Belgium is considered a leader in the production of first-class firearms. Today it is difficult to imagine any other country where people are interested in high-quality weapons. Experts in this matter advise paying attention to the Belgian gun. His country has been producing it for three centuries. It all started back in the 17th century. At that time, production began in a handicraft way, and only after some time did Belgian gunsmiths begin to produce it on machines. It was the use of special types of steel and the unique type of products that made Belgium a favorite in the arms field.

You may be interested in:Coastal defense battleship: names, history of creation, development and characteristics

A little history

The production of guns in Belgium began in the 17th century. At first they were sold within the country, and only after some time they began to be sold abroad. At first the batches were small, but as they gained popularity they began to grow. It is known that in 1860 Belgium was able to sell weapons worth 11,891,960 francs. There are a lot of countries to which goods were exported. Russia is only in thirteenth place on this list. The top ten are headed by:

- Chile.

- England.

- Prussia.

- France.

You might be interested in: Why is there no compression in one cylinder? Checking, measuring and replacing

Belgium now also sells a large number of weapons both at home and abroad.

Similar but different

Despite the fact that the model range of semi-automatics and Berettas is constantly updated, the design of the new models is not much different from the basic ones. The changes concern primarily the design. Therefore, all the pros and cons of these models can be considered using the example of basic samples.

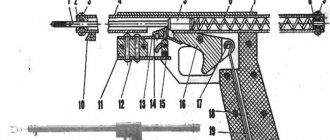

1. Gas exhaust system of a Browning shotgun.

2. Gas piston of a Browning gun: a - retaining ring of the gas coupling; b - the introduction of a second row of gas release holes into the piston design made it possible to reduce the recoil impulse affecting the shooter. 3. Gas exhaust system of the Beretta shotgun. 4. Trigger mechanism: a - Browning shotgun; b - Beretta rifles. APPEARANCE

Considering that both guns have the same layout and almost identical weight and size characteristics, it is difficult to immediately give preference to one model or another. And yet the design of the Urika AL 391 shotgun is more thought out. The appearance of the Gold Fusion gun differs significantly from the previous Browning Gold model. If we talk about design, this is a completely new model. A lot has changed, and certainly for the better. The receiver has smooth contours. The shape of the fore-end lacks a little grace and thoughtfulness, because of this the gun is not perceived as light and graceful as the Beretta AL391 Urika. But this is only externally, in fact the gun is very light. The metal parts of the AL391 Urika shotgun are processed more carefully than in the Gold Fusion. This mainly concerns parts, the trigger, the cartridge limiter, the feeder tray, and the bolt.

"BROWNING GOLD FUSION"

This is a new semi-automatic model. Available with a chamber length of 76 mm. The bore is chrome-plated, the diameter of the 12-gauge bore is 18.85 mm (Back Bore type drill is used). "Gold Fusion" is a semi-automatic shotgun that works on the principle of removing powder gases. The principle of automation with a short stroke of the gas piston rod is used. The receiver is made of light alloy. The trigger mechanism is located on a separate base. The trigger safety is a push-button type, located on the rear of the trigger guard. The cartridge is locked in the barrel chamber by means of a lug lug inserted into the barrel shank. The magazine is under-barrel, tubular, for 4 rounds with a case length of 70 mm and for 3 rounds with a case length of 76 mm. The forend and butt are made of walnut; the butt has a rubber butt pad. The design allows for adjustment of the retraction and height of the butt comb.

"BERETTA AL391 URIKA"

The penultimate model of a semi-automatic smoothbore shotgun. The gun's automatic operation operates on the principle of removing powder gases through two holes into the gas chamber. The design of the gun implements the principle of automation, using a long stroke of the gas piston rod. Currently, the gun is produced only with a 76 mm chamber. The bolt is sliding; the cartridge is locked in the barrel chamber by means of a lug lug inserted into the barrel shank. The trigger mechanism is mounted on a separate base. The trigger safety is a push-button type, located on the front of the trigger guard. The bore is chrome-plated, the 12 gauge has a diameter of 18.4 mm. The magazine is under-barrel, tubular, for 3 rounds with both a sleeve length of 70 mm and a length of 76 mm. The receiver is made of light alloy. The butt and fore-end can be made of either walnut or plastic, and there is a rubber butt pad. The design of the gun allows for adjustment of the side release and height of the butt comb.

BALANCE AND SEATING

We have already noted that both models of the shotguns tested are very light in weight. In both models, it is possible to adjust the lateral release of the stock and the vertical movement of the butt comb. This makes it possible to ideally adjust shotgun stocks to shooters with different anthropometric data. The balance of both models is good, the posadism, or agility, is also at a fairly high level. Both guns leave a very good impression in terms of grip and overall weight distribution. It is difficult to give preference to any of them.

