The situation with floating speed (jumps) is associated with problems with the automatic power supply system. This occurs on engines equipped with electronic fuel injection. As a rule, the cause of this is excess air entering the combustion chamber.

The electronics (computer) does not have time to calculate the proportion of the fuel mixture entering under the piston. Moreover, the electronics may lose control of the throttle and temperature sensors. This changes the speed in the range of 800÷1500 for only 3 seconds , but is enough to distort the stable idle speed.

Floating diesel speed is often detected by tightening the adjustment screw and closing the air access hole.

The method promotes stable idle speed. Otherwise, there is a need for a proven method of blocking rubber tubes with round pliers.

Description of the problem

The malfunction manifests itself in jerking and floating engine speed, when the tachometer needle can jump from 500 rpm to 1500 rpm and even higher. During normal engine operation, the needle first rises to a level of 2000–2500 rpm in warm-up mode, and then should remain at 700–900 rpm. If there is no tachometer on the dashboard, floating speed can be determined by the sound of the power unit (the roar of the engine either increases or decreases), as well as by the vibrations penetrating the cabin.

As a rule, after the engine warms up, the problem disappears. However, at the next cold start, exactly the same picture occurs: the speed of the power unit again jumps in a wide range. And if the first time can still be attributed to an accident, then the second and subsequent cases are a reason to contact for repairs or to fix the problem yourself.

Instability of speed in intermediate modes

In diesel power units, floating speeds in operating modes most often appear due to the formation of corrosion on the plungers of the high-pressure fuel pump. Rust on these parts appears due to the presence of water in the fuel. Because of this, the diesel engine speed fluctuates even at idle.

The consequences of these considered reasons are:

- High fuel consumption.

- Release of a large amount of carbon monoxide into the external environment.

- Wear of parts of the fuel system and air supply to the engine.

To prevent such consequences, it is necessary to regularly check the functioning of the considered sensors and systems. If a malfunction does occur, you should immediately take measures to repair it.

The considered reasons for floating engine speed are only the main ones, and there are many other reasons. They will help you understand the operation of the car and prevent unnecessary spending of money on auto repair shops. Without understanding the operating features of the power unit, we may be subject to fraudulent actions by car repair specialists. Often, cheap repairs turn into large financial expenses that could not have been made. You should study in more detail the structure and operation of your machine, and it will answer you with a long service life.

Engine idle mode

What engine speed should be at idle (idle)? Average performance for most cars is in the range of 700 - 900 rpm. In idle mode, the internal combustion engine does not experience significant loads, and fuel consumption is minimal.

When set to XX, the engine receives minimal loads, and fuel is consumed sparingly.

Adjusted idle speed is necessary: when warming up the engine, idle time in traffic jams in neutral gear and when the heating stove is running without moving the vehicle.

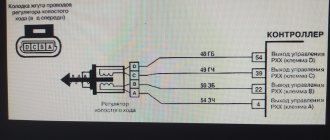

A forced increase in speed when starting a cold engine has its own advantage - the internal combustion engine lubricant acquires the necessary fluidity when quickly heating up. If the XX regulator breaks down, you can use the gas pedal, but it is better to undergo comprehensive diagnostics and eliminate the cause of the floating speed at idle.

Situations arise when the engine simply cannot be turned off due to a breakdown of the starter, generator, or a dead battery.

When driving on the highway, the jump in revs is imperceptible, but in city mode it causes a lot of worries and unnecessary nerves.

Signs of unstable idle

The cause of the malfunction may also be in the automobile command center - the electronic control unit (ECU). Data from various sensors is transmitted to the ECU. If data from any sensor is not supplied or is supplied incorrectly, the computer incorrectly adjusts the fuel dose, which is why the speed fluctuates.

We recommend: Purpose and 4 types of final drive device in a car: 9 requirements for GP operation

Therefore, with floating speed XX, you need to check the following:

- idle speed sensor;

- fuel and air consumption;

- exhaust gas recirculation valve;

- throttle valve, whether it responds in time.

Recently published material about the throttle position sensor. Read it, it might come in handy.

If all electronic sensors are in order, you need to check the parts and assemblies for mechanical damage.

