engine.

"Ural-375": the ideal of a war chariot

Ural-375

Born in NAMI

By the end of the 1950s, the Ural Automobile Plant in Miass was a sad sight: minor modifications to hopelessly outdated UralZIS series vehicles and the absence of a serious design bureau. They couldn’t develop their own car; they could only hope to assemble other trucks created in third-party companies. Naturally, no one in the automotive industry was in a hurry to share defense contracts with the secondary plant in Miass. This means that it was necessary to find an enterprise that can develop machines, but cannot produce them. This is what the Scientific Research Automotive Institute (NAMI, the last time we heard about it in connection with the development of the presidential limousine Aurus) became. Of course, the managers of the Miass plant could hardly dictate their will to Moscow engineers and designers. The Main Armored Directorate of the USSR Ministry of Defense played this role when it placed an order for a 5-ton army truck, distinguished by its original design, that is, not developed on the basis of an already existing model. The chief designer of the vehicle, which received the name NAMI-020, was Nikolai Ivanovich Korotonoshko, who oversaw the development, based on one concept, of several all-terrain vehicles with wheel formulas 4×4, 6×4, 6×6, 8×4 and 8×8.

One of the sketches of the future NAMI all-wheel drive

In December 1956, the first vehicle made in metal was the NAMI-020 with a three-axle all-wheel drive chassis, the direct ancestor of the future Urals. We completed the task with US very quickly: less than three years passed from the moment we received the task and assembled the first prototype. For the domestic industry of those years, this was simply an outstanding indicator, since most of the equipment was developed two and three times longer. It cannot be said that the truck was designed from scratch by US; after all, some of the components and assemblies were borrowed. They took the gearbox from the MAZ-200, the transfer case from the MAZ-502, the Zilov team provided an experienced eight-cylinder engine with a power of 180 hp. s., and GAZ designed the cabin. Even at first glance, it is clear that Gorky did not particularly bother with the design and actually scaled up the GAZ-51 cabin.

Among the progressive developments in the future “Ural”, the middle passage bridge stood out. Compare with the ZIL-157 with its complex five-cardan transmission, borrowed from the lend-lease Studebaker. But “Zakhar” will go into production only in 1958, two years after the release of the NAMI-020 prototype.

Among the purely “military” features of the future “Ural”, a centralized tire inflation system, sealed drum brakes and a hatch in the roof of the cockpit for the gunner stood out. Tests showed the vehicle's high cross-country ability, as well as moderate fuel consumption even compared to the younger GAZ-63 and ZIS-151.

NAMI-020 could have been like this

NAMI-020 - predecessor of the Ural truck series

When the decision was made to launch production of the NAMI-020 car, the Ural Automobile Plant was not the only contender. At first they thought about the Moscow ZIL, then about the distant locomotive plant in Ulan-Ude. ZIL was soon supposed to master the production of lighter trucks of the 130 and 157 series, so it was quickly rejected. Well, Ulan-Ude was not suitable for the obvious reason of excessive distance both from the consumer of the product and from related suppliers. And here the enterprise in Miass turned out to be very useful in a crisis situation. We agreed with the head of the plant A.K. Rukhadze and the chief designer S.A. Kurov about the preliminary reconstruction of the enterprise for such a complex model of truck and sent NAMI-020 to Miass. And in 1958, the institute’s team was awarded a second degree diploma from the All-Union Industrial Exhibition for the creation of an all-terrain vehicle.

There was another modification of the NAMI all-wheel drive vehicle with a 6x6 formula, it had the index 021. This truck repeated the NAMI-020 in almost everything, but was distinguished by a long wooden cargo platform, closely adjacent to the cabin. To do this, it was necessary to place the spare wheel, together with its hydraulic lifting system, under the floor of the body located above.

Transport version of the future "Ural" - NAMI-021

In Miass, a special design bureau was created for a promising vehicle, headed by engineer Anatoly Ivanovich Titkov (now alive) in March 1957. At least twenty specialist developers of the future Ural moved from NAMI to Miass to exchange experience and quickly put the machine on the assembly line. It would seem that everything is ready for the development of production. But then the GABTU Ministry of Defense intervened - their plans for the car changed.

Gold medalist

In Miass, the first joint development with NAMI specialists was a truck with the long name “UralZIS-NAMI-375”, dating back to 1958.

Here we already see the future index of the legendary truck and the old name of the Ural Automobile Plant. By the way, the car was redesigned according to the requirements of the military. Firstly, the front and rear axles were unified, which forced the engine to be raised, and this led to a change in the front part of the cabin. Now all the main gear housings were located in one line, which had a positive effect on the truck’s cross-country ability. Secondly, the gas cabin was removed and a hybrid was made from a ZIL-131 with the famous panoramic glass (divided, however, into two parts) and a front end of our own design. The steering, front suspension were also changed compared to NAMI-020, the frame was strengthened and new wheels were developed.

After modifications, the UralZIS-NAMI-375 was sent for testing, which showed that everything was bad and unreliable. In the book by Evgeny Kochnev “Cars of the Soviet Army 1946-1991.” it is indicated that after the test cycle only part of the transmission and the tire inflation system remained alive. The car had to be modified, and at the same time brought into compliance with the newly changed requirements of the main customer.

