Hunting semi-automatic shotgun Posh

Since mid-May 2014, the range of smoothbore hunting rifles offered by TEMP LLC has been expanded with the Posh gas-operated semiautomatic device. High-quality finishing of external and internal surfaces, good balance, the use of TruGlo light-accumulating elements for the front sight and, of course, a set of 5 choke attachments included - all this has become the “calling card” of hunting semi-automatic devices from the manufacturer Ottomanguns (Turkey).

Despite their almost identical appearance, weight, balance, barrel length and equipment, the Bronco and Posh semi-automatics differ in their reloading system when firing. While the Bronco has an inertia locking design, the Posh has a full gas engine. Traditionally, in Russia, the majority of hunters who purchase semi-automatic shotguns give preference to weapons with a gas-operated reloading mechanism. In many ways, this is some tribute to the established opinion about the higher reliability of the gas engine. In practice, the automatic inertial locking system will not work only if the butt of the gun is pressed against a hard, stationary surface, for example, a concrete floor or wall - in this case, the recoil impulse will not be enough to reload. However, in conditions of hunting or clay pigeon shooting, the very presence of such emergency situations tends to zero. When the inertial semi-automatic machine rests even on the strong shoulder of a “heavyweight” shooter and the projectile is loaded with only 24 g, the activation of the inertial reloading system is guaranteed.

The gas vent reloading system is, of course, completely autonomous, but depends on the mass of both the projectile and the powder charge. But, in any case, the gas engine of Posh shotguns fully performs the full reloading cycle both with factory cartridges with sporting loads (24 grams) and with magnum class cartridges with a projectile weight of up to 50 grams. Not every gas-operated semi-automatic machine has such capabilities. Therefore, to understand how this is possible, let’s study the design of the gas engine of the Posh shotgun.

The beginning of disassembling the Posh is similar to any modern semi-automatic rifle - by unscrewing the nut from the front end of the under-barrel magazine. The spring-loaded ball in the front part of the gas block of the barrel and the counter-grooved breech surface of the nut do not allow this connection to unwind arbitrarily due to vibrations when shooting and carrying the gun while hunting. As a result, there is no need to tighten the nut with all your might and use any tool.

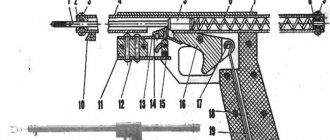

By unscrewing the nut from the end of the magazine, you can remove the forend by moving forward. Below it is a gas engine. To remove the barrel, you need to move the bolt back by its stem about 1.5 cm and remove the barrel from the receiver forward. The barrel can be removed with some effort due to the presence of a seal ring in the front part of the gas chamber. Depending on the degree of contamination of the gas engine, the piston will remain either on the tube of the under-barrel magazine or inside the chamber of the gas block. On a clean gun it will remain in the chamber.

The Posh has a four-piece barrel. From the breech to the chamber, a hardened barrel shank with a recess for the locking cylinder of the bolt is screwed “hot” along the thread. A block with a gas exhaust chamber is installed approximately 2/5 of the barrel length on the chamber side. And finally, along the top of the barrel, almost along its entire length, is a ventilated strip on which the TruGlo front sight is installed. The Posh's barrel, like the Bronco's, is made from 4140 steel (42CrMo4) by drilling. The bore and the entire shank are chrome plated. The chromium layer is quite thick and almost completely hides traces of a metal-cutting tool on the shank. The shank and gas block traditionally have a higher quench hardness.

The Posh piston is also fully chrome plated. Two steel seal rings are installed in the grooves on its body, which have slight play relative to the piston body. This play is selected when overheating from intense shooting from a gun in bench conditions. The piston sits quite tightly inside the gas chamber, minimizing parasitic leaks of powder gases when fired.

The piston is pressed through the cylindrical base of the bolt frame by a massive return spring located on top of the magazine tube. Since the piston and return spring move along the surface of the under-barrel magazine, and also to protect against corrosion, the outside of the under-barrel magazine tube is chrome-plated! It should be noted that chrome plating of the magazine tube is extremely rare, even on much more expensive semi-automatic devices from well-known world manufacturers. The cylindrical base of the bolt frame has a number of holes for removing the combustion products of gunpowder from the surface of the magazine tube.

