What are sensors for?

A power unit with forced fuel injection has undoubted advantages over a carburetor unit. First of all, this:

- Economical.

- Great power.

- Good dynamics.

This can only be achieved by accurately calculating engine operating modes in accordance with the driving parameters. This requires a large amount of data, which is provided by various sensors. Based on them, the electronic control unit (ECU) calculates the optimal ignition timing and composition of the working mixture.

Each sensor has its own purpose and design. They are installed in different places, in accordance with the controlled unit. Despite the fact that “tens” were also produced with two camshafts, this article will discuss VAZ-2110 8-valve sensors.

Oxygen sensor VAZ-2110

The main function of the LZ is to determine the amount of oxygen in the exhaust gases; based on the data received, the sensor sends a signal to the unit that controls the engine electronic system. In accordance with the lambda probe readings, the ECU adjusts the functioning of all elements of the fuel system and ignition, making the engine operate more optimally.

On a VAZ-2110 (2111, 2112) with an 8-valve engine, the oxygen sensor is located on the exhaust pipe of the muffler, in close proximity to its connection with the resonator. Since the lambda probe does not start working immediately, but only when the exhaust pipe warms up to 360 degrees, VAZ sensors are often equipped with a built-in electric heater; such LZs have four wires and a corresponding plug for connecting to the car’s electronic circuit.

The main manufacturers of VAZ oxygen sensors are Bosch and NGK, “Bosch” spare parts are considered universal, they are used not only on “tens” and “dvenashki”, but also on other VAZs, models of other brands, in particular on cars:

- Opel Omega /Vectra/ Astra/ Calibra with C20NE engine (you only need to change the plastic plug);

- VAZ 2108-2115;

- Chevrolet Niva;

- Gazelle Business with Cummins engine;

- UAZ Patriot.

The price of a BOSCH lambda probe with catalog number 0258006537 is on average from 1,500 to 2,000 rubles; you can buy a sensor in almost any auto store; you can often find advertisements for the sale of parts on the Internet.

Currently reading

Internet in cars and more: features of technology...

Coating a car with ceramics: what you need to know

There are 4 wires of different colors suitable for the 4-pin LZ connector:

- black – signal;

- gray – mass;

- two white ones - for connecting an electric heater (the polarity of connecting the wires does not matter).

The BOSCH lambda probe is sold in original packaging, with a protective plastic cap; a special lubricant is applied to the threaded connection of the part to prevent sticking of the sensor.

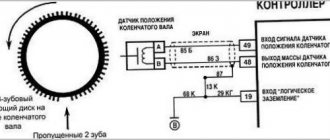

Crankshaft position sensor

Put in first place for a reason. The fact is that it is one of the main sensors of the VAZ-2110. If the DPKV is damaged, engine operation is impossible; it simply will not start. The location - the oil pump cover - was not chosen by chance. The fact is that in this case the sensor is located in close proximity to the so-called drive gear, combined with the camshaft pulley.

Structurally, the DPKV is made in a housing made of polymer materials and filled with a compound mixture for greater tightness. There is an inductor located inside. The gear teeth passing next to the sensor, at a distance of no more than 1 mm, form a magnetic field in it. A sequence of pulses appears at the controller output, which is sent to the ECU. The drive gear is missing two teeth, this is the starting point for the computer and also the start of ignition in the first cylinder.

Correct probe replacement

Replacing a lambda probe on a VAZ 2112 requires the following actions:

- First, disconnect the probe wire from the electrical wiring. The procedure is carried out with the engine completely cooled and the ignition off. To replace an old device, you should purchase a sensor with the same markings as the previous one

- Then, using the key we need, we unscrew the old sensor. From a dead point, it is best to rip the device off with the ignition on, and, of course, the hot sensor and exhaust pipe, otherwise there is a risk of damaging, pulling or stripping the threads; in a cold state, any metal shrinks, and you will have to unscrew it with considerable effort. When you've pulled it off, you can turn off the engine. It will be much easier to unscrew further

- The new probe is screwed in until it stops in order to create a tight seal.