AUTOMATION

Let us immediately note that the tested models have different principles of operation of gas exhaust automation. The AL391 “Urika” model has an automatic system with a long stroke of the gas piston rod, while the “Gold Fusion” gun uses an automatic system with a short stroke.

| Tactical and technical characteristics of guns | ||

| Parameter | Beret AL391 Urika | Browning Gold Fusion |

| Caliber, mm | 12 | 12 |

| Barrel length, mm | 710, 760 | 710, 760 |

| Chamber length, mm | 76 | 76 |

| Bore diameter, mm | 18,4 | 18,85 |

| Weight, kg | 3,0 | 3,0 |

| Total length, mm | 1290 | 1250 |

| Magazine capacity, cartridges | 3 | 4 (sleeve length 70 mm), 3 (sleeve length 76 mm) |

The gas exhaust system of the semi-automatic "Beretta AL391 Urika" was moved outside the under-barrel magazine, which had a beneficial effect on the weight distribution of the weapon, as it made it possible to make the under-barrel magazine tube from light materials, without fear of burning through it with powder gases. The gas exhaust system of the Gold Fusion gun is designed differently than in the AL391 Urika gun. It was in the semi-automatic “Gold Fusion” that the designers were finally able to successfully solve the problem of the effect of powder gases on the body of the under-barrel magazine. The gas piston rod of the Gold Fusion gun is longer than that of the previous Browning Gold model. This change made it possible to eliminate the failure of the gas piston retaining ring during firing, which sometimes happened previously. Polyamide fiber is used as the material for the gas piston rod of the Gold Fusion gun. This is a new solution. The use of polyamide made it possible to improve the weight distribution of the gun and increase the corrosion resistance of an important part of the gas exhaust system, but at the same time, in some cases, after long-term use (more than 7000 shots), cracks form on the walls of the rod, as a result of which it fails. From the point of view of ease of maintenance of the gas unit, namely its cleaning, neither one nor the other model of the tested guns is much more convenient. But still, the gas piston of the Gold Fusion gun is more convenient to clean, since it is separated from the gas chamber. The use of a deflector in the front part of the forend of the AL391 Urika shotgun allows the powder gases to be discharged into the atmosphere, excluding their contact with the wooden parts of the forend. In the Gold Fusion gun, powder gases fall directly onto the wooden parts of the fore-end. This leads to the fact that the inside of the forend must be cleaned after shooting.

TRIGGER MECHANISM (Trigger)

The design of the trigger in the AL391 "Urika" gun differs from the "Gold Fusion" trigger mainly in that it has a disconnecting protrusion with which the trigger interacts during the firing process. The springs of the feeder lever also differ in design. But these differences do not in any way affect the performance of the weapon as a whole. It should be noted that in the trigger mechanism of the “Gold Fusion” shotgun, the safety lock spring is poorly located. When cleaning the “Gold Fusion” trigger, when it is necessary to press the safety lock, you need to make sure that the lock spring does not spontaneously leave its seat. In general, the trigger parts of the AL391 Urika shotgun are made more carefully than the trigger parts of the Gold Fusion shotgun.

RECOIL SHOCK ABSORBERS

1. Buffer shock absorber: a - Browning guns;

b - Beretta rifles. 2. Semi-automatic "Browning Gold Fusion" disassembled. 3. Replacement choke tube for a Beretta shotgun. 4. Replacement choke tubes for Browning shotguns. Both models use recoil buffers. The main purpose of these shock absorbers is to prevent shock loads from the bolt from affecting the rear of the receiver, especially when firing magnum ammunition. It should be noted that the designers coped with this task much better. The materials they use for the shock absorbers in the Gold Fusion gun are more durable and more suitable for Russian conditions (especially when shooting magnum ammunition in winter) than the materials used in the AL391 Urika gun. The principle of mounting shock absorbers in the receiver of the Gold Fusion gun is more successful than in the semi-automatic AL391 Urika. This is especially felt when replacing these parts again.

GATE

The bolt designs of the shotguns tested have differences, and these differences have different effects on the performance of the weapon. If you look closely, you can see that the protrusion of the firing pin beyond the bolt mirror of the Gold Fusion gun is much greater than that of the Urika gun. Therefore, the Gold Fusion shotgun is less sensitive to the quality of the primers used in the cartridges than the AL391 Urika shotgun. For our conditions, this is important, since Russian hunters often load cartridges themselves using various capsules, including domestic ones. Under these conditions, the Gold Fusion gun is more adapted to the ammunition and components used in Russia than the AL391 Urika gun.” For ease of disassembling weapons, quick-release handles are used in the bolt design of the tested guns. Such designs require reliable fastening of the handle to the bolt frame. In the Gold Fusion shotgun, the problem of fastening the bolt handle was solved more successfully than in the Beretta AL391 Urika shotgun. The bolt handle of the semi-automatic “Gold Fusion” cannot be removed until the cartridge stop is forcibly recessed; this design prevents accidental removal of the handle during shooting. It is also impossible to accidentally misplace the handle into its seat when assembling the bolt; it simply will not be assembled. This also prevents the handle from getting lost. When using the semi-automatic AL391 Urika, the loss of the bolt handle cannot be ruled out, most likely due to the carelessness of the shooter himself, who did not move the handle to its seat when assembling the bolt. But in the design of the bolt of the AL391 Urika shotgun there is no insurance against inattention.

CARTRIDGE CUTTER

The shotguns tested use completely different cartridge cut-off designs. The Gold Fusion shotgun uses a traditional cut-off mechanism. The AL391 Urika shotgun uses a kinematic reloading scheme. This scheme involves feeding a cartridge from the magazine into the chamber of the gun only when the trigger is pulled or the feeder tray release button is pressed. The AL391 Urika shotgun has a cut-off device, but its functions are different. The kinematic reloading scheme used in the AL391 Urika shotgun allows you to very quickly replace all the cartridges in the rifle’s under-barrel magazine. To do this, you need to lock the feeder tray in the uppermost position with the cutter and press the bolt stop button: the cartridges in the gun magazine will vigorously leave it. A very convenient feature. But you can take advantage of this convenience only under one condition: it is necessary that the cutter clearly fixes the feeder tray in the upper extreme position. In most AL391 Urika shotguns, the cutter does not secure the feeder tray, which means that it is simply impossible to take advantage of this property of the semi-automatic AL391 Urika.

