The engine vibrates strongly at idle: possible reasons

The normal operation of a serviceable motor requires minimal vibration, which is quite acceptable. It should also be taken into account that in the cold season the engine may vibrate somewhat more strongly. After 3-5 minutes of warming up, the vibration level should return to normal. In parallel with this, there should be no jerks, dips or omissions, as well as extraneous sounds in the engine operation.

The appearance of noticeable vibrations indicates that certain malfunctions are possible. Let us immediately note that increased vibrations are detrimental to the internal combustion engine, so such a problem must be diagnosed and eliminated as quickly as possible.

Among the main reasons why the engine begins to vibrate (shudder, twitch) at idle, experts identify the following:

- engine troits;

- problems with the correct mounting of the motor;

- faulty engine mounts;

- crankshaft imbalance;

For normal operation of the power unit, idle speed is usually around 750-950 rpm, which depends on the type of engine. Reducing the idle speed will cause the engine in this mode to start running less stable and may even stall at idle. An increase in speed naturally leads to increased fuel consumption, as well as an increased load on the CPG and other components of the internal combustion engine. As a result, motor life is reduced. For this reason, an optimal balance is maintained for each engine to achieve maximum efficiency and stability at idle.

Motor troits

If the engine starts to stall, then uneven operation of the cylinders is observed. The most severe engine vibration at idle is felt if one of the cylinders is not working. Pressing the gas pedal allows you to partially compensate for the resulting imbalance by increasing the crankshaft speed, but engine power will still be reduced.

The load on the crankshaft when the cylinder is not working or is misfiring remains uneven, which causes jerking and jerking of the engine. The driver usually feels a noticeable shudder and vibration in the steering wheel, which can also be transmitted to the body. The engine vibrates most strongly at idle, and also under load when driving at low speeds.

It is necessary to eliminate the problem with an inoperative cylinder as quickly as possible, since in addition to vibrations that destroy the engine, normal fuel combustion does not occur in the combustion chamber of the problem cylinder. As a result, excess fuel washes away the lubricant from the walls of the faulty cylinder, thereby increasing wear on its mirror. Also, on worn-out engines, there is a high probability of unburned fuel leaking through the seals, which leads to fuel getting into the engine oil and losing its beneficial properties. In this case, the engine wears out faster, cokes more, etc.

Additionally, it is worth noting the engine vibrations that appeared after replacing the timing belt. In this case, it is necessary to eliminate the possibility of an error when installing the belt, since a displacement of even one tooth leads to a violation of the valve timing. The result is engine malfunctions and engine tripping.

Mounting and malfunction of engine mounts

A common problem that causes increased engine vibrations is a defect in the power unit mounts. Most often, the problem lies in the engine supports (so-called mounts), which can become unusable over time. These pillows are a kind of dampers that not only hold the internal combustion engine, but also dampen vibrations.

Also, an increase in the level of vibrations can occur after replacing one or more pillows with products with greater rigidity.

You can diagnose the problem as follows. Invite an assistant and open the hood, then rock the car with sharp jerks by moving the car forward and backward. The assistant must record the angle and degree of engine deflection during such rocking. Normally, the engine should swing forward, backward, and also to the sides evenly and equally.

If deviations are detected, that is, the motor has a greater tilt in one direction, the corresponding motor mount will need to be replaced. Please note that experts recommend replacing engine mounts even if there are no visible defects or damage on the part itself. Also, after replacing the support, it is necessary to carefully adjust.

Balancing the crankshaft and CPG

During the process of repairing an internal combustion engine, which involves grinding or replacing the crankshaft, it is necessary to subsequently balance the part with the flywheel and clutch. To balance the crankshaft, specialists drill out extra grams in its body. It is also necessary to weigh the pistons, piston pins and other parts of the CPG before assembling the engine. Differences in the weight of parts can cause a serious increase in vibrations.

Signs of unstable operation of the VAZ-2114 engine at idle

The first thing that catches your eye is vibration. Indeed, it is impossible not to notice it - it is transmitted to the steering wheel, to the gearshift lever, and sometimes the entire body begins to vibrate. Not only is vibration itself not the most pleasant phenomenon, it can signal a breakdown or the need for maintenance of many components and systems.

