How to check engine compression

All auto repair mechanics, seasoned and experienced car enthusiasts will immediately say that they already know how to check engine compression without instruments, but as practice shows, most novice car enthusiasts do not know about this method. This method works both for VAZ 2106, 2107, 2108, 2109, 2110 and others, as well as for foreign cars, as in our case Opel Astra.

In our article today we will tell you how not to measure, but to check the presence of compression in a car engine at home or without a compression meter. It should immediately be noted that the method is not 100%. We will check for compression in the cylinders using a rag. This method, as mentioned earlier, is not 100%, but you will still get a general picture of whether there is compression in the engine.

The meaning of the method is as follows. If there is compression in the cylinder, then by inserting a napkin into the spark plug shaft and turning the engine, how this napkin behaves will determine whether there is compression in the engine. If there is no compression, the napkin will fall out or remain in place. And if there is compression, then the following will happen. We put the napkin into the candle shaft. First crumple it tightly.

We move away from the cylinder head. We put a specially trained person behind the wheel and force him to start the engine. Let's see what happens when there is compression in the car. The napkin flew out of the candle shaft at incredible speed. It turned out to be very difficult to photograph this, so at the end of the article you will find a video on how to check engine compression without instruments with your own hands.

When inspecting a car before purchasing, it is unlikely that you will be able to check engine compression in this way. But for your own purposes and interests, this old-fashioned method can be safely used. And by the force of the napkin’s ejection, you can understand what is happening with the compression of the cylinders.

Source

Increase compression level

At home, this is only possible if the cause of its appearance is carbon deposits on the pistons and cylinders.

- You will need denatured alcohol and kerosene. Mix 25 grams of each in a 1:1 ratio. This amount is needed for one cylinder. Accordingly, four cylinders will require four times more mixture.

- Then warm up the engine to operating temperature.

- Approximately 50 grams of the resulting mixture are placed into each cylinder through the spark plug hole. So the car needs to be left for 10 hours. After 10 hours, pour a little oil into each cylinder and start the engine, it should run for 20-30 minutes. The carbon deposits from the exhaust gases should burn out.

Checking compression in UAZ 31519 cylinders

Compression (pressure at the end of the compression stroke) in the cylinders is the most important indicator for diagnosing the condition of the engine without disassembling it. By its average value and by the difference in values in individual cylinders, you can quite accurately determine the degree of general wear of parts of the connecting rod and piston group of the engine, as well as identify malfunctions of this group and parts of the valve mechanism.

Compression is checked with a special device - a compression meter, which can currently be freely purchased at large auto parts stores.

This is what a compression gauge looks like. There are other options for compression meters, in which a rubber tip is installed instead of a threaded fitting for screwing in instead of a spark plug. When checking compression, such compression gauges must be pressed firmly against the spark plug hole.

An important condition for correct readings when checking compression is the serviceability of the starter and its electrical circuits, as well as the full charge of the battery.

You will need a 21" socket wrench to remove the spark plugs.

1. Start the engine and warm it up to operating temperature.

2. Stop the engine, disconnect the low-voltage wiring harness block from the ignition module.

Cranking the engine with the starter while the tips of the high-voltage wires are disconnected and the ignition module is not disconnected can lead to breakdown of its high-voltage circuit.

3. Remove all spark plugs (see “Replacing and servicing spark plugs”).

4. Disconnect the fuel pump by removing the wire block from the fuel pump relay terminals.

5. Screw a compression gauge into the spark plug hole of the cylinder being tested.

6. Press the accelerator pedal all the way to fully open the throttle.

7. Turn on the starter and turn the engine crankshaft until the pressure in the cylinder stops increasing. This corresponds to approximately

four compression strokes.

8. After recording the compression gauge readings, set its needle to zero by pressing the air release valve.

For compression meters of a different design, readings can be reset in other ways (in accordance with the instructions for the device).

9. Repeat steps 5–8 for the remaining cylinders. The pressure must be no lower than 660 kPa (6.65 kgf/cm2) and should not differ in different cylinders by more than 98 kPa (1 kgf/cm2). Reduced compression in individual cylinders can result from loose valve seats, damaged cylinder head gaskets, broken or burned piston rings. Reduced compression in all cylinders indicates wear of the piston rings.

10. To find out the reasons for insufficient compression, pour about 20 cm 3 of clean engine oil into the cylinder with reduced compression and measure the compression again. If the compression gauge readings increase, the piston rings are most likely faulty. If the compression remains unchanged, this indicates a loose fit of the valve plates to their seats or damage to the cylinder head gasket.