REFLECTOR

The design of the reflectors in the tested models is also different. In the AL391 Urika shotgun, the reflector is mounted on the receiver body and is spring-loaded. A spring-loaded reflector has a longer service life than a regular one, and most importantly, it allows for a gentler extraction of the cartridge from the chamber of the gun, which significantly reduces the possibility of losing the cartridge, especially when hunting on water. It can be replaced. The reflector of the “Gold Fusion” gun is mounted on the shank of the barrel, has the simplest design, is not spring-loaded, and if it breaks, replacement is somewhat problematic. The design of the AL391 "Urika" shotgun reflector is more advanced, more durable and easier to use.

MUZZLE TUBE

Both shotgun models use interchangeable choke tubes. And here there are design differences that affect the performance of the guns being tested. In the AL391 Urika shotgun, the seat in the barrel and the thread for the attachments, as well as the attachments themselves, are chrome-plated. The thread is large, located in the upper part of the barrel. Chrome plating prevents corrosion of the nozzle-barrel threaded connection. This simplifies the operation of interchangeable muzzle devices. Access to and cleaning of the threads in the AL391 Urika shotgun is easier than in the Gold Fusion shotgun. In the Gold Fusion gun, the threads are small and located deep inside the barrel. The replacement tips themselves are not chrome plated. The use of a homogeneous material for the threaded nozzle-barrel pair and the absence of a chrome coating means that the replaceable nozzles of the Gold Fusion shotgun require more careful maintenance than the AL391 Urika shotgun. They are more prone to corrosion, which can make replacing them difficult.

The latest model (Browning Fusion Evolve) is also not without its shortcomings. The handguard at the rear has play and a very flimsy design. The upper swivel touches the barrel, creating noise that can interfere, for example, during a game hunt. The design of the stock is such that cracks sometimes form. The bolt group does not completely cover the window in the receiver, which allows various debris to get inside. In general, the model is as lightweight as possible when it comes to 12 gauge. Traditionally, semi-automatic machines are unpretentious in terms of the quality of cartridges. Which model to choose is a matter of taste for the hunter himself.

Dmitry KOPAEV Photo by Vladimir KISELEV

Brand

In the production of Belgian hunting rifles, much attention was paid to the mark. They began to brand it in the 17th century, even at a time when weapons were made by handicraft. This was done so that every knowledgeable person could see whether this or that gun was of high quality or not. Since all gunsmiths had different levels of ability, the quality and reliability of each differed.

In 1672, it was decided to correct this circumstance and it was decided that every Belgian gun must pass a test before it was put on sale. Those models that passed the test were branded by applying a drawing on it, which depicted a column on the city’s coat of arms.

Larger inspections began during the time of Napoleon in 1810. It was tested at a station built in Liege. Firearms that were not tested were not branded and were not allowed for sale.

Over time, new laws were issued that spoke of more careful and strict control over the quality of weapons produced. Thanks to this, they gained fame and became a standard among their brothers. Now these rules are used not only in Belgium, but also in other countries involved in the production of firearms.

Browning Maxus shotgun

Home | Weapons | Smoothbore weapons | Belgium | Browning Maxus

The receiver of the Browning Maxus small-bore self-loading shotgun is made of durable aluminum alloy and has grooves for installing mounts for additional sighting devices.

The ammunition supply system is equipped with a cut-off device that allows the shooter to replace a cartridge without feeding the next one from the under-barrel magazine. A capacity limiter is installed in the under-barrel magazine. Thanks to the Turnkey Magazine Plug system, shooters can easily increase magazine capacity to maximum capacity when needed.

To power the magazine, the company's patented Speed Load Plus loading system is used, which allows for rapid loading of a cartridge into the chamber and rapid discharge of the under-barrel magazine.

To reload the Browning Maxus shotgun, the Power Drive Gas System is used, which allows the use of cartridges from 24 g to 64 g with maximum efficiency. The Lightning Trigger System provides an easy and at the same time confident trigger release with minimal trigger idling.

The Browning Maxus smoothbore semi-automatic shotgun has open sights: a ventilated rib with anti-reflective notches and a replaceable Hi-Viz fiber optic front sight for improved aiming in low visibility conditions.

In the production of the Maxus shotgun barrel, BackBored drilling technology is used - the bore diameter increases from the standard 18.4 mm to 18.8 mm. This increase in barrel diameter makes it possible to achieve an increase in flight speed and penetration power of the charge, better discharge of the charge and low recoil when fired.

The Browning Maxus hunting rifle features VectorPRO extended bullet entry technology. Together with the BackBored barrel drilling technology, this allows for minimal deformation of the shot charge when fired.

The wooden parts of the Browning Maxus shotgun are made from grade 2 walnut and oiled. The handguard has an original design developed by Browning specialists and fine checkering for better grip and control of the shotgun.

The handguard received a patented Speed Lock system, which allows you to quickly disassemble this unit for the necessary manipulations with it.

The ergonomic pistol grip stock has a wide range of options to tailor the shotgun to the shooter's individual characteristics. For this purpose, a set of gaskets is used to adjust the bend of the butt and a gasket to lengthen the butt (adapts to the butt plate). To dampen recoil, a butt pad made using Inflex Technology is used, which allows you to minimize its effect after the shot.

