Many cars with powerful turbine engines contain in their design an unusual part - an intercooler. What is it in a car, how does the part work and work, and how to handle the repair yourself - these are the questions that owners of modern cars are increasingly asking.

The intercooler is a technically unique part of a turbocharged engine, thanks to which the car receives an additional 15-20 horsepower without dangerous consequences. If problems arise, repairs must be made immediately, otherwise the engine turbine will begin to lose power, and over time the power unit will fail.

- 2 Diagram of the part and its location in the engine

- 3 The principle of operation of the intercooler and its effect on engine power

- 4 Types of intercoolers

4.1 Air

- 4.2 Water

Diagram of the part and its location in the engine

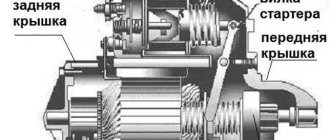

Externally, the intercooler resembles a radiator consisting of plates and pipes. In order to additionally cool the air, copper or aluminum plates are welded to the tubes.

Externally, the intercooler is not much different from the radiator

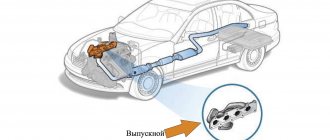

In the engine, the part is mounted between the intake manifold and the turbine compressor. It is mounted in the front part of the engine below the radiator, or above the engine. In some car models, the intercooler is located in the wings.

What is an intercooler

In turbine engines, the air is subjected to fairly strong compression, but if its density decreases (during the heating process), then significantly less air mass enters the engine per unit time. This does not allow the development of high power. Therefore, it is necessary for the air to be denser and therefore colder. The intercooler is responsible for this. This is its main difference from a standard cooling radiator. The intercooler does not affect the temperature of the liquid, but the air. In addition, it is equipped with a large number of core and plate connections. In this case, the pipes should be as long as possible and not bend (otherwise, on the contrary, air will be pumped). External plates made of aluminum or copper can additionally be welded to these elements (these metals have the highest heat transfer).

The product is installed in the front of the car, behind the bumper or radiator grille (between the intake manifold and the turbocharger). This allows the unit to capture the first, cool air entering the car. During operation, the device cools the air masses entering it by almost 70%.

Healthy! An intercooler can also be installed on a non-turbocharged engine, but there is no need for this, since such power units use ordinary air rather than compressed air.

A heat exchanger of this type not only lowers the operating temperature and prevents premature engine wear, but also improves the performance characteristics of the car.

The principle of operation of the intercooler and its effect on engine power

The increase in power occurs due to the ability of the intercooler to reduce the air temperature to 55-60 degrees. This improves the quality of air entering the turbocharger, which contributes to better filling of the cylinders and increased engine performance.

The technology is 100% justified, since reducing the air temperature by just 10 degrees gives the engine 3 to 5 percent more power. The absence of an intercooler or its malfunction leads to excessive, sometimes up to 200 degrees, heating of the air sucked in by the turbine. This in turn reduces the power of the motor, and subsequently can lead to its breakdown.

The operation of the intercooler affects fuel consumption. The combustible mixture burns more efficiently, which means the required amount of gasoline is also reduced. The efficiency of a part is measured by the reduction in engine temperature compared to ambient air temperature. Additionally, the intercooler reduces the boost pressure thanks to the resistance created by this part. For a good intercooler, a pressure drop of 1-2 psi can be considered acceptable.

Cost of intercoolers of various types

The range of intercoolers is quite large. For domestic cars (for example, VAZs), you can choose inexpensive front intercooler options. The cost of an air-type device will range from 3,500 to 5,400 rubles. The exact price may depend on the size of the heat exchanger, the diameter of the inlet pipe, the quality of the material and design, as well as the manufacturer. An average liquid intercooler will cost between 5000-7000 rubles.

Owners of foreign cars will have to spend a lot of money to buy a good intercooler. Its price is much higher than for domestic cars. It is difficult to give an exact value, because a certain type of device is suitable for each model. But for example, let’s say that installing an intercooler on an Audi A3 will cost about 50,000 rubles.

But this is not the price limit. The most expensive intercooler models are those for sports cars. For example, an HKS Intercooler designed for a Subaru Impreza GRB will cost about 120 thousand rubles, for a Toyota Supra car model - 118 thousand rubles, and for such a famous car as the Nissan GT-R R35 - from 250 thousand rubles or more.

Types of intercoolers

Depending on the design and operating principles, intercoolers are divided into two types:

Air

An intercooler of simple design consists of a series of tubes connected to each other by rows of plates. In fact, the purpose of the part is to pass air coming from outside through the tubes. The plates make it possible to increase the heat transfer area, and due to this, the air has time to cool before it enters the turbine.

An air intercooler allows you to reduce the temperature of the air supplied to the turbine by 40-50 degrees, which gives a 12 to 15% increase in engine power. The performance of the part can only be assessed at speeds above 30-40 km/h.

