Every detail is important for the smooth operation of a car engine. A special position in the crank mechanism system is occupied by the crankshaft liners. Thin semicircular steel-aluminum plates surrounding the main and connecting rod journals are the outer races of the plain bearings, and the overall performance of the engine depends on their condition.

When is it necessary to replace crankshaft bearings?

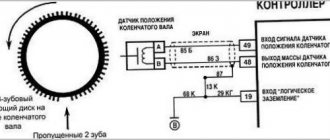

Under the conditions of the physical and thermal loads that the crankshaft has to endure, only plain bearings can keep it on the axis and ensure the operation of the crank mechanism. The main and connecting rod journals serve as internal races, and the liners, respectively, serve as external races. The engine block system has a network of oil lines through which engine oil is supplied to the liners under high pressure. It creates a thin oil film that reduces friction and allows the crankshaft to rotate.

Physical wear is the first and main condition due to which the liners have to be changed. No matter how much we would like to avoid wear, the surfaces of the journals and bearings are gradually worn away, the gap between them increases, the crankshaft becomes free to move, and the oil pressure drops sharply. All this leads to engine breakdowns.

Another reason for forced repairs is a situation where the crankshaft liners rotate. Every car owner has heard about such malfunctions, but not everyone knows how and why this happens. A thin plate of the liner is placed in the so-called bed. On the outer walls of the half rings there are special antennae (protrusions), which, after assembly, rest against the end parts of the block or bearing cap.

Sometimes, when certain conditions occur, the antennae are not able to hold the liner and it sticks to the crankshaft journal and rotates. If the crankshaft liners are turned, the engine cannot run. Typical causes of such a breakdown:

- too viscous lubricant, lack of it, abrasive ingress;

- too little interference when installing bearing caps;

- insufficiently viscous lubricant and operation of the motor in overload mode.

Selection of crankshaft liners

Replacing crankshaft bearings

Whatever the reasons why the car owner is forced to disassemble the engine and change the liners, grinding the crankshaft is indispensable. New liners are installed either on a new crankshaft or after grinding it. Even if only one neck is damaged or worn, all of them undergo grinding to the same size.

At the factory, when assembling the motor, standard liners are installed. For VAZ engines, liners are available in 4 repair sizes. Accordingly, grinding the crankshaft can be carried out no more than 4 times. The step between sizes is 0.25 mm. Accordingly, after the first grinding it is necessary to buy inserts marked “0.25”, after the second - 0.5, after the third - 0.75, after the fourth - 1.0. Motors that are installed on GAZ and Moskvich cars have two more borings available, up to 1.25 and 1.50 mm.

The dimensions of the crankshaft liners that need to be purchased can only be calculated by a specialist who grinds the crankshaft. Sometimes it happens that damaged necks require grinding not to the next size, but after one. Inserts are sold only as a set for all main or connecting rod journals.

How to replace crankshaft bearings with your own hands

Considering that to access the crankshaft you will have to completely disassemble the engine, such repairs can only be started if the car owner has the necessary knowledge and skills in this matter. First of all, you need to remove and completely disassemble the motor. This can be done in a garage, but it requires a full set of car keys and other tools, as well as a mechanical winch. To remove the motor, do the following:

- remove the hood and battery;

- drain the oil and coolant;

- remove the engine from attachments: carburetor, starter, generator, fuel pump and cooling system pump, ignition distributor, remove the radiator and cylinder head;

- then unscrew the clutch cover, the nuts of the pillows and remove the block;

- Having placed the engine on the workbench, you should remove: the flywheel, pulley, camshaft drive cover, oil pump drive chain and gear, auxiliary drive shaft, flywheel, and rear cuff holder;

- after the 14 bolts of the pan are unscrewed, the crankshaft itself will become available to us;

- in order to remove it you will need to unscrew the bolts of the five main bearing caps and the bolts of the four connecting rod caps.

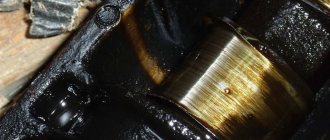

By removing the bearing caps, you can immediately notice where the bearings have rotated. It is strongly recommended that you do not remove the covers or remove the crankshaft until it has been seen by a professional. Based on the characteristic signs of uneven wear, a specialist will be able to determine where the displacement or curvature has occurred. To do this, it is necessary that each liner remains in its place.

Is it worth it to install the crankshaft yourself?