After removing the bolt stem, the bolt and bolt carrier assembly can be removed forward from the receiver of the gun.

The bolt and bolt carrier are made of 4140 steel (42CrMo4) by milling. The barrel bore is locked onto one massive milled lug that moves vertically inside the bolt body. An interesting feature of the Posh is an additional automatic safety feature against firing when the bolt is unlocked - the lowered lug of the cylinder blocks the firing pin. Being in the upper position inside the reciprocal groove in the barrel shank, the larva unlocks the gun's firing pin.

The locking cylinder of the bolt is moved to the upper and lower positions by a slider, which is part of the bolt frame. The bolt frame itself consists of a cylindrical base, two rods and a slide. On Posh shotguns with a wooden fore-end and butt, the bolt is chrome-plated and polished; on Posh shotguns with a plastic fore-end and butt, as well as in camouflage, the bolt has a matte blued finish.

Shotguns made of plastic and wood also have a number of differences from each other. In addition to finishing the surfaces of the receiver (receiver), the Posh with plastic fittings is equipped with a butt plate with a more effective shock absorber, designed to more comfortably absorb recoil from a lighter, hollow polymer stock. Also, the plastic forend has holes for removing excess powder gases on the sides, and the wooden one - in the upper end.

Let's return to the Posh gas engine. There are 2 holes in the barrel wall at an angle of 60 degrees to the breech. The holes are drilled after soldering the gas block, which eliminates any misalignment of the holes in the barrel wall and the gas block. Also, the gas outlet holes located at an angle are noticeably easier to clean and, most importantly, the obtuse angle of meeting the shot container when firing does not lead to the formation of polyethylene shavings and their entry into the gas outlet chamber. To improve sealing, the chamber is equipped with a seal ring in the front part, which significantly reduces parasitic leakage of powder gases into the working gap between the walls of the chamber and the magazine tube.

Despite the abundance of chrome parts, the gas engine needs cleaning even after several shots. It is worth keeping in mind that after cleaning the gas engine, the gas exhaust chamber, the piston, the surface of the under-barrel magazine tube and the cylindrical base of the bolt frame must be thoroughly wiped dry to remove any remaining weapons cleaning chemicals and oil! The presence of even slight traces of oil on the working surfaces of a gas engine leads to rapid contamination. The gun, of course, will not fail even during intense clay pigeon shooting, but oil-based powder deposits that have stuck to it will subsequently be difficult to remove from gas engine parts.

The volume of the gas chamber is designed for a full recharge cycle with small “bench” samples starting from 24 grams. Cartridges with a projectile weight of 28-30 grams and above, as well as with an increased powder charge and projectile weight (“semi-magnum” and “magnum”), create excess pressure in the gas chamber, however, the special shape of the front part of the piston allows the excess gases to be released smoothly into space inside the forend and bring them out through the bleed holes into the atmosphere. Naturally, after a long period of shooting with semi-magnum and magnum cartridges, more thorough cleaning of the gas engine assembly will be required, but the presence of chromium on the working surfaces of the gas exhaust mechanism allows you to postpone this process until you return home from a hunt or stand.

The receiver (receiver) of the Posh shotgun is identical in external geometry to the Bronco and is made from a solid aluminum billet (7075 aluminum) on CNC machines. The firing mechanism block (trigger block) is made in the same way from aluminum 7075. The trigger itself is completely identical to the Bronco and is interchangeable with it. That is, the Posh, like the Bronco, has expanded trigger capabilities tied to the cartridge feed lock lever (located under the index finger of the right hand in front of the trigger guard). If the cartridges are in the magazine and chamber, then after activating this lever and firing, the bolt of the gun will remain in the rearmost position on the bolt stop, and the next cartridge from the magazine will not be fed into the tray. This allows you to manually place a cartridge with the currently required type and weight of the projectile on the tray. If the chamber is empty and there are only cartridges in the magazine, then when the locking lever is activated, the manually retracted bolt will move to the rearmost position on the bolt stop, and the next cartridge from the magazine will not jump out onto the tray. Then the gun can be loaded with the type of cartridge needed at the time of hunting. The push-button safety is located at the rear of the trigger guard and can be easily turned off with the index finger of your right hand.