"UralZIS-NAMI-375"

It must be said that the first real “Ural”, which received the index 375T, after large-scale alterations, was published quite quickly - already in 1959. Interestingly, the cabin now had a fabric top and folding windows, but this was not done for the air transportability of the truck. The main goal of this innovation is to enhance the anti-nuclear resistance of machines buried along the line of windows in the ground. In addition, all transmission and frame components were strengthened, and the engine was modernized.

Strictly speaking, the Ural-375T was a pre-production vehicle in a “transport” modification, that is, with an elongated wooden body, but the Ural-375 was an artillery tractor, which went into production on January 31, 1961. The tractor was designed to tow 5-ton trailers off-road and 10-ton trailers on hard roads.

Among the borrowings from serial trucks were components from the MAZ-200: single-plate clutch, gearbox, front suspension, towing unit, pneumatic brake system equipment, middle axle drive shafts, steering mechanism and intermediate cardan. Even the Moskvich-407 passenger car shared with the giant the universal joint of the driveshaft, which Ural used in the steering shaft. The CV joints were also “one-piece” in design from the MAZ-501 timber truck. The Zilovites gave Ural individual components of the tire inflation system, since they were almost the only ones in the world who knew how to make them. The engine was also a Moscow ZIL-375 with a power of 175 hp. With.

What was Uralic about “Ural”? In fact, only a transfer case, a center differential and a spring-balance suspension. Having absorbed all the most progressive things from the domestic automobile industry, the Ural-375 hit the assembly line as a frankly crude car. During the pre-production state tests, a paradoxical thing happened: the order to put the vehicle into production was signed even before the end of the research cycle. At the same time, the truck did not behave in the best way on the off-road conditions of the Chelyabinsk region. The clutch failed, radiators leaked, electrical equipment failed, springs and shock absorbers broke, and the main problem was the brakes, which jammed and overheated... On one car, on a descent in a mountainous area, the brakes failed, then the handbrake, and when trying to brake with the engine at speed At 90 km/h the clutch fell apart. It was only by miracle that the driver was able to hold the car until it came to a complete stop on the road.

The first serial "Ural-375"

Despite all the dismal results of state tests (the result was dozens of pages of comments), the Miass plant received a plan to produce 300 cars for 1960. The army's need for an artillery tractor of this class was very high, and, obviously, the GABTU decided to correct the shortcomings during the production process. This matter dragged on for several years, but in 1969 it was crowned with international success: the Ural-375D received a gold medal at an exhibition in Leipzig.

To be continued…

Permissible filling volumes

For all main modifications, the filling volumes of working fluids are basically the same.

The difference is in the number of fuel tanks and, accordingly, the volume of fuel to be filled. Thus, models “375”, “375D” and “375K” have a fuel tank with a capacity of three hundred liters and an additional fuel tank of 60 liters.

The 375C truck tractor and its configurations have an additional fuel tank with a capacity of 110 liters. “375A” with a van body are not equipped with an additional tank and only have a standard one of 300 liters.

For normal operation of the engine and components, other liquids are filled, for example:

- oil to the engine lubrication system - maximum 9 liters;

- antifreeze for cooling the internal combustion engine - maximum 30 liters;

- gearbox oil - 4.5 liters;

- oil for transfer case - 3.5 liters;

- in the gearboxes of each axle - 4 liters;

- to the RU hydraulic system - 4.5 liters;

- to ensure the operation of the brake system - 2 liters.

Manual

Service documentation, instructions, and operating instructions recommend:

- Change the speed of the transfer gearbox only when the vehicle is stationary.

- Continuous operation of equipment with a locked center differential is prohibited.

- Do not reduce tire pressure below 0.5 kgf/cm². During long periods of inactivity, close the wheel taps.

- Do not start movements when the pressure in the pneumatic system is below 4 kgf/cm².

- Check and adjust the gaps between the drums and pad linings.

This is interesting: Fuel tanker Ural-4320 ATZ-10: design and technical characteristics

Motor

The powerful Ural 375 petrol engine had good technical characteristics for that time. An unpretentious engine, a V-shaped 8-cylinder, was installed. The engine was developed at the plant named after. Likhacheva. The Zil-375 engine model has proven itself well in any operating conditions. It can also be seen on various modifications of the Zil-131 truck, but with some differences in design.

Load capacity of "Ural-375D"

The new Ural-375D model had an increased load capacity, which varied depending on the type of road surface on which the truck was moving. If the Ural-375 could transport only 4 tons, the 375D model increased this figure to 5 tons on paved roads and up to 4.5 tons on dirt roads. The vehicle, which had an extended wheelbase (Ural-375A), was capable of carrying cargo weighing up to 5.8 tons.

All modifications of the Ural-375D, which were intended for use in the national economy, had the ability to transport cargo weighing more than 5 tons. In addition, the weight of the towed trailer could reach 10 tons.

Timber tractors, which were produced under the designation “357C”, could tow semi-trailers with a total cargo weight of up to 12 tons. The “375SN” and “375SNM” models, which appeared a little later, transported semi-trailers with a total load of up to 18.5 tons along asphalt roads.