A car engine is a rather complex and specific device. Many car enthusiasts successfully carry out its complete disassembly and repair. However, in order to correctly install the crankshaft liners, you must have certain skills. It is better if this work is performed by an experienced mechanic. This is necessary primarily in order to avoid excessive or insufficient tension, which can cause the liners to rotate.

An internal combustion engine is a complex mechanism consisting of hundreds of parts. And each and every one of them is important for the balanced and correct operation of a complex system, to one degree or another. But at the same time, in no case can the degree of importance of each of them be assessed equally. One of the most important elements, of course, is the crankshaft and all its parts that interface with it, which transmits the energy of the burning fuel to the wheels, thereby rotating them. We will further discuss the components of this mechanism, namely the crankshaft liners, which are small half-rings made of soft metal with an anti-friction coating. During long-term operation of the car’s engine, they should be the very first to leave their post, and not the crankshaft journals.

- What are crankshaft repair liners, their types

- Reasons for replacing crankshaft bearings?

- How to determine the wear of the crankshaft liners and help the mechanism?

- How to install liners on the crankshaft - procedure?

- How to choose the right crankshaft bearings?

What are crankshaft repair liners, their types

Essentially, crankshaft bearings are plain bearings for the connecting rods that rotate the crankshaft. This rotation is the result of a micro-explosion in the combustion chambers of the engine cylinders. This system is dominated by high speed and heavy loads, as a result of which it is necessary to minimize the friction of parts, otherwise the engine will simply fail, and instantly. In order for friction to be reduced as much as possible, all significant parts of the internal combustion engine are coated in a so-called “oil film” - a thin micron film, which is ensured by a special lubrication system of the automobile engine. The appearance of a film that envelops metal parts is only possible if the oil pressure is strong enough. And between the crankshaft journal and its bearings there is also a similar oil layer. And only thanks to it the friction force is minimized as much as possible. From this we can conclude that the crankshaft liners represent a certain protection, the effect of which increases the service life of such an important part for the engine.

We recommend: Fuel supply system for a gasoline (carburetor) engine

To begin with, the crankshaft liners must be divided into two categories:

connecting rod and main. The connecting rod bearings, as we said above, are located between the crankshaft connecting rods and its journals.

The radicals, in turn, play a similar role, but they are located between the crankshaft and the places where it passes through the engine body.

For different engines, factories produce crankshaft liners that differ in their inner diameter. Repair inserts differ from each other and, of course, from new ones installed on a newly released car. Their minimum difference is calculated from a quarter of a millimeter and increases with a similar step. Thus, we have a size range of crankshaft repair liners in increments of 0.25 mm along the internal diameter: 0.25; 0.5; 0.75; 1 mm, etc.

Reasons for replacing crankshaft bearings?

Under conditions of extreme temperature and physical stress that the crankshaft constantly endures, only the crankshaft liners help it stay on the axis, ensuring the operation of the crank mechanism. The main and connecting rod journals operate on the principle of internal races, and the crankshaft liners serve as external races, respectively. The engine block system has a whole network of oil lines through which engine oil is supplied to the bearings under high pressure. It is this that creates the very microscopic film mentioned above, which allows the crankshaft to rotate.

The primary reason for replacing crankshaft bearings is their physical wear . Whatever the desire to protect the liners from wear, physics is physics. The surfaces of the journals of the crankshaft liners wear out over time, increasing the gap between them, which leads to free movement of the crankshaft and less oil supply due to a sharp decrease in pressure. And this already leads to breakdowns of car engines.

The second reason for forced repairs is the rotation of the crankshaft liners . Probably every car owner has heard about such situations, but, alas, not everyone knows about the reasons for this state of affairs. So how and why does this happen? The thinnest plate of the liner goes into a makeshift bed. The outer walls of the half rings are framed by special protrusions, which in the new engine rest against the front parts of the block. Under certain conditions, the antennae simply cannot withstand the liner, and it begins to rotate, sticking to the crankshaft journal. If this happens and the liner turns, the engine simply stops functioning. Typical causes of such failure are:

- extreme viscosity of the lubricant, penetration of abrasive compounds into it or its disappearance altogether;

— insufficient tension of installed bearing caps;

- too thin lubricant and operation of the engine in constant overload modes.

How to determine the wear of the crankshaft liners and help the mechanism?

Once it has happened that engine repair is already inevitable, the question arises of how to further determine the wear of the crankshaft liners and what size will they need to be purchased for the next replacement? Basically, a micrometer is used for measurements, but it is still calculated quite accurately visually, as they say, “by eye.” Immediately evaluate the possibility of the next crankshaft boring.