The cause of insufficient compression can also be determined by supplying compressed air to the cylinder, in which the piston is pre-installed at TDC of the compression stroke. To do this, remove the tip from the compression gauge and attach the compressor hose to it. Insert the tip into the spark plug hole and supply air to the cylinder at a pressure of 200–300 kPa. To prevent the engine crankshaft from turning, engage the highest gear and brake the vehicle with the parking brake. The release (leakage) of air through the throttle assembly indicates a leak in the intake valve, and through the muffler indicates a leak in the exhaust valve. If the cylinder head gasket is damaged, air will escape through the neck of the expansion tank in the form of bubbles or into the adjacent cylinder, which is detected by a characteristic hissing sound, and when the compression rings wear out, air will escape through the oil dipstick.

Video about “Checking compression in cylinders” for UAZ 31519

https://youtube.com/watch?v=ARLXKnU7XVk

Source

Reasons why there is no compression in the cylinder

Poor (small) compression in one or all cylinders indicates engine wear. There is an old and simple way to determine why compression has disappeared. You need to pour a tablespoon of engine oil into the spark plug hole and repeat the measurements:

- if the pressure has increased noticeably, it means the piston rings have poor sealing;

- if the pressure has not changed, then there may be several reasons (for example, leaking valves, broken gaskets under the cylinder head, there is a crack or burnout in the walls of the combustion chamber, in the piston bottom).

There is another, more accurate way to find out why compression has disappeared. To do this, you will need to modify the spark plug. We remove the insulator from it, and weld the valve of the car camera to the metal body.

Next, set the cylinder piston to the ignition timing position, remove the radiator caps and oil filler neck, screw in the manufactured adapter and pump air into the cylinder using a pump (create pressure in it):

- if air enters the exhaust pipe, it means the exhaust valve is poorly sealed;

- If air goes into the intake manifold, there is a problem with the intake valve.

- if bubbles appear in the expansion tank, then check the cylinder head gasket;

- If there is a hissing sound in the oil filler neck, it means that the piston rings are not properly sealed.

Engine diagnostics using compression measurements in the cylinders allows you to quickly and accurately determine its condition without disassembling, and in some cases will help avoid major repairs of the power unit. Have you ever experienced a lack of pressure in the cylinders? What was the cause of the malfunction? If engine problems persist, check the fuel rail pressure.

Keywords: Lada Granta engine | Lada Kalina engine | Lada Kalina 2 engine | Lada Priora engine | Lada Largus engine | Niva engine | Lada Vesta engine | lada xray engine | universal article

00Found an error? Select it and press Ctrl Enter..

Signs of decreased or lack of compression in the cylinders

List of possible “symptoms” of lack of compression in one, two or all cylinders of the internal combustion engine (internal combustion engine) of a vehicle:

- A malfunction of a diesel or gasoline engine, in which the power unit stops “pulling” - it does not start or starts with difficulty. The engine can be started by cranking the crankshaft for a long time using the starter mechanism. The inability to start is due to the fact that one of the cylinders (or all at once) has low pressure or it is zero.

- Engine operation has become unstable. The revolutions of the power unit float when idling, and while driving at speed they will be unstable. Different compression leads to a loss of normal power or to the fact that this parameter is completely absent after overheating or when cold.

- Increased fuel consumption.

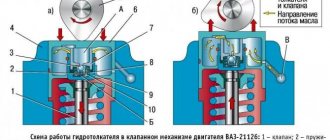

- Problems with the cylinders. If the compression is bad and continues to fall, when driving uphill, a knocking sound from the hydraulic compensators appears (the “clatter” of metal under the hood). This problem is especially obvious if you drive with an injector or carburetor at low speeds.

- On diesel engines, the malfunction is accompanied by popping noises appearing in the internal combustion engine.

- With low compression in 1, 4 or other cylinders (up to 3, 5, 6, 7, 8, 9 atm (atmospheres)), the pressure level in the cooling system lines may increase. This will cause the system to begin to squeeze out refrigerant from under the sealing components. If there is no coolant and the car has leaks, it is necessary to test the compression in the third, fourth and other cylinders.

- The appearance of exhaust gases escaping in the engine compartment from the connection of the cylinder head (cylinder head) with the main module. This problem is usually due to damage or wear to the gasket.

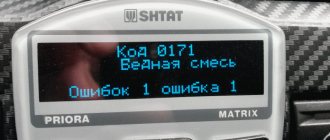

Error code

It is important to know

P030X is an error code that appears when compression in one or more cylinders decreases on most modern cars.