Transmission characteristics

The Ural-375 is equipped with a YaMZ-24U mechanical three-way gearbox. Five gears shift forward, another one shifts backward, synchronizers are present in the third, fourth and fifth. Gear ratios:

Chassis Ural-375

- first – 6,17;

- second – 3,40;

- third – 1,79;

- fourth – 1,00;

- fifth – 0,78;

- reverse – 6,69.

The truck's manual transfer case is a two-speed one. Its design depends on the year of manufacture of the car. In the early years, cars were equipped with boxes equipped with a cylindrical locking center differential, in which the torque between the rear axles was twice as high as that between the front axles. In other words, the front axle was forcibly connected.

Cars of later years of production were equipped with transfer cases that were simpler in design. They already had an asymmetrical, rather than cylindrical, planetary class center differential, and the front axle was constantly on.

The service brake of the Ural-375 was installed as a hydraulic drum type and was additionally equipped with a pneumatic booster. Shoe brakes were placed on each ear and were of the open type. The drive was pneumohydraulic, common for the front and middle axles, and one more for the rear.

Technical characteristics of "Ural-375D"

Since the Ural-375D was significantly modernized, its technical characteristics also differed from the Ural-375:

- For example, the basic modification of the car already had a metal body, with folding benches for soldiers;

- The sides could be built on using special structures. There was also an awning that was installed to protect passengers or cargo from bad weather conditions;

- The car's cabin was completely metal. The front glass in it no longer lowered onto the hood, but it received a stiffening rib in the middle to strengthen the structure. In the side doors, the windows could be lowered using special rotary handles (the so-called “oars”);

- Thanks to the installation of a new engine, the maximum speed of the Ural-375D increased. Now it reached 75 km/h.

The transmission used was a standard dry double-disc clutch with a simple lever drive and a 5-speed manual gearbox. The car was equipped with a mechanical transfer case with a center differential. An interesting feature of the Ural-375D was the automatic tire inflation system, which even now is very rarely found on modern cars.

Specifications

Engine

On the Ural 375D series model, 2 types of power plants were installed:

- gasoline engine ZIL-375. The 4-stroke unit has 8 cylinders rotating one crankshaft. This design is more reliable compared to the 6-cylinder. The motor is highly balanced and operates confidently at high loads and low speeds. The cylinder block is made of cast iron, the cylinder head is made of aluminum alloy. Characteristics: working volume – 7 l, rated power – 180 hp. For ZIL-375 it is recommended to use AI-92 gasoline;

- diesel unit KAMAZ-740. The engine has proven itself well in difficult conditions. The motor complies with the Euro-1 environmental class. Characteristics: displacement – 10.85 l, rated power – 210 hp, number of cylinders – 8 (V-shaped arrangement), maximum torque – 667 Nm.

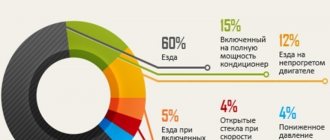

Fuel consumption

According to the operating manual for the Ural of any configuration, fuel consumption in mixed mode is 48 liters.

However, during actual operation it was found that depending on the conditions in which a particular machine operates, fuel consumption also changes. In this regard, gasoline consumption standards have been established, which vary depending on the circumstances.

The amount of gasoline consumed by a car per 100 kilometers is influenced by many factors. This includes the height of the relief, the climatic conditions (less in hot climates, and much more in the Far North), and the degree of wear and tear on the machine and components.

The road surface or its complete absence also has a significant impact.

So, when driving off-road, gasoline consumption can increase by 50 percent. Therefore, in the technical specifications for the 375C truck tractor, the range is 650 km, despite the presence of an additional tank of 110 liters.

At the same time, the power reserve for the 375D is 750 kilometers. It is assumed that the truck tractor works as a timber carrier and moves along forest terrain or transports heavy semi-trailers.

Currently, they can be purchased at prices ranging from 300 to 800 thousand rubles. Despite the high fuel consumption during operation, interest in this equipment remains due to its unique maneuverability and fairly simple maintenance.

The production of Ural-375 and all its modifications ended in 1992. Nevertheless, these machines can still be purchased on the market. This is explained by the fact that a large amount of such equipment was mothballed for military needs.

Transmission

A double-disc clutch is used to transmit torque from the engine to the transmission. The YaAZ-204 gearbox is equipped with five forward gears, with the fifth speed being an accelerating speed and the fourth being a forward gear.

To expand the traction range and distribute the drive to three axles, a transfer case is used. Both speeds in the gearbox are reducing.

The gearbox of the Ural-375 vehicle includes a differential that proportionally divides the torque between the gearboxes of the front axle and the rear bogie. The differential is equipped with a forced locking mechanism.

A special feature of the transmission of the Ural-375 all-terrain vehicle is the permanently connected front axle drive. The design of the cardan shafts uses joints from ZIL and MAZ trucks. Early releases of the all-terrain vehicle were equipped with a transfer gearbox, which made it possible to disable the front axle drive.

Suspension

The front suspension of the Ural-375 includes two springs, complemented by telescopic shock absorbers.

The suspension elements are borrowed from the MAZ-500 flatbed truck.

The rear bogie has a balancing design and is equipped with two springs. The ends of the springs are inserted into support brackets placed on the stockings of the middle and rear axles. The middle axle is equipped with suspension travel limiters. The limiting elements are made of steel cable. The suspension includes reaction rods designed to transmit pushing and braking forces that arise when the Ural-375 all-terrain vehicle moves.