An air intercooler, also known as an air-to-air intercooler, uses a stream of advancing air as the coolant.

Air models are installed in three places:

- Under the hood, directly above the engine.

- Behind the front bumper.

- In the side spaces of the wings.

The second and third installation options are more expedient and are more common, since they provide intense airflow. An air intercooler is most often installed on SUVs and trucks.

The disadvantages of air models are their large mass and impressive size.

Water

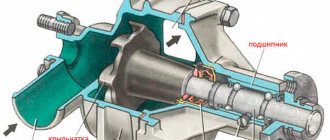

It uses water as a coolant, which copes with the task much more efficiently. The water intercooler is more compact and does not take up much space under the hood of the car. Although when installing it you have to find space for the pump and temperature sensor. But the efficiency of this type of part is several times higher.

On average, a water intercooler lowers the temperature by 60-70 degrees. In more advanced and expensive models, a refrigerant liquid acts as a coolant: antifreeze, antifreeze, liquid nitrogen. Due to the properties of such coolants, heat transfer doubles compared to models running on water.

Liquid absorbs heat much more intensely, which is why water-to-air intercoolers are much more efficient than their air-based counterparts

However, this type of part also has some disadvantages. The water model has a more complex design. The operation of the part is controlled by a water pump, a temperature sensor and a control unit. This leads to an increase in the cost of the structure and the complexity of repair in the event of a breakdown. Therefore, models in the lower price range mainly use air intercoolers. In addition, this device requires systematic monitoring of the coolant.

This is interesting! Domestic car models are mostly equipped with intercoolers costing about 10 thousand, while imported ones cost from 50 thousand rubles. There are more advanced models, the price of which amounts to hundreds of thousands of rubles. Sports cars manufactured on special projects are equipped with a special type of intercooler - custom, in which cooling is carried out using ice and a special liquid.

Functions of an intercooler in a car

The owner of a car with an air intercooler needs to know what it is for and how to operate the unit. When the turbine impeller operates, the air flow is compressed, accompanied by an increase in temperature and a decrease in density. The supply of superheated gas to the working chambers of the cylinders leads to incorrect mixture formation, a drop in power and torque. Detonation processes occur that destroy the walls of the cylinder head and block, as well as parts of the gas distribution mechanism.

The described negative effects do not depend on the method of ignition of the working mixture. But diesel engines are characterized by a higher compression ratio, which allows the gas temperature in the cylinder to be raised at the end of the compression stroke to 550°C. This means that a supercharged diesel engine requires the use of a heat exchanger if a 2-stage compressor is installed to provide increased pressure.

The installed intercooler allows you to reduce the temperature of the gas flow before entering the combustion chambers. From the description of the function of the compressed air heat exchanger, it becomes clear why the unit is not used on atmospheric engines.

Such power units take air flow into the cylinders without intermediate compression; the gas temperature increases due to heating by the walls of the intake manifold.

Is it possible to remove the part?

An intercooler is an additional engine part, without which the engine can function quite well. Eliminating it lightens the car by a couple of tens of kilograms and frees up space under the hood. However, experts do not recommend using the intercooler if it is provided for in the design of the car’s engine.

Failure to use a coolant will result in premature engine wear due to exposure to high temperatures. The engine power will immediately decrease. Removing the part from turbocharged car models is strongly discouraged.

Selection criteria for self-installation

Tuning your own car involves replacing or installing the intercooler yourself. If the car owner is interested in replacing the part with a more advanced model, it is worth considering the following selection criteria:

- Heat exchanger area. The size of the tubes and plates directly affects the performance of the part. There are very compact models on sale, about the size of a book. However, the feasibility of their installation is quite questionable, and is unlikely to provide an optimal increase in engine power. Before purchasing, you need to calculate the installation location of the part so that it fits exactly in the seat.

- The size of the internal section of the tubes. The design must ensure the free passage of air through it.

- Thickness of heat exchanger plates. The work is affected by the area of the part, but not the wall thickness. Chasing thick metal will only add weight to the part, but will not affect its performance in any way.

- Tube shape. The optimal choice is conical segments with the maximum possible bend radius.

- High-quality connection of pipes. This is especially important when choosing a water intercooler, since poor connection of parts will lead to coolant leakage.

Which intercooler to choose - optimal technical characteristics

An air-to-air intercooler should be selected depending on the engine type and its characteristics. The main design parameters when designing the device are:

- Total area of all tubes and plates. The higher its indicator, the more efficiently the intercooler will cope with its task. For each engine there is an optimal area value. It guarantees excellent efficiency. Larger heat exchangers can provide an increase in efficiency, but it will be insignificant.

- Internal section. The optimal value allows you to avoid loss of air pressure in the intercooler.