- Connecting the electrical wiring

- We check the performance of the new oxygen sensor using an oscilloscope, and a voltmeter, as well as an ohmmeter, the engine temperature is not lower than 350 degrees, at this point the replacement of the VAZ 2112 lambda probe is completed

That's all, good luck in replacing and checking your sensor, and in addition we recommend video material on replacing it.

The operation of internal combustion engines of modern cars is controlled using special electronic devices (controllers). One of the main tasks of the controller is to regulate the composition of the fuel mixture supplied to the cylinders of the power unit. It is on this that the fuel consumption, the stability of the engine, as well as its power and traction properties depend. To do this, the electronic control unit collects and analyzes information coming from various sensors. Based on the received data, the ECU sends the necessary commands to the appropriate devices.

In this article we will talk about what the VAZ-2110 oxygen sensor is and what it is intended for. We will also look at its design, possible malfunctions and diagnostic methods.

Mass air flow sensor

One of the most capricious and delicate sensors of the VAZ-2110 injector. However, it is also quite expensive. The sensor measures the amount of air passing through the car filter and transmits the data to the ECU, which, based on them, forms the optimal composition of the working mixture.

The main element of the VAZ-2110 air flow sensor is a platinum thread. It is used as a spiral, i.e. it is heated to a certain temperature and cooled by an air flow. The more it passes through the filter, the less the thread heats up. The flow meter is a high-speed device; it transmits data to the computer every 0.1 s.

A malfunction of the mass air flow sensor causes engine malfunction in all modes. In this case, characteristic symptoms will be:

- unstable idling;

- lack of engine power;

- poor dynamics;

- increased fuel consumption.

However, such malfunctions are also typical for damage to many other components, including VAZ-2110 sensors. The operating principle and purpose of the mass air flow sensor determine its location in the car. It is installed immediately behind the air filter.

Oxygen sensor for VAZ 2112

The oxygen sensor (hereinafter referred to as OS) is designed to measure the amount of oxygen in the exhaust gases of a car for the purpose of subsequent adjustment of the enrichment of the fuel mixture.

A rich and lean mixture is equally “bad” for a car engine. The engine “loses” power, fuel consumption increases, and the unit operates unstable at idle.

Domestic car brands, VAZ and Lada, among others, have one oxygen sensor preinstalled. European and American technical means are equipped with two controllers:

They are no different from each other in design and size, but perform different functions.

Knock sensor

Designed to prevent explosive ignition in cylinders. Only on the verge of detonation can the engine achieve maximum power and dynamic performance. On the other hand, it is very harmful to the engine and significantly reduces its service life. An appropriate sensor is used to instantly prevent this phenomenon.

The knock sensor is a selective microphone. This means that it is tuned to a specific frequency, in this case 25-70 Hz. It is in this range that detonation occurs. To the ear it sounds like a metallic ringing, which is what the controller detects. The result is transmitted to the ECU, which changes the ignition timing accordingly.

The knock sensor is located between the second and third cylinders, on the front wall of the block. The location was not chosen by chance. It is in these cylinders that explosive ignition occurs first due to the higher temperature.

Idle speed control

One of the main sensors of the VAZ-2110. It is responsible for stable engine operation at idle. The importance of this is clear to any motorist who constantly has to move in dense city traffic. Endless traffic jams, numerous junctions and traffic lights, it is impossible to drive here without idle.

Another task of the idle speed controller (IAC) is to warm up the engine at subzero temperatures. It is thanks to it that after startup, increased crankshaft speeds are maintained, which then gradually decrease.

Externally, the DXH is very similar to a small electric motor. This is true, although the motor is not an ordinary one, but a stepper one. This means that the algorithm of its operation is completely dependent on the control device. So, the XX sensor is a stepper electric motor, the shaft of which is connected to the rod by a worm gear. The motor has two windings. When voltage is applied to one of them, the sensor takes a step forward, i.e. the rotor rotates to a certain angle, the rod moves slightly out of the housing.