Chassis

The chassis of the Ural-375 all-terrain vehicle is based on a riveted frame. Frame elements are made by stamping. There are rigidly mounted tow hooks on the side members at the front.

Towing devices of various designs may be located on the rear part (depending on the modification). Truck tractors are equipped with a towing hook rigidly mounted on the frame, as well as a saddle borrowed from the MAZ-200V tractor. The remaining all-terrain vehicles are equipped with a hook with a lock and a spring shock absorber operating in both directions.

Bridges

The front axle on the Ural-375 all-terrain vehicle is equipped with rotating axles. The transmission of torque to the rotary wheels is carried out using constant velocity joints. On the civilian version of the Ural-377, a forged beam with an I-section is mounted at the front.

The rear axles have an interchangeable design.

The middle axle gearbox is a through-type gearbox, used to drive the rear axle. The axle gearboxes use a double main gear. The transmission includes a bevel pair and an additional cylindrical gear. The civilian and northern versions of the all-terrain vehicle were equipped with a gearbox with a gear ratio reduced to 8.05 (standard 8.9).

Steering

The steering of the Ural-375 all-terrain vehicle consists of a worm gearbox and a hydraulic booster. The gearbox includes a worm shaft with a double-start screw thread and a sector.

To operate the amplifier, a vane pump is used. The pump is mounted on the engine and is belt driven from a pulley on the crankshaft.

Brake system

The Ural-375 all-terrain vehicle is equipped with working brake mechanisms of a drum design. A special feature of the system is a combined drive, consisting of a pneumatic and hydraulic part.

The pneumatics operate from a 2-cylinder compressor installed on the power unit.

The pneumatic part of the drive has one circuit. The pads are directly driven from the hydraulic part, divided into two circuits. The first circuit is responsible for the operation of the front and middle axles. The rear axle brake drive is made from a secondary circuit. To hold the all-terrain vehicle in the parking lot, a separate drum brake is used, mounted on the secondary shaft of the transfer gearbox.

Devices

In front of the driver there is a dashboard with a standard set of instruments for Soviet trucks. A speedometer is installed in the center of the dashboard, on the right are indicators of the amount of fuel in the main tank and an on-board network status indicator, on the left is a coolant temperature indicator and an oil pressure indicator in the lubrication system. The all-terrain vehicle's shield is equipped with two backlight lamps covered with visors.

On the lower part there is a high beam headlight indicator and a turn signal indicator (with a green filter). To the left of the dashboard there are air pressure gauges in the tires and in the brake drive.

Under the instrument panel there is a number of indicators and switches (listed from the driver's door):

- red warning light for low oil pressure;

- light switch;

- red lamp for minimum tire pressure;

- a red lamp indicating an emergency condition of the brake system;

- cabin light switch;

- egnition lock;

- switches for the ventilation system and turning lights.

Fuel containers

The fuel supply on the Ural-375 all-terrain vehicle is located in the main tank with a capacity of 300 liters, as well as an additional tank designed for 60 liters. On civilian versions there is no additional tank. The main tank is mounted on brackets riveted to the left frame side member.

The northern version of the 375K all-terrain vehicle uses an additional 120-liter tank, and the truck tractor uses a 110-liter tank. On 375SK1 cars produced after 1977, there is no additional tank. The 375CH civilian truck tractor was equipped from the factory with a canister canister designed for 20 liters of gasoline.

Load capacity

The new Ural-375D model had an increased load capacity, which varied depending on the type of road surface on which the truck was moving. If the Ural-375 could transport only 4 tons, the 375D model increased this figure to 5 tons on paved roads and up to 4.5 tons on dirt roads. The vehicle, which had an extended wheelbase (Ural-375A), was capable of carrying cargo weighing up to 5.8 tons.

All modifications of the Ural-375D, which were intended for use in the national economy, had the ability to transport cargo weighing more than 5 tons. In addition, the weight of the towed trailer could reach 10 tons.

Timber tractors, which were produced under the designation “357C”, could tow semi-trailers with a total cargo weight of up to 12 tons. The “375SN” and “375SNM” models, which appeared a little later, transported semi-trailers with a total load of up to 18.5 tons along asphalt roads.

Technical characteristics of the Soviet all-terrain vehicle

Since the release of the truck, work has been constantly carried out to modernize it. Several more versions of the Urals were released with different technical characteristics. Unlike the base model, later cars were equipped with a metal cabin, the wind windows were blank, and rotating windows were added to the door windows.

A bypass line was also installed to cool the engine when the radiator was turned off, a full-flow centrifuge and a more powerful interior heating system. The changes did not affect only the platform, which remained metal with a folding tailgate.

To work with peripheral devices and drive through impassable terrain, the Ural 375 was equipped with special equipment.

| Name | Meaning |

| Winch | |

| Type | Drum with built-in cable handler |

| Winch drive | Three driveshafts from the car's transfer case |

| Gearbox | Gear-helix globoidal pair |

| Ultimate traction force, kgf | 7000 |

| Working length of cable, m | 65 |

| PTO | Designed to drive additional units |

| Type | Mechanical, two-speed |

| Power take-off | From the gearbox shaft |

| Performance | Produces 20% of maximum engine power |

| Gear ratios (including gearbox) | |

| first gear | 2,99 |

| second gear | 1,44 |

| Additional power take-off | Designed to drive a winch |

| Type | Mechanical, single-speed, equipped with an oil pump |

| Power take-off | Through the transfer case input shaft, |

Fuel consumption

According to information from the operating instructions, the Ural-375 truck, regardless of configuration, will consume 48 liters of fuel when operating in mixed mode.

