One of the main components of an automatic transmission is the automatic transmission valve body. We will tell you about common breakdowns of this unit.

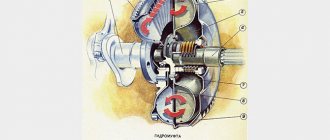

Purpose and design of the valve body

The valve body is a valve plate with numerous channels, inside of which electric regulators (solenoids) and various sensors are located. While the vehicle is operating, oil flows through these channels through the valves, which allows the transmission to be effectively lubricated.

During vehicle operation, it is the automatic transmission valve body that bears the maximum load, and if we take into account the structural complexity of this unit, it is not surprising that it is this element that most often fails in an automatic transmission. It must be said that due to its complexity, this can only be entrusted to professional specialists who use modern diagnostic equipment. This is the only way you can be guaranteed to restore the operation of a failed transmission and will be spared the need to replace the automatic transmission or valve body.

Major valve body failures

The main cause of hydraulic unit failures is the use of low-quality transmission oil. During operation, chips and other deposits appear in the oil. The car owner invariably fails the solenoids in a timely manner, and the oil channels in the valve body begin to coke, which in turn negatively affects the operation of the entire transmission.

Causes of breakdowns:

- Valve contamination with low-quality oil.

- The use of lubricating compounds with chips from friction clutches or with sealant inclusions.

- Regular overheating of the transmission, which is caused by contamination of the radiator honeycomb.

- The presence of scoring on spools, channels and couplings, which also deteriorates the quality of the oil and damages the valve body.

- Fatigue of the springs responsible for the movement of the plungers when the solenoid is turned off.

- Rapid acceleration of the car, which leads to wear of the clutches.

- Oxidation of solenoids contacts.

To extend the service life of the automatic transmission and valve body, it is recommended to promptly change the oil and flush the valve body. Solenoids are replaced with a regularity of 80-150 thousand kilometers.

Valve block repair

It should be said that due to the structural complexity, such repairs can only be trusted to specialists who have extensive experience working with gearboxes of a particular brand of car. If there are problems in the operation of this unit, either the valve body is restored or completely replaced. In this case, it all depends on the nature of the breakdown. Ultrasonic cleaning of the block and replacement of solenoids is often sufficient to fully restore the functionality of the automatic transmission.

A visual video to understand the principles of operation of the valve body

Unfortunately, many car owners do not pay attention to the existing signs of valve body failure and continue to operate their car. As a result, extreme wear of the unit occurs, which can no longer be repaired. In this case, only an expensive replacement of the valve body with a major overhaul of the automatic transmission is possible. That is why, at the first signs of automatic transmission breakdowns described above, we recommend immediately contacting specialized service workshops, which will allow you to reduce your car repair costs.

The automatic transmission of a modern car has a rather complex device. This is explained by constantly increasing engine power, and, therefore, higher demands on various components of the transmission. One of the most important components of an automatic transmission is its control unit, or automatic transmission valve body. Today we will tell you about the operating principle of this integral component and find out why it is so important for the proper operation of the car?

Purpose

A manual transmission, unlike an automatic transmission, is somewhat simpler. This is due to the fact that it lacks a large number of functional elements, electronics and mechanics, which ensure the proper operation of the artificial intelligence of the transmission.

Thus, one of the main features of an automatic transmission is the absence of the need to change gears independently and the implementation of the most effective interaction between the engine and the drive axle. Robotic transmissions use a system of electric drives for this purpose, which promptly activate the clutch mechanism and connect the drive and driven shafts properly.

In an automatic transmission, everything is arranged somewhat differently.

The main difference in the principles of operation, compared to a robot, is that here the bulk of the tasks are not performed by electronics. The lion's share of the tasks here is carried out by the hydraulic system, which allows the shafts connecting the wheels and the engine to interact effectively and promptly change their position relative to each other.