Causes of engine vibration VAZ-2114

If the engine operates quite normally in transient modes and at medium and high speeds, do not rush to draw conclusions about the malfunction of the idle system. First of all, let’s analyze the symptoms, and they can be like this:

- After starting, the engine vibrates when cold, and the speed can fluctuate from 800 to 2000 revolutions spontaneously. In this case, after warming up, vibration may be absent and the idle will be in the normal range, 800-850 rpm.

- After the engine warms up, the vibration does not disappear.

- When cold the idle is normal, after warming up the speed fluctuates and the engine knocks.

- The idle may disappear while driving, when coasting or at an intersection after a short vibration. In this case, you can catch the speed with the accelerator pedal.

Our editorial car! VAZ-2114. If you don't adjust the valves, it will vibrate!

Vibration at idle. At gunpoint - ignition

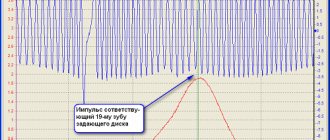

One of the main reasons for vibration at idle in an injection engine is incorrect operation of the ignition system.

Even in the case when the fuel-air mixture is supplied to the cylinder in the required quantity and on time, the passage of a spark, constant or periodic, will certainly lead to vibration. Moreover, at medium and high speeds the engine can operate stably, with nominal fuel consumption and good dynamics.

First of all, we check this:

- Any gaps in spark formation will lead to uneven emission of exhaust gases; you can check this simply by placing your hand near the exhaust pipe of the muffler; the gaps will be immediately audible.

A good engine should have uniform exhaust

Breakdown of high-voltage wires can cause engine vibration

We check the spark plugs by removing the caps one by one

Changing the ignition module

In addition to these problems, difficulties may arise in the operation of electronics; this mainly applies to injection engines. And only these were installed on the VAZ-2114, with the exception of the Samar-2 line being the VAZ-2115 - there were carburetor versions.

Electronics and sensors as causes of vibration

Another suspect in the story of engine vibration at idle is the electronic engine control unit. No one will repair it; most often it must be either replaced or re-flashed. For example, in injection engines with a Bosch 7.9.7+ controller, flashing ER19 instead of the standard ER16 often helps, fuel consumption remains within normal limits, and vibration disappears.

In addition to the ECU, the following sensors may be to blame:

- Idle speed regulator. The regulator sensor is mounted on the throttle body, and to check it you need to remove the terminals and use a multimeter in ohmmeter mode to check the resistance between the contacts. The nominal value is 60-80 Ohms. If the sensor does not produce the required resistance, replace it with a new one.

Checking the idle air control

Checking the mass air flow sensor

Engine vibration at idle speed: main causes and solutions

One of the reasons for incorrect engine operation, leading to significant and expensive car repairs, is strong engine vibration at idle.

Timely diagnostics and subsequent measures taken to eliminate vibration can fully insure the car owner against many troubles, including not only the comfort and safety of car operation, but also significant financial investments in major repairs.

The operation of a serviceable engine implies the presence of minimal vibrations. When the air temperature drops, the motor may vibrate slightly more. However, after five minutes of operation, these fluctuations should disappear completely.

The appearance of fairly noticeable vibrations, skips, jerks, dips and/or extraneous sounds during engine operation indicates that the vibration mode is disturbed due to the occurrence of situations of a certain nature.

Speed

This is 800-1000 rpm. If the number of crankshaft revolutions is lower, the engine will begin to stall; with a higher number, fuel consumption will increase and engine parts will wear out faster. It is worth noting here that in the cold season, slight vibration after start is a normal phenomenon, which disappears after 5 minutes as the power plant warms up. If the engine shaking does not disappear, it is necessary to consider the reasons for its occurrence.

How to adjust the engine?

So, we have a vibration at idle. What can be adjusted here? To do this, you need to pay attention to several components and assemblies included in the fuel system. Depending on the type of power supply of the car, this can be a carburetor, an injector, as well as a lot of various electronic and mechanical sensors, the number of which on modern cars varies by dozens. In addition to these elements, the fuel pump is also adjustable.