Ural-375 - rear view

But in practice, it turned out that actual fuel consumption depends on many factors: terrain, quality of the road surface (for off-road driving you need 50% more fuel), temperature (driving in hot weather requires more gasoline than in cold weather), wear level car and its parts.

In addition to the above factors, the model of the truck also affects the range. So, according to the instructions, the 375C truck has a power reserve of 650 km, and the 375D – 750 km.

Such high gasoline consumption is the only significant drawback of the Ural-375. In an effort to solve it, specialists at the Ural plant began producing new cars that ran on diesel and required less fuel. They became increasingly popular, and by 1992 they had displaced gasoline-powered trucks from production.

Related video: Ural-375

Price Ural-375

Since many people are very interested in how much the Ural-375 costs now, it is worth answering this question. Due to the fact that production of this car and model ended back in 1991, today you can buy it as a used one or find offers for sale from conservation. The average price will be about 400,000 to 800,000 rubles. You can also find advertisements for the sale of Urals manufactured in 2001-2013, however, these are more modern modifications of vehicles, the index of which is 4320. The cost of such a truck can reach up to 3,500,000 rubles.

It’s also good that most sellers are ready to offer brand new parts along with the car. Since the car was quite popular in the USSR, today finding spare parts for it will not be a problem. Generally speaking, the machine, which was created mainly for the military, is distinguished by its good reliability, practicality and ease of repair.

Frame

The Ural-375 has a strong, high-quality riveted frame. It consisted of various stamped elements. Tow hooks were placed on the front side members.

| Ural-375, main characteristics | |

| Length | 7 360 mm |

| Width | 2,674 mm |

| Height | 2,980 mm |

| Load capacity | 5,000 kg |

| Maximum speed | 75 km/h |

| Curb weight | 8,300 kg |

| Full mass | 13,300 kg |

| Maximum towed trailer weight | 10,000 kg |

| Power unit | |

| Engine | ZIL-375 |

| Fuel consumption | 50 l, AI-92 |

| Power | 180 hp |

| Volume | 7 l |

| Platform | |

| Length | 3,900 mm |

| Width | 2 430 mm |

| Other characteristics | |

| Wheel formula | 6x6 |

| Transmission | YaMZ-24U, mechanical. |

| Fuel tank | 300+60 l |

| Tires | OI-25 |

Ural-375: execution cannot be pardoned

The Ural-375 cars of the first series were manufactured in August 1958 and were a factory modification of the NAMI-020 and NAMI-021 cars. They used the ZIL-130 cabin. The military did not like these cabins, and they demanded cabins with a soft convertible top made of canvas. Such a cabin could reduce the height of the car by 600 mm. However, on the Ural-375, the spare wheel rose 415 mm above the cab connector. In addition, the overall height along the intake pipe of the air cleaner was also larger and amounted to 2445 mm.

Before this, the experimental trucks NAMI-020 and NAMI-021, manufactured by NAMI in December 1957, were tested. The tests actually failed due to the unsatisfactory performance of the ZIL-E129 engines. It was stated that the ZIL-E129 engine is one of the models of the family of V-engines developed by the ZIL automobile plant in accordance with a promising type for use on a new city bus. The fact that the all-wheel drive trucks under development would be equipped with an engine produced by MosZiS was agreed back in 1954. The terms of reference specified brief engine characteristics: power - 180 hp. at 3200 rpm, working volume – 7.0 l.

- State tests of prototypes of three-axle off-road vehicles Ural-375, manufactured by the Ural Automobile Plant named after. Stalin, were carried out from June to October 1959. Three prototypes of the Ural-375 car of various modifications were tested:

- traction Ural-375, chassis No. 003, engine No. 003 (test number 1);

- transport Ural-375T, chassis No. 004, engine No. 002 (test number 2);

- car with a closed body, van Ural-375A, chassis No. 005, engine No. 001 (test number 3).

All three modifications of the Ural-375 car had the same general layout and differed in cabs, design and size of bodies, location of the spare wheel, presence or absence of a traction winch, as well as some other features. Two cars were from the second experimental series, and one van (Ural-375A) from the first.

In accordance with the program, the total volume of mileage tests for each prototype was supposed to be 25 thousand km, but due to the failure of engines, unsatisfactory performance of brakes and the presence of other defects in the vehicles tested, it actually turned out to be 13,367–13,931 km.

The tested Ural-375 vehicles were equipped with 8-cylinder V-shaped engines ZIL-6E129 with a displacement of 7 liters. Cylinder diameter – 108 mm, piston stroke – 95 mm, compression ratio – 6.5. ZIL-6E129 was supposed to develop a maximum power of 180 hp. at 3200 rpm, maximum torque – 47.5 kgm at 2000–2200 rpm.

When tested by NAMI-020 and NAMI-021, the tested engine developed only 153 hp. The engines could only run on high-octane gasoline B-70 or A-74. When refueling cars with the prescribed A-70 gasoline under load, detonation and a noticeable loss of power were observed.