If the nozzle is clogged, then a rich mixture will be supplied to the combustion chambers of the cylinders, hence the engine speed will be very low.

Cleaning or replacing spark plugs. Their service life is from 50 to 100 thousand kilometers.

If the insulation of the magnetic valve is worn out or burned out, you must first go to a car service center and repair the damage.

Now there are few cars with carburetor engines, but if you have a carburetor engine, then you need to check the location of the floats and adjust the fuel level. If there is a drip of engine oil on the engine, it means the gasket has burned out or the cylinder head (cylinder head) was not tightened with the proper torque.

After cleaning the throttle body the speed fluctuates

So, it would seem that the whole procedure is over. The damper was cleaned with a cleaner, the air filter was replaced with a new one, the sensors were reconnected, that is, everything was assembled and tightened. Now you can proceed to starting the engine. If the engine starts after cleaning the throttle valve and then runs normally, then the procedure can be considered successful.

It should be added that this is not always the case. Many people are faced with the fact that after cleaning the throttle valve, high engine speeds remain constant and do not drop. Also, many drivers notice that after cleaning the throttle valve, fuel consumption has increased. A likely cause could be an error in connecting some sensor during reassembly, but this rarely happens.

Most often, after cleaning, the throttle also needs to be additionally calibrated and adjusted, which not everyone knows about or does it incorrectly. In other words, high idle speeds after cleaning the throttle valve are a clear example and at the same time an answer to the common question of whether the throttle valve needs to be trained after cleaning this unit. Let's figure it out.

We recommend: UAZ Patriot speed sensor: purpose, location, device

Let's start with the fact that in some cases a pure throttle valve really needs to be adapted (trained). Typically, throttle valve adaptation is often necessary when the electronic throttle valve has been cleaned before. There are fewer problems with a mechanical damper, but they still exist. In systems with an electronic throttle, the ECU independently sets the throttle position; in mechanical systems, the idle air control is set. To put it simply, after removing the layer of dirt, the position of the cleaned damper changes, but the ECU does not know about this and continues to supply fuel in accordance with the previous parameters before cleaning. To solve the problem, it is necessary to set the idle speed using diagnostic equipment, since it is possible to reset the previous parameters.

You can also try teaching the throttle manually. The simplest way to learn without diagnostic equipment or a scanner for adaptation is to unscrew the negative terminal of the battery from a few seconds to 10 minutes (depending on the make and model of the car). This allows you to reset the settings, that is, the existing adaptation is reset and returned to the factory settings. After connecting the terminal to the battery and restarting the engine, the idle speed should stabilize.

Note that this method works on a limited number of cars. In such a case, you can take advantage of another opportunity to train the throttle assembly without a computer. This method is suitable for a range of vehicles from different manufacturers. Let's consider such an adaptation using the example of a Japanese Nissan car.

- First, the engine must be warmed up to operating temperature, after which the engine should be turned off.

- Next, you will need to wait 5-10 seconds, then turn on the ignition for 3 seconds.

- Now you need to press the gas pedal all the way and immediately release it. This is done 5 times, you need to do it in 5 seconds (one press per second). The interval should be timed using a stopwatch so as not to get lost.

- After the last press, you should wait 7 seconds, after which the gas pedal is again pressed “to the floor” and held in this position until the “check” begins to blink on the dashboard, and then this light comes on constantly.

- After the moment when the check code starts to light up constantly, you need to wait another 3 seconds. Now the gas pedal can be released.

- Next, the engine needs to be started, the idle speed should return to normal.

Let us add that during such adaptation of the throttle valve it is important to accurately maintain the timing at each stage, as well as to fit into all time intervals. In this case, we can talk about successful training. It is also recommended to clarify the features and the possibility of manual adaptation for a specific car model.

Causes

Unstable engine speed at idle.

Possible reasons for unstable idle speed are:

- Air in the system.

- Low starter speed, fuel quality, compression.

- Fuel injection pump malfunction, lack or insufficient fuel supply. Perhaps the uniformity of supply of the mixture under the piston is affected.

- Changes in injection timing and fuel compression ratio.

Each of the reasons is based on a variety of arguments and signs.