When making adjustments, you need to remember that the number of revolutions directly depends on the compression ratio of the throttle valve, which regulates the air supply to the cylinder, as well as on the operation of the idle valve, which supplies oxygen independently of the first part. This value is increased using the accelerator pedal. This way you can level the idle speed to 800-1000 rpm.

Engine mounting

Strong vibration of the engine at idle speed can be caused by poor fastening of the power plant to the body. In some cases, it is possible to identify breakdowns of the protective cushion through which the motor is attached. It is advisable to carry out diagnostics together with an assistant, who will sequentially switch gears in the gearbox. An observer looking under the hood will identify which gears are causing problems.

Even after replacing the airbags, the shaking does not always leave the car. This is due to the need to properly configure and adjust the fasteners.

Failure can occur for any of the four supports (rear, front, bottom or top). However, practice shows that the most vulnerable is the front support. It is subject to increased static and dynamic load. As soon as one of the pillows breaks, then if no measures are taken, the rest will quickly break .

For novice drivers, vibration in the steering wheel at idle is not always obvious, so we recommend periodically undergoing diagnostics in specialized workshops or from experienced technicians. Otherwise, trouble cannot be avoided. If you decide to look for the cause yourself, then you need to use the method of exceptions, moving from simple to complex causes.

Triple

So, the first reason that provokes engine vibrations. Engine tripping is the most likely cause of unstable operation of the internal combustion engine, since when the cylinder is not working, a significant imbalance and improper distribution of the load on the crankshaft occurs. As a result, you can see the motor jerking from side to side. Also, when driving, vibration of the steering wheel is noticeably felt. At idle speed all these signs are more noticeable. The more the shaft rotates, the less strange vibration will be noticeable. But at the same time, you will notice how the car begins to absorb more fuel and noticeably lose power, especially when driving downhill.

There is only one solution in this situation - to urgently repair the non-working cylinder. If this is not done in time, coking of the crankshaft parts will soon occur. At the same time, their service life will noticeably decrease, since the fuel does not burn in the chamber, but only washes away the lubricant.

Balancing the cylinder-piston group and crankshaft

Often, during repair work on a power unit, it is necessary to grind the crankshaft or replace it. This leads to weight changes. It usually becomes higher than with the old part. So that after this the engine does not tremble at idle, balancing is performed - to balance the balance of the crankshaft with the clutch mechanism and the flywheel. This is done by drilling out parts of the part to reduce weight.

Vibration may be a consequence of installing new elements of the cylinder-piston assembly. Especially if they have a different weight compared to old components. To prevent weight changes from leading to increased shaking of the running engine, it is necessary to weigh the parts of the cylinder-piston system before assembling the power unit.

Other factors

In addition to a bad cylinder and an improperly mounted engine, vibration at idle can be caused by a number of other factors. Of course, they are much less common, but still they cannot but be considered as an option.

First of all, it is necessary to note the elements of the fuel system. If they are heavily contaminated, the fuel-air mixture will not burn sufficiently. This causes increased consumption, strange sounds (possibly even popping noises) and vibration. It's even worse if water gets into the gasoline. In this case, in addition to a large waste of fuel, there is a risk of coking of the cylinders. As a result, the engine does not work properly. Sometimes motor oil and soot can penetrate into the fuel system, which also negatively affects the operating cycles of the internal combustion engine.

The second reason is the different weight of the parts of the cylinder-piston group. Operating a car, especially if its mileage is more than 200 thousand kilometers, requires increased attention to the engine, and sometimes replacement of parts in it. Even a small difference in weight can have a significant impact on engine performance later on. Moreover, this applies to all engine parts, be it a piston, connecting rod or skirt.

On some small cars with an electronic throttle control system, interior vibration at idle may occur due to increased load on the generator. This happens especially often in the winter, when the car’s headlights, heater, and heated windows, seats, and mirrors are on at the same time. Often on such cars vibration occurs when stopping. When the driver releases the accelerator pedal, the on-board computer sends a signal to close the throttle to idle, and a load from the generator appears on the engine - it is at this moment that severe engine shaking occurs. As a rule, it disappears after 3-5 seconds. Such vibration at idle for small cars, especially with automatic transmission, is considered normal, and in most cases it can be solved by using higher quality fuel and replacing the air filter.

