Scheduled repairs of the automatic transmission torque converter are carried out at a mileage of 100 - 150 thousand km. By this time, consumables wear out and the friction lining wears out. The breakdown of the torque converter is determined independently by sound, sensations, and tests. Knowledge of the structure and operating principle of the hydraulic system will help you draw the right conclusion.

What is a torque converter?

A torque converter (GDT) of an automatic transmission is an analogue of a clutch in mechanics, designed to transfer engine power to the gearbox. The driver does not directly control the hydraulic drive, but by pressing the gas pedal he increases the rotation of the engine, and therefore the gas turbine engine. Due to its design, the torque converter is capable of increasing torque.

Externally, the hydraulic drive resembles a torus, for which it received the nickname “donut” from auto mechanics. The donut clutch operates smoothly and quietly, but uses more oil than a manual clutch.

According to sales statistics, when choosing between automatic transmission, DSG and CVT, drivers prefer the “classic” automatic transmission with a torque converter. The choice is justified by the proven reliability of the design, long service life, and ease of maintenance.

Automatic transmission torque converter design

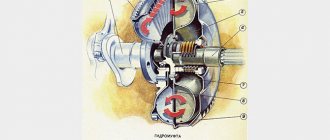

The working elements of the donut are enclosed in a sealed housing filled with ATF oil. You can see the internal condition after cutting the weld.

The torque converter consists of three bladed wheels that are not mechanically connected to each other. A pump wheel is welded to one half of the housing bowl. It is rigidly connected to the engine flywheel, so it begins to rotate when the engine starts.

Read

Do-it-yourself diagnostics and repair of Mazda automatic transmission

A turbine wheel is installed opposite the pump. In the center of the wheel there is a hub and a bearing through which the turbine rests on the gearbox shaft. When the engine starts, the turbine is stationary.

Between the wheels there is a reactor with an overrunning clutch. The reactor is designed to automatically switch torque converter modes.

A large volume of oil in the donut leads to waste of engine energy on mixing and heating the liquid, and hence increased fuel consumption. To compensate for losses, engineers added a locking clutch to the design: a plate with a friction lining and a torsional vibration damper.

Principle of operation

The operation of the hydraulic drive is based on the conversion of mechanical energy into hydraulic energy and back into mechanical energy for transmission to the transmission:

- When the engine starts, the oil pump is connected and the pump wheel of the gas turbine engine begins to rotate.

- Under the influence of centrifugal forces, the oil is repelled from the wheel blades and transferred to the turbine blades. The shape of the blades is selected so that the speed and direction of oil flow creates maximum torque converter efficiency.

- As the speed increases, the pressure force on the turbine increases. It begins to rotate and reaches the speed of the pump wheel.

- The reactor redirects oil flow, helping to accelerate the pump, increasing torque.

- The energy is transmitted along the shaft to the gear shift mechanism and then to the wheels.

In new automatic transmission models, the gas turbine blocking clutch is connected at second speed or earlier, based on a signal from the ECU. Control occurs by releasing the pressure between the plate and the gas turbine engine body. The pressing force from the turbine forces the coupling to engage with the surface of the housing. As a result, the engine is directly connected to the gearbox.

Read

Maintenance and repair of Hyundai ix55 Veracruz

Automatic transmission torque converter: how it works

The operation of the torque converter, based on the transmission of torque from the internal combustion engine to the transmission, occurs without a rigid connection between the engine and the gearbox. The force is transmitted through a recirculating fluid flow inside the gas turbine engine. The pump wheel, rotating together with the flywheel, creates a fluid flow and directs it to the turbine blades, ensuring the transmission of force.

All components of the torque converter are enclosed in a sealed housing filled with a special ATF transmission fluid. The housing is a closed toroidal chamber with blade wheels located inside it (pump, reactor and turbine wheels).

The torque converter itself, as a rule, is located on the flywheel of the internal combustion engine of the car, while the turbine wheel of the automatic transmission “donut” has a rigid connection with the gearbox shaft.