Air in the system

The presence of air in which:

- The fine filter element becomes clogged or the pump sucks air from cracks, holes, loose connections, or other defects.

One of the reasons for air leaks is a clogged fuel filter element.

The reason is wear of the pump shaft seal, through which air leaks.

- It gets in at high performance of the fuel injection pump, when the filter cannot cope with its functions (filtration). That is, air vacuum occurs.

- Weak density of pipe connections located before and after the fuel pump.

- Contamination of the tank ventilation system.

Video about solving the problem of air leaks diesel SsangYong Kyron 2.0 XDI

Low starter speed, fuel quality, compression

Reduced starting speed

- Starter malfunction (armature, bushing), minimum shaft speed.

3 main units that most often fail: 1 - brush unit; 2 - traction relay; 3 - armature collector.

- Sulfation (oxidation) of battery terminals, which oxidize power wires, causing a loose connection between the “mass” and the body. Loose contact often causes wires to heat up.

The reason for sulfation of battery terminals is poor contact.

- Possibility of tightly assembled engine, generator braking, pump via belt drive.

- Lubricant used (thick).

- The battery is discharged due to the points stated above.

Fuel quality

Low quality diesel fuel will inevitably damage the engine . Operating defects begin with pressure valves. The lean mixture, falling under the piston, burns partially. Part of it penetrates under the plunger. The situation is worsened by the fact that the mixture is poorly formed at high speeds.

The fact of filter clogging, poor quality of injectors and cetane number bring the engine, to put it mildly, to complete technical exhaustion.

Compression

- Called air filter clogged, defective head gasket (broken or of non-standard thickness), wear of the cylinder walls.

A loss of compression can be caused by a broken cylinder head gasket.

- Valves burning, jamming of the rod, loosening of the seat in place.

Compression drops due to burnt out valves.

- The piston ring is broken ; their locks are installed in the same plane.

- Violation camshaft installation according to marks, wear on the back surface of the cam, defective shaft.

Camshaft cam wear.

Fuel injection pump malfunction, lack or insufficient fuel supply

- The reason is the low cetane number of the fuel , which contributes to an increase in the combustion rate (induction period), with a subsequent deterioration in starting a diesel engine.

- Signs of viscosity , density of diesel fuel, leads to poor-quality atomization, deterioration in the formation of the mixture. At the same time, the length of the torch is distorted, and incomplete combustion of the fuel occurs. Carbon deposits form, smoke appears from the muffler and, as a result, a decrease in the economical operation of the car.

- Presence of water in fuel.

Cause of insufficient or incomplete supply of mixture

- Injector malfunction, weak fastening, wear of the plungers, problems with the regulator reducing the flow rate through the nozzles are serious problems that cause a floating idle mode.

Faulty injectors cause floating speed.

- Air leaks , its presence in the power system, dirty fuel filter, poor ventilation of the engine block.

- the crankshaft speed The appearance of air vacuum, disruption of unit ventilation.

Changes in injection timing and fuel compression ratio

Injection timing, compression ratio

- Due to the presence of air in the system, which leads to injection delay.

- The reason is also injection pressure , which causes early or late fuel supply. The situation affects the residual pressure in the fuel pump. The injection period is significantly affected by a damaged injector cross-section, loss of hydraulic density with late injection, and also problems with the fuel advance element.

- A commonplace sign is the installation of a fuel injection pump on the engine, loosening the pump drive belt tension, wear of the cam shaft.

The timing of fuel injection may vary due to the tension of the injection pump belt.

We recommend: Possible malfunctions of the engine cooling system

Video on how to set the ignition on a diesel engine (injection timing)

Seemingly simple violations

- Using a low-quality gasket, or more often laying two at once.

- Rotating the connecting rod bearing, which leads to knocking in the engine crankcase, rapid failure of the crankshaft, cylinder and piston group.

Rotated connecting rod bearing.

- The use of defective connecting rods, sometimes deformed, pistons of unknown origin.

- The plane of the head and cylinder block are ground above the required standard.

Compression ratio

Calculation of the compression ratio and combustion chamber volume.