This combination appears when there is a malfunction in the ignition system. Instead of the X symbol, the diagnostic equipment displays the number of the cylinder (for example, 10 or 16) in which the error was registered.

Video: what is the reason for the lack of compression

User Alexander Stepanov spoke about the “symptoms” and reasons why there is no compression in the engine cylinders

What should the compression be?

To identify the point of maximum wear of engine parts, you need to know the permissible pressure values. It is related to the degree of compression in direct proportion - the more, the higher the pressure.

Today you can find 3 types of engines in operation with different characteristics:

- Old engines with a low compression ratio - up to 8.5.

- Modern gasoline engines in which the air-fuel mixture is reduced in volume by up to 9-11 times.

- Diesel engines capable of compressing the fuel mixture from 16 to 24 times.

The combustion chamber of an engine running on diesel fuel is characterized by a small volume. Therefore, the motor does not require an electric spark, just strong compression.

The amount of compression is influenced by various factors:

- tightness of valve seating;

- cracks in valve seats;

- presence of lubricant in the cylinders;

- ring wear;

- wear of parts of the cylinder-piston group.

Norm and minimum

Through testing, data on the optimal pressure in the cylinders for different types of engines was obtained. When the engine has reached operating temperature and the battery is fully charged, the compression should be:

- On older engines equipped with carburetors, the lowest value is 1 megapascal. In old units - 10 bar. If the engine is new, the pressure can reach 13 bar.

- The optimal pressure in a gasoline engine is 1.5 megapascals. The minimum level is 1.1 MPa.

- For a diesel engine, the normal value is 2.4-3 MPa.

If we more accurately determine the indicated coefficient, then for 4-stroke gasoline engines it is in the range of 1.2-1.3, for diesel engines - 1.7-2.

Signs of poor compression

Identification of the lower compression limit indicates increased engine wear. Friction occurs between the piston rings and the cylinder, which increases the gap between the parts. For this reason, compression is reduced.

The following signs can indicate that the compression is insufficient:

- There is a lot of smoke coming out of the breather. This is a valve that serves to remove crankcase gases from injection and carburetor engines.

- Reduced power of the power unit, especially noticeable on small engines.

- A lot of smoke comes out of the exhaust pipe as the engine oil burns in large quantities.

- High oil consumption due to wear of oil scraper rings and caps.

If at least one of these signs is noticed, then there is a reason to conduct a full engine diagnostics.

This will allow timely measures to be taken to restore its functionality. If we consider the reasons for the decrease in compression, we can highlight the main ones:

- Operating a car with a cold engine, thermostat failure.

- Overheating of the power unit.

- Use of low quality lubricant.

- Maintenance and oil changes are not carried out in a timely manner.

- The service life of the engine has expired.

If the head gasket is burned out or the valves are damaged, then changing the lubricant will not help. In these cases, engine repair will be required with replacement of piston group parts and other elements.

Permissible compression difference in cylinders

If the measured compression differs between cylinders, this complicates matters. The engine will have to be disassembled and overhauled. Not only will it be necessary to replace rings, valves and sealing caps.

Compression less than the minimum value in one cylinder means that there are defects in the piston or cylinder. In this case, all elements of the cylinder-piston group are usually changed, otherwise the difference in compression will remain and the problem will not go away.

The normal value is considered to be a pressure of 10-12 bar, depending on the car model and engine. But the permissible difference in compression in different cylinders has also been established. For example, in cylinders 2 and 3 this value may be 0.5 bar lower, which is quite acceptable. It depends on the load on the pistons - where there is more, there is more wear.

Advice! If the pressure in different cylinders differs greatly, for example by 3 or 4 atmospheres, then this is abnormal. The motor will run intermittently. This can happen in several cylinders at once, which brings a major overhaul closer.

How to check compression on a 417 engine

The manual says that the compression should be at least 6.6 points, but what is the compression of a new or fresh engine (so to speak)? Thank you!

This is not the COMPRESSION that should be, but the DEGREE OF COMPRESSION.

The minimum compression for 76 gasoline is 8. The spread between the pots is no more than 0.5 For all engines 9 - 9.5

For 92 gasoline 10-11. The spread between pots is also no more than 0.5

The compression ratio is a purely geometric characteristic, the ratio of the volumes of the cylinder and combustion chamber. Compression is a gas-dynamic characteristic. When the gas in the cylinder is compressed, it also heats up. Some of the heat is lost during heat exchange with parts. Some of the pressure is lost at the seals. The final degree of increase in pressure in the pot based on the sum of all these processes is COMPRESSION. It is always higher than the compression ratio. The compression meter measures exactly this.