The hydraulic fluid in the speed change control device is officially called ATF. This oil has a fairly high viscosity, and therefore, with little effort, reaches high pressure and is capable of transferring mechanical energy from one element to another.

In an automatic transmission, it is necessary not only to distribute the oil evenly under different operating modes. It is necessary that in each individual mode, hydraulic fluid flows in only one specific direction in order to move the clutches to the required position.

It is for these purposes that the hydraulic unit serves. Its job is to distribute ATP properly. Moreover, the direction of oil movement will change depending on the number of engine revolutions, the selected speed and mode.

Principle of operation

Those who have never encountered the need to study an “automatic machine” at a sufficiently detailed level mistakenly believe that the valve body consists of a large number of functional elements. In fact, this element has the simplest and most primitive device compared to other transmission components, but its design is extremely precisely calibrated to avoid breakdowns and sudden wear of the functional unit.

As mentioned above, the main task of the valve body installed on an automatic transmission is to distribute transmission oil properly and in the required direction.

This oil must be supplied to the valve body input under high pressure so that the shafts can interact with each other and move synchronously.

The function of the oil supercharger is performed by a special high-pressure pump, which is capable of creating a value in its housing that reaches several atmospheres. As the engine speed increases, the pump begins to operate more intensively and, therefore, higher pressure is created.

The task of the hydraulic unit is to quickly take over the oil stream from the pump and redirect it to the clutches, which must be opened to switch to a higher or lower gear.

This is achieved due to the specific structure of the control element, which at the same time is quite complex. Thus, the valve body is made of a special hardened alloy, which is forced to withstand high loads both in temperature and pressure during operation. In this regard, the walls of the valve body are made of thick sheet metal.

Inside, the hydraulic unit of the “automatic machine” has a large number of channels, reminiscent of a labyrinth. Despite the fact that outwardly this system seems archaic, in reality it is not. It is designed so that when the pump applies pressure, the oil is distributed properly. The direction of oil movement is determined by the current position of the clutches. This is facilitated by the ECU, which electronically analyzes all current indicators.

An automatic transmission is an expensive component. There is no point in delaying repairs if they start to malfunction. In a car service, such repairs are an expensive pleasure. You have to pay for the work of specialists and for parts. Having studied the market and the price range of services in this segment, motorists come to the conclusion that repairing an automatic transmission with their own hands is not such a pointless undertaking. The prices of service station masters cannot be called modest, and their professionalism does not always correspond to the price. And, after some thought, car enthusiasts may decide to fix the problems themselves.

Automatic transmission repair diagram

Wherever you decide to repair the gearbox, the whole process follows this scheme:

- diagnostics,

- dismantling the box

- disassembling the box

- complete with spare parts,

- assembly (installation),

- installation on a car,

- diagnostics after repair.

To fix the problem yourself, you will need some car mechanic skills, tools, a certain amount of time to work, patience and perseverance.

All automatic transmissions are designed the same, but there are two types of transmission control - hydraulic and electronic.

Their repair has some differences.

Signs of breakdown

It is important to notice transmission problems at the earliest stage. Then, with , you can avoid complex repairs. Quiet and smooth operation of the automatic transmission is considered normal. There are a lot of signs that something is wrong with the box. Most often these are extraneous sounds when changing gears or during transmission operations. It may be crunching or clicking. An unpleasant odor also indicates problems. It can appear during long-term or short-term operation of the box. It’s worse if the gear shift slows down, or one of them doesn’t work at all. Then immediate intervention is required.

Don't be lazy to look under the car, it should be clean.

Red spots will indicate an oil leak from the gearbox. Regularly checking the oil level is a must. Normally, it should be translucent and reddish in color. No burnt smells or cloudy overtones! If they appear, it’s time.

Automatic transmission malfunctions

often arise due to improper operation. The transmission becomes unusable due to insufficient oil level or overheating. For this reason, gears wear out, and the machine may jerk when changing gears. As a result, any part of the automatic transmission can fail. Shocks when driving indicate overheating of the oil and problems in the valve body.