It is measured by the ratio of the volume of the cylinder when the piston is at BDC to the volume of the combustion chamber, that is, when the piston is at TDC. It is determined, for example, for a diesel engine, as 18÷22 to 1 . This value indicates efficient operation of the engine, since complete combustion of the mixture occurs, high pressure and compression. This is an economical consumption of diesel fuel coupled with an increase in power. The latter indicator is achieved by reducing the volume of the combustion chamber.

This can be obtained by boring the cylinder block. That is, increasing the compression ratio reduces the volume of fuel combustion.

Video about the reasons for floating revolutions

Possible causes of malfunction

Floating engine speed at idle is almost always caused by a violation of the composition of the fuel mixture or excessive air intake into the engine. The complexity of this problem lies in the fact that a wide range of malfunctions in the fuel supply system can lead to this.

In carburetor cars

Most problems with floating engine speeds with carburetor injection of the fuel mixture are directly related to the device itself (carburetor). As a rule, jumps in engine speed are associated with depletion of the incoming fuel mixture, caused by:

- incorrect adjustment of the idle speed by “craftsmen” or its failure as a result of operation;

- contamination of jets, fuel and idle air channels;

- breakdown of the solenoid valve of the device;

- sucking in excess air and subsequent depletion of the fuel mixture;

- incorrect fuel level in the carburetor float chamber (high or low);

- breakdown of the throttle valve or oil deposits that prevent the valve from opening and closing correctly;

As a result of these malfunctions in the fuel supply system, the engine begins to stall at idle.

In injection cars

In cars with forced fuel supply, most causes of engine stalling are often associated with electronic malfunctions. The operation of the electronic control unit (ECU), responsible for fuel injection, is based on the data received, which is transmitted by sensors. Jumps in engine speed occur due to the fact that, due to incorrect data transmitted by the mass air flow sensor (MAF), more air enters the injection valves than necessary. Due to excess air in the engine cylinders, the ECU “gives” a command to the injector valves to open slightly to supply fuel. As a result of its combustion, a jump in engine speed occurs. After the fuel burns, the engine speed drops again.

Also, the reasons for speed jumps on injection models can be:

- worn and clogged spark plugs;

- damage to high-voltage wires, causing incorrect operation of all car electronics;

- breakdown of the idle air regulator (IAC);

- malfunction of the EGR exhaust gas recirculation system;

- The oil pan ventilation valve is clogged.

In diesel cars

In cars with a diesel engine, the reasons for jumps in engine speed can be the same as in a gasoline unit. However, another reason may be the failure of the high pressure fuel pump (HPF). Corrosion or mechanical damage to the moving fuel injection pump blades leads to floating engine speeds, both at idle and while driving at low engine speeds.

When is an adaptation reset necessary?

Here's what the official Chevrolet manual says:

— Replacement with a new ECM controller

— Replacement of new throttle body (MTIA, ETC)

— Replacement with a new IAC valve

— Cleaning the throttle body from carbon deposits

I would also add this point:

- Errors and failures during the operation of the TPS and IAC. I'll dwell on this moment a little.

The fact is that there is a certain relationship between the position of the remote control and the position of the IAC. That is, if the DZ position = 2.5%, then the IAC position will be approximately equal to 20-25 Steps.

But from time to time people come in with unstable idle speeds, and during diagnostics you can see a picture when the DS position = 0, and the IAC steps = 40! Resetting the adaptations helps with this problem, although the owner of the car has not previously carried out any manipulations with the throttle assembly.

This is a consequence of some short-term failures in the system. Here is one example on our forum where manipulations with the crankcase ventilation valve led to a similar failure. Therefore, keep this point in mind as well.

This phenomenon also occurs due to incorrect adjustment of the accelerator pedal cable.

Well, now let’s look at the process of resetting adaptations itself and why it is necessary after cleaning the throttle valve.

The normal position of the throttle body at idle speed of a warm engine without load is 2 - 3.5%.

It is open exactly as much as necessary to allow the required mass of air to pass through to ensure the specified idle speed.

Over time, the valve and throttle body become overgrown with dirt, reducing the clearance for air to pass through.

