Causes of knocking noise from serviceable hydraulic compensators

A short knocking sound immediately after starting the engine is normal. When the valves of some compensators are open, oil leaks from the channels, and the pump does not have time to fill them immediately after starting. After seconds, the extraneous sound stops. However, in a number of cases, knocking can be caused by malfunctions in the operation of perfectly serviceable hydraulic compensators, the normal operation of which is hampered by the following shortcomings or malfunctions of the internal combustion engine lubrication system:

- unsuitable oil for this type of engine

- motor oil that has exhausted its service life or is not viscous enough

- Engine oil level is higher than the established norm

- insufficient engine oil level

- heavily contaminated oil filter or faulty oil pump

Reasons for knocking of hydraulic compensators when hot

In most cases, there may be one of two reasons why hydraulic compensators knock when hot - the viscosity of the heated oil is too low or its pressure is insufficient. This can occur for various reasons.

- Low oil level . This is a very common reason why hydraulic compensators knock when hot. If there is not enough lubricating fluid in the crankcase, then there is a high probability that the hydraulic compensators will operate “dry”, without oil, and, accordingly, will knock. However, overfilling oil is also harmful for hydraulic compensators. In this case, foaming of the lubricating fluid occurs, which leads to airing of the system, and as a result, incorrect operation of the hydraulic compensators.

- Clogged oil filter . If this element has not been changed for a long time, then over time a coating of dirt forms in it, which prevents the normal movement of oil through the system.

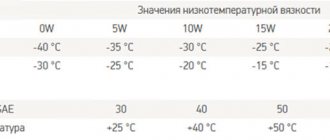

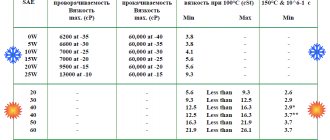

- Incorrectly selected viscosity . Car enthusiasts are often interested in the question of why hydraulic compensators knock when hot after an oil change . In most cases, the problem is precisely due to an incorrectly selected oil viscosity or it turned out to be of poor quality. It’s not that hydraulic compensators like some oil and some don’t, you just need to choose it correctly. If the oil is too thin, there may not be enough pressure to completely fill the hydraulic fluid. And when it is of poor quality, it simply quickly loses its performance properties. Changing the oil will help solve the problem, and do not forget that the oil filter needs to be changed along with the oil.

- Faulty oil pump . As a rule, this reason is typical for cars with high mileage, in which the pump has simply worn out and is not able to create the proper pressure in the engine lubrication system.

- Use of oil additives . Most oil additives perform two functions - they change the viscosity of the oil (lower or increase it), and also change the operating temperature of the oil. In the first case, if the additive has lowered the viscosity of the oil, and the hydraulic compensators are already quite worn out, then conditions arise when the hydraulic valves knock on a hot engine. As for the temperature regime, the oil works optimally when it’s hot, and an additive can change this property. Accordingly, after pouring the additive into the oil, the hydraulic compensators may knock when there is not enough pressure to push the oil into them. Usually due to too thin oil.

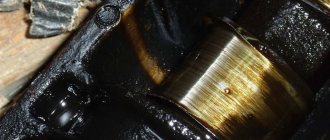

- Problems in the plunger pair . With such a malfunction, oil leaks from the cavity under the plunger, namely between the plunger bushing and the plunger itself. As a result, the hydraulic compensator does not have time to select the working gap. This breakdown may occur due to wear or clogging of the ball valve in the plunger pair . The ball itself, the spring, and the working cavity (channel) may wear out. If this happens, then only replacing the hydraulic compensators will help.

Knock is different, because the consequences are different.

How are these devices convenient? Because they perform their functions without requiring maintenance or special care.

You don’t have to think about them until you hear a certain, specific knocking sound from the hydraulic compensators.

Moreover, it can appear only at startup and disappear as it warms up, or it can continue all the time.

What happens when hydraulic compensators knock:

- the functioning of the plunger pair stops;

- the dynamic load on timing parts and components increases;

- fuel consumption increases;

- valve heads burn out with subsequent damage to the block head;

- noise occurs in the engine, making general diagnostics difficult;

- Acceleration dynamics deteriorate.

Why do hydraulic compensators knock? There may be several answers, depending on the circumstances. It is necessary to establish the moment when the knocking starts. This helps clarify the situation.

If you hear a knocking sound from the hydraulic compensators when cold, that is, immediately after starting and continues until the engine warms up, then the probable causes may be the following:

- The plunger valve allows oil to pass through when the engine is off.

- Narrowing of oil-conducting channels by pollutants. At the moment of start-up, the oil has a high viscosity and does not enter the plunger, which is why the hydraulic compensators knock when cold. When heated, the viscosity decreases and its penetrating ability increases.

- High oil viscosity. The knocking noise disappears as fluidity increases.

This phenomenon is not very critical, although it should not be ignored.