Replaceable Invector-Plus chokes provide excellent shot spray. The shotgun is equipped with 6 interchangeable Invector-Plus choke tubes. The Browning Maxus shotgun comes with an ABS case.

Technical characteristics of the Browning Maxus shotgun Caliber: 12/76 Weapon length: 1295 mm Barrel length: 760 mm Weight without cartridges: 2.9 kg. Magazine capacity: from 4 rounds

Smoothbore weapons

- India

- South Korea

- South Africa

- USA

- Russia

- Türkiye

- Belgium

- Ukraine

- Italy

- Philippines

Belgian arms manufacturers

A huge number of factories in Belgium produce high-quality Belgian guns. Let's consider the most popular and widely known companies:

- State Factory (abbreviated as FN). Located in the city of Erstal, which is located near Liege. It produces 90% of hunting weapons in all of Belgium. The company produces serial models that include self-loading, smoothbore shotguns and double-barreled shotguns with vertical barrels. Known as "Brownings", named after the master who made them, John Browning.

- "Dumulin." This factory produces mainly hunting rifles and rifles with a horizontal barrel.

- "Lebo-Kuralli". One of the revered companies, founded in 1865. The first guns it produced were produced under the August Lebeau brand. Thanks to the masters of their craft, original works appeared, which, in their quality, were in no way inferior to their English counterparts of the highest class. Such Belgian guns were highly valued even outside the country. For example, in Russia, the presence of this model in a gun store was considered prestigious, and therefore many owners tried to get at least one copy for their sales premises.

- "Augustus Francotte". They were also highly valued among us. These models were produced in several variations, from cheaper models to the most expensive.

Unfortunately, in the early forties, a huge amount of Belgian weapons were confiscated by representatives of the NKVD and sent for melting down, so most of the first models of hunting weapons did not survive to this day.

My experience with the Browning Gold shotgun

The vast majority of avid hunters and true fans of hunting weapons I know, for a number of reasons, have updated or expanded their hunting arsenal. For example, in almost fifteen years of hunting and shooting at the stand, I have done this many times.

The reasons that prompted me to purchase a new hunting rifle were different each time. Either dissatisfaction with technical or operational characteristics, or a desire to expand your hunting capabilities, or simply a tribute to fashion, and sometimes a whim.

Of course, the notorious financial issue also played a huge role. Although I bought one of my best shotguns, the “vertical” MTs-6-12, in 1984, as an almost penniless Soviet student, in a second-hand shop on Solomennaya Storozhka Street for 980 rubles (very old). The amount at that time was more than fantastic, and I was able to complete this purchase only thanks to the help of my many friends and parents, who had no idea about the real price of this thing. A lot of water has flown under the bridge since then, my “emtseshka” brought me a lot of joy with its quality, reliability and beauty during the hunt and at the stand. And she had no equal either among the elegant “Germans” or among her angular compatriots. Even when the latter were equipped with new clothes from master stock makers. I thought that I would no longer have to burden the Internal Affairs Directorate with my request for a purchase permit, especially since the procedure for obtaining it becomes more and more strange from year to year. But somehow I came across a catalog from Browning.

Frankly speaking, the Browning legend, the well-known AVTO-5 model, never attracted me (due to a number of, in my opinion, objective reasons), as well as all sorts of modifications of the Model 25 vertical, not to mention pump-action engines. But the company’s new offer - the GOLD model, even interested me very much.

Undoubtedly, the main reason that prompted the purchase of another gun was the desire to change the characteristics of the gun by simply replacing the choke.

Just think, in less than a minute, right in the “field” or while resting after hunting snipe with a cop, having the same gun, I can easily switch to duck hunting in flight, for example!

I have never had a gun that has such capabilities. And frankly speaking, none of the guns that I had, not excluding the beloved MTs-6, were fully suitable for hunting with a cop in the swamp “trifles”, hunting, which I truly discovered for myself only with the appearance in my the hunting life of a devoted prankster and, undoubtedly, a talented gun dog, a shorthaired pointer named Nice.

Everything seemed to be going well for us, but the only consequence of firing at a snipe that flew out from under the rack, from a gun that had a standard set of choke constrictions for a double-barreled shotgun - half/choke and a barrel length of 750 mm, as a rule, was either a miss and bad looks from the dog at me side, or presented to me in a state of extreme excitement, a shapeless set of legs, beak and frightened snipe eyes, or rarely a full-fledged trophy, and even then only after an accidental hit by peripheral or severely deformed pellets of a shot sheaf.

So, the Browning-GOLD 28” model was chosen as the starting option. Lightweight (3, 150 kg) and theoretically quite reliable gas outlet with a barrel length of 710 millimeters, a magnum chamber and a set of interchangeable choke constrictions was ideal for all types of hunting that I practiced in all seasons of the Russian hunting year.

With it I could spend the “holy” ten days of spring hunting, shooting woodcocks, I could take a capercaillie on a lek, or, having accepted the invitation of friends, go goose hunting in the Arkhangelsk region, grabbing magnum cartridges and screwing a choke/extension into the barrel, or preparing accordingly , shoot black grouse on a lek or drakes with a decoy. And in the fall, having loaded light cartridges with a “nine” and installed a cylinder, shoot snipe from under a cop and with the same cylinder go on an elk or wild boar hunt in the snow, all with one gun!!! THIS IS OPPORTUNITY!