In order to maintain the set speed, the ECU is forced to gradually open the idle speed control more and more. Over time, these values increase to 50-60 IAC steps or 5-7% of the DS position.

This means it's time to clean the throttle body.

We clean it safely and then start the engine. And here the problems begin, because the ECU remembers the values of 7% of the remote control position for this operating mode, but the speed has now increased significantly, because now there is no obstacle in the way of the incoming air (the speed begins to hover at high values). The ECU cannot understand what is happening and begins to try to adjust them (the revolutions begin to float).

It is at this stage that our intervention is necessary. We need to return the ECU to factory settings again, set it to the starting position again, so that it begins to adapt again.

This can be compared to a regular 10 liter bucket. Let's say we filled it completely by pouring 10 liters of beer into it. In order to pour another 10 liters into it, we first need to pour out the ones already in it.

The same is the case with the ECU. We erase the adaptive memory so that the unit begins to learn and adapt again.

How to stabilize floating speed

- Penetration of foreign air into the engine . It is necessary to check the tightness of the air system channels with the intake manifold. For such purposes, it is necessary to dismantle each hose separately and pump it with a pump or compressor, but you can try spraying liquid -40 on the hoses, where it will quickly evaporate; there is most likely a crack in the hose. In such a situation, it is better to replace the damaged hose with a new one rather than wrap it with electrical tape.

- Replacing the IAC . The condition of this device is checked with a conventional multimeter, which needs to check its resistance. If the resistance readings are in the range of 40-80 Ohms, the regulator is faulty and such a device requires immediate replacement.

- Cleaning the valve and elements of the engine ventilation system . In this case, you will have to disassemble the oil sump and get to the ventilation valve. It should be pulled out and washed in a product for cleaning engine elements from an oil film. You can use regular kerosene. Next, dry the valve thoroughly and then put it in its place.

- Replacing the air flow sensor . This is the most delicate part and most often cannot be repaired. Therefore, if the cause is the air flow sensor, then it is advisable to replace it. It is known from practice that even professionals cannot repair a hot-wire anemometer.

- Flushing the throttle valve and then installing it in the correct position . There are two methods for cleaning the throttle valve from oil contaminants: without removing it from the car, and also with removing the throttle valve. When removing the damper from the car, you must disconnect all wires and hoses from the damper, loosen it and pull it out. Next, place it in a container and fill it with cleaning aerosol. If the oil stains on the surface of the throttle valve are already old, you can clean them with a brush. Next, dry the damper surfaces with a rag and put them in place, connecting all the wires and hoses. If the damper is not removed from the car, then it can be washed on a hot power unit with a similar aerosol. Before spraying cleaning agent, disconnect power from the throttle valve. First you need to pour the product inside the throttle valve, wait a few minutes and start the engine. With the power unit operating, continue cleaning the damper with the same product. If, during such cleaning, white smoke comes from the damper, then this is normal, since oil contaminants are cleaned in this way. At the end of the work, you should connect the wires and adjust the operating order of the throttle valve on the computer, setting the required opening gap.

- Idle speed adjustment . This procedure can be carried out using a regular screwdriver, adjusting the screws for the quality of the fuel mixture and the number of engine revolutions.

- Replacing the solenoid valve . If the carburetor idle valve malfunctions, the engine can only operate when the choke handle is pulled out. Therefore, in order to prevent idle speed fluctuations, it is advisable to replace the valve with a known good one or a new one.

- Cleaning the idle air jet . Even in the old days, cleaning the jet from oil deposits was considered a very labor-intensive task. Currently there is no need to remove the jet from the carburetor. To do this, you just need to pour a specialized product into it, designed for cleaning carburetors, and wait in this state for several minutes. Then you need to clean the nozzle from dirt using compressed air.

- Treatment of parts of the fuel pump on a diesel engine from rust . To perform this task, you will need a specialized corrosion cleaning agent. This can be either an imported or a domestic product. It is simply sprayed into the fuel tank by opening its neck before refueling with diesel fuel at a gas station. The cleaning agent will clean the pump parts from rust on its own. In order to prevent similar corrosion of the high-pressure pump in the future, it is recommended to pour a glass of motor oil into the tank, which can form a protective film on the surface of the pump parts when moving.