Often hydraulic valves knock only at the moment of start-up. This occurs because when stopping, some of the engine valves freeze in the open position and the plunger valve “bleeds” some oil. These sounds should not be considered signs of a malfunction. This is acceptable on a cold engine. New hydraulic compensators will knock when starting up, because during long-term storage some of the oil may leak out. Well, what if the hydraulic compensators knock when they’re hot? Although the question is posed somewhat incorrectly. Let's figure out why the knocking appears when the engine starts and does not stop as it warms up. In this case, as in the previous one, there are several probable reasons:

- Poor quality oil initially or has not been changed for a long time. The knocking noise most often stops after an oil change.

- Malfunction of the hydraulic compensator itself.

- Oil filter dirty.

- The knocking of hydraulic compensators when hot occurs if the oil pump does not develop the required pressure.

There is another reason that, for some reason, appears on the Priora. A knocking sound in the compensators appears after replacing 5W40 oil with 0W40.

Oil and hydraulic compensators. Need some advice. — logbook of the 1989 Ford Sierra Hatchback on DRIVE2

Hello. I left and am already riding. Only traveled 300 km. I ride without music or stress, listening to the engine. Everything seems to be ok - only the hydraulic compensators are straining. They rattle a little, not much. Moreover, not always. During a cold start, when warming up, the motor just whispers and runs quietly. But as soon as you drive a few kilometers, hydraulic compensators enroll in a drum club. They don't rattle too much, but it's annoying. I consulted with the engine mechanics - the verdict is the same - first of all, change the oil manufacturer. Here, yes, I’m ready to say that the oil I took was not expensive - I planned to drive 1000-1500 km on it so that it would collect debris that could get into the engine during assembly and then switch to normal oil. But what is normal?

And one more question - the mechanics also told me that you need to pour oil into DONS at the maximum mark on the dipstick, and not, as I did, between the marks... Is this really so? It won't fit out of all the holes.

Tell me what kind of oil you use, what viscosity. And can hydraulic compensators knock due to oil?

I will be grateful to everyone for advice.

If possible, I will post a video of the engine running cold and hot.

This is the oil I filled in at the moment.

I poured this oil into the old engine. What can you say about him?

Incorrect engine oil

For each engine, the manufacturer recommends using oil that corresponds to a certain viscosity class and contains special additives. A suitable composition of which will ensure normal functioning and better performance of the power unit. As well as its long service life. An oil that is not suitable in properties for a certain type of engine will obviously lead to improper operation of its components. In particular, the first sign may be the knocking of hydraulic compensators.

The appearance of knocking noises after changing the engine oil in a car

Based on the existing options for the appearance of knocking noises from hydraulic compensators in a car engine, we can confidently say that their appearance after a complete change of engine oil or its partial topping up occurs for the following main reasons:

- Using low-quality oil.

- A motor lubricant has been filled that does not meet the technical requirements of the engine, primarily in terms of viscosity.

- When changing the oil, the oil filter was not changed, as a result of which wear products from the filter clogged the supply channels.

To avoid these malfunctions, it is necessary to fill the car engine with motor lubricant recommended by the manufacturer and having the appropriate approvals. It is necessary to buy oil from trusted sellers or carefully check the integrity of the packaging of the purchased products. Be sure to change the oil filter when changing the oil. Following these simple rules will help you avoid possible troubles when operating your car.

Choosing the right engine oil

Sometimes drivers have a question, which oil is best for hydraulic compensators? It is connected with the fact that sometimes unpleasant situations can occur due to the wrong type. In fact, oil is not selected specifically for hydraulic compensators, since it must first of all correspond to the type of engine as recommended by the manufacturer.

Also, the type of oil depends on the time of year. But incorrectly selected engine oil can negatively affect the operation of hydraulic compensators. This leads to rapid wear of this part and those associated with it. Therefore, it is important to understand not only what hydraulic lifters are in an engine, but also that they must work under suitable conditions. Otherwise, an unpleasant knock will come from under the hood soon enough.

Consequences if hydraulic compensators knock

Interestingly, failure of the hydraulic compensator is not a direct cause of damage to other engine components. Knocking compensators only lead to a violation of the thermal gap, which results in a decrease in throttle response and engine power. Consequently, fuel consumption increases.

Perhaps knocking sounds indicate poor performance of the oil system. Here you will have to take the car to a service center for diagnostics, so that the technicians can determine the cause of the knocking noise and eliminate it, taking into account the manufacturer’s requirements.

In the case of DOHC and SOHC gas distribution systems, they differ only in the number of hydraulic compensators present inside the engine. But if you do not take the car for service and use it every day in this condition, an increase in fuel consumption will lead to increased wear on the grinding elements. Therefore, it is better to diagnose hydraulic compensators in advance, so that later you do not have to carry out major engine repairs.

Low viscosity class or expired engine oil

Engine oil that is too thin is not able to maintain the required degree of pressure on the working piston of the hydraulic compensator, even if it is fresh and clean. Also, any oil for an internal combustion engine has a certain resource. The components and additives in its composition, which provide the required viscosity for effective lubrication of rubbing surfaces, are produced over time under the influence of constant loads and high temperatures. The oil becomes diluted and also becomes contaminated. Pollution products create additional interference with the free movement of moving parts of the mechanism.

