Notes

- ↑ 123

Theater encyclopedia. Ch. ed. P. A. Markov. T. 4 - M.: Soviet Encyclopedia, Nezhin - Syarev, 1965, 1152 stb. with illustration, 6 l. ill.

Category:

- Ambiguous terms

Wikimedia Foundation. 2010.

Synonyms

:

See what “Ramp” is in other dictionaries:

- rampada - rampada ... Russian word stress

- A ramp is a structure designed for loading and unloading operations. One side of the ramp is adjacent to the warehouse wall, and the other is located along the railway track (railway ramp) or road access (car ramp). Source... Dictionary-reference book of terms of normative and technical documentation

- RAMP - (theater) a place in front of the proscenium where a row of lamps is installed. Dictionary of foreign words included in the Russian language. Pavlenkov F., 1907. RAMP (French, from ramper to crawl, cling). 1) railings at the stairs. 2) a row of lamps at the proscenium, which ... ... Dictionary of foreign words of the Russian language

- Ramp - Ramp: a structure designed for loading and unloading operations. The ramp is adjacent to the wall of the warehouse on one side, and the other is located along the railway track (railway ramp) or car entrance (car ramp).... ... Official terminology

- Ramp is a structure designed for loading and unloading operations. The ramp is adjacent to the warehouse wall on one side, and the other is located along the railway track (railway ramp) or car entrance (car ramp).... ... Encyclopedia of terms, definitions and explanations of building materials

- ramp - barrier, collector, pipeline, highway Dictionary of Russian synonyms. ramp noun, number of synonyms: 4 • barrier (15) • ... Dictionary of synonyms

- ramp - s, m. rampe f. railings, slope 1. fort. Shoots for guns and soldiers in fortifications. Kurg. Eng. sl. 1777. || Above the gate there are two tiers of chambers: the first tier below them is surrounded by a covered gallery, or parapet, on which on the eastern side there are double ... Historical Dictionary of Gallicisms of the Russian Language

- RAMP - (French rampe, from ramper to rise gently, to be sloping), 1) an inclined platform between two different levels, used for moving vehicles (for example, in warehouses, on railway platforms, in shops). 2) Lighting ... Modern encyclopedia

- RAMP - (French rampe) 1) An inclined platform for the entry and exit of loading and unloading machines into vehicles and warehouses. 2) An inclined platform for drying and cooling coke after extinguishing. 3) Lighting equipment on the floor of the stage along its ... ... Large encyclopedic Dictionary

- RAMP - RAMP, ramps, women. (French: rampe). 1. A long, low barrier along the proscenium, covering lamps and other devices for lighting the stage (theater) from the side of the auditorium. “She sat at the very edge, put her hand on the ramp.” L. Tolstoy. || The same thing together... Ushakov’s Explanatory Dictionary

- RAMP - RAMP, s, female. A low barrier along the proscenium that blocks lighting fixtures aimed at the stage from the audience. The play saw the ramp (translated: staged on stage). | adj. ramp, oh, oh. Ozhegov's explanatory dictionary. S.I. Ozhegov, N.Yu. Shvedova.... ... Ozhegov's Explanatory Dictionary

Books

- Ramp and life, Leonidov Leonid Davidovich. Memoirs of the famous Russian entrepreneur Leonid Leonidov, whose life and work were closely connected with Russian theatrical art and, in particular, with the Moscow Art Academic... Read more Buy for 400 rubles

- Ramp at the microphone, Alexander Sherel. Theater and radio, their joint searches, mutual joys and involuntary sorrows are the subject of the author’s attention. There have been many discoveries along the way; talks about them and the people who committed them... Read more Buy for 300 rubles

- Footlights and life, Leonidov L.. Memoirs of the famous Russian entrepreneur Leonid Leonidov, whose life and work were closely connected with Russian theatrical art and, in particular, with the Moscow Art Academic... Read more Buy for 291 rubles

Other books on request "Ramp" >>

Design Features

The pressure of the fuel in the rail is controlled using a pressure gauge connected using a special fitting, the hole for which is provided in its design. In the normal position, the fitting is closed with a plug that protects its threads from contamination. The pressure in the ramp is monitored during inspections of the technical condition of the vehicle.

To improve fuel atomization, in some engines the fuel rail design provides for the possibility of preheating it. Also on the ramp there are fittings for supplying and draining fuel.

Features of design and location

The main task of the fuel rail is the delivery and distribution of fuel between the engine injectors. In this case, as already mentioned, the fuel must be kept there under pressure. In order to ensure a long service life, the fuel rail is made of special corrosion-resistant steel.