2 somehow began to run worse on long hills and just measured the compression on cylinders 1, 2, 3, 4 = 7.5 7.5 5.5 9.5, apparently for repairs? (I drove without an air filter in March, April, May) Could this be the reason?

2 somehow began to run worse on long hills and just measured the compression on cylinders 1, 2, 3, 4 = 7.5 7.5 5.5 9.5, apparently for repairs? (I drove without an air filter in March, April, May) Could this be the reason?

Repairs cost 100 pounds and the reason is also 100 pounds. I wonder what prompted such feats - 3 months without air? - this is the guaranteed death of ruts and sleeves.

2 somehow began to run worse on long hills and just measured the compression on cylinders 1, 2, 3, 4 = 7.5 7.5 5.5 9.5, apparently for repairs? (I drove without an air filter in March, April, May) Could this be the reason?

TsED is 100% right. If the 1st and 2nd cylinders jumped out of the range of cylinders, then the 3rd cylinder completely failed. According to my estimates, the spread in the difference should not exceed more than (15%) Muscheki, do not confuse the compression ratio and the compression itself. I have a compression ratio of 8. And the compression on all cylinders on a hot engine is 9.5...9.8. The engine has already done about 200 thousand.

I’ll bring up an old topic So the engine is 417, head 421 under 80. The engine does not pull normally, compression is 7 everywhere (to avoid cries about a crooked compression gauge, I additionally measured it with a motor tester with a pressure sensor in the cylinder) Well, it seems like a clear matter to sort through, although it does not consume oil and does not breathe. I open the engine, there is no wear and tear in place, I filled the head with diesel fuel, the 3rd day has not run away. Where to dig?

You definitely need kerosene .. I hope it’s hot? And maybe it won’t pull because of the small rotation of the camshaft gear .. maybe they did something else?

We could have installed the wrong group of piston during assembly.

And what do the groups have on the traction? If they are matched to the cylinders, they can be... I have a motor from the capital back in 1989 (I bought it in an ambulance garage) so there are 3 groups of pistons worth A, B and 2 G.. the engine has driven 30 thousand and struck gasket I replaced the gasket and is now driving. There are no problems whatsoever!

I’ll also raise an even older topic. What kind of compression should an engine with this layout generally have (417 motor + 421 heads)? I measured 9 everywhere and only 8 in the third cylinder!

I don’t know what modern science says, but I was taught that the absolute value of compression is not important. The only thing that matters is the difference in cylinders

If there is no oil burn, the spark plugs are not full of oil and the breather does not float, the engine is working properly.

Source

How to check compression without a compression gauge

Without a device you won't be able to measure compression. Because the word “measurement” itself implies the use of a measuring device. So it is impossible to measure compression in an engine without a compression gauge. But if you need to check to determine whether it exists at all (for example, after a broken timing belt or a long period of inactivity of the car, etc.), then there are several simple ways to check compression without a compression gauge. A sign of poor compression is the atypical behavior of the car, when, for example, at low speeds it works sluggishly and unsteadily, and at high speeds it “wakes up”, while their exhaust smoke is bluish, and if you look at the spark plugs, they will be in oil. As compression decreases, the pressure of crankcase gases increases, the ventilation system becomes dirty faster and, as a result, CO toxicity increases and combustion chamber contamination increases.

The most basic way to check engine compression without instruments is by ear. So, as usual, if there is compression in the engine cylinders, then by rotating the starter you can hear how the engine works out each compression stroke with a characteristic sound. Moreover, in most cases the engine may sway a little. When there is no compression, then neither clear beats will be heard, nor will there be any trembling. This behavior often indicates a broken timing belt.

Video on how to check engine compression without instruments

By plugging the spark plug well with a plug of a suitable diameter (rubber, cortical plastic or thick rag), and first unscrewing the spark plug of one of the cylinders, you can check if there is at least some compression. After all, if it is there, the cork will fly out with a characteristic pop. If there is no compression, it will remain where it was.

We will apply additional force when turning the CV. This method of checking compression has no accuracy at all, but, nevertheless, people sometimes use it. You need to unscrew all the spark plugs, except for the first cylinder, and turn them by hand using the crankshaft pulley bolt until the compression stroke ends (determined by the timing marks). Next, we repeat the same procedure with all other cylinders, approximately remembering the applied force. Since the measurements are rather arbitrary, it is preferable to use a compression meter. Every car owner should have such a device, because its price is too high to avoid buying it, and its help may be needed at any time. You can find out the required compression value for your car from the service manual, or at least find out the compression ratio of your car's engine, then the compression can be calculated using the formula: compression ratio * K (where K = 1.3 for gasoline and 1.3-1, 7 for diesel internal combustion engines).