Aggressive driving with sudden acceleration and braking leads to abrasion of parts. Driving in traffic jams and slipping does not add durability to the box. All this leads to overheating of the box and has a bad effect on its general condition.

All faults are divided into two subgroups. They can occur in

- electronic control system,

- mechanical and hydraulic parts of the gearbox.

If a malfunction occurs, the automatic transmission goes into emergency mode, that is, it switches to third speed and does not shift. The corresponding icon appears on the display.

If problems arise with the electronics, they cannot be eliminated by repairing the automatic transmission. Therefore, it is important to understand the nature of the faults.

Typical automatic transmission valve body malfunctions

According to many car mechanics, valve body repair is one of the most difficult areas of car maintenance, and at the same time the main component of an automatic transmission. This unit performs the extremely important function of directing the flow of transmission coolant. In addition, he is responsible for the process of switching speeds using an electronic unit. The hydraulic unit designs may be different, but the operating principle and its functions are always the same.

When driving a car with an automatic transmission, the valve body is subject to heavy loads, so failure to comply with the correct operating mode can lead to its breakdown.

For example, in the cold season, it is very important to warm up the transmission fluid before starting to drive. This is necessary for the normal operation of the valve body and the box as a whole.

What causes problems with the valve body?

Malfunctions of the automatic transmission valve body often arise as a result of problems in the cooling system if the owner does not regularly change the coolant. It should be noted that this is not only the most important, but also the most fragile element of the transmission. Due to constant loads, it wears out faster than other components. It is very difficult to fix the breakdown yourself, as well as to determine the cause of the malfunction, since the gearbox must be dismantled for diagnosis. An automatic transmission is technically much more complex than a mechanical one, so repairing or replacing its components will cost a lot of money. In this case, amateurish actions can cause more harm than the breakdown itself.

A malfunction of the hydraulic unit can be recognized by shocks and high levels of vibration. If the driver hears grinding and extraneous sounds when changing gears, this is a reason to contact a professional auto mechanic. If the automatic transmission valve body malfunctions, the symptoms are clearly visible when the car is moving. For example, switching the selector from one mode to another is accompanied by a complete stop of the engine. Also, do not ignore the readings of on-board sensors, which display a message on the display about a breakdown or incorrect operation of the gearbox. To eliminate the breakdown, it is necessary to find out the causes using a number of auto repair measures. Computer diagnostics will help identify which valve body element has failed. However, to determine the nature of the failure, it will need to be opened and disassembled.

Self-repair of the valve body - is it possible?

Some drivers who observed the work of the technician in the salon do not see any difficulties in independently repairing an automatic transmission. After removing and opening the transmission housing, checking the valves will most likely show that they need cleaning. But without special equipment it is almost impossible to do this. All that a driver can do at home, even with experience, is to replace the springs, which wear out quite quickly. Now you need to reassemble. As practice shows, making even a small mistake when assembling a gearbox is fraught with dire consequences.

Quite often, the cause of valve body failure lies in contamination of parts from the operation of the clutches. Sticking spools also cause jolts when shifting gears. Faulty operation of even one valve of the valve body leads to loss of pressure in the clutch, malfunction of the clutches, and loss of one of the speeds.

If malfunctions occur, the sooner the driver organizes a valve body overhaul, the less cost it will cost. During the overhaul process, the technician will completely overhaul the valve body, clean the valves, change springs and consumables. This procedure will give the unit several more years of life. Drivers who wait until the last minute with repairs are often forced to buy a new brain center of the box. In some cases, a complete replacement of the automatic transmission is required.

Fault diagnosis methods

The main thing in diagnostics is to collect the necessary information and interpret it correctly. Therefore, it is better to contact specialists. Determine what the problem is at a service station, and do the repairs yourself. Without the proper experience and equipment, you will waste a lot of time on diagnostics. There is mechanical and.