The design of most fuel rails provides a special fitting for connecting a pressure gauge. which controls pressure. In addition, a separate valve may be located on the fuel rail to drain fuel during repairs and maintenance.

The fuel rail is located on the engine intake manifold and is securely bolted. The injectors can be connected to the ramp either directly or through outlet pipes.

Skateboarding

Board riding requires a comfortable platform. The ramp provides skateboarders with waves similar to those used by surfers. This is a metal structure, low in the center and high at the edges. There are ramps of varying sizes and difficulty. They are installed in almost all skateparks.

The most exotic ramp is a structure installed in Namibia, right in the desert. Engineers were able to build in the sands what became a landmark of this unusual country. Anyone can ride the ramp in the desert. The most popular is the mini ramp.

What kind of ramps are there? There are single-level and two-level ones, fenced at the edges and without fence. There are simple metal and complex structures using wood. Instances differ from each other in height and difficulty of skating. Acceleration on the ramp is ensured by the steepness of the slope and the length of the spot.

When is it necessary to check the fuel pressure in the rail?

There are several signs that indicate problems with the fuel system:

- Increased fuel consumption in all operating modes.

- Unstable operation at idle speed, the engine may often stall, especially after sharply pressing the gas pedal.

- All cylinders do not start - the engine “troubles”.

- Long-term starting after inactivity due to reduced pressure in the injectors.

- The intensity and toxicity of the exhaust increases.

Similar symptoms often occur with other breakdowns, but before making more complex and expensive diagnostics, it makes sense to check the fuel pressure in the rail yourself. If it is low, you need to react immediately, identifying the malfunction.

Ramp manufacturing and operation

The material for the manufacture of the fuel rail is alloy steel, which protects the internal cavity in contact with the fuel from corrosion. After manufacturing, the ramp undergoes mandatory testing for its ability to withstand excess pressure.

To check the ramp for defects, it is sometimes necessary to remove the device from the engine. First, the fuel supply is turned off, and then the hoses are disconnected. Next, remove the drain hose to remove the ramp from the body by unscrewing the mounting bolts with a wrench.

Then you will need to remove the injectors with utmost care so as not to damage the structure. The fittings are first closed with plugs for protection. After a technical inspection and possible defects, the ramp is repaired. Then it can be used again.

The fuel rail is an essential element in the vehicle system. Therefore, it is extremely important for drivers to know the principle of its operation and periodically monitor its operation. If malfunctions are identified, it is strongly recommended not to use the vehicle until repairs are carried out.

Aviation

What is a ramp? The aviation definition is that it is a device that is indispensable in aircraft hangars. The term refers to the mechanism by which cargo is unloaded and loaded.

The ramp is a mechanized hatch capable of descending to the surface of the earth. It is located on the nose or tail side directly in the fuselage. The specific design allows air transport to be unloaded and loaded under the side when the truck is parked close to the aircraft. In some cases, it is possible for a vehicle to enter the cargo compartment.

The ramp is indispensable when loading heavy objects. In particular, this is the only way armored vehicles are loaded onto an airplane. Using this hatch, you can even load the fuselage of another into one aircraft, if the dimensions and power of the air transport allow this. If military air transport is equipped with an open ramp, it is used for parachute landing.

Fuel Rail Operation

To inspect and troubleshoot the fuel rail, it may be necessary to remove it from the engine. In this case, the fuel supply is turned off, after which the fuel supply hose is disconnected. Then the drain hose is removed, which allows you to remove the ramp from the body by unscrewing the mounting bolts with a wrench. Next, the injectors are removed with extreme caution, the fittings of which are prudently closed with protective plugs. After inspection and elimination of identified defects, the ramp is mounted on the engine in the reverse order.

Source

What is a fuel rail?

The fuel rail (or fuel rail) is a special tube that serves to supply fuel and distribute it between the injectors. The fuel in the rail is under pressure.

Initially, in the era of carburetors, such an element was not provided for in the design of automobile engines - there was no need to supply fuel under pressure. With the development of technology and the improvement of gasoline engines, this element migrated from diesel cars and became an unchanged part of the design.

Gas industry

A ramp is a device used to connect one object to several gas cylinders at the same time. The role of gas consumer is usually:

– slabs;

– fireplaces;

– boilers.