Immediate replacement is necessary if the crankshaft bearings are rotated. An indicator of this problem will be a loud knocking of the crankshaft and constant attempts by the engine to stall. If the necks jam, then you won’t be able to drive any further. In any case, a detailed inspection of the mechanisms should be carried out. If you find wavy potholes on the journals that you can easily feel with your hands, then you cannot avoid boring the crankshaft and then installing repair liners of the appropriate size. We strongly recommend that you purchase inserts only after boring them. After all, a lot of wear can lead to carrying out this procedure by one, or even two sizes.

How to choose the right crankshaft bearings?

Whatever the reason for disassembling a car engine and replacing the crankshaft liners, grinding it is indispensable. New liners are mounted either on a new crankshaft or on an already bored one. Even if only one neck is subject to damage, then all the others must undergo grinding adjustments for it.

When assembling the engine on a conveyor, standard crankshaft liners are installed. For example, for VAZ models, liners are produced in four repair variations. Consequently, it will be possible to bore the crankshaft no more than four times. For engines installed on GAZ and Moskvich, fifth and sixth borings of up to 1.25 and 1.50 mm are available.

The dimensions of the crankshaft liners are determined only by the person who bored the crankshaft. Depending on the depth of damage to the necks, grinding may go two sizes forward. Inserts are sold as a set for all, both for main and connecting rod journals.

Subscribe to our feeds on social networks such as Facebook, Vkontakte, Instagram, Pinterest, Yandex Zen, Twitter and Telegram: all the most interesting automotive events collected in one place.

Required special tools and accessories:

- micrometer;

- passimeter;

- torque wrench with 15, 17 and 19 mm heads;

- probe plate 0.08 mm thick.

When deciding whether to replace the bearing shells, it should be borne in mind that the diametric wear of the bearing shells and journals of the crankshaft does not always serve as a determining criterion. During engine operation, a significant amount of solid particles (wear products of parts, abrasive particles sucked into the engine cylinders with air, etc.) is embedded in the antifriction layer of the liners. Therefore, such liners, often having insignificant diametrical wear, can cause further accelerated and increased wear of the crankshaft journals. It should also be taken into account that connecting rod bearings operate under more severe conditions than main bearings. The intensity of their wear is slightly higher than the intensity of wear of the main bearings. Thus, to resolve the issue of replacing bearings, a differentiated approach is required in relation to the main and connecting rod bearings.

In all cases of satisfactory condition of the surface of the antifriction filling of the main bearing shells, the criterion for the need to replace them is the size of the diametrical clearance in the bearing.

We recommend: Pneumatic braking system for tractors and trailers. Design

When deciding whether to replace connecting rod bearing shells, you must be guided by the following rule.

If the connecting rod bearing shells at the time of disassembling or repairing the engine have worked for a time corresponding to a vehicle mileage of 45,000 km or more, they should be replaced with new ones, regardless of the condition of the surface and the degree of wear. In such cases, liners of normal or first repair sizes are suitable for replacement. Preventative replacement of liners allows you to maintain the connecting rod journals in a state of preservation for a long time.

When assessing the condition of the liners by inspection, it should be borne in mind that the surface of the antifriction layer is considered satisfactory if there are no scuffs, chipping of the antifriction alloy and foreign materials (inclusions) pressed into the alloy. The dark color of the pouring surface is not a rejection sign.

To replace worn or damaged bearings, spare parts include main and connecting rod bearing shells in standard and six repair sizes. Repair size liners differ from normal size liners by being reduced by 0.05; 0.25; 0.50; 0.75; 1.00 and 1.25 mm internal diameter. The liners are sold as a set, in quantities required for one engine.

After replacing the liners, either with or without simultaneous regrinding of the crankshaft journals (and for the main journals also if the old liners are used in the engine), be sure to check the diametrical clearance in each bearing. This will allow you to check the correct choice of repair inserts.

You can check the diametrical clearance in a bearing by measuring the diameters of the crankshaft journal and liners (in pairs) of a given bearing, followed by simple calculations. The diameter of the bearing is measured with the liners inserted and the bearing cover bolts tightened with the required force.

The diametrical clearances in the main bearings should be in the range of 0.025-0.082 mm, and in the connecting rod bearings - in the range of 0.025-0.076 mm.

You can also check the diametrical clearance in the bearing using a feeler plate placed between the shaft journal and the liner.

The plate for both connecting rod and main bearings should have a thickness of 0.08 mm, a width of 13 mm and a length 5 mm less than the length of the bearing. The plate is cleaned along the edges with a whetstone, lubricated with engine oil, and placed on the surface of the liner so that its long side is located along the longitudinal axis of the bearing.