The trigger block is removed after knocking out the spring-loaded axis in any direction and pressing the bolt delay reset button. Like the Bronco, most parts of the Posh USM are made of steel by electroerosion, the rest are made by casting with subsequent processing. The only part made by stamping from sheet steel is the feeder tray.

The main loads during a shot are taken by the barrel, barrel shank and bolt, thereby unloading the receiver. Thanks to this, it became possible to make it from lightweight and corrosion-resistant aluminum. The refusal of a plastic trigger block in favor of an aluminum one indicates the manufacturer’s desire to make the trigger assembly more dense and not skimp on the aesthetic perception of the gun as a whole. The gun turned out to be very handy and light - 3.1 kg without cartridges. The capacity of the under-barrel magazine is 5 rounds of 12x70 or 4 rounds of 12x76. Additionally, a sixth or fifth cartridge, respectively, may be located in the chamber of the gun. Posh is equipped with five choke attachments, four of which, along with the key, are in a small, lightweight plastic case that is convenient to take with you when hunting. Various choke constrictions (cylinder, 0.5, 1.0, 1.25 and 1.5) significantly expand the capabilities of a smoothbore gun both for hunting and on the bench.

Such equipment allows you to immediately provide a solution to any problems both during hunting and at the stand, and can fully satisfy the needs of a buyer who wants to have a classic gas-operated semi-automatic machine with a high degree of reliability and operational strength. Three versions of Posh shotguns (with a butt and fore-end made of wood or black plastic, as well as a fully camouflaged version with plastic forend and butt) allow you to choose a model for any hunting conditions. Therefore, we can confidently recommend Posh shotguns from the Turkish manufacturer Ottomanguns as high-quality and reliable weapons that occupy a leading position in the price/quality/equipment ratio.

M6 Survival Weapon

Even during the Second World War, American pilots, shot down and forced to wait for help at a distance from their bases, noticed that standard army weapons were not the most convenient survival tool. Small-sized serial samples, suitable for inclusion in a portable emergency supply, performed poorly on the hunt, and also did not allow them to fight off the enemy. After the war, American gunsmiths created several special rifles and shotguns for survival, including the M6 Survival Weapon .

The first example of a specialized weapon for pilots was the M4 Survival Rifle small-caliber rifle . For transportation, it was disassembled into several units and packaged in a compact holster bag. The .22 Hornet cartridge made it possible to hunt small and medium game. The rifle suited the military and was adopted for service. Over the course of several years, more than 29 thousand of these products were produced, which were soon distributed among units of the air force and army aviation.

The M4 Survival Rifle was a decent weapon, but it had some drawbacks. First of all, the practical characteristics and capabilities of the low-power cartridge were criticized. To solve this problem, it was proposed to create a new weapon with a different appearance. At the very beginning of the fifties, specialists from the US military department formed a new technical specification, and then launched another competition.

Some of the requirements for a promising survival weapon were directly borrowed from the previous technical specifications: the product had to be small in size and weight, and also folded for greater ease of storage and transportation. At the same time, it was necessary to improve ergonomics and simplify the use of weapons. The main innovation of the technical specifications affected the barrel group and ammunition. Now the military wanted a double-barreled system capable of using small-caliber cartridges and shot ammunition. As experts assumed, this would lead to an increase in the potential of weapons in the context of hunting.

General view of the M6 Survival Rifle.

The project for a new weapon for pilots was created by Ithaca Gun Company. At the development stage, its project bore the working designation T39. The order for the adoption of a promising product into service, signed in 1952, introduced a new name - M6 Survival Weapon. The names Aircrew Survival Weapon or USAF Survival Weapon are also used. The latter pointed to the customer in the person of the US Air Force.