When voltage is applied to the other winding, the reverse process occurs. Thus, the rod, in accordance with the controller commands, can change its length from minimum to maximum. At the very end it has a cone-shaped point. By extending, the rod reduces the amount of air passing bypassing the throttle valve closed at idle. For this purpose, it has a recess for a cone. The idle speed sensor is also installed here on the VAZ-2110.

Main signs of a faulty lambda probe

The average service life of an oxygen sensor is 80-120 thousand km, but the service life of the part is often reduced for various reasons:

- Low-quality gasoline is poured into the car tank;

- the engine overheats;

- the ignition is incorrectly adjusted, resulting in detonation;

- a defective part has been installed.

Often the lambda probe fails prematurely due to impact; the fragile ceramic element is easily destroyed by impact load. It is for this reason that the oxygen sensor must not be struck or dropped from a height onto a hard surface.

A faulty lambda probe can be identified by various indirect signs and engine malfunctions:

- the engine is unstable at idle, the speed is constantly changing, more often this happens when the engine is not warmed up;

- Fuel consumption has increased and black smoke is coming out of the muffler pipe;

- the Check Engine light comes on on the instrument panel;

- spark plugs quickly become covered with soot;

- the engine is “stupid” - it does not develop speed, does not allow the car to accelerate to the required speed.

If you remove the lambda probe from the car, you will notice that its inside is covered with soot (soot) - this indicates that the fuel does not burn completely and the proportion of the fuel mixture is incorrect.

Throttle controller

Designed for dosing fuel in cylinders. When you press the gas pedal on an injection engine, only the air damper mechanically opens. The amount of gasoline to create the working mixture changes according to a command from the ECU. This is what the throttle position sensor (TPS) is designed for.

The controller is a variable resistance, essentially the same as the volume control on a car radio. Only the voltage supplied to the control unit changes here. Roughly speaking, TPS converts the force of pressing the gas pedal into a certain electrical signal. It goes to the ECU, in which the voltage/fuel quantity relationship is hard-wired with great precision.

The signal amplitude varies from 0.7 to 4 V (with the damper fully open). The incoming gasoline also changes linearly. The TPS is installed directly on the throttle assembly.

Signs and causes of lambda probe malfunction

According to statistics, oxygen sensors fail gradually, so you can identify its malfunction if you pay attention to the following “symptoms” in time:

- The idle speed began to drop or “float”.

- The car jerks, and after starting the engine, popping noises uncharacteristic of the engine are heard.

- The engine power has decreased and when you press the gas pedal there is a slow response.

- The engine overheats greatly and fuel consumption has increased.

- The smell in the exhaust pipe has changed (exhaust gases have become more toxic).

As a result of a failed sensor, the quality of the fuel mixture entering the combustion chamber deteriorates, which disrupts the smooth operation of the engine. There can be many reasons for this:

- Incorrect operation of the filament circuit or reduced sensitivity of the sensor tip.

- Low-quality fuel with a high content of iron, lead, oil decay particles and other harmful inclusions. All these substances stick to the platinum electrodes, causing the sensor to malfunction.

- Problems with the lambda probe heating system. If the heating stops functioning as it should, the oxygen sensor will produce inaccurate data.

- Overheating of the regulator housing. This happens if the ignition timing is incorrectly set.

- Worn oil scraper rings. In this case, engine fluid enters the exhaust pipe, which affects the lambda probe.

- If the engine is started repeatedly.

- Using sealants (especially silicone) to install lambda probes.

- The compression level in the engine cylinders is impaired. In this case, the combustible mixture burns unevenly.

- Clogged engine petrol injectors.

If you notice that the lambda probe is not working, you should not ignore the symptoms, as otherwise you will cause yourself a lot of problems with your car. The fact is that most modern cars are equipped with an emergency locking unit, which can work at the most unfortunate moment. However, the impossibility of further movement is not the worst thing. If the sensor becomes depressurized, the injection system will fail and you will have to pay for expensive repairs to a more serious unit.

Therefore, it is recommended to periodically check the condition of the lambda probe. You can do this yourself.