General scheme of diagnostic procedures:

- check the oil,

- check the operation of the engine at idle speed, the connection points of electrical wiring and cables,

- determine error codes for the operation of transmission and engine control units (CU),

- check the box in a car without moving,

- check the automatic transmission while driving,

- check the pressure inside the control system.

Electronic control system and diagnostics of its malfunctions

If the cause of the malfunction is problems with the electronics, then most likely you will not need to dismantle and disassemble the automatic transmission. Diagnostics of faults in this system is carried out by the control unit. It monitors sensor signals, transmission ratios and output circuit resistance. Malfunctions of the following parts and assemblies may occur:

- input sensors,

- electronic control unit,

- control system actuators,

- violation of the integrity of electrical wiring connections.

The transmission computer receives signals from various sensors. If any parameters are abnormal, it stores a problem code (DTC) in memory. Such numbers can be deciphered using a special scanner.

Diagnosis of mechanical and hydraulic problems

These are the main problems of the automatic transmission itself. They are conventionally divided into three subgroups:

- Damage to friction groups, bushings and housings, calipers, planetary gears, pump and other mechanics.

- Transformer fault. This includes:

- broken wire splines,

- mechanical destruction of the blades,

- overrunning clutch,

- wear of the main locking clutch,

- depressurization of the piston seal.

- Problems with the mechanics of the hydraulic plate.

The most common valve body failures

Computer settings are optimized for fuel economy and fast acceleration. In 6- and 8-speed automatic transmissions, robots, and CVTs, the driver can squeeze the maximum out of the engine even in aggressive modes. But such freedom of choice is paid for by the rapid wear of the valve block and the entire automatic transmission.

This happens due to rapid wear of the torque converter lock-up clutch. Dust and adhesive resins spread throughout the box along with oil. The liquid loses its properties and does not have time to cool.

The valve body channels and valves become clogged with dirt. Springs do not return plungers to their original position. Solenoids cannot open a stuck valve. This is where jolts and jerks appear when changing gears. The metal abrasive wears out the separator plate and the channels of the plate, changing their geometry. Oil leaks appear.

Overheating causes wiring and board elements to melt as the temperature rises above 120℃. The solenoids fail. Sensors overheat. Finely tuned electronics block the operation of the faulty unit, and the automatic transmission can no longer engage a certain gear.

Similar symptoms and typical faults are common in the DSG. Problems in the mechatronics unit are indicated by:

- shifting gears with jerks and impacts;

- vibrations due to sharp clutch of discs;

- oil leaks;

- transition to emergency mode.

Automatic transmission dismantling

If the diagnosis was successful and dismantling is not possible, then we proceed to this stage of automatic transmission repair.

You will need a special lift, or at least an inspection hole. As well as a transmission jack and a set of keys. It is better to carry out this procedure in a specially equipped garage or box. It would be useful to invite several physically strong guys to help move the removed box. Its weight is beyond the strength of even a very strong person. Further plan of action:

- disconnect all communication tubes and cables;

- unscrew the torque converter mounting bolts, as well as the engine flywheel membrane;

- remove and move the gearbox;

- assess the extent of the damage and begin repairs.

Before removing the gearbox, the oil does not need to be drained. However, then do not forget to place a container in the place where the oil supply pipes are attached when you disconnect them - otherwise you will end up with an ugly puddle under your feet.

All actions must be careful. Sudden movements can damage the splines of the diaphragm input shaft.