To eliminate this defect, the engines installed on pre-production Ural-375 vehicles received aluminum cylinder heads instead of cast iron ones, which, however, did not solve all the problems. Structurally, the ZIL-6E129 engine differed from its predecessor ZIL-E129 in its oil filtration system. The ZIL-E129 engine was equipped with a coarse plate oil filter and a centrifuge. In the ZIL-6E129 engine, a filter with an ASFO filter element installed in parallel was used for fine cleaning. This change was made due to the fact that the centrifuge was not placed under the hood of the Ural-375.

During testing, the first break of the exhaust valve occurred in the Ural-375T after a run of 6524 km. Then the valve breaks recurred at runs of 10,111 and 10,377 km. At a run of 11,852 km, all exhaust valves were replaced, but after a run of 1,956 km, the valve collapsed again. On the Ural-375A car, the valve broke off after a mileage of 10,273 km. All valves were also replaced. There were no valve breaks on the Ural-375 car, however, due to a noticeable elongation of the rods, the valves were replaced with new ones after a mileage of 12,064 km.

With a mileage of 3,948 and 10,377 km on the Ural-375T, the valve guide sleeve broke along the annular groove of the retaining ring. Scoring of the rocker arms, fracture of the rocker arms due to their scuffing, deterioration of the ball bearings of the rocker arms, chipping of the end surfaces of the pushers and jamming of the plunger pairs were observed, as a result of which they were repeatedly replaced throughout the entire test period.

With a mileage of 5,350 km on the Ural-375, scuffing and partial melting of the connecting rod bearings, a crack in the piston boss bridge, and a chipping of the boss were observed. The connecting rod broke at 11,561 km. On a Ural-375A car with a mileage of 15,731 km, the crankshaft broke down. This was the end of the engine's agony.

L.S. Kiselev, member of the commission from the Moscow Automobile Plant named after. Likhachev, explained that the engine was proactively manufactured on the basis of experimental samples of high-class ZIL-111 passenger car engines, solely for the purpose of installing them on experimental ZIL-129 city buses, due to the lack at that time of an engine specially designed for this purpose. Due to defects revealed during testing at ZIL, the production of experimental samples of these engines was discontinued. Currently, the plant has begun manufacturing a batch of ZIL-375 engines intended for installation on Ural-375 vehicles.

The ZIL-375 engine will be equipped with reinforced exhaust valves with stellite surfacing along the working chamfers and with sodium cooling. The hydraulic pushers of the ZIL-6E129 engine will be abandoned. The pistons will be strengthened and the strength of the connecting rods will be increased. The ZIL-375 engine will receive connecting rod and main bearings manufactured using proven technology. The four-chamber K-85 carburetor (Rochester type) in the ZIL-375 engine will be replaced by a two-chamber K-89. The K-85 carburetor systematically over-riched the working mixture due to problems with the shut-off valve and poor operation of the automatic choke control mechanism.

The test results of the Ural-375 were to be considered unsatisfactory. In addition to the engine, low reliability and serious deficiencies were identified in the clutch, transfer case, drive axles, front suspension, service and parking brake systems, cooling system and electrical equipment, and the tires did not meet the requirements. The recognition of the Ural-375 car as unfit for production disrupted the implementation of Resolution No. 442 of the Central Committee of the CPSU and the Council of Ministers of the USSR dated April 17, 1958 on the release in 1960 of a production batch of 300 cars. It was decided to modify the car and ask the State Committee of the USSR Council of Ministers for Automation and Mechanical Engineering to instruct US to provide assistance to the Ural-ZIS directly at the plant.

The ZIL-375 engine also turned out to be unable to develop the specified power on standard fuel. The result was a military truck that runs on high-octane fuel, which is not used in the national economy. The nonsense of the appearance of the Ural-375 truck was also that it could not be used on the country’s roads, since in terms of external dimensions all its variants exceeded the width established by GOST 8891–58 for general purpose trucks (2500 mm).

Device

The basis of the Ural 375 chassis was a stamped riveted frame made of sheet steel. It was originally equipped with a wooden platform for transporting goods and people and a metal cabin. The front towbar consists of 2 rigid towing hooks, the rear towbar is a 2-way towing device.

The front suspension included 2 longitudinal semi-elliptical springs, the front ends of which were attached to the frame by means of pins and lugs, and the rear ends were sliding. The suspension used double-acting hydraulic telescopic shock absorbers. The rear suspension was balanced and was based on 2 semi-elliptic springs on sliding supports. Restriction cables were provided for the middle bridge. The pushing forces were transmitted by reaction rods. The truck was driven by a front steered axle. The axle shafts included angular velocity disc joints.

The car used open-type foot brakes. Pads were installed on all wheels. The braking system included a joint pneumohydraulic drive for the middle and front axles and a separate pneumohydraulic drive for the rear axle. A drum-type hand brake with internal shoes was installed on the output shaft of the additional box. The drive was interlocked with the brake valve of conventional brakes to brake the trailer while parked.

The Ural 375 was equipped with a mechanical transmission model YaMZ-204U with 5 forward and 1 reverse gears. The gearbox had synchronizers at 2, 3, 4 and 5 speeds. Clutch – 2-disc dry with peripheral springs. The cardan transmission is open with 4 shafts.