Application of additives for hydraulic compensators

The use of additives for hydraulic compensators allows you to solve the following problems:

- Effectively copes with cleaning valves and channels from various contaminants and deposits;

- Eliminates knocking and extraneous noise during operation of this system;

- Increases the service life of this mechanism and all related units.

Good oil additives not only solve the problems described above, but also increase the efficiency of the hydraulic compensator itself, due to the fact that they make the lubricant more viscous.

Naturally, in order for the purchase of such a product to be a profitable and effective investment of money, you need to know which options are best to choose. It is recommended to make such a choice based on two factors:

- Rating of the best products of this category;

- The opinion of real car enthusiasts who use additives in motor oils for hydraulic compensators in their vehicles.

What is a hydraulic compensator?

The hydraulic compensator, to put it simply as a “hydric,” is presented in the form of a device that regulates the gaps between the valves and the camshaft. To do this, it uses oil pressure. As a result of the combined work, it turns out that dynamic properties are improved and fuel consumption is reduced.

Hydraulic compensators were invented to replace mechanical regulators. If previously you had to adjust the valves manually, now you don’t need to do this. The mechanism independently sets the gap, and it works for quite a long time without replacement.

Today the device is used in timing systems. In total, 4 types of designs have been invented, all of them differ significantly from each other. A modern hydraulic compensator includes more than 10 interconnected elements. The package includes a cylindrical piston. It is this component that receives the force from the shaft cam. The plunger located inside the piston moves freely, while creating a thermal gap. Through it, force is transferred from the fist to the valve stem.

To better understand why hydraulic compensators knock, you need to study its operating principle. When the motor is turned on, the cam moves to the bottom of the hydraulic valve, displacing it. After which the piston presses the valve with a plunger. The valve opens. The clearance regulates the oil by supplying pressurized fluid to the head.

How to check hydraulic compensators

Common methods for testing functionality include applying force to each hydraulic compensator cap. The protruding part of the cam should be directed in the direction opposite to the pusher. The gap between them is first checked; if it is present, this already indicates the need to clean or replace the part.

To push through a working hydraulic compensator, you will need to apply significant force. To do this, you can use a drift made of soft metal or wood so as not to damage the surface. The force applied for pushing should be approximately the same for all parts being diagnosed, as well as the speed of their movement relative to the vertical. Obviously “weak” ones must be replaced. This is one of the ways to properly check hydraulic compensators for functionality, but if you lack experience, it is better to entrust the procedure to specialists.

Why are hydraulic compensators knocking?

A hydraulic compensator is a device responsible for automatically adjusting the thermal gap in a separate valve. Thanks to their use, engine operation becomes easier. The reason is that you don’t have to adjust the valves manually. They also increase the service life of the gas distribution mechanism. It functions more evenly because the thermal gap is always within the manufacturer's tolerances.

But it happens that the hydraulic compensator starts knocking. Over time, the knocking becomes stronger and becomes impossible to ignore. Often there are three reasons.

- Severe natural wear and tear or manufacturing defects in design.

- The engine lubrication system operates intermittently.

- The engine oil is not compatible with the engine, or it has been used for too long, as a result of which it has lost its original properties.

What to do if hydraulic lifters are knocking

If hydraulic compensators start knocking, what should you do in this case? There are two ways to solve the problem - complete replacement of the kit or repair of defective units. Let's consider each of them separately.

Replacement

The advantage of replacement is a guarantee of a good result. There are two disadvantages. A set of original catalog parts will be expensive. It is unlikely that you will be able to install it correctly yourself, so the car will have to be sent to a service center. Here you will also have to wait two or three days.

It must be taken into account that some foreign-made machines are subject to a shortage of parts. You have to wait for the complete set to arrive, spend money on postage, and make an appointment for repairs at a service center. For proper installation, you will also have to allocate some money for disposable parts - sealant and gaskets.

If the case is neglected and the driver does not try to take action to restore normal operation of the engine, the consequences can be dire. At first, when starting up, the knocking noise gets stronger over time. Then the smooth idle speed disappears. Since the thermal gap is not adjusted properly, it becomes more difficult to gain momentum each time. Ultimately, the entire valve mechanism wears out, and engine repair becomes inevitable.

Repair

To quickly troubleshoot the problem, you must first find out which compensator is starting to knock. Repair is possible if the malfunction begins to manifest itself when cold. With regular use of high-quality lubricant, with timely replacement, you just need to buy original oil, change the filter and check the result again. Most likely, the owner, without realizing it, bought a fake canister.

At the initial stage, it is worth buying flushing oil. Along with it you will have to acquire two filters. One is used when pouring flushing material, the other must be screwed on when the technical fluid has had time to circulate through the system in 15-20 minutes of idle operation. For special cases, you will need an aggressive composition. For example, pharmaceutical dimexide. Its chemical structure contains hard elements that are capable of removing soot and other deposits, regardless of their thickness.

Note!

Repair by flushing with pharmaceutical dimexide does not always help. Much depends on the initial state of the engine. There should be no fragile plastic parts or painted elements inside.