The main requirements for the project presented by the military department were fulfilled using well-known ideas and solutions. Serious innovations that were complex or excessively bold were not envisaged. The pilots' NAZ was proposed to include a folding weapon with two barrels of different calibers. Taking into account possible use in the northern regions, the weapon had improved ergonomics. Due to the need for mass production, it was also distinguished by its extreme simplicity of design.

.22 Hornet (left) and .410 M35 (center and right) cartridges.

Fire characteristics that meet hunting requirements were obtained through the use of two barrels chambered for different cartridges. Thus, the T39 / M6 product belonged to the class of combined shotguns. The two barrels were placed one above the other and secured to the front of the receiver. The rear element of the latter housed some mechanical devices and also served as a butt. For greater ease of storage, the gun was folded in half, but the separation of the articulated units was not provided.

The project proposed the use of two barrels at once for different ammunition. The barrels had the same length of 14 inches (355 mm), while the lengths in calibers differed noticeably. Two tubular parts were placed one above the other. The breech chambers were rigidly fixed in the receiver. The muzzle parts were fastened with a vertical part, which also served as the base of the front sight.

M6 shotgun folded.

The upper rifled barrel, 62 caliber long, was proposed to be used with small-caliber .22 Hornet centerfire cartridges (5.7x35 mm R). The lower barrel had a smooth bore .410 caliber (10.41 mm) with a relative length of about 34 calibers. This barrel was designed to use special M35 shotshells. The barrels were located in the same vertical plane, which made it possible to reduce the dimensions of the weapon and simplify its folding.

The barrel breechs were rigidly fixed to a common base, which was the front element of the receiver. This part had the simplest possible design and was actually a cast metal block with several channels and recesses. At the rear of this block, between the barrels, there was a spring-loaded extractor that interacted with the flanges of the cartridge cases in both chambers simultaneously. Below the rear cut of this part there was a hinge for connection with the rest of the gun’s components.

On the upper surface of the barrel block there was a longitudinal ridge with fastenings for additional parts. In front of it was a reversible sight rear sight, and its rear part was intended for installing a swinging latch connecting the weapon units during shooting. Moving this part upward disengaged the elements of the gun and made it possible to reload.

sportguns®sporting shotguns

Arms companies that produce standard guns can only attract the attention of hunters, and even more so of well-trained and demanding athletes, with the high quality and modern impeccable finishing of their products. Another way, but not very common, is to offer models with some design or application features. Even those few companies that combine these two areas still shift their main focus to the technology of standard classic models, as the most popular on the market and known even in remote corners. Original guns of rare or unusual designs, such as folding guns, are an addition to the main production.

THREE BROTHERS

The Investarm spa company is one of the prominent manufacturers of sports models in Italy; many athletes shoot from guns with large inscriptions on the barrels - Investarm. In addition to the traditional over-and-under shotguns for the Italian industry, the company also produces folding shotguns, which are currently rare - single-barreled and double-barreled shotguns.

The company was founded in 1975 by three brothers from the Salvinelli dynasty - Angelo, Maigo and Luca, who by that time had accumulated 20 years of experience in gunsmithing. The eldest of them first became interested in hunting weapons back in 1955. The meaningful name turned out to be justified - investments in the production of sports and hunting weapons established the company’s position in the market.

In the town of Marcheno, she owns a modern production facility with a large number of machines, allowing her to create flexible technology and immediately make the necessary changes. All working stages are concentrated in one large building: production of barrels, blocks, percussion mechanisms, stocks, assembly and finishing. The number of employees in the company is limited, since the main labor-intensive operations are automated, and the interchangeability of parts, their quality and accuracy are guaranteed.

By now, the company has already established itself as a manufacturer of high quality shotguns. Now she has proclaimed a difficult but honorable goal - in the 21st century. take a leading position in the production of sporting shotguns. Achievements in recent years are associated with the Sydney model (“Sydney”) with a block of vertically connected barrels, which has become the basis for numerous hunting and sporting rifles.

IN HONOR OF THE OLYMPICS

Modern over/unders are descended from the high-end Sydney 2000 shotgun of the same name, created in honor of the 2000 Sydney Olympics. When creating its vertical guns, the company took advantage of all the latest advances in weapons technology. The Boss & Co. system was adopted as the basis for these guns, which made it possible to develop a compact barrel block and block. The weight and dimensions of the block of barrels, blocks and guns are optimized and standardized.