Self-repair of automatic transmission valve body 01M

FAQ VW Audi Skoda Seat

Automatic transmission type 01M was installed on cars:

Volkswagen Golf 4 / Volkswagen Golf 4 (1J1, 1J5) 1997 - 2004 Volkswagen Bora / Volkswagen Bora (1J2, 1J6) 1999 - 2005

Volkswagen Passat B4 / Volkswagen Passat B4 (3A2) 1994 - 1997 Volkswagen Passat Variant B4 / Volkswagen Passat Variant B4 (3A5) 1994 - 1997

Volkswagen New Beetle / Volkswagen New Beetle (1C1) 1998 - 2010 Volkswagen New Beetle Europe / Volkswagen New Beetle (9C1) 1999 - 2002

Skoda Octavia A4 / Skoda Octavia A4 (1U2) 1997 - 2010 Skoda Octavia Combi A4 / Skoda Octavia Combi A4 (1U5) 1998 - 2010

SEAT Leon / Seat Leon (1M1) 1999 - 2006 SEAT Toledo Mk2 / Seat Toledo (1M2) 1998 - 2004

SEAT Ibiza 2 / Seat Ibiza 2 (6K1) 1993 - 2002 SEAT Cordoba / Seat Cordoba (6K2) 1993 - 2002

Audi A3 / Audi A3 (8L1) 1997 - 2003, etc.

So. I purchased a VW Bora with an automatic transmission 01M 2002 with a modern AVU 102 horsepower engine. In good condition, minimal mileage and original paint. The machine was kicking.

Having passed the silent machine, the machine became staked and repairs began. Repairing the mechanical part is not difficult. Carefully repair everything, replace the clutches, check for clutch leaks, repair the donut and replace the plastic reverse retainer with metal.

The report is on this website.

The main problem of the valve body is overheating!!! On cars with my engine, the fluid temperature is 110 degrees. This is 120-130 with an automatic transmission.

Hence the good condition of my car. HE DIDN'T DRIVE!

The cooling system does not provide good cooling up to 90 degrees, and even more so at a liquid temperature of 110 degrees!

The main pressure valve in the valve body jams and the machine burns out!

Therefore, it is necessary to provide the machine with an external cooler, preferably with a thermostat. But about this in the next report. Now about the valve body

After going through the machine, I bought a used valve body on Ebay from the USA. It was in excellent condition. All valves fell out under their own weight and were in perfect condition. After 10 thousand, I was driving to the garage and the automatic transmission started to shift into neutral, I could barely get it into the garage, and the drained oil was black and smelled burnt! The main pressure valve is jammed, jammed due to overheating... I can’t describe the words that I sent to everyone... but oh well.

And so repairing a valve body costs 15,000 rubles and our technicians do not replace the valves with repair ones, they carry out exactly the procedure described below.

And so let's get started! The hydraulic box was removed, washed with gasoline and brought home. The valves no longer fall out under their own weight! They sit there tightly. Repair!

We unscrew the caps and solenoids, without losing the balls. We put everything in a box. We have in our hands a bare hydraulic box with valves.

We start defecting with solenoids. We call the solenoids with balls and their resistance is 55-65 Ohms. We put them aside. We check the pin solenoids for a resistance of 4.5-5.1 Ohms. We supply power to them, the rod should retract. The rod of the pin solenoids should move under its own weight without jamming.

Ball solenoids are reliable! Don't rush to change them. There is nothing to break there; the coil magnetizes the ball, which closes the channel. But pin solenoids work intensively!

One pin solenoid blocks the donut, the other slightly lowers the pressure when shifting gears.

It does not regulate the pressure.

It is better to replace the pin solenoid regulators!

But I tried to repair it. Flare it, disassemble it, wash it.

Pin with wear on the bushing!

We take 1500 sandpaper and grind the pin itself. We take 1500 sandpaper and grind the bushing. We check that the pin moves without scuffing, change its position in the solenoid by 180 degrees. We check that the rod moves freely when assembled; this is a mandatory condition. Let's roll it up. We take out the valves and wash everything.

IF THE VALVES HAVE LONGITUDINAL SEARNS ON THE WORKING SURFACES, THE COATING IS DAMAGED, DO NOT WASTE YOUR TIME. Buy another valve body on ebay, for example. The renovation is then complete!