The appearance of this model, manufactured for the European market, in my opinion, is quite consistent with the canons of modern rifle design. The gun has a strict, functional and at the same time not devoid of some attractive shape. True, the forend looks a little heavy, but it can’t be otherwise, there is a gas-operated reloading mechanism inside, and not just a tubular under-barrel magazine, like the Benelli. The pistol stock with a thin and comfortable neck is in perfect harmony with the slightly chopped shape of the stock. In general, the gun looks quite finished. And the presence of longitudinal, so-called “tiger” stripes on the “nut” of the gun stock shown in the catalogue, even gives it a certain element of grace.

The presence of swivels, which every model from Browning (and other foreign companies) cannot boast of, makes the gun even more convenient and suitable for the conditions and specifics of Russian hunting.

But later, upon closer acquaintance with the gun, it turned out that swivels have both an advantage - the ability to quickly remove from the gun, and disadvantages - excessive length and mobility, and therefore a tendency to make all sorts of “clunking” sounds when colliding with the stock and the trunk. But this is not such a problem, especially since it is easy to deal with, at least by simply fastening the shoulder strap.

Among other things, the company promised a “unique” opportunity to easily change the vertical angle of the gun stock due to spacers between the block and the butt. These spacers have a different angle between the upper and lower planes. This, in the opinion of the creators, gives the hunter the opportunity to adjust the characteristics of the box to the individual characteristics of his figure. In fact, it does add some value to the gun, but only to some extent. For example, a spacer that increases the angle of decline ultimately suited me. Having placed it, I thereby lowered the butt itself down, fitting it under my neck. And an additional three-millimeter leather gasket between the butt plate and the butt made it possible to almost completely adjust the individual grip and fit of the gun. But, it seems to me, I have not been able to completely merge with the gun until now.

After the purchase, it turned out that the stock did not have any kind of butt in the horizontal plane. Probably, the creators thereby wanted to make the stock generally universal and suitable for shooting by both right-handers and left-handers. Oddly enough, the absence of this death does not bother me, at least for me. Although a small die to the right (for right-handers) and at the same time the presence of a “cheek” on the left side of the stock would not in any way damage, but on the contrary, would give the gun a more attractive appearance, undoubtedly to the detriment of its versatility and, as a consequence, some increasing its price. But maybe the creators should have done this, at least with expensive one-piece copies of this model.

I would like to note that the quality of the material (walnut), as well as the quality of its manufacturing and processing on ordinary “production” guns, is very good, judging by the year of operation of my gun.

Although, frankly speaking, immediately after purchasing the gun I took a number of preventive measures and, in my opinion, conducive to preserving the stock of the gun. Namely, after removal from the block, the entire internal part of the very thin-walled (tribute to the struggle for weight) and unreliable-looking stock was treated with linseed oil and carefully heated over gas (to better absorb it). I once studied painting and know well that linseed oil, used in painting, has the ability to polymerize in the air, creating a fairly durable water-repellent coating. A day later, on the oil that had not yet completely dried, I applied a layer of natural beeswax dissolved in lighter gasoline. Once the gasoline had evaporated, the stock was carefully heated and the wax was sanded off with a brush. And so on up to three times.

I repeat that the main purpose of this procedure was the desire to cover the inner surface of the butt, which was completely unprotected by the manufacturer. Why this was not done at the factory remains a mystery to me. After all, the forend is perfectly protected. Having modern materials, capabilities and technologies, this is how to make a compassionate consumer suffer.

There is a lot of talk about the barrel and barrels in general in the hunting community. And in any hunting store, from opening to closing, there will always be at least one “specialist” who will suggest: “Come on, let me take a look.” Otherwise, he will insert a cartridge case without a capsule into the chamber, and after looking into the barrels, like Galileo through a telescope, he will say: “The ring sits within the ring.” Ten pieces in total.” And the verdict: “Get the guns you need, you won’t regret it.” This can often be heard in our stores, and the reason for this is our gun industry. Believe me, the former owner of such serial guns, including two single-barreled MTs-21-12 and one MTs-20-01 that I had at different times.

Everyone knows that when soldering two barrels it is difficult to achieve alignment, and even so that the barrels do not “lead”. It is more difficult to ruin a single-barreled gun; in the worst case, you have to solder the bar, and in the best case, a platform for the front sight. But no, our manufacturer can ruin everything.

I know this for sure, because I recently helped one novice hunter choose a gun. The gun is so-so, IZH-81, the barrel length, if memory serves, is 600 mm or so, the muzzle constriction is a cylinder, and there is no strap, and of the five barrels examined, I found only one, and even then with the least visible curvature and variation in thickness . I know, I know, it doesn’t affect the battle, but it’s a shame for our modern left-handed gunsmiths. So the specialists walk around “Hunters”, looking at frankly poorly made guns.

Of the three “golds” I examined when purchasing, none had any complaints regarding the quality of the barrel, and therefore the main criterion when choosing a gun was the selection criterion for the beauty of the wood of the stock. And looking ahead, I will say that I was not mistaken. You don't have to look at the barrels and mechanics.

Drilling the bore is originally written back bore. The name “back bore,” which is difficult to translate into the native language, in practice means that the diameter of the bore is slightly increased in relation to the standard accepted by Browning for 12-gauge shotguns and ranges from 18.5 to 18.9 mm. In fact, according to the company, this should inevitably lead to an increase in the flight speed of the shot by reducing the friction of the projectile on the walls of the barrel, as well as to the inevitable improvement of such an indicator as the uniformity of the scree. The consequence of this, as the company guarantees, will immediately be an increase in the number of game heads brought by the hunter to his wife. As proof, several bright color drawings were provided, actually showing that the diameter of the bore had actually increased, as well as a photograph of a target, picturesquely and fairly evenly pierced in various places with shot.