Basic torque converter malfunctions: symptoms

Modern automatic transmission torque converters are fully computer controlled, that is, numerous sensors monitor the pressure and speed of the shafts inside. All this is necessary for the torque converter lock to operate. This design improvement led to a decrease in the reliability of this automatic transmission unit.

More precisely, there was a clear decrease in operating life under the most severe and even moderate operating conditions in terms of loads. It is also important that malfunctions in the gas turbine engine that arise over time can cause problems with the internal combustion engine and automatic transmission of the car. Therefore, it is very important to quickly find and fix the breakdown.

List of main problems:

- Wear of the intermediate bearing or support bearings (operation of the transmission without load is accompanied by an extraneous rustling sound). The problem is eliminated by disassembling, troubleshooting and replacing worn parts;

- Oil filter contamination (the appearance of gas turbine engine vibrations at almost all speed modes). The problem is eliminated by replacing the filter and transmission fluid;

- Damage or wear of the overrunning clutch (acceleration dynamics decrease while accelerating). The problem is solved by replacing the coupling;

- Damage to the splined connection of the turbine wheel with the gearbox shaft (vehicle movement is impossible). The problem is solved by restoring the damaged connection or replacing the torque converter as a whole;

- Partial or complete damage to the wheel blades or reactor (the appearance of a metallic grinding sound). Eliminated by replacing damaged elements;

- Poor quality ATF or insufficient amount of transmission fluid, clogging of the transmission cooling system (overheating and failure of torque converter elements). They eliminate the problem by replacing damaged elements, cleaning radiators, filters, changing the lubricant, etc.;

- Malfunction of the control system (spontaneous gear shifting). The problem is eliminated by diagnosing and replacing electronic elements;

- Worn torque converter locking linings. The result is malfunctions, jerking, slipping, loss of traction, etc. It is necessary to remove the torque converter, disassemble, troubleshoot and repair.

Symptoms of a problem

The driver does not feel the operation of a working torque converter, so the appearance of new sounds, vibrations, and jolts indicates a problem in the donut. Indirect signs include increased fuel consumption and high engine speeds.

| Problem | Possible reason |

| Oil leak | Wear of clutch, oil seals, seals |

| At the start the car slips, but after 60 km/h it drives normally | Wear of the turbine wheel hub, which causes slipping at high speeds |

| You can hear the impact of a metal part, rustling noise when changing gears | Bearing damage |

| Metallic knocking at idle, loss of smooth gear shifting | Friction lining wear |

| Strong vibrations and jerking when driving at a speed of 60 km/h | Uneven friction wear |

| Metal particles in oil | Destruction of parts |

| Rattling, grinding | Destruction of wheel blades |

| The car does not move, there is no push when switching the selector or the car is slipping | Oil pump or torque converter turbine does not work |

| The car drives “cold”, after warming up it slips in place | Contamination of the gas turbine engine and filter mesh, causing the pressure in the system to drop |

If during repairs you only change the part that has failed, then the problem will soon return. To prevent the situation from reaching the point of replacing the torque converter, you need to look for and eliminate the cause of the problem.

Do-it-yourself torque converter diagnostics

The sequence for diagnosing an automatic transmission donut with your own hands:

Read

Replacing the automatic transmission torque converter oil seal with your own hands

| Degree of troubleshooting | What to do | When will it help? |

| Easy. Diagnosis can be made without tests | Check level, change ATF and filter | · the appearance of jerks or delays when changing gears; · slight vibration at speeds of 60-80 km/h; · dirty oil; · incorrect fluid level; Bubbles on the dipstick. |

| Average. Diagnosis can be made without dismantling | Clear fault codes from the on-board computer | · faulty wires, solenoids; · sensor malfunction; · problems with the locking clutch; · breakdown of parts. |

| Remove and inspect the pan for metal and plastic particles and sediment | ||

| Check system pressure | ||

| Test the blocking of the gas turbine engine: as the engine speed increases, the speed should increase | ||

| Heavy. An autopsy is necessary for an accurate diagnosis. | Disassemble the donut | · the oil smells like burning and contains large particles; · strong vibrations and knocking; · oil leak; · rattling, grinding; · the car does not move or is slipping. |

Most often, a torque converter needs to be repaired due to baldness of the lock-up clutch or aging of the seals. In this case, you have to additionally flush the valve body, change clogged solenoids, and worn out friction discs. Such service repairs are not cheap, but they will help prolong the operation of the original automatic transmission.