If the valves are not damaged, we proceed to repair.

There are three valves in the valve body that work most actively: Two pressure regulator valves and a donut pressure regulator valve.

If the pressure control valve Converter reg. then there will be kicks when starting, it will not roll when the pedal is released, and in general it can burn the coupling in the donut. The pressure control valves jam and the clutches burn out. K1, K3.

I took 1000-grit sandpaper. I measured the diameter of the valves and, having selected a mandrel, began grinding.

DO NOT RUMBLE THE VALVES WITH SANDY! If the valve is stuck, then only replacement

Main valve:

We rub it in with passion, we rub it in until it easily falls out under its own weight. Inside, the marks from the operation of the valve in the hydraulic plate are clearly visible. We rub it in, wash it, try it... rub it in again. Until it moves easily in the slab under its own weight.

In this way we grind all the other valves in the valve body, except one.

This is the regulator valve under the ratchet plug. We measure the position of the plug. We unscrew it, measure the valve, select a mandrel and grind it CAREFULLY.

We screw the plug to the same depth!

Grinding in of this valve depending on the condition of its seat. If you grind hard, the position of the adjusting plug will change greatly.

You can also grind the donut pressure adjustment valve, the one in the mandrel, if it’s not stuck up, if it’s stuck up, then we replace it with a repair one from Sonnax... the mandrel is very soft, use three 1500-grit sandpaper to accurately select the two mandrels by diameter.

We collect everything and put it on the car. We check the pressure, if 3.6-4 atm is not normal, then add a plug.

Final view before assembly and installation:

I selected the mandrels for the emery from my grandfather’s set of Soviet drills. Screwdrivers and a core were also used. The diameter of the mandrel must be smaller than the valve and is selected experimentally.

After assembling the block body with valves, the valves can be moved with a thin screwdriver. But you need to move using the non-working surfaces, with the flat part and without making much effort, everything should move smoothly without jamming with the same force at the beginning and at the end. If the force applied to the valve is initially greater and it moves with “roughness,” it means there will be kicks during operation or the valve will generally jam. The grinding was not carried out correctly.

Thank you all for your attention. Maybe I'll add something else later.

Continuation and all discussions of the report here

Thanks: Dimidroll

How can I find the information I need here?

Decoding the factory equipment of the car (English) Decoding the factory equipment of VAG in Russian! Diagnostics of

Volkswagen, Audi, Skoda, Seat, error codes.

If you have not found information on your car, look at the cars built on the platform of your car. Most likely, the information on repair and maintenance will be suitable for your car.

Automatic transmission repair

It is better to carry out automatic transmission repairs yourself, having at hand the original manual and a printed diagram of the gearbox.

First you need to inspect all systems that service the gearbox, mounts and blocks. Then we begin the repair. For this:

- We disassemble the gearbox, wash and dry the parts and check them for defects.

- We replace all gaskets, seals, and worn parts.

- Remove the inhibitor block and pan. We clean out the dirt inside. It looks like metal magnetic shavings.

- Remove the ring wires from the plug and push them inside the plug.

- Remove the valve body and loosen the brake band bolts. We wash the hydraulic unit.

- We check clutches, gears and planetary gears for wear. We replace it if necessary. All internal rubber bands must be changed!

- Open the oil pump. We check all the parts, especially the filter. We replace what has already served its purpose. We use the manual so as not to swap parts.

- We take out the valves and springs. We wash the valves. Their sticking may cause incorrect operation of the automatic transmission. We replace the accumulator springs if they are broken.

- Putting everything back in its place. It is important not to confuse anything!

- We replace rings and friction bolts.

- We check the gear shift assembly and the large piston and replace the oil pump.

Assembly occurs in reverse order.