Rice. Laying the control plate-feel in the connecting rod bearing: a - plate-feel

When checking, tighten the bolts of the cover of only the bearing in which the probe plate is placed, while the bolts of the covers of the remaining bearings remain untightened. The bolts must be tightened carefully, turning the crankshaft from time to time.

If significant resistance is felt when turning the crankshaft by hand on the flywheel, the diametrical clearance in the bearing is within acceptable limits. If the crankshaft turns almost as easily as without the control plate, the clearance in the bearing is greater than normal.

In some cases, the required diametrical clearance in the bearing can be achieved without regrinding the journal, only by using repair liners reduced by 0.05 mm. In all other cases, the required clearances are obtained by grinding the journals and installing repair liners in the bearings.

If, as a result of repeated grinding, the diameters of the crankshaft journals are reduced so much that the liners of the last repair size turn out to be unsuitable, then during the next repair it is necessary to assemble the engine with a new shaft. For such a case, spare parts kit 408-1000107 is supplied, consisting of a crankshaft from a set of normal-sized bearings.

Thin-walled replacement liners for connecting rod and main bearings of the crankshaft are manufactured with high precision. The required value of the diametrical clearance in the bearing is ensured only by the proper diameters of the crankshaft journals obtained during grinding. Therefore, when repairing an engine, the liners are replaced without any adjustment operations and only in pairs. Replacing one earbud from a pair is not allowed. It also follows from the above that in order to obtain the required diametrical clearance in the bearing, it is strictly forbidden to saw off or scrape the joints of the bearing liners or caps, solder the joints of these parts with babbitt, or install gaskets between the liner and its bed.

Failure to follow these instructions leads to the fact that the correct geometric shape of the bearings will be disrupted, the heat removal from them will deteriorate and the liners will quickly fail. But what is more dangerous is that new bearings of repair sizes cannot be installed in the future in bearings with sawed off or scraped caps. At the same time, bearing caps damaged by mechanical adjustment cannot be replaced with new ones, since at the factory they are processed together with the cylinder block and connecting rod. Since the bearing caps are not interchangeable, they are not supplied as spare parts, and therefore an engine with damaged caps cannot be repaired later.

When installing connecting rod and main bearings, you need to ensure that the locking protrusions a at the joints of the liners fit freely (by hand) into the sockets b in the cover (or body) of the bearing.

Rice. The fixing protrusion of the liner and its socket in the bearing cover

After replacing the connecting rod or main bearing shells (or both) and assembling the engine, you must follow the break-in rules.

Connecting rod bearings

Connecting rod bearings are an incredibly important part of a car, without which its correct operation is not possible.

Very often in the conversations of mechanics or experienced drivers you can hear phrases like “The liner turned” or “The engine caught”, after which it immediately becomes clear that this means an internal combustion engine failure, or more precisely, that the crankshaft plain bearings have failed, more precisely, connecting rod and main bearings.

Perhaps, such breakdowns occupy a significant place among all others and are considered very serious. Most often, motorists find the culprit in such breakdowns to be low-quality oil.

But professionals can identify many more reasons for the failure of this mechanism, most of which are absolutely not related to the quality of the engine oil.

It is very important to know what factors can cause bearings to fail, since you can achieve such a result that during operation of the car you can avoid at least such a problem in the engine.

Most often, connecting rod bearing shells are made of tin, copper or lead, but there are situations when aluminum alloy becomes the material for the manufacture of bearings.

It is thanks to the manufacture of parts from the latter material that some positive results can be achieved, such as:

- A certain consistency of the cover layer. The fact is that this material has a fairly smooth and soft layer, which gradually wears out in order to match the dimensions of the shaft. True, it is worth noting some inconsistency of the described element with the axis of rotation (this is more noticeable during run-in).

- When installing connecting rod bearings from an aluminum warehouse, it is worth noting the large absorption capacity of their cover layer. The soft material of the specified coating layer can absorb the smallest particles of solids, and after which they are already covered with a soft film, which prevents not only various damages, but also wear of the bearing and shaft journal.

- Bearings with such elements are quite resistant to jamming. Any abrasion, corrugation or surface scoring can be attributed to the three-phase welding that was carried out between the sliding surfaces in the event of a rupture of the oil film between the journal and the bearing.

Lead, which is considered the main component of the coating of connecting rod bearings of different sizes, is a fairly soft metal that works well in conditions of fairly poor (marginal) lubrication during engine start/stop.

