How to quickly and accurately determine the condition of the engine? Check the compression in the cylinders! Is the engine running rough, you feel a loss of power, the consumption of engine oil or fuel has increased and the car has become difficult to start in cold weather? All of these problems may be caused by low compression in one or more cylinders.

Cylinder pressure indicators

First of all, you need to understand what compression is and why it worries Niva car owners so much. This term refers to the amount of pressure in the cylinder when measured with a pressure gauge at starter speed. Nowhere in the technical documentation supplied with the car will you find the concept of compression, although many car enthusiasts and auto mechanics operate with it.

But among the technical parameters of the car it is easy to find such a parameter as the compression ratio. For both the regular VAZ 21213 and the Chevrolet Niva, its value is the same and equals 9.3. The reason is that all these machines have the same engine - a modernized 2106 with a strengthened crankshaft and piston diameters increased to 82 mm.

Compression and compression ratio are two different indicators that are practically unrelated to each other. The latter is a constant value and does not depend on the degree of wear of the power unit. It shows how compressed the air-fuel mixture entering the cylinder is when the piston moves to top dead center. The compression ratio is calculated as the ratio of the total volume of the cylinder to the size of the combustion chamber, where the combustible mixture is compressed and flares up.

Compression is determined by practical measurement. The lower its value, the worse the condition of the Niva engine and the closer it is to a major overhaul.

What are the cylinder compression standards for VAZ engines?

Engine specifications must indicate “minimum cylinder compression values.”

If you could not find such data, determine the compression standards yourself using the formula: Compression (kgf/cm2) = compression ratio (see technical specifications of the internal combustion engine) * coefficient (for VAZ min 1.2, max 1.3)

- The compression ratio of modern VAZ 21126 and VAZ 21127 engines installed on Granta, Kalina and Priora is 11. We multiply the values using the formula and get the compression standards: 13,2..14,3.

- For the Vesta engine (VAZ-21129) the compression ratio is 10.45, the compression standards will be: 12,5..13,6.

- For Niva (VAZ 21213, 21314) - 11,3..12,2.

If the compression gauge values in all cylinders are within the normal range, this does not mean that everything is fine. Different compression in the cylinders is also bad. It is important that the difference between all readings is minimal. Compare the minimum and maximum compression values in the cylinders. According to technical standards, the difference should be no more than 1 kgf/cm2 or 10% .

Characteristics of motor 21214

It is believed that the basis of the ICE 21214 was the previous version 21213. In fact, ¾ of the parts in the engine

- the engine layout has changed - an injector instead of a carburetor;

- additional attachments appeared - DPKV, DXX sensor, Bosch MP 7.0 controller;

- crankshaft with a long crank radius of 40 mm, not used in previous AvtoVAZ engines;

- Cylinder head with holes for phase sensor and receiver studs, hydraulic supports for valve levers instead of adjusting bolts.

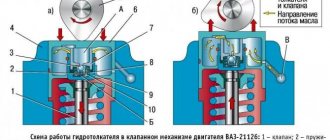

Hydraulic supports

Since the base model bends the valve, the 21214 engine did not escape this fate, so the manual includes not only a description of the engines, but also maintenance regulations in order to ensure at least the minimum declared service life of 80,000 km, which was promised by the manufacturer’s representatives.

Cylinder head 21214

The design of the power drive 21214 provides it with the following technical characteristics:

| Manufacturer | AvtoVAZ |

| Engine brand | 21214 |

| Years of production | 1994 – … |

| Volume | 1690 cm3 (1.7 l) |

| Power | 59.5 kW (81 hp) |

| Torque moment | 127.5 Nm (at 4000 rpm) |

| Weight | 122 kg |

| Compression ratio | 9,3 |

| Nutrition | injector |

| Motor type | in-line |

| Injection | distributed electronically controlled |

| Ignition | modular |

| Number of cylinders | 4 |

| Location of the first cylinder | TVE |

| Number of valves on each cylinder | 2 |

| Cylinder head material | aluminum alloy |

| Intake manifold | duralumin |

| An exhaust manifold | cast iron or welded steel |

| Camshaft | original cam profile |

| Cylinder block material | cast iron |

| Cylinder diameter | 82 mm |

| Pistons | from 21213 |

| Crankshaft | from 21213 |

| Piston stroke | 80 mm |

| Fuel | AI-92 |

| Environmental standards | Euro-2/3 |

| Fuel consumption | highway – 8.3 l/100 km combined cycle 10.5 l/100 km city – 11.5 l/100 km |