It is worth noting that engine shaking can also occur when replacing a timing belt, especially when the balancer shaft gear rotates along with the removed part.

Once displaced, it is unlikely to return to its original place. Therefore, when replacing a belt, you should not rotate the shaft gear with your fingers, unless you want to assess the condition of the bearings. But even here you need to be very careful and careful. Any movement of a part can result in vibration, creating constant discomfort for you and your passengers.

Danger of vibrations

The causes of vibrations that occur must be eliminated as soon as possible after the first signs of problems occur. This is explained by the fact that after vibrations, other problems often develop that can cause enormous damage to your vehicle. As experts themselves note, the greatest damage due to vibrations is caused to the car body. The first to wear out and break are the plastic elements, then gradually all sorts of fastenings, located sometimes in very hard-to-reach places, become loose. When the car shakes for a long time, the paint layer may begin to deteriorate. This already entails the formation of corrosion and the spread of rust throughout the body.

We must not forget about the harm that is caused to the power unit. The engine also suffers significantly from unnecessary vibrations. Vibration causes accelerated wear of parts, destroys the packing in the crankshaft, and then oil begins to leak. As a result, the engine cannot produce the required number of revolutions, the car accelerates more slowly, and fuel consumption increases significantly. And at the same time, engine power decreases, which negatively affects control. If you noticed that the car began to vibrate, but were able to find the reasons and eliminate them, the work is not yet completed. In addition to this, be sure to check all the parts that could have been damaged in any way as a result of the vibrations that have arisen. You can eliminate the source of vibration, but you cannot exclude the fact that some destructive processes have already been launched. The fastener has come loose, the paintwork has been damaged, and therefore new problems will potentially arise soon.

What are the consequences of low idle speed?

Driving and operating the engine at excessively low speeds, especially when attempting to accelerate, can cause rapid wear on the following components:

- Engine pistons (this destroys the cylinder block).

- Crankshaft liners.

- Clutch baskets.

- Flywheel.

- Transmission bearings.

- Timing chains. At low shaft speeds it simply stretches.

- Cylinder liners. Due to soot, their walls are damaged.

Thus, with constant vibrations, rapid wear of engine parts occurs. At the same time, its rotation is much slower, and the crankshaft packing is greatly destroyed. As a result, there is a risk of oil leakage.

Vibration at idle

Vibrations are the rattling sounds produced by the engine and felt by the driver when he holds the steering wheel.

If there are problems with the engine, the rattling from barely perceptible becomes very strong and unpleasant.

Signs

The main symptoms of this problem include:

- increased vibration of the steering wheel, which can be transmitted to the engine body;

- engine popping;

- engine jerks and failures;

- The tachometer readings exceed the permissible values for the car.

It will also be useful for you to know why the car shakes during acceleration and at high speed.

Causes

The main causes of engine vibrations include:

- engine tripping (uneven operation of the pistons or failure of one of them);

- incorrect motor mounting;

- faulty engine mounts;

- the crankshaft is unbalanced;

- the fuel system is dirty;

- improper fastening of other units;

- ignition system malfunction.

- One of the common mistakes associated with engine mounts is installing mounts from different materials.

The above reasons are valid for gasoline cars.

The reasons why the vibrations of a diesel engine have increased, due to the difference in design and operation from a gasoline engine, are slightly different:

- malfunction of the cylinder-piston group or gas distribution mechanism as a whole or in a separate cylinder;

- compression variation in cylinders;

- malfunction of the high pressure fuel pump, diesel injectors or timing belt teeth;

- incorrect injection advance angle.

Why is low engine idle dangerous?

No less a problem is reducing idle speed.

Low speeds can lead to the following consequences:

- fuel detonation in the cylinders does not occur completely;

- oil dilution;

- washing off the lubricant;

- coking of the motor.

It is also worth noting that at low idle speeds the car will stall, as it will not have enough revolutions to maintain operation. This, in turn, will increase the load on the ignition system, increasing wear on the car and reducing its service life.