Recently, researchers have confirmed the fact that the least friction is provided by the film that has a high shear stress and low shear stress on the metal (that is, the coating layer). This fact is confirmed by car operating experience.

It is worth noting that until 1996, diesel engine bearings that did not contain a coating layer could often jam or turn during startup.

The upper bosoms of the connecting rod bearings and the bearings themselves have a coating layer that is resistant to corrosion. This prevents corrosion of the copper-lead part. If you use an oil that does not have a high enough total alkaline number or an oxidized oil, you can destroy lead, which is why it will subsequently be unable to deal with harmful products of fuel combustion, which, among other things, are also acidic.

Lead elements that do not have a covering layer are characterized by vigorous dissolution, and the strength of its structure is significantly deteriorated. In order to reduce the likelihood of corrosion of the coating layer, lead is fused with tin in production, which is resistant to acids and also makes the structure of the coating stronger.

In addition, such parts are characterized by a nickel barrier. The fact is that between them and the covering layer there is a fairly thin layer of nickel, which is simply necessary in order to prevent the migration of tin into the copper-lead element from the covering layer. Most often this happens at high temperatures or under the influence of time.

It is unwise to replace connecting rod bearings with those that do not have a nickel barrier, because then tin can penetrate into their material from the coating layer, which, when paired with copper, can form rather undesirable alloys. In order to avoid the need for a mandatory nickel layer, many manufacturers use a coating layer made of a lead-indium alloy.

In order to avoid knocking of the connecting rod bearings, you need to use only high-quality bearings and you should definitely make sure that they are installed correctly. It is important to follow the oil change intervals recommended by the manufacturer. Under no circumstances should fuel or coolant enter the engine oil.

If you want to purchase connecting rod bearings, you can easily make a purchase using our website; all you need to do is place an ad for the supplier to find you, or contact the supplier directly. On our portal you can also sell high-quality parts.

Connecting rod and main bearings - how to determine wear

The crankshaft of the power unit during operation is influenced by temperature and mechanical influences. The design of the crank mechanism is supported by liners. The latter act as sliding bearings. The elements are made of metal and look in the shape of an even geometric half ring. Since this part bears an increased load, the manufacturer protects it with an additional layer on the surface - an anti-friction coating.

When elements wear out while the engine is running, a knocking noise may occur.

The main rotation parts in an internal combustion engine are secured and operated using these elements. All of them may differ in design and purpose. The main bearings are located inside the engine compartment. The main task of these elements is to fix the crankshaft and facilitate its operation. Parts are made in the shape of half rings that cover the crankshaft journals. This type of liners can be called a crankshaft support inside the engine block. When elements wear out while the engine is running, a knocking noise may occur.

The connecting rod elements are installed in the lower head of the connecting rods to ensure their rotation. For these parts, the liners play the role of support. The crankshaft thrust rings are located in the same place, which prevent axial movement. This type of liner is made of a multilayer structure. It is based on a steel plate with an anti-friction coating.

Both types of liners must be generously lubricated during operation, so there should be no close contact between the rubbing surfaces during operation. The elements have oil holes and locks. All liners used in the automotive industry can be divided into 2 groups - bimetallic and trimetallic. The former are based on a metal plate, the thickness of which is 0.9 - 4 mm. There is an anti-friction coating on the surface of the plate. The protective layer is made of alloys of copper, lead, tin and aluminum. With this protection, the liners can function even with a surface that has geometric defects. Trimetallic elements have a third layer with a thickness of 0.012 - 0.025 mm in their design. It includes alloys of lead, tin and copper.

You can distinguish worn connecting rod and main bearings by sound alone

Wear of liners. Over time, plain bearings begin to wear out and require replacement. This may be indicated by a loss of engine power and knocking noises during operation. Just by the sound you can distinguish worn connecting rod and main bearings. The first ones make a sharper knock. They can be heard well at idle speed while pressing the gas pedal sharply. To carry out diagnostics, you can turn off the spark plug for each cylinder in turn. Another sign of wear after knocking is a sharp decrease in oil pressure. You need to be especially careful as this may be the only reason. Defects on the surface of the elements may indicate that dirt is entering the system. And garbage here is the first reason for the premature failure of elements.

If the crankshaft journal jams, the car will not be able to move. As a rule, this problem occurs due to wear of the main elements. A distance forms between them and the necks, which leads to knocking and other noises. With this phenomenon, the oil pressure drops sharply.

Bottom line . Connecting rod and main bearings in a car periodically fail. This may be indicated by a knocking sound at idle and a drop in oil pressure.