Sports upright Sydney EXL with side decorative plates

The barrels of the Sydney over-and-under, made of nickel-chromium-molybdenum steel grade 40NiCrMo2, are connected using a monoblock system. The block is made of alloy steel grade 18NiCrMo5. The axle shafts on which the barrel block rotates are located in the block at the level of the lower barrel. The locking of the block corresponds to the chosen system: the side rods in the middle of the block shield rest on the side hooks, also installed at the level of the lower barrel. A spring is installed in the forend, pressing its frame towards the end of the block. The trigger mechanism is usually with one trigger, and the shot sequence switch is combined with the safety button. Automatic ejectors are convenient for removing spent cartridges - their working platforms extend by 9 mm.

The company counts on a wide range of hunters and sportsmen and strives to provide everyone with actionable, well-balanced guns. Therefore, when manufacturing an ergonomic stock, seven geometric parameters are taken into account. The forend and stock are made of walnut aged for many years, and for high-end models - from high-grade wood with a contrasting texture.

HUNTING VERTICALS

The group of hunting rifles is represented by the main model Sydney Field 12 gauge. Blocks of barrels with lengths of 660, 680, 700 and 760 mm with continuous connecting strips are provided for it. The weight of a hunting rifle can be considered optimal for its caliber: with barrels 700 mm long, which weigh 1.32 kg, it is 3.3 kg. A hunting-type ventilated aiming bar 7 mm wide with a spherical front sight is installed on the block.

The central figure of the Sydney EXL shotgun composition is precisely inscribed in the proportions of the side plate

The block, made in one piece with the shank and the base of the trigger mechanism from a single piece, has profiled sidewalls, easily recognizable on any Italian vertical. The locks, located in a frame formed by a block, a shank, a base and a rear jumper, are equipped with combat spiral coil springs. Sydney shotguns look solid, but proportionate due to the compact forend and proportionate stock with a pistol-shaped neck and shock absorber recoil pad. All hunting models can be equipped with a replaceable block of 20-gauge barrels.

The category of the gun is indicated by additional letters in the marking, for example, the Sydney L1 Field or Sydney CS model is a gun with a black block, the Sydney L2 Field shotgun is decorated with a protective light coating. A modest design adorns the stock of the Sydney XL1 Field shotgun or the similar Sydney CM. The Sydney XL2 Field model is characterized by completely decorated surfaces of the lasts.

The high grade Sydney EXL Field shotgun is finished with hand engraving and signed by the artist himself. The same model is produced with side decorative plates on the block, which attract a variety of subjects, for example, hunting scenes with images of birds or a naked nymph.

At the top of the range of over-and-unders is the Sydney EXO Field shotgun, decorated not only with hand engraving but with individual gold figures.

SPORTS VERTICAL SHOES

The Sydney Trap, Sydney Skeet and Sydney Sporting sporting shotguns are based on similar hunting models. They differ mainly in the weight of the gun, the length and weight of the barrel block, the shape of the volumetric forearm and the geometry of the stock. The company tried to somewhat reduce the mass of the block and improve its cooling during intense shooting due to ventilation slots on the connecting strips. The 11mm wide ventilated rib is equipped with a cylindrical fiber optic front sight. Sporting shotguns are equipped with a stock with a steep pistol-shaped neck and a wide butt plate-shock absorber.

The position of the central figure softens the geometry of the Sydney EXL over-and-under shoe

The length of the barrel block is standardized and depends on the type of sports discipline and the habits of the shooter. For shooting on a trench stand, Sydney Trap guns are equipped with blocks 750: 760 or 810 mm long. This model with a block 750 mm long and weighing 1.5 kg weighs 3.64 kg. The heaviest gun is produced for the American Trap exercise; it is equipped with a block consisting of a single barrel. With a barrel length of 860 mm and a weight of 1.56 kg, it weighs at least 3.7 kg.