Based on the condition of the exhaust or the condition of the spark plugs, only an experienced mechanic can determine the compression without a device, and then the same thing is relative.

This method is relevant for cars with a worn-out engine, when topping up has become more frequent, and blue-white smoke with a specific odor appears from the muffler. This will indicate that oil has begun to flow into the combustion chambers in several ways. A competent mechanic in the exhaust and the condition of the spark plugs, as well as after analyzing the acoustic noise (to listen to the noise you will need a device, which is a medical stethoscope with a mechanical sensor), will accurately determine what is causing the smoke and oil consumption.

There are two main culprits for the presence of oil, these are oil reflective valve caps or the cylinder-piston group (rings, pistons, cylinders), which indicates deviations in compression.

When the seals are worn out, oil rings often appear around the spark plugs and exhaust, and then a compression test may not be necessary. But if, after warming up the internal combustion engine, the characteristic smoking continues or its intensity increases, we can conclude that the engine is worn out. And to determine why exactly the compression disappeared, you need to perform several simple tests.

Missing compression tests

To get an accurate answer, you need to use all of the listed methods with a comparison of the results obtained.

To determine whether the rings are worn, just spray literally 10 grams of oil from a syringe into the cylinder and repeat the test. If the compression has increased, then the rings or other parts of the cylinder-piston group are tired. If the indicators remain unchanged, air leaks through the gasket or valve, and in rare cases due to a crack in the cylinder head. And if the pressure has changed by literally 1-2 bar, it’s time to sound the alarm - this is a symptom of a burnt-out piston.

A uniform decrease in compression across the cylinders indicates normal engine wear and is not an indicator for a major overhaul.

Boosting with additives: salvation is real, probably confirmed

These additives seem to build up a thin layer on the worn areas of the metal, the thickness of which, however, is sufficient to “replenish” the worn rubbing surfaces of the engine with a certain material, which, moreover, is capable of retaining motor oil. This allows you to further increase the compression in the engine. These additives are available on the consumer market in a fairly wide range, and car enthusiasts can only choose, trusting advertising and the recommendations of friends (if they decide to increase the pressure in the cylinders of their car on their own).

Diagnosing faults

After taking measurements in all cylinders, you should pay attention to two points. The first is whether the measured compression corresponds to the minimum permissible value

The first is whether the measured compression corresponds to the minimum permissible value.

It is determined by the engine developers and is indicated in the repair manual.

The second is the difference in compression values in different cylinders of the same engine.

As a rule, it should not exceed 20% of the nominal value.

If you find that the pressure in any of the cylinders is below normal, inject three portions of oil into it from a manual oil can.

Do not inject more than three portions of oil, as excess oil can lead to the formation of a hydrostatic plug, which can cause breakage of the rings, piston, or even lead to a crack in the cylinder head.

The oil will seal the gap between the rings and the cylinder, and if the reason for the low compression was in this gap, then with such a “wet” test the compression should increase significantly.

Then check the condition of the rings, and if one of them is damaged or stuck, replace it.

If compression behaves this way in all cylinders, then it’s probably time for a serious repair with boring the cylinders and installing rings of the next repair size.

The effect of additives that increase compression is based on the effect of sealing gaps, similar to an oil wedge.

This is the easiest way to restore to some extent the former agility of the engine.

Only in this case you need to remember that their effect is quite short-lived, and repeated use no longer has such an effect.

Therefore, this method is often used before selling a car, so as not to spend money on expensive engine repairs.

If, after injecting oil into the cylinder, the compression changes slightly, then most likely the reason for its drop is a malfunction of the valve group or a broken cylinder head gasket.

From all that has been said, another conclusion follows: low, but approximately equal in all cylinders, compression indicates natural wear of engine parts, but a sharply different drop in one or more cylinders indicates a malfunction.

Sometimes damage or wear to the oil ring can cause compression to rise above the values set for a new engine.

This occurs because the worn ring does not remove excess oil from the cylinder walls, and it seals the gap between the cylinder and the compression rings, and then, during the power stroke of the piston, the oil burns out, forming carbon deposits on the cylinder head.

If this process continues for a long time, then the carbon layer becomes so significant that it leads to a decrease in the volume of the combustion chamber, and therefore to an increase in compression.