Source

What is a connecting rod bearing? Main and connecting rod bearings

The engine crankshaft is a body of rotation. He rotates in special beds. Sliding bearings are used to support it and facilitate rotation. They are made of metal with a special anti-friction coating in the shape of a half ring with precise geometry. The connecting rod bearing acts as a plain bearing for the connecting rod, which pushes the crankshaft. Let's take a closer look at these details.

What to do if the connecting rod bearing has turned

If you notice symptoms of rotating bearings, you should go to a car service center or to your garage if you are going to replace them yourself, but it is better to turn off the engine and transport them by tow or tow truck, if possible.

Turning the connecting rod bearings is less costly and labor-intensive, if you stop operating when knocking is detected, than turning the main bearings. If you did not pay attention to extraneous knocking noises in the engine and continued to drive in this condition, then, perhaps, the cranked connecting rod bearings will lead to an expensive overhaul of the engine.

Basically, if one connecting rod bearing has turned, then it is replaced with a new one and the repair is complete. In this case, since the connecting rod itself has not been changed, the service life of the repaired crankshaft journal-connecting rod pair will be less than expected.

A desirable step in replacing a connecting rod bearing is to also replace the corresponding connecting rod. It often happens that if the connecting rod bearing is turned, the connecting rod lock breaks.

The optimally effective repair for bearing problems is considered to be boring the crankshaft and replacing the bearings with connecting rods. The crankshaft neck on which the rotated liner sat has nicks and scratches. Therefore, it is necessary to grind the crankshaft. All connecting rod bearings have the same dimensions and are completely interchangeable with each other.

The procedure for replacing connecting rod bearings in a garage:

Functions

The rotation parts in the internal combustion engine are equipped with plain bearings. They perform various tasks.

Thus, main bearings are necessary to support the crankshaft and facilitate its rotation. These parts are installed inside the cylinder block. Each part is a half ring, and the liner consists of two halves. The inner surface has a groove - it is through it that the lubricant flows. There is also a hole in the body of the liner - it is necessary to supply oil to the crankshaft journals.

The connecting rod bearing is necessary to ensure rotation of the connecting rod journal. The latter causes the crankshaft to rotate when the engine is running. These elements are installed in the lower head of the connecting rods.

You can also highlight the crankshaft thrust rings - they are designed to prevent axial movements of the crankshaft. Very often, on different engine models, the thrust ring is part of the main liner. This combined part has a special name - bead or flange liner.

The bushings installed in the upper end of the connecting rod are designed to accommodate the piston pin. It connects the connecting rod and the piston. The internal combustion engine also has camshaft liners. They are responsible for supporting and rotating the camshaft. The parts can be seen at the top of the cylinder head or in the cylinder block where the camshaft is located at the bottom.

How to choose crankshaft bearings

Because

You are not logged in. To come in. Because The topic is archived.

1. At the moment you need to order crankshaft main and connecting rod bearings. I need nominal ones (i.e. non-repairable). I look up the wine in the catalog - it produces a table where the sets are divided in some other way:

STD-AA, STD-A, STD-B, STD-C, STD-D

How can I determine which ones I need? what are these categories?

2. crankshaft thrust half-rings are only nominal, do I understand correctly?

Here are photos of the main and connecting rod bearings that were installed. marking on mains 6A B

(or

Q

)

A22E

on connecting rods:

5LZE A22E

is there at least something to cling to in order to accurately determine under what part number they are included in the catalogs? ¶

Every detail is important for the smooth operation of a car engine. A special position in the crank mechanism system is occupied by the crankshaft liners. Thin semicircular steel-aluminum plates surrounding the main and connecting rod journals are the outer races of the plain bearings, and the overall performance of the engine depends on their condition.

When is it necessary to replace crankshaft bearings?

Under the conditions of the physical and thermal loads that the crankshaft has to endure, only plain bearings can keep it on the axis and ensure the operation of the crank mechanism. The main and connecting rod journals serve as internal races, and the liners, respectively, serve as external races. The engine block system has a network of oil lines through which engine oil is supplied to the liners under high pressure. It creates a thin oil film that reduces friction and allows the crankshaft to rotate.

Physical wear is the first and main condition due to which the liners have to be changed. No matter how much we would like to avoid wear, the surfaces of the journals and bearings are gradually worn away, the gap between them increases, the crankshaft becomes free to move, and the oil pressure drops sharply. All this leads to engine breakdowns.

Another reason for forced repairs is a situation where the crankshaft liners rotate. Every car owner has heard about such malfunctions, but not everyone knows how and why this happens. A thin plate of the liner is placed in the so-called bed. On the outer walls of the half rings there are special antennae (protrusions), which, after assembly, rest against the end parts of the block or bearing cap.