I will probably refrain from further bilious comments. But I can definitely say only one thing: during the hunt with the Browning, the number of lost wounded animals sharply declined, however, in my opinion, solely due to the fact that the start of hunting with a new gun coincided with the period of creative growth of my dog. But seriously, in the spring of 1998, out of the eleven woodcocks I shot, we didn’t find one at all, and two turned out to be wounded animals that had to be killed, which is always unpleasant. Autumn also pleased us with fairly effective shooting and a virtual absence of lost game.

The chamber is three inches or 76 mm long, according to the developers, allowing the use of both standard 70 mm long cartridges and also magnum cartridges, which are quite exotic in Russia. This was tested at the first opportunity on the stand and at the first practical hunt in the same spring of 1998. At the capercaillie lek, a single shot was fired with a Taiga magnum cartridge, shot No. 0, 46 g, at a leering rooster at a distance of 55 of my steps (about 40-45 meters). This lucky shot is not for statistics. He is the only one. The barrel contained a 50 mm choke/extension, D/S-1/1.

The standard set of chokes for this model, or, more correctly, invectors, consists of a cylinder with pressure or D/S-1/4, half choke D/S-1/2, three-quarters of the choke D/S-3/4 and a full choke D/ S-1/1. Later I purchased a cylinder and a 50 mm choke/extension with D/S-1/1.

As a result of practical application, the following were selected: on the stand (circle and sporting) - a cylinder with pressure (D/S-1/4) and a cylinder, cartridges mainly Taiga-sport; on draft - pay (D/S-1/2) very confidently replaced the cylinder with pressure (D/S-1/4), coupled with standard Taiga cartridges 32 grams of shot No. 7, as well as cartridges of their own shell, about which I I will say below; on capercaillie current, as already mentioned, the choke/extension cord (D/S-1/1) is beyond competition (since there are simply no competitors); in the swamp for snipe - the cylinder was successful, nothing else was installed; a cylinder with pressure (D/S-1/4) and a cylinder that I intended to use for wild game hunting, but I didn’t have to shoot (for testing the combat with a bullet and buckshot, see below); in the fall I shot ducks from the rise with a cylinder, a cylinder with pressure (D/S-1/4) and less often with a half-shot (D/S-1/2) with the same success, it seemed to me; during the flight - the choke/extension (D/S-1/1) was slightly superior to the pay (D/S-1/2); the three-quarter choke invector (D/S-3/4) has never been used at all. In any case, neither I nor the dog remember this.

In general, the main advantage of a gun with interchangeable choke constrictions is its unique versatility in practical use, which is very convenient and completely justified.

The gas exhaust mechanism of the Browning-GOLD model also deserves a special mention. This is an interesting and, in my opinion, too complex engineering solution. The fact is that the company set out to produce a universal gas vent reloading mechanism that works flawlessly with a very large variation in the pressure of powder gases (when firing both light sports cartridges with a shot load of 24 grams and powerful magnum cartridges with a shot load of 46 grams). To achieve this goal, a special piston/compensator was introduced into the mechanism. Externally, it is a small cylinder, structurally consisting of seven parts and working simultaneously both as a piston/pusher for the reloading mechanism and as a kind of bypass device. When the pressure of the powder gases exceeds a certain norm, the bypass device simply opens slightly and releases excess gas, thereby reducing the operating pressure in the system. In general, when purchasing, I was frankly afraid for this very piston/pusher. Well, how can the unburnt remains of the “Falcon” gunpowder, having treacherously penetrated into this unit, disable it at the most crucial moment. But practice has shown that there is nothing to be afraid of, it works impeccably reliably, and requires minimal maintenance: a few drops of gun oil (a little!) during the next cleaning. Not so long ago, for complete peace of mind, I disassembled this unit, washed, cleaned, lubricated and reassembled. But if I had not done this, it would not have gotten worse.

To be fair, it should be noted that other arms companies (Beretta, for example) solved the exact same problem no less effectively, but using simpler methods.

Another seemingly unreliable element of the reloading mechanism, the bolt pusher (a plastic cylinder with a steel rod), did not remind of itself at all during a year of intensive use, and in fact turned out to be a very “decent” unit.

The trigger mechanism with a cartridge feeder is made as standard for semi-automatic machines. I am glad that there is simply no medieval plate mainspring. Instead, there is a more reliable and “fast” spiral one. Before buying a gun, I often heard the opinion that the domestic “Zhevelo” was too tough for Gold’s trigger mechanism. I have a certain amount of “zhevelo” capsules left in stock from the old days, and, of course, I loaded about a hundred rounds of ammunition and successfully shot them all. Although, for the sake of interest, I conducted a kind of research, comparing the efforts that must be made to cock the trigger of the MTs-6 and Browning-GOLD shotguns, while not being too lazy to remove the trigger mechanism of the MTs-6. For gas exhaust, this effort was clearly less. “Research”, of course, is extremely inaccurate and subjective. There are a huge number of factors that influence the reliability of breaking the capsule, the size and shape of the force of the flame of the igniting composition: this is the diameter of the striker, the radius and shape of its working part, the power of the return spring, and finally, the thickness of the walls of the capsule itself. Draw your own conclusions.