Diagnostics

To carry out diagnostics, you should pay attention to the following points:

- check the injector/carburetor;

- take readings from the tachometer and pressure sensor and compare them with normal values;

- check the fastening of the motor and other components;

- run computer diagnostics of the car (if there are appropriate electronics on board).

Separately, it is worth mentioning the process of checking engine mounts, since their incorrect installation quite often causes problems, although they are easily diagnosed and corrected.

Important! Since visible problems may hide other, more serious ones, if any problems occur, you should contact a car service center.

Checking the airbags is carried out as follows: one person sits behind the wheel, opens the hood and drives back and forth in place, the second person watches the engine at this moment - it should tilt evenly in all directions. If the engine rolls a little more in one direction, then the cushion on that side should be replaced.

What measures to take in case of strong vibration

When faced with strong vibrations, you can begin to combat the problem.

Engine adjustment

Adjusting the motor, first of all, includes checking the fastenings of the parts, as well as their condition. Having ensured that they are in good working order and correctly secured, it is necessary to calibrate their joint work.

The best way to do this is to check the factory settings in the instructions and reset all settings to them. Tuning includes not only tuning the operation of the engine itself, but also related systems - fuel supply, ignition, and so on.

If parts have been replaced, it is necessary to ensure that the parts in weight and material match those that were replaced - otherwise imbalance will occur.

Did you know? If the crankshaft is too heavy, it is lightened by cutting out holes, thereby knocking off the extra grams.

Correct installation of the timing belt

Another important element in solving the problem is installing the timing belt. The belt is responsible for the connection between the crankshaft and the camshaft, and its incorrect installation will inevitably lead to disruption of the gas distribution system.

The belt is replaced as follows:

- the protective belt cover is unscrewed;

- disconnects from the sensor;

- checking the coincidence of the marks on the camshaft gear (or shafts, if there are several of them), the gas distribution mechanism drive, the flywheel, the crankshaft - this will ensure the correct valve timing;

- the old belt is removed;

- a new belt is put on: first on the crankshaft pulley, then on the camshaft gear and pump;

- two revolutions of the crankshaft are carried out, after which the marks are checked - if the belt is installed correctly, they will coincide.

Ways to eliminate the causes of vibration

If you feel an unpleasant vibration emanating from under the hood of a car, you should not immediately blame the power unit for it. It is necessary to carefully understand the reasons and find the only one that caused the engine vibration.

- It is recommended to start diagnostics by checking the engine mounting elements. A car engine vibrates slightly during operation, but this vibration should not be transmitted to the body. To do this, the engine is attached to the body using special rubber-metal mounts. If at least one of them is damaged, then itching instantly begins to be felt in the car interior.

- Having discovered a “dead” pillow, it is changed. If the reason lies in a faulty airbag, then the engine vibration at idle speed will disappear. According to car service specialists, 9 out of 10 calls regarding engine vibration at idle are related specifically to “dead” airbags.

IMPORTANT! It is necessary to ensure that the motor is properly balanced after completion of work. Even a slight distortion will again cause vibration in the cabin.

Quite often, engine vibration at idle speed occurs due to uneven operation of the cylinders. This happens in cases where one of the cylinders fails. The fuel does not burn in it, the load on the crankshaft is distributed unevenly, and the engine begins to jerk from side to side.

In addition, the fuel entering the cylinder is mixed with engine oil and enters the crankcase. Oil diluted with fuel ceases to perform its functions, which ultimately leads to:

- mechanical damage to parts of the cylinder-piston group;

- violations of the lubrication regime of other rubbing parts of the engine;

- overheating of the engine, since the oil also serves as a heat sink.

The presence of an inoperative cylinder is detected “by ear,” as the engine begins to “trouble.” There are many reasons why one or two cylinders may not work. Most often they lie in system malfunctions:

- Ignition

It is recommended to check the serviceability of: spark plugs; high-voltage wires; ignition distributor.

- Fuel supply

Check the performance of: injectors; injector; fuel pump.

Attention: injectors are diagnosed and cleaned on a special stand.

- Gas distribution mechanism (GRM)

There are many reasons for the timing belt not working properly: the drive belt is installed incorrectly; the elements of the drive belt tensioner are worn out; burnout of the cylinder head gasket; wear of the camshaft and/or hydraulic compensators.