This phenomenon is dangerous due to engine detonation. It also leads to increased oil consumption.

What could be the consequences of low or no compression?

List of possible “symptoms” of lack of compression in one, two or all cylinders of the internal combustion engine (internal combustion engine) of a vehicle:

- A malfunction of a diesel or gasoline engine, in which the power unit stops “pulling” - it does not start or starts with difficulty. The engine can be started by cranking the crankshaft for a long time using the starter mechanism. The inability to start is due to the fact that one of the cylinders (or all at once) has low pressure or it is zero.

- Engine operation has become unstable. The revolutions of the power unit float when idling, and while driving at speed they will be unstable. Different compression leads to a loss of normal power or to the fact that this parameter is completely absent after overheating or when cold.

- Increased fuel consumption.

- Problems with the cylinders. If the compression is bad and continues to fall, when driving uphill, a knocking sound from the hydraulic compensators appears (the “clatter” of metal under the hood). This problem is especially obvious if you drive with an injector or carburetor at low speeds.

- On diesel engines, the malfunction is accompanied by popping noises appearing in the internal combustion engine.

- With low compression in 1, 4 or other cylinders (up to 3, 5, 6, 7, 8, 9 atm (atmospheres)), the pressure level in the cooling system lines may increase. This will cause the system to begin to squeeze out refrigerant from under the sealing components. If there is no coolant and the car has leaks, it is necessary to test the compression in the third, fourth and other cylinders.

- The appearance of exhaust gases escaping in the engine compartment from the connection of the cylinder head (cylinder head) with the main module. This problem is usually due to damage or wear to the gasket.

Error code

P030X is an error code that appears when compression in one or more cylinders decreases on most modern cars.

This combination appears when there is a malfunction in the ignition system. Instead of the X symbol, the diagnostic equipment displays the number of the cylinder (for example, 10 or 16) in which the error was registered.

If the pressure drop in one or more engine cylinders is critical, then the problem may be due to engine overheating. Long-term use of a machine with such a malfunction will lead to complete breakdown of the motor.

Operation of the vehicle if there is no compression in one or more cylinders is permitted. This problem can become critical over time, that is, the engine randomly stops during operation. Then using the machine will be, at a minimum, inconvenient.

Let's look at the symptoms that can be used to determine weak and low compression in all, two or the first cylinder. If your blood pressure is low or absent, the signs are:

- Difficulty starting the power unit. In order to start it, the driver needs to turn the starter longer. And as a result of a complete loss of pressure, the engine cannot be started at all.

- The engine began to function less stable. Due to the drop in compression, its speed at idle and when driving in gear will be unstable.

- Increased fuel consumption. At first glance, identifying this symptom is problematic, but if you monitor this parameter, you can calculate it.

- Problems appear in the functioning of the cylinders. When going uphill, there is a knocking sound from the hydraulic compensators (“fingers”). This is especially obvious when driving at low speeds.

- In a diesel engine, the problem manifests itself as popping noises.

- The pressure in the cooling system lines may increase. As a result, antifreeze will begin to squeeze out from under the sealing elements.

- If there is poor compression in one or more cylinders and this is due to damage to the cylinder head gasket, then the tightness of the system as a whole is compromised. By opening the hood, you can diagnose this problem by the presence of exhaust gases that exit through the gap that appears. Such a malfunction leads to stuck piston rings, which ultimately increases fuel and oil consumption. In some vehicles, this symptom is complemented by an increase in the power of the power unit and the appearance of abundant smoke from the muffler.

Analysis of compression meter indicators

Measuring compression in cylinders most often gives the following results:

- The pressure indicator is in the range of 11-15 with a difference in individual cylinders of no more than 1. This means that the indicator is normal, but for correct conclusions you need to check the data with the technical documentation of the car.

- The presence in some cylinders of pressure much less than in the others indicates a malfunction. If the problem is in the cylinder, pour 5-10 ml through the spark plug hole. engine oil and repeat the measurement. A significantly increased compression indicates wear or stuck piston rings. Eliminating such a breakdown involves decoking the engine rings.

If the compression has not changed, then the problem lies in the tightness of the valve closure, namely in their poor fit, burnout or incorrect adjustment. Alternatively, the piston, cylinder block gasket or crack in the cylinder head may burn out.

A compressor is used to find the location of the breakdown. The search procedure is performed as follows:

- The piston in the cylinder being tested is placed at TDC.

- The car is put on the handbrake and 4th or 5th gear is engaged.