| Oil consumption | maximum 0.7 l/1000 km |

| What kind of oil to pour into the engine by viscosity | 5W30, 5W40, 10W40, 15W40 |

| Which engine oil is best by manufacturer | Liqui Moly, LukOil, Rosneft, Mannol, Mobil |

| Oil for 21214 according to composition | synthetics, semi-synthetics, mineral |

| Engine oil volume | 3.75 l |

| Operating temperature | 95° |

| ICE resource | declared 80,000 km actual 160,000 km |

| Adjustment of valves | hydraulic compensators |

| Cooling system | forced, antifreeze |

| Coolant volume | 7.8 l |

| water pump | with plastic impeller |

| Candles for 21214 | BCPR6ES from NGK or domestic AU17DVRM |

| Spark plug gap | 1.1 mm |

| Timing drive | single row chain |

| Cylinder operating order | 1-3-4-2 |

| Air filter | Nitto, Knecht, Fram, WIX, Hengst |

| Oil filter | with check valve |

| Flywheel | from 21213 with clutch bore diameter 200 mm or 215 mm |

| Flywheel mounting bolts | M12x1.25 mm, length 26 mm |

| Valve stem seals | manufacturer Goetze, light inlets, dark exhausts |

| Compression | from 12 bar, difference in adjacent cylinders maximum 1 bar |

| XX speed | 800 – 850 min-1 |

| Tightening force of threaded connections | spark plug – 31 – 39 Nm flywheel – 62 – 87 Nm clutch bolt – 19 – 30 Nm bearing cap – 68 – 84 Nm (main) and 43 – 53 (rod) cylinder head – three stages 20 Nm, 69 – 85 Nm + 90° + 90° |

With the advent of hydraulic thermal valve lash compensators, it is recommended to use exclusively high-quality engine oil.

What should the compression be in VAZ cars?

The average compression rate for unboosted VAZ engines is 8-9 atmospheres, for forced ones with a reduced combustion chamber - 11-13 atmospheres.

In order to accurately determine the standard compression ratio, use the table that indicates the compression ratio in the cylinders of eight- and sixteen-valve VAZ engines.

| Number of valves | 16 | 16 | 8 | |

| Engine volume, l | 1,5 | 1,6 | 1,5 | 1,6 |

| Cylinder diameter/piston stroke, mm | 82/71 | 82/75,6 | 82/71 | 82/75,6 |

| Compression ratio | 10,5 | 10,3 | 9,9 | 9,6 |

Design Features

Initially, the 21214 engine was developed for distributed injection, that is, for an injector. It was planned to ensure an environmentally friendly standard, which was carried out successfully - during the finalization process, the internal combustion engines had Euro-2 - Euro-4, and for the export versions of Niva and Nadezhda, even Euro-5.

The main feature of 21214 was the factory boost:

- injector instead of carburetor;

- modified cylinder head (hydraulic pushers);

Hydraulic support ramp (bottom)

In turn, this required improvement of other designs:

- the volume of engine oil has increased, the pump sprocket now has 30 teeth to increase its performance;

- the double-row chain is replaced by a roller-type single-row modification to drive attachments and the timing camshaft;

- The camshaft cams have changed shape.

Design 21214

Upgraded chain tension system:

- the spring creates pre-tension when the engine is off;

- After starting, pressure is created in the system, the tension is regulated by hydraulics.

Hydromechanical chain tensioner

The manufacturer has provided additional do-it-yourself tuning due to the +50 hp potential built into the design. With. Overhauling the simplest internal combustion engine design does not cause any problems, including in a garage on your own.

Bosch 0280158110 injectors were first installed on the fuel rail, then yellow Siemens VAZ 20734. The ignition has a modular design with Bosch MP 7.9.7 and January 7.2 controllers. Pair-parallel injection provides Euro-2, phased injection – Euro-3.

Taking a measurement

Measurements of the compression value are carried out in each cylinder separately, and the power unit must be in a warm state. In a cold engine, the readings will be lower than actual ones, although in the presence of a glaring malfunction they will also be able to reflect the picture. To measure you will need the following tools and devices:

- spark plug key;

- a pressure gauge (otherwise known as a compression gauge) of a threaded or clamping type;

- rags.

A pressure compression gauge is a steel tube with a handle, at one end of which a rubber cone and valve are installed, and a pressure gauge is screwed to the other. The device is inserted with a rubber cone into the threaded part of the cylinder and pressed using the handle. In this case, you cannot do without the services of an assistant who turns on the starter. A pressure gauge with a hose and a thread at the end will have to be screwed into each hole one by one, but you can check it yourself. The procedure for performing measurements is as follows:

- Remove the high-voltage wires from the spark plugs and move them as far away as possible to avoid electric shock.