How to remove an automatic transmission torque converter

Work on removing the torque converter requires not only certain knowledge, tools and special high-precision equipment, but also skills. Improper work, as well as errors during assembly, can lead to damage to the torque converter elements and the box itself, as well as in some cases to the internal combustion engine.

The general procedure is as follows:

- drive the car into a pit or lift it on a lift

- Taking into account the fact that the automatic transmission is heavy, you need to consider how to lower the removed box (it is optimal to have a transmission jack).

- Before removing from the automatic transmission, you need to disconnect all connections of different car systems (pipes, connectors, rods, etc.)

- Carefully unscrew the box mounting bolts (special wrenches may be required);

- Although removing an automatic transmission is similar to dismantling a manual transmission, you don’t have to drain the oil from it before removing the box. However, when disconnecting the oil supply pipes to the oil cooler, they must be turned off to avoid oil leakage

- several vacuum lines can be connected to the vacuum corrector (if available) and other elements of the box;

So, after you have managed to disconnect the torque converter from the automatic transmission, you can begin to disassemble it for repair work. Main stages:

- drilling a technological hole to remove the working fluid;

- dividing the body into two parts by cutting off the weld;

- initial disassembly of the torque converter and washing of all its internal elements;

- inspection for damage or defects, troubleshooting;

- replacement of necessary parts;

- torque converter lockup repair;

- replacing the oil seal and O-rings;

- welding the torque converter, checking welds, balancing.

Donut repair and its cost

Repairing automatic transmission torque converters or CVTs with your own hands is problematic. You need knowledge about the operation of a specific donut model, a lathe, welding equipment, and stands for testing the assembled product. Repairs made by an inexperienced person can “kill” the hydraulic drive.

Find out exactly how much rub. Repairing the torque converter at a service center will cost you only after a full diagnosis, since the price is affected by:

- age and general condition of the car;

- automatic transmission brand and donut model;

- difficulty of torque converter failure.

Average prices for donut repair work:

| List of works | Price, rub |

| Removal and installation of automatic transmission | 12000 |

| Disassembling the torque converter | 800 |

| Assembly and testing on stands | 2000 |

| Pump wheel: | |

| Repair | 800 |

| Hub replacement/repair | 1000/600 |

| Turbine: | |

| Wheel repair | 500 |

| Hub replacement | 600 |

| Locking Clutch: | |

| Friction lining sticker | 400 |

| Locking system repair | 2000 |

| Reactor: | |

| Repair | 500 |

The cost of rebuilding a torque converter is affected by the complexity of the automatic transmission:

- for the repair of a donut 4, 5, 6-speed gearbox they will charge 5,000 - 10,000 rubles;

- for repairing a donut 8-speed gearbox - 10,000 - 15,000 rubles.

The most expensive torque converters to repair are installed in automatic machines:

- The most expensive torque converters to repair are installed in automatic machines:

4HP24;

- 5HP19;

- 6HP26;

- ZF6HP26/28/32;

- ZF8HP45/55/70;

- ZF9HP48;

- 722.9;

- 4R100;

- 6R80;

- A750F;

- TR60-SN;

- TR80-SD.

How the repair works:

- The craftsmen remove the box and dismantle the torque converter.

- Drain the liquid.

- The gas turbine engine is fixed on a lathe and the weld is cut.

- Clean parts from dirt manually or in a washing machine.

- The master examines the components of the donut and rejects the faulty ones. Parts are restored or replaced with new ones.

- On a special machine, a friction lining is glued onto the locking clutch.

- The next stage is assembling the unit with new consumables.

- The body is welded on a machine.

- Check the pump hub runout, bearing clearance, and tightness. Carry out balancing.