If the check shows that all systems that ensure the normal operation of the power unit are functioning normally, begin searching for the faulty cylinder. To do this, you need to measure the compression value in each of them.

The amount of compression in each cylinder of the power unit must comply with the standards specified in the technical documentation for the car. If a significant deviation from the standard value is observed in any cylinder, this indicates the presence of a malfunction in this particular cylinder.

Low compression

One of the reasons for engine tripping is low compression levels in the cylinders. This may occur due to the failure of any part that is part of the cylinder-piston group. In order to fix this problem, you will have to resort to disassembling the engine itself.

The cause of low compression may be a worn piston, piston rings and/or valves. In this case, the most optimal and rational option for eliminating vibration will be only a complete professional replacement of defective parts.

If you replace it yourself or restore it, further, more significant breakdowns may occur, and therefore costly repairs of the entire power plant.

Uneven air flow

If air enters the combustion chamber disproportionately, this can be corrected by simply replacing the air filter. You should also carefully inspect the air supply system for cracks and chips. It is recommended to replace the mass air supply and throttle sensors.

Incorrect fuel supply

In this case, professional car mechanics advise performing the following algorithm of actions:

- carefully inspect and clean the injectors;

- if after this the problem has not been resolved, then the injectors must be completely replaced;

- carry out an inspection of the condition and operation of the fuel pump, if necessary, replace the assembly;

- identify and reset ECU errors

Ignition system

When diagnosing early or, conversely, later ignition timing in the system, you should pay attention to the condition and soot of the spark plugs, as well as the integrity of the high-voltage wires. If replacement is required, it is best to do this with the entire set.

Engine mounts

If the fastening elements become loose or the engine mounts fail, it is necessary to strengthen the fastenings accordingly and consistently. Check the pillows for cracks and other defects; if necessary, replace them in pairs or completely.

In addition to the above measures, to eliminate strong vibrations emanating from the engine, proper installation of the timing belt, professional balancing of the crankshaft, as well as replacement of CPG elements of different weights (worn out) may be relevant.

Thus, the “dancing” of the power unit can occur for various reasons, which are also eliminated accordingly, each according to its own algorithm. Eliminating the causes of vibrations is a necessary process, since such vibrations, in addition to causing discomfort to the driver and passengers, can lead to expensive repairs of the car engine itself.

In addition, one of the common causes of strong vibration is the spontaneous loosening of fasteners. And if a major engine overhaul is an expensive procedure, but still fixable, then loose bolts and nuts, especially while the car is moving, can lead to irreparable consequences.

Disorders in the nutrition system

Ultimately, they come down to improper formation of the composition of the combustible mixture. Typically, vibration at idle is a consequence of its depletion. It is possible to understand exactly which node or element is the source of the problem only with the help of special equipment. There are many reasons, below are just a few of them:

- fuel pump failure;

- contamination of the filter and (or) fuel line;

- clogged jets in the carburetor or nozzles in the ramp;

- incorrect carburetor settings, faulty sensors in the injection engine, etc.

Tips and tricks

As you can see, to prevent vibrations, regardless of whether the engine is carburetor or injection, it is necessary to maintain the cleanliness of the fuel system, the functionality of the ignition system, etc.

The fuel pump and ECM sensors, fuel and air filters deserve special attention; you need to adjust the fuel injectors, idle air valve, accelerator pedal

It is important to understand that vibrations that are not eliminated in a timely manner lead to the following negative consequences:

- cracks in the car body;

- gradual unscrewing of even the most tightly tightened nuts and bolts (which can lead to an emergency);

- premature wear of parts, resulting in, for example, oil leakage, destruction of bearings, seats, fasteners, etc.

Also, drivers often deliberately lower idle speed to save fuel (especially if they have LPG). At the same time, the consequences of engine vibrations will subsequently lead to repairs, which in cost will cover all the savings on fuel.

Even while driving, it is important to consider at what speed to drive. The fact is that if the car is used incorrectly, vibrations can also occur.