- The compressor pumps pressure into the cylinder and controls air leakage:

- When the hissing sounds into the adjacent cylinder, air passes through the burnt-out cylinder block gasket. In this case, the gasket will have to be replaced;

- If there is a breakdown in the cooling system, the plug in the radiator or expansion tank is unscrewed. If there is a leak, there will be an increase in the level of antifreeze, or bubbles coming from the liquid;

- If there is a hissing sound coming from the manifold or muffler, the problem is a loose valve.

How to increase compression in cylinders yourself?

If the compression is below the normalized value, then it can be increased in several ways:

- If the valves are incorrectly adjusted in 2 or other cylinders, then adjusting them will solve the problem of low compression. If the thermal clearances are not set to normal and the motor does not work, you will have to change the valves and grind them in.

- A damaged cylinder head gasket must be replaced.

- If the problem is the appearance of defects on the block head as a result of overheating, then the easiest way to increase compression is by trimming the surface of the unit. Serious defects in the body of the device can only be eliminated by replacing it.

What will you need?

To carry out decoking you will need:

- alcohol;

- kerosene;

- gloves;

- spark plug key.

Checking engine compression with your own hands without a compression gauge

There are only two tools to check this important motor parameter:

- pressure gauge to check engine compression;

- the car owner's own hands.

Undoubtedly, these two methods are incomparable in terms of the accuracy of the obtained values. No professional would check compression by hand. However, you can use this method in a situation where there is no station or device nearby. After all, even an approximate compression value will help assess the condition of the engine.

Despite the simplicity of manual compression measurement, you still need to develop a little skill in this matter and have certain knowledge. Taking into account the above, even beginners can do the procedure.

The procedure for checking compression in engine cylinders is as follows:

- The first step is to unscrew the spark plugs, except for the first cylinder.

- The crankshaft is turned, trying to place the piston in the first cylinder at the top point of the compression stroke.

- Checking the marks will help determine the exact position of the piston.

- Remember the force required to manually crank the crankshaft.

- Unscrew the spark plug from the first cylinder and replace the spark plug of the second cylinder. Then they repeat everything from the beginning.

The purpose of these measures is to use the method of elimination to find out in which of the cylinders the compression value is lower than in the others. This will be clearly visible if the crankshaft turns easier when checking a given cylinder than in other cases.

The method does not claim to be absolutely accurate. However, even with this simple method it is possible to clearly determine which cylinder needs repair. Specific pressure values can only be obtained using a device designed for this purpose - a pressure gauge for checking compression.

Video “Measuring compression in the engine”

We invite you to learn how to measure blood pressure yourself.

What is the first thing they do when diagnosing an engine? That's right, they measure the compression in the cylinders. Many believe that its value determines the health of the engine. The authors find out whether this is so during the next analytical examination.

Compression is a vulgarism. That's right - the pressure at the end of the compression stroke. This is the pressure that is created in the cylinder when the ignition is turned off (or without fuel supply - for a diesel engine) with the piston position at top dead center. So, many diagnosticians, based on the measured compression (sorry, science, for the jargon!) give a conclusion: “the patient is alive” or “to the morgue,” that is, for major repairs.

According to many advanced motorists, compression is almost everything for an engine! But is it?

What's the result?

As you can see, the need to measure compression may arise for various reasons. This procedure is often used as part of a general diagnosis of the internal combustion engine. Measurements are also taken after the engine has been assembled after repair (both major and overhaul). This is necessary to identify possible defects after assembly.

Also, if necessary, the device can be made independently, using a pressure gauge, tubes and various adapters. For this reason (especially owners of cars with significant mileage) it is recommended to have a separate ready-made measuring device in the car.

- Signs of burnt valves

How to determine a burnt engine valve yourself. The main symptoms of a burnt valve, exact clarification of the causes of engine tripping. Diagnostics, useful tips. Read more

- Signs of a broken cylinder head gasket

How to independently determine that the cylinder head gasket has burned out. Recommendations for pulling the cylinder head after replacement. Which gasket is better to choose? Read more

- Engine trouble: what is it?

Engine trouble: symptoms. Why does tripping occur and how to find the reason why the motor starts to trip. Checking power, ignition, compression, etc. Read more

- Valve knocking on a cold engine

Valves knock on a cold engine or after warming up the engine: possible causes of valve mechanism knocking. Fault diagnosis, useful tips. Read more

- Increased compression in the engine: reasons

High compression in the engine and the main reasons for increased compression. Why does compression also decrease across the cylinders? Tips and tricks. Read more

- Low compression in a diesel engine

Problems starting a diesel engine. Signs of low compression and causes of malfunction: timing belt, cylinder mirror, piston and rings. We measure the compression. Read more

What to do if the engine has no compression or low compression

It is quite obvious that a decrease in compression indicates the need to repair the power unit, which involves disassembling and troubleshooting the internal combustion engine. Only after these procedures can you get an idea of the condition of the CPG and timing belt, as well as other elements and components of the engine.