Oil pressure sensor

“Ten” only has an alarm for problems in the lubrication system. A drop in pressure is signaled by the corresponding lamp turning on. The VAZ-2110 oil sensor is designed quite simply. At its end there is a movable membrane, which is connected to normally closed electrical contacts. The sensor is screwed directly into the vehicle's lubrication system. If the pressure is normal, then the oil acts on the membrane, it bends and opens the contacts. The control lamp does not light up. In the event of an accident, the membrane returns to its original position, including the corresponding indication.

Despite its simplicity, the pressure indicator quite often fails. In this case, the control lamp is constantly on, although the pressure in the system is normal. You can verify that the sensor is faulty only by replacing it with a known good one. Naturally, you shouldn’t continue moving without complete confidence.

Less commonly, there are cases when the indicator does not light up when the ignition is turned on. That is, the alarm will not turn on in the event of a real accident. This symptom also indicates a malfunction of the oil sensor. In any case, it needs to be replaced with a new one, since it cannot be repaired. The indicator is screwed into the cylinder head, next to the timing belt cover.

Installation and replacement of an oxygen sensor on a VAZ 2112

- Key to "17";

- New controller;

- Rags;

- Multimeter;

- Additional lighting (optional).

Do-it-yourself diagnostics of the controller on a VAZ 2112:

- We turn off the engine, open the hood;

- Disconnect the terminal from the DC;

- We connect the limit switches of the multimeter (pinout);

- We switch the equipment to the “Resistance” mode;

- We read the scale readings.

If the arrow tends to infinity, the controller is working properly. If the readings go to “zero” - there is a short circuit, a malfunction, the lambda probe dies. Since the controller is not dismountable, it cannot be repaired; it must be replaced with a new one.

The process of self-replacement is not at all difficult, but requires care on the part of the repairman.

- We install the machine on the inspection channel for ease of work. If there is no inspection hole, then use a roadside overpass or a hydraulic lift;

- We turn off the engine, open the hood, wait until the exhaust system cools down to a safe temperature, so as not to get burns to the skin of the hands;

- Near the resonator (coupling) we find the oxygen controller. Remove the block with wires;

- Using a key set to “17”, unscrew the sensor from its seat;

- We carry out preventive maintenance, clean the threads from deposits, rust, and corrosion;

- We screw in the new controller;

- We put on the block with wires.

We start the engine, it idles. It remains to check the serviceability, functionality, and stability of the engine stroke. We look at the dashboard, error indication of the electronic control unit.

Temperature display

Serves to monitor the cooling system. The temperature sensors of the VAZ-2110 are a regular thermistor. It linearly changes its resistance depending on the heating of the coolant. In full accordance with Ohm's law, the voltage drop across it also varies, which is recorded by the ECU, which outputs the temperature value to the dial gauge.

In addition, these sensors on the VAZ-2110 injector act as a fan switch. The cooler starts on command from the control unit when the appropriate temperature is reached. This eliminates the main disadvantage of a mechanical sensor - low reliability.

All malfunctions are most often associated with lack of contact and electrical wiring breaks. Basically it rubs against various moving parts. However, it is rare that injuries characterized by inaccurate readings do occur. The danger here lies in turning on the fan untimely. It may operate at normal temperatures or not turn on when overheated. The latter, of course, is much more dangerous from the point of view of engine life. In any case, the sensor cannot be repaired and must be replaced.

The sensor is installed in the cooling system pipe. To remove it, you will need to dismantle the air filter and at least partially drain the coolant.

Signs of a malfunctioning oxygen sensor

Failure of the lambda probe is usually accompanied by the following external symptoms:

- Deterioration of traction and reduction of dynamic characteristics of the car.

- Unstable idle. In this case, the speed value can jump and drop below optimal. In the most critical case, the car will not hold idle speed at all and, without accelerating the driver, it will simply stall.

- Increased fuel consumption. Usually the overrun is insignificant, but can be determined by software measurement.

- Increased exhaust toxicity. In this case, the exhaust gases become opaque, but have a grayish or bluish tint and a sharper, fuel-like odor.