We recommend: Mass air flow sensor: what is it

You need to know that if uneven engine speed occurs at idle, you must immediately contact a service station and carry out detailed diagnostics of the operation of all engine systems. Timely detection of faults will protect you from costly repairs.

Resetting throttle adaptations

What is it and why do it?

As we understand, the engine control unit constantly adapts to real conditions. It remembers the optimal values of fuel corrections and idle air control positions in order to ensure the stable operation of the engine the next time it was started, as it was before it stopped.

Therefore, it is more correct, of course, to say not resetting the throttle valve adaptations, but resetting the ECU adaptations to the position of the idle air control. This is obvious for two reasons:

- The throttle valve cannot adapt to anything, because there is nothing there except the motor and rheostats. It's just a beautiful and expensive piece of hardware without any memory chips. Therefore, we will not reset the throttle adaptations, but reset the ECU adaptations to the throttle position!

- Since on some cars (including Lacetti 1.4/1.6) the idle air regulator controls the throttle valve directly, everyone is accustomed to calling this process - throttle valve adaptation reset.

We recommend: Buying a DVR is the right decision

Let's say that on the Lacetti 1.8 the idle air control is installed in a separate bypass channel and has nothing to do with the throttle valve, but when replacing or cleaning it is also advisable to reset the adaptations. Because sometimes it happens that after flushing the IAC, the steps remain in their place and do not decrease. In this situation, only resetting the adaptations helps reduce the IAC steps.

Stabilizing engine idle speed

Adjustment and stabilization of engine idle speed is carried out in the following ways:

- Clean the valve from deposits (on the oil sump). It will be necessary to dismantle the crankcase and subsequent flushing with cleaning agents to remove oil deposits, dust and mechanical accumulations of sludge. The parts are cleaned, washed in kerosene and dried. Install the valve and assemble the system.

- Crankcase gas ventilation (CVG). When fuel and oil burn, gas pressure is created in the engine, which is cyclically released by valves through pipes of complex geometry. Maintenance and cleaning of the VKG system will normalize speed, reduce fuel consumption and eliminate excessive oil consumption.

- It is important to check the air supply lines. You will have to check the cylinders for leaks, blow out the hoses with a compressor and inspect the manifold. Air leaks can occur through cracks, which can be identified by treating the pipelines with WD-40. After the liquid evaporates, visually visible etching areas remain. Damaged hoses cannot be sealed (only replaced with new ones).

- The throttle valve is flushed to remove oil-type deposits. After dismantling, the position can be reconfigured. The hoses are removed, the mounting bolts are unscrewed, and the damper is inspected for wear, sprayed with an aerosol and the deposits are cleaned off with a brush. After washing the planes, adjust the position (working clearances) of the damper and assemble the system.

- Air flow is controlled by mass air flow sensors. The operating principle is based on reading the readings of a hot-wire anemometer. Mass flow sensors cannot be repaired (replacement only).

- Jumps in idle speed are observed when the solenoid valve in the carburetor fuel supply system breaks down. A complete replacement is being carried out. You can get to the nearest service station using an extended choke flap.

- The XX jets in the carburetor are cleaned with special means (aerosols) without removing them from the structure. After treating the nozzle with the additive, blow the channels with a compressor to remove any remaining mechanical particles.

- You can clean traces of corrosion on the fuel injection pump blades with XADO VeryLube or with a product from another manufacturer. The composition is sprayed into the neck of an empty fuel tank (before full refueling). The substance settles and reacts on the pump blades, and a chemical process of corrosion neutralization occurs. In private practice, the “motor oil addition method” is used - about 150 ml is added to the tank with diesel fuel. The metal surfaces of the blades will be covered with a protective film, protecting them from the appearance of premature corrosion stains.

Cleaning procedure

To clean the element, the first step is to remove it. Disassembly of the spare part begins with removing the air duct corrugation and disconnecting the wires from the idle air control regulator and the part position sensor. The dismantling procedure does not require any special effort.

Note! When dismantling the throttle valve, it is important that the power unit is not hot. Because there is a risk of getting burns.