- Install the gas turbine engine and automatic transmission in place.

Torque converter repair stages

Repair of gas turbine engines is carried out in several stages. First, the torque converter is cut, then it is thoroughly washed, removing wear products, faulty or worn parts of the unit are replaced, after which, upon completion of the above work, it is welded again.

The repair of torque converters is completed by checking the tightness of the weld, the alignment of the parts (their location is geometric, on the same line) and comprehensive balancing of the entire unit.

A torque converter repaired in accordance with technical requirements fully restores its service life and works like new for many years. This will allow you to save significantly on the purchase and installation of a new unit. And in addition, repair of automatic transmission torque converters, carried out in a timely and high-quality manner, allows you to avoid major transmission repairs and increase the service life of the vehicle.

What is a fluid coupling

Unlike a torque converter, a fluid coupling does not change engine torque, but transmits it directly to the transmission. Therefore, the design of a fluid coupling is simpler and includes: a housing, pump and turbine wheels rotating in an oil environment.

The unit is installed in transmissions of trucks, buses, tractors and agricultural machinery.

Signs of a fluid coupling malfunction

Since the fluid coupling is a “simplified version” of the torque converter, their malfunctions are similar:

- car slipping due to broken hub splines;

- metallic knock from a faulty bearing;

- leakage of liquid through worn seals, etc.

Like the torque converter, the fluid coupling suffers from overheating and contamination of the oil in the automatic transmission. If there is no pressure, the unit will not work properly, which means the machine will not move.

Fluid coupling repair

Repairing a fluid coupling is similar to restoring an automatic transmission donut. Due to the absence of a friction lining and a reactor, the cost of work and materials will be lower.

Replacing an automatic transmission torque converter in Moscow

Replacing the torque converter of an automatic transmission of a car is a procedure for repairing the main transmission unit. Note that failure of its components usually occurs at fairly long mileage. However, there are many factors that contribute to reducing the safety margin of an automatic transmission. Firstly, these are overloads. They can have different shapes. For example, this could be constant aggressive driving or frequent transportation of heavy loads. Secondly, they include untimely or poor quality service. An oil and filter change is necessary every 30-40 thousand kilometers. It is important to use high quality materials. Thirdly, minor problems that are not resolved on time. Even if the defect is not very significant, it must be corrected as soon as possible.

Features of automatic transmission

The gearbox serves to transpose torque from the engine crankshaft to the drives. The chain may also include a transfer case (for all-wheel drive models), gearboxes (for all- and rear-wheel drive vehicles), as well as a driveshaft. Unlike mechanics, the driver's participation in the process is minimal - he only needs to select the transmission operating mode. Further processes occur due to liquid pressure. All this greatly simplifies the process of operating the car.

The torque converter is an important element of the automatic transmission. It is connected to the crankshaft flywheel and serves as a torque transmitter and converter. It is a housing that encloses a turbine, reactor, and pump. All these elements constantly work in a special liquid. The service life of the unit largely depends on its condition.

Recovery process

The problems that lead to replacing the automatic transmission torque converter of a car appear quite clearly. These are, most often, shocks and jerks when changing speeds. Of course, at first they appear rarely and not very significantly. But if the situation is ignored, then the strength of the defects will only increase. Of course, in many such cases, repair of the mechanism is suggested. But there are also options for replacing it with a used one or a new one. Naturally, their prices will vary significantly.

Let's consider the main stages:

- Oil drain

- Removing the pallet

- Partial troubleshooting of the gearbox

- Removing the torque converter

- Surface cleaning

- Installation of a new mechanism

- Assembly

- Pouring new material

If you choose a used mechanism, then you should purchase it only from trusted suppliers. Otherwise, you may find yourself having to carry out repairs again in a very short period of time.

Masters' choice

The torque converter should be replaced at a technical center that provides a full range of automatic transmission repair services. Only experienced specialists are able to perform the necessary operations properly. For example, in Moscow you can contact Tokyo Service, which has highly qualified employees on its staff. Consequently, even the most serious problem will be resolved quickly and with a guarantee of quality.