It is worth mentioning that the signs listed above may indicate other failures of the engine or other vehicle systems. Therefore, in order to determine malfunctions of the oxygen sensor, several checks are needed using, first of all, a diagnostic scanner and a multimeter to check the lambda signals (control and heating circuit). As a rule, problems with the wiring of the oxygen sensor are clearly detected by the electronic control unit. At the same time, errors are formed in its memory, for example, p0136, p0130, p0135, p0141 and others. In any case, it is necessary to check the sensor circuit (check the presence of voltage and the integrity of individual wires), and also look at the operation schedule (using an oscilloscope or diagnostic program).

Fan controller

Serves to force cooling on. The VAZ-2110 fan sensor was installed only on the first “ten” models equipped with a carburetor engine. Structurally, it is a sealed brass cylinder, inside of which there are bimetal contacts. When heated, they bend and close the electrical circuit, the fan turns on. True, its high current consumption (about 15 amperes) does not allow it to be powered directly, through bimetallic contacts. For this purpose, there is a special relay in the circuit.

The main disadvantage of the controller is its low reliability. The sensor often stops working, which can lead to engine overheating. Its location at the bottom of the radiator makes replacement quite labor-intensive. The coolant will need to be completely drained.

Gasoline level indicator

The fuel sensor of the VAZ-2110, like any other car, is a rheostat made of nichrome wire. Its moving contact is mechanically connected to a float, which is located in the tank on the surface of the gasoline. The fuel level changes, and along with it the resistance of the rheostat, which is recorded by the device on the panel.

In addition, there is an indication of the reserve amount of gasoline. It works thanks to the same float. In a certain position, it closes the contacts, which causes the warning lamp to turn on. The fuel gauge cannot be called an accurate and reliable device. However, these are the disadvantages of all mechanical sensors. The main malfunctions are associated with damage to the nichrome wire, which simply wears out due to the constant movement of the “runner”.

The sensor is naturally installed in the tank, and replacing it does not present any difficulties. True, you will have to remove the fuel pump and partially drain the fuel if the car is “filled to capacity.”

Speed sensor

Installed only on “tens” with an injection engine. During its production, the VAZ-2110 was equipped with various types of sensors. On the first models they were mechanically driven, after 2006 they were electronic.

Symptoms of sensor malfunction:

- Speedometer and odometer do not work.

- Their readings clearly do not correspond to the true speed.

- The speedometer needle periodically drops to zero.

All malfunctions, as a rule, are associated with a not very good location of the sensor. It is installed in close proximity to the exhaust manifold, which leads to damage to the insulation of the wires and their short circuit to each other or to ground.

Purpose of the oxygen sensor

The oxygen sensor is installed in the exhaust manifold (the specific location and quantity may differ for different cars), and monitors the presence of oxygen in the exhaust gases. In the automotive industry, the Greek letter "lambda" denotes the ratio of excess oxygen in the air-fuel mixture. It is for this reason that the oxygen sensor is often called a “lambda probe”.

The information provided by the sensor about the amount of oxygen in the exhaust gases is used by the electronic engine control unit (ECU) to adjust fuel injection. If there is a lot of oxygen in the exhaust gases, it means that the air-fuel mixture supplied to the cylinders is poor (voltage at the sensor is 0.1...0.3 Volts), and if there is a lot of oxygen, it means it is rich (voltage at the sensor is 0.6...0.9 Volta). Accordingly, the amount of fuel supplied is adjusted if necessary. Which affects not only the dynamic characteristics of the engine, but also the operation of the exhaust gas catalytic converter.

In most cases, the effective operating range of the catalyst is 14.6...14.8 parts of air per part of fuel. This corresponds to a lambda value of one. Thus, the oxygen sensor is a kind of controller located in the exhaust manifold. Some vehicles are designed to use two oxygen concentration sensors. One is located before the catalyst, and the second is after. The task of the first is to correct the composition of the air-fuel mixture, and the second is to check the efficiency of the catalyst. The sensors themselves are usually identical in design.