Sometimes, when certain conditions occur, the antennae are not able to hold the liner and it sticks to the crankshaft journal and rotates. If the crankshaft liners are turned, the engine cannot run. Typical causes of such a breakdown:

Selection of crankshaft liners

Whatever the reasons why the car owner is forced to disassemble the engine and change the liners, grinding the crankshaft is indispensable. New liners are installed either on a new crankshaft or after grinding it. Even if only one neck is damaged or worn, all of them undergo grinding to the same size.

At the factory, when assembling the motor, standard liners are installed. For VAZ engines, liners are available in 4 repair sizes. Accordingly, grinding the crankshaft can be carried out no more than 4 times. The step between sizes is 0.25 mm. Accordingly, after the first grinding it is necessary to buy inserts marked “0.25”, after the second - 0.5, after the third - 0.75, after the fourth - 1.0. Motors that are installed on GAZ and Moskvich cars have two more borings available, up to 1.25 and 1.50 mm.

The dimensions of the crankshaft liners that need to be purchased can only be calculated by a specialist who grinds the crankshaft. Sometimes it happens that damaged necks require grinding not to the next size, but after one. Inserts are sold only as a set for all main or connecting rod journals.

How to replace crankshaft bearings with your own hands

Considering that to access the crankshaft you will have to completely disassemble the engine, such repairs can only be started if the car owner has the necessary knowledge and skills in this matter. First of all, you need to remove and completely disassemble the motor. This can be done in a garage, but it requires a full set of car keys and other tools, as well as a mechanical winch. To remove the motor, do the following:

By removing the bearing caps, you can immediately notice where the bearings have rotated. It is strongly recommended that you do not remove the covers or remove the crankshaft until it has been seen by a professional. Based on the characteristic signs of uneven wear, a specialist will be able to determine where the displacement or curvature has occurred. To do this, it is necessary that each liner remains in its place.

Is it worth it to install the crankshaft yourself?

A car engine is a rather complex and specific device. Many car enthusiasts successfully carry out its complete disassembly and repair. However, in order to correctly install the crankshaft liners, you must have certain skills. It is better if this work is performed by an experienced mechanic. This is necessary primarily in order to avoid excessive or insufficient tension, which can cause the liners to rotate.

An internal combustion engine is a complex mechanism consisting of hundreds of parts. And each and every one of them is important for the balanced and correct operation of a complex system, to one degree or another. But at the same time, in no case can the degree of importance of each of them be assessed equally. One of the most important elements, of course, is the crankshaft and all its parts that interface with it, which transmits the energy of the burning fuel to the wheels, thereby rotating them. We will further discuss the components of this mechanism, namely the crankshaft liners, which are small half-rings made of soft metal with an anti-friction coating. During long-term operation of the car’s engine, they should be the very first to leave their post, and not the crankshaft journals.

Design Features

Sliding bearings in internal combustion engines are composite and consist of two flat half rings that completely surround the crankshaft. The part has several elements - one or two holes for supplying oil to the lubrication channels, locks for fixing the liner in the bed, and a groove for lubrication.

The connecting rod bearing is a multi-layer structure. It is based on a steel plate with a special coating. It is thanks to this antifriction layer that friction is reduced. The coating is often made of soft materials and can consist of several layers. The liner is coated on top with a less soft material, and thanks to this coating, the part absorbs wear particles from the crankshaft, jamming and the formation of scuffing and other defects are prevented. Structurally, connecting rod and main bearings can be divided into bimetallic and trimetallic.

Bimetallic

The simplest are bimetallic liners. It is based on a steel plate - its thickness on different internal combustion engine models ranges from 0.9 mm to 4 mm. The main bearing is always thicker, the connecting rod bearing is thicker. An anti-friction coating is applied to the plate - its thickness ranges from 0.25 mm to 0.4 mm. The layer is made of copper-lead-tin, copper-aluminum, copper-aluminum-tin and other soft alloys. These alloys contain about 75% aluminum and copper. The rest is tin, nickel, cadmium, zinc.

In bimetallic liners, the thickness of the antifriction coating is a very important property. They can be run-in and adjusted even to large geometric defects. The bearing has good adsorption abilities.

What are liners for internal combustion engines

An internal combustion engine is indeed a very complex device; its design was achieved thanks to the engineering mind of many designers and motorists.