The steering mechanism was located in the cabin on the left. On the latest modifications of the model, power steering appeared.

The wiring system in the Urals is 375 - 12 V (negative terminals are connected to the machine body). The DC generator is shielded, waterproof and driven by a V-belt from the crankshaft pulley.

For the Ural 375, special wheels with conical flanges, a spacer ring and split rims were used. The basic version came with OI-25 tires with variable pressure. Tire pressure control was centralized with an internal air supply. The adjustment was controlled directly from the cab.

The first models were equipped with a 3-seater metal cabin with folding window frames and a soft top. However, it was soon replaced by a 3-seater all-metal cabin with rotating windows, a blind wind window and sliding windows. Heating in the cabin is water-based from the cooling system (used to heat the glass and the cabin). The windshield was divided by a metal frame, providing additional rigidity. The side windows rolled down. Everything inside the cabin was as ascetic as possible. Hard seats and a minimal number of sensors (speedometer, mechanical clock, pressure gauge and several indicators) made the working conditions spartan.

Starting with the Ural 375D version, the car was equipped with a metal platform with a tailgate. It was equipped with a removable awning and folding benches. The front and side sides were extended and lattice.

Model dimensions:

- length – 7350 mm;

- width – 2690 mm;

- height – 2680 mm;

- height with awning – 2980 mm;

- wheelbase – 3525 + 1400 mm;

- ground clearance - 400 mm;

- rear track – 2000 mm;

- front track – 2000 mm;

- minimum turning radius – 10500 mm.

The vehicle weight is 8400 kg, load capacity is 4500 kg. The model can accelerate to 75 km/h. Braking distance at a speed of 40 km/h is 15 m. The maximum climbable grade is 40 degrees.

On the first versions of the Ural 375, fuel consumption was 65-70 l/100 km, on later versions - 48-50 l/100 km. Fuel consumption changed taking into account the conditions and characteristics of operation. So, when driving off-road, consumption increased by 40-50%. The car's power reserve was 650-700 km. The fuel tank of the model contained 360 l (300 l - main tank, 60 l - additional tank).

The truck has a 6 by 6 wheel arrangement, providing good cross-country ability.

Design and performance characteristics

Ural-375 with an open cargo platform

The basis of the Ural-375 design is the chassis, made on the basis of a stamped riveted frame. It housed a metal cabin and a platform for the cargo compartment, which was originally made of wood. There were two rigid hooks at the front as a towing device, and at the rear there was a double-sided towing device.

For this car, special wheels were used that had conical flanges, spacer rings and split rims. For the main version of the truck, OI-25 tires with variable pressure were provided. Pressure control was centralized, control was provided from the cabin. Air supply is internal.

Cabin and body

In the first Ural 375 trucks, the cabin was metal, with folding window frames and a soft top. Later it was replaced with an all-metal one with rotating windows, a blind wind window and sliding windows. The windshield was divided into sections, which provided additional rigidity.

The interior of the cabin was as simple as possible. Hard seats, a minimal set of control devices and sensors. Water heating from the cooling system also did not appear immediately.

The first platforms were wooden. Starting with sample 375D, they became metal, the rear side was hinged, the front and sides were lattice and add-on. For the transportation of goods and people there was a removable tarpaulin awning and folding benches.

Engine

Ural-375 with a canopy for transporting people

The first truck models were equipped with a ZIL 375 engine. The power plant was four-stroke with eight cylinders and rotated one crankshaft. Good balancing allowed the engine to operate stably at high loads and low speeds.

The cylinder block was made of cast iron, the cylinder head was made of aluminum alloy. The working volume was 7 liters, the rated power was 180 liters. With. Recommended gasoline is A-92.

Later, KamAZ-740 eight-cylinder diesel engines began to be installed on Ural-375 trucks. The unit complied with the Euro-1 environmental standard and coped well with high loads. The working volume was 10.85 liters, the rated power was 210 liters. s., torque - 667 Nm.

Fuel system

The fuel system has a two-chamber carburetor. AI-92 gasoline was used for filling; AI-72 was allowed to be used as a temporary measure. There are two fuel tanks, a main one of 300 liters and an additional one of 60 liters.

Chassis and brakes

The front suspension of the Ural-375 truck consists of two semi-elliptical springs. Their front ends were attached to the frame with fingers and lugs, while the rear ends remained sliding. Double-acting hydraulic telescopic shock absorbers were also used.

The rear suspension was balanced, also based on two springs with sliding supports. The middle bridge had limit cables, shocks were transmitted by reaction rods. The front steering axle was driven, and angular velocity joints were provided for the axle shafts.

The brake system is foot type, pads are installed on all wheels. There was a joint pneumohydraulic drive for the front and middle axles. For the rear, a similar drive was separate. A drum-type hand brake with internal shoes was mounted on the output shaft of the additional box. At a speed of 40 km/h, the braking distance is 15 m.

Gearbox and transmission

The Ural-375 truck has a YaMZ-204U mechanical transmission, designed for five forward and one reverse gears. In the Ural 375 gearbox, the gear ratios were combined with synchronizers at 2, 3, 4, and 5 speeds. The clutch was double-disc dry and had peripheral springs. The cardan transmission is open, with four shafts.