The longest period of operation (ten days) without cleaning the trigger mechanism occurred in the spring of 1998. The presence of unburned powder, needles and other specks of dust has never led to delays or malfunctions in the operation of the mechanism.

By the way, during operation it turned out that the firing mechanism with a cartridge feeder can be conveniently cleaned by simply rinsing in a container of hot water with a small amount of dishwashing detergent, such as Fairy, dissolved in it, followed by rinsing under running hot water, drying and lubricating. It is convenient to use a hair dryer for drying. This type of cleaning quickly and reliably removes carbon deposits, unburned powder residues and old grease.

The block is made of light alloy. In general, the block with a tubular under-barrel magazine and shank built into it weighs extremely little. All this was disassembled only once, cleaned and lubricated. No traces of corrosion were found on the magazine springs and shank. But on the outer surface of the store, just opposite the gas outlet channels, hot powder gases left visible traces.

The shutter is made simply and conscientiously. All parts are chrome plated and require minimal maintenance. True, one detail, the shutter blade, let me down once. It seems that I put it back in place after cleaning, but it’s not completely visible. And after the first shot during the flight, I suddenly noticed that he was not there. I found it in the grass under my feet completely by accident and amazingly quickly. I was lucky, I was standing on a railway embankment, and it was still light. In general, now I automatically feel it several times during the hunt.

It is also very frustrating that the developers did not think at all about the possibility of quickly and silently emptying a magazine for moving from one hunting spot to another, for example. No matter how hard I tried to adapt, “it was all to no avail.” Therefore, now I either pull the bolt until the magazine is empty, which is not always convenient, it’s noisy, and in general, after this operation, sometimes I have to take the cartridges out of puddles, snow or sand, or I turn on the cartridge cutter, put the gun on safety and pull the bolt , removing the cartridge from the chamber. And as you know, transporting a gun in this condition is unsafe and generally illegal.

Every detail in this gun is made with a high degree of unification. And when you look at the individual components and parts, the thought itself arises that take a dozen of these guns, take them apart piece by piece, mix all the parts and reassemble the ten guns - and each of them will work normally. On the one hand, this seems to be good - an indirect indicator of reliability. On the other hand, in my opinion, even in an ordinary hunting rifle the soul and hand of the master should be felt. Still not an AK-47 and not an M-16.

What can you say about the quality of coatings? During operation, no traces of corrosion appeared either on the internal (chrome-plated) or on the external surface of the barrel. The coating of the box also turned out to be quite resistant to external climatic and not at all gentle mechanical influences. But the absence of any kind of protective coating on the inner surface of the butt is very alarming. But as experience shows, this can be fought (see above). There are probably no special care features. I used the usual objects, devices and materials for this. However, it should be noted that to clean the gas outlet channels, a brush was used to care for the channels of smoking pipes and mouthpieces. “Glukhar” and “Berkut” oils are quite suitable, but experience says that sports-active Extra Gun Oil is better, especially for various kinds of semi-automatic and pump-action guns, apparently due to the presence of modern Teflon and silicone additives. The barrel itself was washed a couple of times in hot water. Legia aerosol was used to care for the wooden parts, but linseed oil and, in camping conditions, sunflower oil are quite suitable, especially in rainy weather.

The use of standard Taiga cartridges leads to the inevitable deposition of a small amount of unburnt powder residue on the inner surface of the barrel, the bolt and the inner surface of the box. But this has never led to failures or delays in the operation of the gun’s automation. When shooting with “Sport-Active” cartridges, old bench cartridges “Hubertus”, “Record” and “Taiga” cartridges on a round stand, no difference in recoil, quality and results of the shot was found.

Loading cartridges for a hunter is a kind of ritual, an opportunity to renounce everyday problems and troubles, at least for a while to create in one’s imagination pictures of past and upcoming hunts, even to express oneself in some places. Everyone understands the need to check the engagement and zero the gun, but not everyone does this. This was interesting to me, so, in spite of everything, the gun was shot. Sighting was carried out in early spring at the dying Moscow Lokomotiv stand at a temperature of about 0 degrees at a distance of 15-20 meters with shot No. 9, based on shooting snipe from under a pointer, as well as shot No. 7 at a distance of 20 and 37.5 meters (woodcock ) and shot No. 5 (duck) at a distance of 37.5 meters. The optimal selection of the charge and projectile was assessed by the absence of “windows” in the area of shot scree with a diameter of 750 mm. A “window” was considered to be an arbitrary area of the target, no less than the size of the intended prey (the silhouette of a woodcock carcass, devoid of at least two holes, was taken as a reference point). There was no testing of the combat or shooting of the gun with standard factory shells and magnum shells at all. As a result of the zeroing, it turned out that the optimal charges of gunpowder, shot shells and equipment conditions are: for short-shooting cartridges - sleeve L = 70 mm, Sokol gunpowder - 2.0 g or Sunar - 1.9 g, polye seal , greasy felt, cardboard spacer, shot No. 9 - 30 g, rolling with an asterisk, regular twisting, soldering the junction of the petals. When shooting, an invector was installed - D/S-1/4 (I didn’t have a cylinder at that time). The possibility of using the now available polyethylene seals-dispossessors was tested, but in this case, when shooting at a distance of 15 meters, the appearance of “windows” was noted on the target; for shooting at a distance from 20 to 40 meters, depending on the invector used, I selected the following ratios and conditions for the projectile: with a cartridge case L = 76 mm, “Falcon” gunpowder - 2.0 g or “Sunar” - 1.95 g or “ Salyut” – 1.9 g, cardboard with a thickness of at least 3 mm, felted wad, fiberboard, cardboard, shot No. 7 or 5 – 36 g, star, twist, soldering. With a sleeve L=70 mm, “Falcon” gunpowder – 2.05 g or “Sunar” – 1.95 g, plastic wad container, shot No. 7 or 5 – 35 g, asterisk, twist, soldering.