There are certain points that it is advisable to take into account during repairs. Often the transmission problem is related to the filter. You won't be able to change it without removing the valve body. And when you remove it, the gasket breaks. To replace it, you will need to completely disassemble the valve body. The same applies to the accumulator spring from first to second gear. A special limiter does not allow it to be removed without disassembling the valve body. All valve body gaskets are very similar, do not mix them up. When assembling the valve body, we tighten it with a torque wrench. It’s important not to over-tighten here.

Features of maintenance of automatic transmission 01M

The oil level should only be checked with the engine running, at a temperature of up to 30°C, so as not to burn your hands with hot oil; the automatic transmission position is “P”.

The 01m automatic transmission differential has a separate oil pan, isolated from the main lubrication system thanks to the main gear bearing cap. The lubricant used for a differential is different from that used in a planetary gear.

Checking the level and condition of the oil in the automatic transmission

Replacing transmission fluid in an automatic transmission

At 01m, 5.6 liters of gear oil G 052 162 A2 are filled (analogues may be G 052 162 A1 and G 052 162 A6). For the final drive, 0.75 liters are refilled. G 052 162 A2.

Be sure to change the filter (01M 325 429) and gasket (01M 325 443).

Procedure for changing automatic transmission oil:

Post-repair installation of automatic transmission

If all the breakdowns are eliminated, we install the automatic transmission. This is a crucial moment; there is no hurry here. When doing this work, you should adhere to the following recommendations:

- When installing the automatic transmission in its place, the membrane is checked for mechanical runout using an indicator head. If such a defect occurs, then it must be replaced.

- The radiator is flushed until the gasoline is clean. Then pour a liter of transmission oil into the gas turbine engine and place it on the input shaft. It is necessary to achieve a reliable connection and complete landing. Then you need to dock the engine with the gearbox along the guide centering pins. The crankcases must be completely adjacent.

- Tightening the bolts in the box is the next step. After which the absence of gaps along the entire plane is checked. After connecting all the lines, the correct connections are checked.

- At the final stage, add oil and check the operation of the automatic transmission at low engine speeds.

When installing the box, be sure to check the presence of centering pins on the engine crankcase flange - there should be two of them. If at least one is missing, you cannot mount the automatic transmission.

Automatic transmission repair and diagnostics

with your own hands is not an easy but doable task. When choosing, novice car enthusiasts believe that repairing it at home is impossible. This is wrong. But before you decide to carry out such important work at home, you need to weigh all your options. Then you won't have any unpleasant surprises during the renovation.

The hydraulic valve plate (Valve Body, valve body, valve block) is a hydraulic “dispatcher”, a gearbox assembly consisting of valves, sensors, batteries and channels connecting them.

The valve body is controlled using electrical signals from the computer and distributes/directs oil pressure from the oil pump to the desired clutch drum for shifting gears in the automatic transmission

Valve body repair cost

Repair of the valve body ranges from 15,000 to 35,000 rubles, depending on the automatic transmission model and the complexity of the work:

- the simplest and fastest repair is replacing the wiring that powers the solenoids and sensors;

- at an early stage of the disease, the valve body is cleaned, the gasket and solenoids are changed;

- in severe cases, the slab is restored using Sonnax instructions, materials and tools.

Hydraulic plates are expensive to repair: TF-81SC, 5L40E, JF506E, 722.9, 6HP, 8HP.

Replacing the valve body is rarely done due to the high cost. The unit is selected by VIN number, since modifications of the same box differ.

| Automatic transmission model | Price of a restored valve body, rub | Price of a new hydraulic unit, rub. |

| TF 80SC/81SC | 25 000 — 40 000 | 80 000 — 98 000 |

| AW55-51SN | 20 000 — 39 000 | 40 000 — 90 000 |

| 09D | 24 000 — 40 000 | 93 000 |

| U140 | 23 000 — 27 000 | 58 000 |

| DP0 | 15 000 | 37 000 |

| JF011E | 25 000 | 49 000 |

Read

How to diagnose an automatic transmission yourself