Controls

Dashboard Ural-375

The dashboard of the Ural 375 is simple. All systems are represented by sensors and indicators that allow you to monitor the condition of the machine in any conditions. The steering mechanism is worm gear with a gear sector and hydraulic booster, the gearbox is mechanical.

Fuel consumption

For Ural 375 trucks, the fuel consumption of the first models was up to 70 liters per 100 km. Later, with the replacement of the engine and modernization of the fuel system, the figure was reduced to 50 liters.

Fuel consumption depended largely on the type of terrain. On highways at high speeds, consumption is minimal. On rough terrain, as well as in cold climates, fuel consumption increased by up to 50%. Taking this aspect into account, the power reserve is indicated in a mixed form and amounts to up to 750 km.

Maximum speed and load

The permissible speed of movement of the Ural-375 is 75 km/h. The engine power made it possible to overcome climbs of 40 degrees. The turn on the outer track had a radius of 10.5 meters.

The carrying capacity of the vehicle according to its basic characteristics was 5 tons. However, this figure largely depended on terrain conditions and road surfaces. The weight of the towed trailer was 10 tons.

Dimensions and weight

In terms of dimensions and weight, the Ural-375 trucks have the following technical characteristics:

- length - 7.35 m;

- width - 2.69 m;

- height - 2.68 m, along the awning - 2.98 m;

- ground clearance (clearance) - 0.4 m;

- track width - 2 m;

- own weight - 8.4 tons.

Depending on the modification and model, some parameters may differ. The wheel formula of the car remained unchanged - 6x6.

Tuning and modernization

Modernization of the Ural-375 continued throughout the active use of these trucks. Soon after release, the new cars received all-metal cabins, as well as metal platforms with folding tailgates.

Separate tuning was also done within the same line of cars. Some samples were equipped with special equipment, for example, a 65 m drum-type winch. Single-pass mechanical power take-offs for the gearbox and transfer mechanism were also installed. They provided drive for auxiliary devices and better control of the machine.

Truck suspension, chassis and axles

Suspension Ural-375

The design of the front suspension of the Ural-375 car is a pair of semi-elliptical springs, the front part of which is held on a riveted steel frame using special fasteners, and the rear part is sliding.

The driving axle of the truck is the front one, which has completely unloaded axle shafts with disk joints. On the middle bridge there are cables that act as a limiter. Pushing forces are transmitted through reaction rods. The Ural-375 axle housings are made of steel and equipped with pressed axle tubes.

The truck wheels are equipped with special OI-25 tires. Additionally, the car is equipped with a mechanism responsible for centrally changing tire pressure.

Dashboard

The status of all important vehicle systems is shown by sensors and indicators. Can be controlled:

— oil pressure;

- fuel level;

— water temperature;

- speed.

Additional options were included with toggle switches or levers.

Advantages and disadvantages

Among the advantages of the Ural-375 off-road truck are:

- Powerful appearance;

- Excellent maneuverability;

- Load capacity;

- High ground clearance;

- Ability to change tire pressure;

- All-wheel drive system;

- The car is not so difficult to operate and repair;

- There are no problems with purchasing parts and spare parts;

- You can “upgrade” the car yourself;

- Small turning radius;

- Not afraid of different temperature conditions;

- Built for off-road use;

- Rich history of the machine;

- Relatively low price.

There are also disadvantages, and they are as follows:

- Just huge fuel consumption;

- The cabin looks spartan;

- Low dynamic characteristics;

- Weak braking system.

Number of reviews Leave a review

Sort by:

Be the first one to leave a review.

show more

Leave feedback

Steering

The steering of the Ural-375 all-terrain vehicle consists of a worm gearbox and a hydraulic booster. The gearbox includes a worm shaft with a double-start screw thread and a sector.

To operate the amplifier, a vane pump is used. The pump is mounted on the engine and is belt driven from a pulley on the crankshaft.

Devices

In front of the driver there is a dashboard with a standard set of instruments for Soviet trucks. A speedometer is installed in the center of the dashboard, on the right are indicators of the amount of fuel in the main tank and an on-board network status indicator, on the left is a coolant temperature indicator and an oil pressure indicator in the lubrication system. The all-terrain vehicle's shield is equipped with two backlight lamps covered with visors.

On the lower part there is a high beam headlight indicator and a turn signal indicator (with a green filter). To the left of the dashboard there are air pressure gauges in the tires and in the brake drive.

Under the instrument panel there is a number of indicators and switches (listed from the driver's door):

- red warning light for low oil pressure;

- light switch;

- red lamp for minimum tire pressure;

- a red lamp indicating an emergency condition of the brake system;

- cabin light switch;

- egnition lock;

- switches for the ventilation system and turning lights.

Fuel containers

The fuel supply on the Ural-375 all-terrain vehicle is located in the main tank with a capacity of 300 liters, as well as an additional tank designed for 60 liters. On civilian versions there is no additional tank. The main tank is mounted on brackets riveted to the left frame side member.

The northern version of the 375K all-terrain vehicle uses an additional 120-liter tank, and the truck tractor uses a 110-liter tank. On 375SK1 cars produced after 1977, there is no additional tank. The 375CH civilian truck tractor was equipped from the factory with a canister canister designed for 20 liters of gasoline.