Thanks to the ramp, the gas pressure is maintained constant, the supply is uninterrupted, and the cylinders do not freeze. The need to install a ramp arises if the consumer needs a large volume of gas, and one container is not enough. Since frost extinguishes the burner, the ramp is indispensable for ensuring the operation of the heating system. If the device urgently needs to be disconnected from the gas, the ramp allows you to do this in one movement. This property is highly valued in emergency situations.

An automatic valve is sometimes included in the package. If available, the system automatically switches from vessel to vessel, blocking access to unused containers. A simplified system operates on a manual valve. With such a ramp, it is necessary for a person to constantly monitor the operation of the device and independently switch the gas supply from one container to another.

The use of a ramp allows the simultaneous operation of two or more cylinders. To do this, you will need special adapters, tubes and hoses with which to connect all the elements. Remember that with direct gas supply it is impossible to avoid pressure drops, and this often leads to burner malfunctions. The ramp guarantees correct inlet values, that is, the gas supply occurs without interruption.

Design and main malfunctions of the fuel rail (video)

The fuel systems of modern internal combustion engine vehicles include many important elements. One of these is the fuel rail. Essentially, it is a hollow tube with closed ends from which smaller diameter tubes branch off and are connected to the fuel injectors. This is one of the systems that first appeared in diesel units, but then found application in gasoline units.

Avto.pro experts will help you understand the structure of modern fuel supply systems, the fuel rail itself, its malfunctions and replacement features.

Removal and inspection of the fuel rail

Often, a loss of pressure in the fuel system can be quickly diagnosed, but it is not always possible to immediately determine the location of the leak, for example. If there is a need to inspect the fuel rail, it will first need to be dismantled. In fact, even an inexperienced car enthusiast can handle removing the ramp. The set of tools is minimal. Free time is another matter. You will need a lot of it, so all work should be done on the weekend. The work itself looks like this:

- Put the car on the handbrake or move the gearshift lever to the neutral position;

- Reduce the pressure in the supply system (we'll talk about this a little later);

- Disconnect the corresponding wire from the negative terminal of the battery;

- Disconnect the wiring harness connectors from the injectors;

- Similarly, disconnect the pads from the knock sensors, throttle position, antifreeze temperature, disconnect the idle speed control and all other sensors working in tandem with the engine;

- Disconnect the fuel hose from the ramp (the reliability of its fixation is determined by the clamp, which will have to be disconnected);

- Disconnect the clamp that connects the ramp to the oil dipstick guide;

- Remove the fuel rail mounting bolts from the intake manifold side;

- Remove the ramp and optionally the injectors.

The above-mentioned reduction in pressure in the supply system is carried out as follows: proceed as in point 3

; remove the fuel module hatch cover; disconnect the wire block from the module; connect the negative wire to the corresponding battery terminal; start the engine, allowing it to exhaust all the fuel from the ramp - after that it will stall. All that remains is to turn off the engine and return to working with the ramp. As you might have guessed, during further dismantling you will have to repeat the manipulations with the battery cable.

In general, dismantling the ramp on almost all car models is similar. to keep in mind here.

. Firstly, the injector O-rings must be lubricated with engine oil during subsequent installation of the ramp. Secondly, when connecting a fuel hose to the rail, you must ensure that the connection is tight. Many experts recommend carefully inspecting not only the ramp, but also the fuel injectors attached to it, because now they can be examined from different perspectives and make sure that their seats are in proper condition.

Search for fuel rail components

During inspection and diagnostics, it may turn out that the ramp needs repair and replacement of components. abbreviated RTD) is most often required for repairs.

) and seals. As a rule, it is the regulator that breaks. You can check it without the help of a technician: if the regulator releases pressure while the starter is operating, it is faulty. Everything you need for repairs can be found at:

- VIN code of the vehicle;

- Code of required spare parts;

- Vehicle parameters: make and model, year of manufacture, engine parameters.

The last option is by far the simplest and most popular among ordinary car enthusiasts.

Thanks to the development of electronic catalogs and the emergence of online stores, drivers now have tree-like catalogs at their disposal in which they can search for the necessary spare parts step by step - first specify the make and model, then indicate the category of the spare part, specify the year of manufacture of the vehicle, and only then find in the list what what is required for repairs. We would like to draw the attention of motorists to the fact that fuel system components must be selected with an eye on the manufacturer.

. The world experts in gasoline and diesel systems are the following companies:

- Bosch (Germany);

- Denso (Japan);

- Siemens VDO (Germany);

- Delphi (USA-UK);

- Pierburg (Germany);

- Stanadyne (USA).