- Heat exchanger wall thickness. Don't think that thick walls are better. For efficient operation of the device, average thickness values are suitable.

- Frontal area value. The amount of air that passes through the device depends on this parameter. The more air mixture passes through the pipes, the higher the cooling capacity of the intercooler.

- Intercooler pipe shape. In order to avoid loss of flow, it is necessary to ensure that the transition parts have conical segments, and that maximum radii are always left at the bends of the tubes.

- Tightness of connecting pipes. Lack of tightness will lead to loss of pressure during boost. The material from which the pipes are made must be highly resistant to gasoline, engine oil or high temperatures. High-quality material will protect the pipes from damage and leakage.

- Direction of flow in the heat exchanger. It must create all the conditions for the maximum flow area.

Having studied the design parameters, each car owner will be able to understand what affects the operation and choose the intercooler he needs from the entire range presented.

Features of operation and main causes of failure

Modern intercooler models do not require special care for a long time. However, periodic inspection and timely diagnosis of failure are necessary. The following damage may be found in the part:

- Rupture of a pipe or heat exchanger due to excessive pressure. This breakdown is indicated by a sharp drop in the car’s power and increased fuel consumption. There is no point in repairing broken pipes, since under air pressure they will immediately fail again. In this case, only replacing the pipe will help restore functionality.

- Oil getting into the interior. Normally, a small amount of oil enters the intercooler during turbine operation. Acceptable values are 0.7-1 liter per 10,000 km. If the indicators are higher, you should think about repairing the part.

- Cracks in tubes and plates. An intercooler installed in the fenders or under the front bumper is subject to increased mechanical stress.

- Clogged tubes. This happens especially intensively in winter. Therefore, in winter, it is necessary to clean the part from chemicals and sand as often as possible.

DIY intercooler repair

Repair of a part begins with its dismantling. It is not practical to describe specific removal steps, since everything depends on the location and method of installing the part in the car. For example, if a part is installed above the motor, it is simply “pulled off” by loosening the clamps. When the intercooler is installed as one unit with radiators (main, automatic transmission, air conditioning), you will have to make some effort.

It is important! The intercooler can only be removed from a completely cooled engine with the ignition system turned off.

For a complete repair, it is necessary to dismantle the part.

After removing the part, take the following steps:

- Cleaning. This procedure can last about 2-3 hours. Oil stains are especially difficult to get rid of. But it is necessary to remove all contaminants: the performance of the intercooler in the future will depend on the quality of the work performed. For cleaning, remove all parts and disconnect the pipes. The outer surface and channels are thoroughly washed with special auto chemicals, and for better removal of oil, they are soaked for several hours. Do not use gasoline or other oil solvents: they can damage the material from which the part is made.

- Sealing cracks. The cracked element is removed from the part body, the damaged area is cleaned with a file and a platinum patch is soldered onto it. The material of the insert must match the material of the removed tube.

- Pressure testing in a water bath or testing with a smoke generator. Before installing the repaired part in place, it is a good idea to check the quality of the repair. This will save the motorist from the need for repeated removal in case of poor quality work. The real test of the part is driving at a reasonable speed. If the engine operates with its former power, and no extraneous whistles are heard during gas changes, it means that the performance of the part has been restored.

It is important! The most serious failure is a violation of the ventilation crankcase, which occurs due to the excess oil level in the part. Local repairs in this case will not solve the problem. The engine will need to be overhauled and the intercooler replaced.

Any car owner can handle minor repairs and maintenance of the intercooler. In the event of a serious breakdown or if it is necessary to replace the model with a more advanced one, you should contact a specialist auto repair shop.

- Author: Andrey

Rate this article:

- 5

- 4

- 3

- 2

- 1

(14 votes, average: 3.9 out of 5)

Share with your friends!

Home →

Maintenance and Repair →

Methods of application

The efficiency of such cooling equipment becomes noticeable at speeds that exceed 30 km/h. In addition to the possibility of increasing productivity, incorrect placement can disrupt the operation of the intercooler, which will lead to unpleasant consequences.

It may also be interesting: The clutch pedal has fallen in and won’t return, what’s the problem?

Most often, the intercooler is placed close to the radiator. Specifically, in front of him, in the bumper area. This gives a good opportunity to connect with the cooling from the radiator. This way the system will need less clutter to function fully (fewer pipes). Obviously, since the radiator itself runs on water, then an intercooler with a water operating system will be more efficient in its efficiency, and will also save more space. By the way, when tuning the Passat B3, you can also install an intercooler in it.

We recommend: Crankshaft bearings - what are they?

But even the air-to-air system is still more efficient to place in this position. Additional cooling above the engine, as well as from the side of any wing, also looks acceptable. But in general, the location of the heat exchanger should be convenient and easy to install, so it is best to place it in the front, as mentioned above.