However, it also happens that the cause of a decrease in compression can be eliminated without disassembling the engine. We are talking about removing coke, carbon deposits and deposits. This solution allows you to clean the combustion chamber, restore mobility to the piston rings, remove carbon deposits from the valves and ensure their tight fit.

To more accurately determine how serious the problem is, without disassembling the internal combustion engine, you first need to pour 7-8 “cubes” of engine oil into the problem cylinders. Then the compression needs to be measured again.

If adding oil does not change the situation, then valve related problems are likely. If the compression increases after adding oil, then you should look for the problem in the wear of the CPG elements. So, in this case, the rings could have stuck, and decoking the piston rings in some cases can correct the situation.

Let us immediately note that this method will not necessarily help, but it is worth a try, especially since the owner will not require significant financial investments.

- In short, to decarbonize the engine, you need to purchase a special cleaning fluid.

- Next, you need to unscrew the spark plugs and pour 30-40 grams into each spark plug hole.

- Then the spark plugs are not screwed in (you can cover the holes with a clean rag), and the car itself should be left in the garage for 10-12 hours.

- After the specified time, you will need to crank the engine with the starter with the spark plugs removed. Next, the spark plugs are cleaned and reinstalled.

Please note that after pouring the decarbonizer, you must not immediately screw in the spark plugs and try to start the engine! In this case, residual liquid in the combustion chamber can cause water hammer.

After the engine has started, the engine needs to warm up a little, after which you will need to go on the highway. Then the car is accelerated to 110-130 km/h, after which you need to drive 25-30 km at high speeds.

We also recommend reading the article about why the engine has high compression. From this article you will learn about the main reasons for increased compression in engine cylinders, why this phenomenon also negatively affects the operation of the internal combustion engine, like a decrease in compression, and also what to do in this case.

Upon completion, compression measurements must be repeated. If nothing has changed, then bracing the rings did not help or the problem lies in severely worn parts. In this case, the engine only needs to be repaired.

We also add that some car owners seek to avoid internal combustion engine repairs and actively use various additives to restore compression. It is important to understand that in practice such solutions can help in some cases, but they are simply not capable of removing burrs and “smoothing out” other defects.

In fact, such compositions are also decarbonizing agents, but the price may differ significantly from more affordable analogues. Some other additives for restoring engine compression can further complicate the inevitable repair of the power unit if the composition is positioned as a metal revitalizer, that is, it tends to form a so-called protective and restoring layer on worn surfaces.

conclusions

Checking compression is the most practical way to determine the condition of the mechanical parts of the engine without the need to disassemble it. These diagnostics will help you identify problems that are negatively impacting engine performance. Once you get accurate results, it will be easier to make an informed decision about what to do next.

The cylinder-piston group of the unit can be determined after assessing its current condition. Once the cause of the malfunction in the performance of the unit is established, the engine can be repaired to ensure 100% efficiency. Checking engine compression does not require unnecessary waste of time. A special diagnostic method has been developed, which is carried out in the service under the supervision of a qualified specialist.

To determine the cylinder-piston group, you will need to use a special diagnostic device. This unit is also called a compression meter. According to experts, it is necessary to measure compression pressure in order to diagnose the cylinder-piston group. However, this is not considered the most informative way.

For further procedures, specialized diagnostic equipment is prepared. A damaged cylinder can be identified by measuring compression. Car owners can carry out the procedure themselves. First you need to unscrew the spark plugs.

Experts say that to carry out diagnostics, it is necessary to order a special compression meter. The cost of this device varies from four hundred and reaches up to eight hundred rubles. Such a device can be used only two or three times.

In order not to make a mistake in choosing a compression gauge, it is advisable to use a device with a threaded tip. This way you can easily check the corresponding engine compression measurement. It is necessary to clarify the parameters of the compression gauge pressure fixing valve. These elements must be in the head. Accordingly, the valve is screwed into the spark plug hole.

By measuring engine compression, car owners can avoid underestimating the indicator in this unit. But, for example, diesel cars are best checked at a car service center. Since removing spark plugs and injectors requires certain knowledge and skills. Therefore, for those who do not understand these features, it is better to entrust the matter to a real specialist. In this case, the use of special tools is necessary.