To prevent this from happening, you should adhere to the following rules:

- upshifting must be done between peak torque and peak power;

- when vibration occurs, it is necessary to switch to a lower gear to avoid engine damage;

- if the car does not pull, you must also switch to a lower gear, but do not allow vibrations to occur.

This approach will avoid premature wear of parts, while ignoring it will quickly damage engine pistons, transmission bearings, clutch basket, crankshaft liners, etc. Carbon deposits and wear appear on the walls of the cylinder liners; due to constant vibration, oil seals begin to leak, and shafts begin to run out.

How to reduce engine vibrations

If the car has a carburetor, then to reduce vibrations this element requires careful adjustment, after which the idle speed is set. At the same time, the fuel pump is checked.

On injection cars, the fuel pump, injectors, electronic control system sensors, and fuel pressure regulator in the fuel rail are also checked. Additionally, it is recommended to clean the throttle valve and check the idle air valve, which supplies air bypassing the throttle valve at idle. Vibration of a diesel engine at idle may indicate certain malfunctions of the fuel injection pump or injectors, which will also require careful diagnosis and subsequent adjustment.

Causes of vibration in a car engine

The processes of converting thermal energy into mechanical energy that occur in the power unit of your car are in any case accompanied by vibration, however, thanks to the design features of the crank mechanism, we practically do not feel it. But sometimes it happens that the engine begins to vibrate with a greater amplitude than usual, especially at idle. This is already evidence that something is wrong with the engine. There can be dozens of reasons for this behavior of the power unit. But most often in a gasoline engine, vibration occurs due to:

- violations of valve timing;

- problems with the ignition system;

- power system malfunctions;

- depressurization of the vacuum brake booster;

- malfunctions of the control sensors of the electronic engine control unit (oxygen, mass air flow, idle speed, phases, speed, detonation, throttle position, crankshaft position, first lambda probe, etc.);

- engine mount malfunctions.

Best driving instructors:

Automotive instructor Svetlana Automatic transmission: Hyundai Accent Trains in Northern Administrative Okrug, North-Western Administrative Okrug, Khimki REVIEWS

Driving instructor Elena Automatic transmission: Chevrolet Lacetti Teaches in the Southern Administrative District, South-Eastern Administrative District, Vidnoye, Domodedovo REVIEWS

Driving instructor Marina Automatic transmission: Kia Cerato Manual transmission: Chevrolet Lanos Trains in Northern Administrative Okrug, Dolgoprudny REVIEWS

Automotive instructor Irina Automatic transmission: Kia Cerato Trains in SZAO, JSC REVIEWS

Driving instructor Natalya Automatic transmission: Kia Spectra Teaches in the Eastern Administrative District, Balashikha, Reutov REVIEWS

Driving instructor Oleg Automatic transmission: Chevrolet Lacetti Manual transmission: Chevrolet Lanos Trains in Northern Administrative Okrug, Dolgoprudny REVIEWS

Driving instructor Yana Automatic transmission: Kia Spectra Teaches in the Northern Administrative Okrug, Dolgoprudny REVIEWS

Driving instructor Yulia Automatic transmission: Chevrolet Lacetti Manual transmission: Chevrolet Lanos Trains in the Eastern Administrative District, South-East Administrative District, Lyubertsy, Reutov, Zheleznodorozhny REVIEWS

Automotive instructor Svetlana Automatic transmission: Chevrolet Lacetti Trains at Northwestern Administrative Okrug REVIEWS

Driving instructor Tatyana Manual transmission: Chevrolet Lanos Automatic transmission: Kia Spectr Teaches in Krasnogorsk REVIEWS

Driving instructor Peter Manual: Daewoo Nexia Trains at Northwestern Administrative Okrug REVIEWS

Automotive instructor Oksana Automatic transmission: Hyundai Accent Teaches in North-Eastern Administrative District, Mytishchi, Korolev, Pushkin REVIEWS

Driving instructor Dmitry Automatic transmission: Volkswagen Golf Manual transmission: Chevrolet Lanos Trains in North-East Administrative District, Northern Administrative District, North-Western Administrative District, Dolgoprudny REVIEWS

Driving instructor Oksana Automatic transmission: Kia Spectra Manual transmission: Chevrolet Lanos Trains in the Southern Administrative District, South-Western Administrative District, Vidnoye, Podolsk REVIEWS

Automotive instructor Dmitry Manual transmission: Lada Granta Teaches in the South-East Administrative District, Lyubertsy REVIEWS

When driving

If your vehicle experiences vibration at speed that increases as it accelerates and does not stop while driving, the problem may be wheel imbalance. In addition, shaking when driving is associated with a malfunction of suspension and electrical parts:

- shock absorbers, struts;

- support bearing;

- tie rod end;

- hinges;

- high-voltage wire break.