We categorically do not recommend purchasing fuel system repair kits from little-known manufacturers. Firstly, the quality of their products is not always stable. Secondly, many of them are in fact packers

, which offer products from companies from the list above, but sometimes with the caveat that the products themselves have not passed quality checks and were offered for sale on the secondary market under the names of third-party brands.

The most reliable options are to buy the original or fuel equipment from Bosch and Denso. Relatively good analogues at an affordable price can be found in the catalogs of Monark, Lucas and Hans Pries. If necessary, the car enthusiast can also find a fuel rail assembly. original ramps can be found on sale.

, however, in order to save money, the product can be found at auto wrecking yards.

In this case, you need to pay special attention to checking the condition of the ramp - fuel system components that have been in operation for a long time often have a small residual life.

Lobsang Rampa

The meaning of the word "ramp" is not limited to technical terms. It is also a name: Lobsang Rampa is a pseudonym used by Cairil Hosking, an English writer and New Age activist. Hoskin convinced people that his body was possessed by the spirit of Tuesday Lobsang Rampa, a lama from Tibet. He explained that the Lama's name was Tuesday because of the Tibetan tradition of naming children by the day of the week on which they were born.

Lobsang Rampa was born in a princely house in the twentieth century in Tibet. The boy's father controlled Tibet during the first Chinese occupation, after which he fled the country and hid under false names. Lobsang's mother came from the most distinguished Tibetan houses. The parents provided the child with excellent opportunities to study in Chakpori, famous for its developments in the field of traditional local medicine. Since ancient times, Chakpori specialized in training healers, herbalists and even surgeons. The monastery is located near the capital of Tibet, Lhasa.

Operation process and main malfunctions

Due to the simplicity of the design and the materials used, the fuel rail has a very long service life. The main type of malfunction is loss of tightness, which leads to a drop in pressure and fuel leakage. The causes of malfunctions may be mechanical damage or the natural aging process. This is especially true for the junction points of the ramp with other elements of the fuel system. Troubleshooting occurs through a thorough visual inspection.

It is best to remove/install the fuel rail in a car service center - since in this case there is a higher probability of complying with the technological process. When handling the fuel rail, special attention should be paid to the connection points - do not allow contaminants to get inside the rail and do not wash it in aggressive environments (so as not to damage the sealing elements of the connections).

You need to select a fuel rail only in the original catalog. And when pricing and choosing analogues, you need to pay special attention to high-quality and proven brands.

Source

Instruments and devices of the Common Rail system

High pressure accumulator (fuel rail)

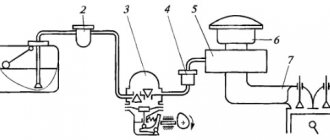

In general, a high-pressure accumulator has the shape of a tube (Fig. 1). Depending on the engine design, the specific battery design may take different forms. A fuel pressure sensor and a pressure limiting valve can be installed on the battery. Fuel flow limiters and a pressure control valve can be installed as additional equipment if it is not located on the fuel injection pump.

Fuel from the injection pump is directed through the high pressure line to the inlet fitting of the accumulator (rail). From the fuel rail it is distributed to individual injectors.

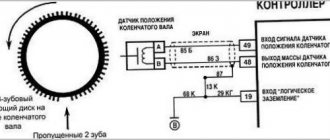

The pressure inside the accumulator is measured by the fuel pressure sensor (Fig. 2) and is limited by the pressure control valve (Fig. 3) to the maximum permissible value depending on the parameters of the specific injection system. Through a fuel flow limiter, which throttles the fuel flow, the latter is supplied under pressure to the injectors.

The volume of the accumulator (ramp) is constantly filled with fuel under pressure. The value of this pressure is maintained at a constant level even under heavy engine loads, when fuel consumption through the injectors increases.

Pressure control valve

The pressure control valve sets the pressure in the high pressure accumulator (fuel rail) depending on the engine load. If the pressure in the rail is too high, the valve opens and part of the fuel from the rail is diverted through the return line back to the fuel tank. When the pressure in the fuel rail drops, the valve closes and opens the high and low pressure circuits.

Pressure control valve 3 (Fig. 2, a) is installed either directly on the injection pump or separately. Attached via a flange to the fuel injection pump housing or high-pressure accumulator. Armature 2 presses valve ball 1 to the seat under the action of valve spring 4 so as to separate the high and low pressure circuits. The switched on electromagnet 3 moves the armature, applying additional force to press the ball against the seat. The entire anchor is washed with fuel, which lubricates the rubbing surfaces and removes excess heat.

The pressure control valve has two circuits:

We will consider the operating principle of the valve for two positions.