Then you should remove the hoses that are connected to the spare part, and then the cable from the drive. Thus, the path to the damper is open. Simply unscrew a couple of nuts and bolts and remove the position sensor and idle air control.

Cleaning consists of washing the element. To do this, it is recommended to use a special product designed for cleaning carburetors. The substance should be sprayed onto all surfaces and channels. Upon completion of the process, the part should be wiped with a rag.

We recommend: How to choose stylish accessories for your car

Special attention should be paid to the idle air control. Due to excessive contamination, the needle may jam and not work properly. And before installing elements, you should check the general condition of this element. If the needle has a large free play, the part must be replaced.

It is also necessary to assess the condition of the gasket before installation. If damage is present, the element should be replaced.

Note! After completing the installation of the throttle valve, the cable tension should be adjusted.

When do you need to clean the Lacetti throttle body?

If, during computer diagnostics, it is revealed that the throttle valve on a warm engine in xx mode does not close by more than 5%, then this unit requires mandatory cleaning.

The damper must also be cleaned if there is heavy visual contamination. This will affect not only the smooth operation of the engine, but also fuel consumption.

How to clean the Lacetti throttle body?

Many people clean the throttle assembly without removing it from the engine. This is not entirely correct, since contamination remains from the inside and, especially on the damper axis! Therefore, it is better to remove the damper. Moreover, I do it in 10 minutes.

- Removing the decorative trim of the engine

2. Loosen the two clamps on the corrugation

Loosen two clamps on corrugation

3. Use pliers to loosen the clamp and remove the crankcase ventilation hose from the valve

Remove the crankcase ventilation hose from the valve

4. We dismantle the corrugation along with the crankcase ventilation hose and this is what we get:

We dismantle the corrugation along with the hose

5. Pressing the latch from below, disconnect the wire block from the Chevrolet Lacetti throttle assembly

Disconnect the wiring block from the throttle assembly of the Chevrolet Lacetti

6. Turn the throttle drive pulley clockwise and remove the accelerator pedal cable through the groove.

Removing the drive cable from the Lacetti throttle assembly

7.Now many people disconnect the coolant supply hoses to the throttle body, but I don’t do that. First of all, it's faster. Secondly, there is no need to be tricky with plugging the hoses to prevent coolant from flowing. Thirdly, air will not get into the cooling system.

I simply remove the hoses from the holders and they are long enough to remove the throttle assembly.

8. Unscrew the three nuts and bolt securing the Chevrolet Lacetti throttle assembly and remove it from the studs

Unscrew the three nuts and bolt securing the Chevrolet Lacetti throttle assembly

As you can see, there is not a lot of pollution, but there is still

Lacetti throttle valve dirty

9. We place a rag under the throttle assembly so as not to smear the engine and wash off the dirt from the cylinder

Cleaning the Lacetti throttle body

10. It is advisable to replace the gasket, clean the end of the intake manifold and the DDA fitting, the adsorber and the crankcase ventilation

Lacetti throttle body gasket

11. It is advisable to immediately flush the Lacetti crankcase ventilation valve. To do this, we unscrew it...

Crankcase ventilation valve Lacetti

...and wash it so that the spring works without jamming

Flushing the Lacetti crankcase ventilation valve

We also wash the corrugation with the tube

This is the result that makes me happy

Clean throttle body of Chevrolet Lacetti

12. Putting everything back together in reverse order.

Here is a video on how to clean the throttle body

How to clean the throttle valve?

Nowadays, the choice of means for this procedure is simply huge. Everyone will find something more suitable for their needs and financial capabilities.

For example, I use this tool

Throttle Body Cleaner

It costs us 3-4 USD. It washes everything quickly and efficiently, which suits me.

The instructions say that you can even flush the fuel system by pouring it into a tank of gasoline. It also cleans the intake tract.

Throttle body cleaner

After cleaning the throttle body, the Lacetti's revolutions fluctuate

After cleaning the throttle body, the throttle position adaptation must be reset.

This can be done through a special adapter and the Chevrolet Explorer program. Or at the service station.

You can see in this short video what happens and how when resetting adaptations with the throttle valve

Peace to your home and good luck on your journey!