For the “skeet” exercise, the Sydney Skeet model is produced with barrels 680 and 700 mm long. The mass of such a gun with barrels 700 mm long, which weigh 1.4 kg, is 3.45 kg.

A wider range of barrel blocks is available for the Sydney Sporting shotgun for the popular sporting discipline: barrels can be 700, 720, 760 and 810 mm long. With a block weight of 1.43 kg, which has a length of 720 mm, the gun itself weighs 3.47 kg.

The marking of sporting models belonging to one category or another is the same as for hunting rifles. For example, the Sydney L2 Trap shotgun is finished with a light protective coating, the Sydney XL1 Skeet model and the Sydney EXL Sporting shotgun are covered with fine engravings of small arabesques.

FOLDING SHOTS

At the company, craftsmen treat folding shotguns - single-barreled and double-barreled - with the same serious attitude as they do with Sydney hunting and sporting over-and-unders, despite their simple design and minimal number of parts. By the way, a minimum of well-processed parts determines the high quality of the finally assembled gun.

The frame of the folding models is made of steel, carefully machined and modestly finished. For single-barreled and double-barreled guns, its dimensions are different. The barrel block is assembled on a breech coupling, pivotally connected to the block. When completely disassembled, this bolt is unscrewed; the transverse hinge bolt has a slot for a flat-head screwdriver. The bore after processing and polishing is protected by a chrome coating. The barrel block is locked in the block by a latch that fits into the groove of the rear under-barrel hook.

The shape of the block and forend makes the Investarm Combo folding double-barreled shotgun stand out against the background of over-and-unders

The percussion mechanism of folding shotguns, mounted on a powerful base together with the trigger mechanism, has a durable combat spiral cylindrical spring. All of these guns are equipped with a push-button safety on the tang of the block. The pistol-shaped stock and fore-end are made from seasoned but affordable walnut or beech wood. The basic single-barrel Model 70 is a simple under-lock shotgun. The 710 mm long barrel for all calibers from 12 to .410 is opened using a locking lever mounted on the bottom of the block in front of the trigger guard. The 70LS features a locking mechanism that is operated by a traditional top lever. These two models have the simplest sighting device - a spherical front sight mounted directly on the barrel. Shotguns model 80 with a lower lever locking and 80LS with an upper lever differ from the basic ones in that the barrel is equipped with a ventilated rib.

The 90AT top-lever shotgun continues the 80 and 80LS model series and is designed specifically for the American trap sporting discipline. It is equipped with a larger block and only a 12-gauge barrel with a length of 810 or 860 mm with a high rib. The bar has a cylindrical front sight made of optical fiber and an intermediate one of spherical shape. The cross-pivot bolt changes as it wears, as the 90AT gun has to endure more stress.

The group of folding shotguns with a block of vertical barrels starts with the Model 100 with a flat wide block and the same block locking as on a single barrel. The barrels are connected by a breech coupling, side strips and soldered. Double-barreled shotguns 100 are equipped with barrels 710 mm long and are available in any caliber from 12 to .410 with the exception of 16 and 24. The barrel block is equipped with a 7 mm wide ventilated sighting rib. The same 100L gun differs only in the finishing of the block and a higher grade of walnut on the stock and fore-end.

The folding Combo model (“Combo”) with a combined block of vertically connected barrels is produced on the basis of the 100 shotgun with a flat block. The following combination of barrels in the block is provided: 20th and .410th or 28th and .410th.

The 200 and 200L double-barreled shotguns are only 12-gauge with 710 mm long barrels and 76 mm chambers - the most solid and massive models. They have a stronger shoe with smooth surfaces without a protrusion for the pivot bolt. Outwardly, they give the impression of an ordinary collapsible vertical gun with a removable block of barrels.

Sydney hunting and sporting shotguns and folding single-barreled and double-barreled shotguns are not limited to modern production. Since the end of 2005, the company has been mastering the production of the new model Hunter 66 (“Hunter 66”), which should attract the attention of hunters.

from the book by Evgeniy KOPEYKO “HUNTING AND SPORTING WEAPONS OF THE WORLD (ITALY)”, VECHE Publishing House, 2008