When a high-voltage wire breaks, the car begins to vibrate when driving and a characteristic crackling sound is heard. Finding the location of the breakdown is quite simple; a spark is noticeable when the engine is running and idling. But if the electrical wiring is in order, but the appearance of extraneous sounds under the hood is noticeable, you should check the electronic sensors.

Signs of Engine Vibration

On premium cars, especially if they have a multi-cylinder internal combustion engine, vibrations may not be felt on the body. All supports, fastenings, cushions are made of high quality material. In this regard, even turning off one cylinder does not particularly cause vibrations on other components. The engine seems to be isolated from the rest of the car.

Especially at idle, engine vibration affects the body of domestically produced cars. Also, in foreign-made cars with 4-cylinder engines, the impact on other components is felt.

Thus, the imbalance is always transmitted to the body and the gearbox handle. Let's look at how to identify and eliminate vibrations in engine components on a car with your own hands.

Improperly secured motor

This is also one of the common reasons why vibration occurs in the body at idle. Most often, this problem is associated with wear and tear on one of the mountings on which the engine is mounted.

Also, vibration in the body at idle speed occurs due to the use of too rigid fastening elements. But no matter where this problem is hidden, it definitely needs to be solved. Of course, an improperly mounted engine is not as bad as a malfunctioning cylinder in it. But still, in order to avoid constant shaking and sounds, you should change the supports or adjust their position in the right direction.

How to find out flaws in engine mounting? It's very easy to do. To do this, you need to open the hood and call an assistant to alternately engage neutral, reverse and forward gears. And at this time you should pay attention to the position of the engine on the supports. Thus, you alternately unload the pillows that hold the motor. With each new gear change, the engine will deflect in different directions at the same angles. If it deviates more than usual in any direction, it means that the pillow needs to be replaced in that place.

Diesel vibration at idle

At first glance, everything is simpler here: there are no spark plugs, no distributors. However, the “shaking” of a car equipped with a diesel engine indicates more serious and “costly” problems:

- Failure of the injection pump, which can only be checked using special equipment.

- Injector contamination. Their cleaning is carried out in specialized technical centers.

If vibration occurs at idle, checking the diesel unit should begin by determining the compression in the cylinders. If it does not meet the standard, the mixture will not ignite and the engine will begin to shake. The second stage of testing is to check the alignment of the marks on the power unit cover and the camshaft pulley. If the injection angle is incorrect, the diesel engine will operate unstably.

How to preserve the life of engine parts in different operating modes?

In order to extend the life of the engine, you need not only to monitor the normal number of rotations of the crankshaft. It will also be necessary to be able to operate the vehicle correctly, choosing the optimal range of work. Experts recommend upshifting in the rpm range between peak torque and maximum power. At the same time, when driving under high load (for example, when driving uphill), there is no need to allow the shaft rotation torque to drop to values close to idle speed.

As soon as you feel the characteristic vibration of an overloaded engine, immediately switch to a lower gear. Otherwise, the motor parts will be subject to high loads. This can cause failure of the entire cylinder-piston group. Remember that high speeds for an engine (especially a gasoline engine) are not as bad as low ones. If you have a gasoline car, change your driving style so that the engine speed when driving does not drop to 2 thousand or below. In this case, it is allowed to spin the crankshaft to 6000-8000 rpm. As soon as you feel that your car has stopped pulling and is about to run out, switch to a lower gear and under no circumstances allow the speed to drop to the point of vibration, especially if you are driving downhill. Operating the car in this mode will save parts from premature wear. At the same time, this “high-speed” driving style does not in any way result in increased fuel consumption.