How to change the pressure sensor on a car's fuel rail

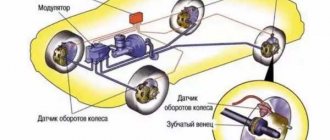

The fuel rail sensor, like any part of the fuel system, can malfunction, usually resulting in a rough running engine, ignition problems, or other instances where the check engine light comes on.

The ATC fuel rail pressure sensor is a part that can reduce evaporative emissions by delivering a specific amount of fuel to the engine to keep it running properly. A pressure sensor ensures that excess fuel does not remain in the conductive channel.

The sensor's job is to determine the pressure directly in the fuel rail, thereby determining the exact amount of fuel in the rail. When the sensor detects the presence of fuel, an electrical signal is sent to the fuel pump for further pumping. As soon as the fuel pressure reaches a certain point, the fuel pump receives a signal to stop working. When the pressure decreases, a request is made to renew the fuel supply.

When a pressure sensor malfunctions, it can be determined by some initial signs that will tell you that something is wrong. Usually there are difficulties with ignition: it takes longer than expected to start the starter. In addition, the engine begins to operate unevenly. Sometimes problems with the pressure sensor on the fuel rail even lead to the engine simply stalling during normal operation.

The following are the alarm codes (for machines with a computer system) that correspond to the pressure sensor: P0087, P0088, P0170, P0171, P0172, P0173, P0174, P0175, P0213, P0214, P0190, P0191, P0192, P0193, P0194.

First stage: checking the condition of the pressure sensor

Step 1: Start the engine. Look at the warning lights on the dashboard. Listen to the engine. Determine whether all cylinders are working properly and whether there is vibration in the engine.

*Note. If the pressure sensor is not fully functional, the engine may not start. Do not try to run the starter more than five times, otherwise this will only reduce the battery charge.

Step 2: Stop the engine and open the hood. Check the wiring near the pressure sensor for damage or breaks. This may be the reason for its failure.

maxleshiy › Blog › Fuel rail.

The fuel rail is an essential element of the fuel system of an internal combustion engine with distributed injection.

A fuel rail or rail is a section of a hollow tube with ends closed on both sides and outlets for connecting smaller diameter pipes through which fuel is supplied to the injectors.

The fuel rail is one of the elements “inherited” to a gasoline engine from a diesel engine. Another well-known element that “migrated” from there to direct injection systems is the injection pump.

In some cases, the injectors are attached directly to the ramp. The fuel rail is used in almost all multipoint injection systems, although in some designs the fuel is discharged to the injectors from the regulator body.

History of the creation of the fuel rail

The fuel rail design of the injection system comes from the practice of creating diesel engines, which, due to their design features, have been equipped with distributed injection since their invention. The article is taken from the public page “MACHINES”. In the era of carburetor injection, the fuel rail was not used on gasoline engines, since in these systems the fuel is supplied centrally and not under pressure.

Design and location of the fuel rail

Typically, the ramp is installed on the engine intake manifold. In addition to the outlet pipes, the ramp has a hole with a shut-off fitting for connecting a pressure gauge, which controls the fuel pressure. To prevent contamination, it is closed with a threaded plug. Most often, the ramp is made of seamless steel pipe that can withstand high pressure. In the case of a diesel engine equipped with a common rail system, this pressure can be very high.

The main purpose of the fuel rail is to supply fuel and distribute it to the injectors.

When removing fuel injectors from the rail, extreme care must be taken. One wrong move can lead to the need to replace the injector.

When the injection pump operates, fuel enters the supply line located in the block head. vk.com/kars.best Once in the ramp, the fuel moves in the direction of the farthest cylinder. Some injection system designs provide for heating the fuel with the heat generated by the engine during operation. Warming up improves atomization.

Fuel rail operation issues

If for some reason the fuel rail needs to be removed, you must proceed with extreme caution, as there is a high risk of damaging the injector nozzles and connector contacts. Under no circumstances should dirt be allowed to get into open channels and pipelines, since after assembly it will inevitably get into the injectors and the matter will end, at a minimum, with washing them. During maintenance, the holes must be closed with plugs. Before removal, the fuel rail can be cleaned using a can of injector cleaner. Under no circumstances should the ramp be placed in flushing solvent without disconnecting the injectors. The fact is that all the holes in the fuel rail are equipped with rubber sealing rings, which will fail if placed in an aggressive environment. By the way, in any repair manual you can find a recommendation to change the rubber gaskets in any case, even if they are not externally damaged.

Source