When firing the bullet, ready-made cartridges from Fiocchi were used, a Brenecke bullet weighing 31.5 g with a felt shank. Shooting was carried out at a distance of 37.5 meters from a stop. An invector – D/S-1/4 – was installed in the barrel. A total of fifteen shots were fired at the target. All the holes, with the exception of one, fit into an oval 300 mm high and 150 mm wide. Some of the holes touched each other. The central point of impact clearly did not want to coincide with the aiming point and was located 100 mm above and 50 mm to the right of the bull’s-eye. But it’s not scary, the main thing is to know about it. The result of firing with standard Taiga magnum cartridges, 8 mm buckshot/15 buckshot in a shell, a series of five shots, D/S-1/4, was the presence on average of almost 10 holes in a 1x1 m target at a distance of 37.5 meters and a bruise on the right forearm.

The center of gravity of an unloaded gun is located at a distance of 165 mm in front of the trigger, which is quite a lot. But the successful location of the centers of mass makes the gun very maneuverable. In any case, you can successfully shoot doubles from it, as well as take “fast” targets on the eighth place of the round stand. After all, the gun is designed for a physically developed person above average height. The “grip” stock also lies confidently in the hands when shooting in the rain, with wet hands and gloves. The large front sight clearly “sits” on the bar and in general it is convenient to aim both when shooting “in flight” and at a stationary target in the twilight. Recoil during intensive shooting with standard cartridges is very easily tolerated, but when shooting with sports cartridges with a 24 g load of shot, it is simply not felt. But shooting with magnum cartridges, and even in light clothing, reminds you of yourself the next day with severe pain in the forearm. But this is tolerable, since you don’t have to shoot such cartridges often, and in the moment of excitement you simply don’t pay attention to such little things. The safety guard is located very conveniently - under the middle phalanx of the index finger. And in order to turn it off, it is enough to lightly press the fuse during a jump or immediately after it. All this can be done without being distracted from aiming.

I think many hunters would benefit from having dovetail slots on the shoe for mounting optics, etc. This option is available on Browning models produced for the American market.

By the way, I am pleased to see the appearance of a gun for shooting supermagnum charges in the Browning-GOLD lineup. Such a gun is not always and not everyone needs it, but the fact itself suggests that the gun has stood the test of time, and its performance and strength characteristics are at a high level.

There is a promotional photo in the Browning catalogue. It depicts how a dashing foreign hunter stands in the pouring rain, with a wild smile and waist-deep water, placing, of course, a piece of Gold on his right shoulder. The hunter pretends to confidently overcome either a stormy mountain river or an African mudflow. The picture must have been designed to completely amaze the potential buyer and prove to him the resistance of this model to the most incredible atmospheric influences.

I can say one thing.

During its operation, my gun was completely submerged in water once, was used ten times in the rain and pouring rain, spent the night with me in the open air on a capercaillie current several times, lay in the grass, hay, snow and on pine needles, a couple of times once it fell together with the owner and separately, just like that and in the mud, with all this, nothing happened that would lead to delays in the operation of the gun or the need to stop using it. The gun continued to be used after purely external cleaning of foreign objects. In total, more than two thousand shots were fired from it during the year of operation. In this case, mainly sports cartridges from 24 to 32 grams of shot No. 7, 7 1/2 or 9 were used, as well as hunting cartridges of 32 grams (Taiga, Sport-Active) or their own shells of 30-36 grams of shot (9, 7, 5, 3, 1), bullet and buckshot cartridges of factory shells. About 100 shots were fired with magnum cartridges while hunting and on a stand, at air temperatures from -22 to +25 degrees Celsius. As a result, not a single mechanical failure, not a single crack in the wooden parts of the gun and not a single delay in the operation of the mechanism! Pah-pah-pah. See also:

How to choose and buy the right gun

For a clearer observation of the rings, it is advisable to look not at the light, but at the light on the floor, or more precisely, you need to point the barrel at a window frame, so that the floor of the barrel is illuminated by light and the floor is not, that is, the barrel should be partially darkened

Belgian 12 gauge shotguns

Among smoothbore shotguns, 12 gauge is especially popular. This is because this model is easier to handle. You can easily handle the size of the powder charge. There are also no restrictions when choosing a charge: bullets, buckshot, shot. Any types and numbers can be used.

Among the Belgian 12 gauge shotguns, the following models are widely known:

- "Walrein" ("Legrand"). This type is famous for its high quality steel.

- "Grand Rus". A distinctive feature is the fine engraving that completely covers the block.

- "Prince Albert" Minimal engraving applied to the sides of the boards.

- "Count Kodashev" Weapons with small patterns in the English style.

- "The Parisian Count". It has one escapement and a wide reinforced strap.

- "Colorado". Also has one descent. The rounded block is covered with a small pattern.

- "Boss Verre." Low-set barrel and small block. This model was released in memory of the late J. Verne. He ruled the company until 1982.

These are the most popular and widely known models of this caliber.