It consists of a huge variety of different parts, the purpose of which is to best help the engine operate. Each detail has its place and its shape. However, the expression - there is no limit to perfection, is also relevant for the engine. The rotation of wheels or shafts in any unit, not only in a car, is ensured by parts such as bearings. These can be either rolling bearings or plain bearings. The latter are more often used in internal combustion engines for such a rotating part as the crankshaft.

The designers, working on the perfection of the engine, made a proposal to replace this bearing with a liner. This is the same bearing, but very modified. It is a steel sheet, which, thanks to calculations, has a special shape and size. It is lubricated with an antifriction compound. This is the same bearing in essence, but not in shape.

The liner is installed in a certain place, which is also called the bed, and is strictly fixed. The surface on which the liners are installed must be prepared; the holes for the lubricant on the liner and on the beds must match.

To prevent the liners from turning and moving out of their places, there are special antennae. In addition, the interference must be structurally specified for each liner.

The liners are divided into the following types: connecting rod and main. The connecting rods are located between the crankshaft connecting rod and its journal. The radicals play the same role, but their place is in the passage of the crankshaft through the engine housing.

Each engine is provided with its own liner size, which is determined by the internal diameter. Additionally, there is a size difference between new liners and repair liners. Conventionally, with each repair we add a step plus 0.25 mm. Indeed, despite the lubrication and accuracy of installation, the liner wears out and the surface of the neck where it is installed wears out.

At the same time, the clearance increases, the crankshaft has a larger stroke, the pressure decreases and little oil is supplied. This is already an emergency situation.

Sometimes it is necessary to change the liner because it rotates. This occurs due to breakage of the antennae. This happens in case of poor quality or poorly selected lubricant or in case of poor selection of liner tension.

Usually, engine repairs and replacement of liners, if you do not have sufficient experience in disassembling and assembling the engine, are carried out by a service station. The main thing is the correct selection and quality of liners.

Read more about inserts on the website.

Source

Trimetallic

In addition to anti-friction coating, trimetallic connecting rod bearings also have a third layer. Its thickness is very small - only 0.012-0.025 mm. It provides the protective properties of the part and improves anti-friction characteristics. Sputtering is most often made from a lead-copper-tin alloy.

Most often, such alloys contain up to 90% lead. Tin increases corrosion resistance. Copper is needed to strengthen the coating. Due to the low thickness of the coating, fatigue strength increases, but anti-friction characteristics decrease. This is especially noticeable if the soft covering is worn out.

Geometry

Naturally, the sizes of connecting rod bearings are different for different internal combustion engines. The most basic parameter is the oil gap. It is equal to the difference between the inner diameter of the liner and the diameter of the shaft. Another important indicator is the size of the oil gap. If the gap is very large, then the oil flow increases, which reduces the heating of the bearing. But oil also causes uneven load distribution, which increases the likelihood of bearing failure due to fatigue. A large gap will result in operating noise and vibration. A small gap will cause the engine oil to overheat and reduce viscosity.

The landing tension is needed to ensure a reliable fit of the VAZ connecting rod bearing in its socket. Reliably and firmly seated bearings are in even contact with the surface of the seat - this will prevent the possibility of bearings moving during operation. Effective heat dissipation is also ensured.

Metal fatigue

This can be caused not only by operation longer than necessary, but also by high loads on the KamAZ connecting rod bearings. Among the signs are metal particles torn out from the body of the liner, especially in those places where the load is very high.

When operating the engine on low-quality bearings, there may be a risk of severe overload. The force moves to the edges of the parts. To eliminate the malfunction and diagnose it, check the axial shape of the crankshaft journal and the geometry of the liner supports. In this case, it makes sense to install a high-quality liner.

Source

Rotating the crankshaft connecting rod bearings

This is also one of the popular faults. Many car owners have faced this problem. But not everyone knows about the reasons. Let's figure out what happens to the element. The connecting rod bearing plate is quite thin.

It is installed on a special seat. The outer walls on the half rings have special protrusions, which, even in a non-run-in and undeveloped engine, rest against the front part of the cylinder block. At a certain point, the seat simply cannot hold the connecting rod bearing. The result is a typical situation - the liner has turned. The plate not only rotates, but also sticks to the crankshaft journal. In this case, the engine stalls and will not start again.

What are engine bearings made of?

Contacts: cell phone, tel./fax: +7(842-35) 6-76-51, tel./fax: +7(842-35) 6-71-06, e-mail: This address email is protected from spam bots. You must have JavaScript enabled to view it.

Catalog

| Lock hardware | Valve products | Drive cables and body fittings | Steering and reaction fingers | Crankshaft bearings | Compressors |