- Unscrew all spark plugs and wipe their seats with a rag. It is advisable to arrange them in the order of unscrewing, so that during diagnostics you can determine which cylinder the spark plug was removed from.

- Insert or screw the end of the device into the hole of cylinder 1 and turn on the starter for 3-6 seconds.

- Record the readings and move on to the next cylinder.

If for some reason the measurement did not work or you held the compression meter askew, the procedure must be repeated. Take your time to clean the spark plugs; their condition can tell a lot during the test analysis.

Reasons why there is no compression in the cylinder

Poor (small) compression in one or all cylinders indicates engine wear. There is an old and simple way to determine why compression has disappeared. You need to pour a tablespoon of engine oil into the spark plug hole and repeat the measurements:

- if the pressure has increased noticeably, it means the piston rings have poor sealing;

- if the pressure has not changed, then there may be several reasons (for example, leaking valves, broken gaskets under the cylinder head, there is a crack or burnout in the walls of the combustion chamber, in the piston bottom).

There is another, more accurate way to find out why compression has disappeared. To do this, you will need to modify the spark plug. We remove the insulator from it, and weld the valve of the car camera to the metal body. Next, set the cylinder piston to the ignition timing position, remove the radiator caps and oil filler neck, screw in the manufactured adapter and pump air into the cylinder using a pump (create pressure in it):

- if air enters the exhaust pipe, it means the exhaust valve is poorly sealed;

- If air goes into the intake manifold, there is a problem with the intake valve.

- if bubbles appear in the expansion tank, then check the cylinder head gasket;

- If there is a hissing sound in the oil filler neck, it means that the piston rings are not properly sealed.

Engine diagnostics using compression measurements in the cylinders allows you to quickly and accurately determine its condition without disassembling, and in some cases will help avoid major repairs of the power unit. Have you ever experienced a lack of pressure in the cylinders? What was the cause of the malfunction? If engine problems persist, check the fuel rail pressure.

Article rating:

How to check compression on a Chevrolet Niva Link to main publication

Related publications

- How to determine TDC without labels

To ensure that the compression test gives accurate results

Compression depends not only on the technical condition of the engine, but also on the conditions under which it is measured. Make sure that during the check:

- the compression gauge was working properly;

- the engine has been warmed up to operating temperature (up to 90 degrees);

- the throttle valve was fully open;

- spark plugs in all cylinders must be turned out;

- the starter was fully operational;

- the battery was fully charged;

- The engine air filter was clean.

Fixing problems

In most cases, when the friction parts of the engine wear out, the pressure drops, although there is a malfunction in which the compression, on the contrary, increases. It is necessary to consider possible breakdowns in order, starting with the causes of low pressure:

- The piston rings are worn. Average engine oil consumption is observed (up to 300 g per 1000 km), and compression is uniformly reduced in all cylinders. To verify this, you can dump 5-7 g of oil inside, crank the crankshaft using the starter and repeat the measurement. If the pressure increases sharply by 2-3 bar, then the problem lies in the rings.

- I developed my resource for the entire piston group. Oil consumption is high. from 300 to 500 g per 1000 km, from the exhaust pipe. gray smoke, and on the candles. oil deposit. When the pressure is re-measured with the addition of oil, the index does not increase because the gaps between the walls of the engine friction parts are too large.

- The valves are poorly adjusted, in the jargon. jammed. If there is no gap between the tappet and the camshaft neck when cold, then when it heats up, the latter expands and opens the channel, it remains open. Because of this, compression can drop to zero and the cylinder does not work.

- The valves may be slightly open due to accumulated deposits on the pressure side. Then the pressure can also drop significantly. Typically, this situation is the result of oil entering the combustion chamber through worn rings. That is, when the cylinder head is removed, a complex fault occurs.

Sometimes in Niva cars, compression may disappear in 4 cylinders and noticeably decrease by 3: this is the result of engine overheating.

The fourth piston, as well as the furthest one from the cooling fan, significantly expanded and damaged the cylinder walls (burnt in the slang). The same thing happens with 3 pistons, although to a lesser extent.

Also interesting: Niva and Chevrolet Niva Tuning Shop from 10:00 to 18:00

The engine runs poorly and smokes, oil consumption. up to 1 liter per 1000 km. Urgent need for major repairs.

Analysis of test results

Based on the measurement results obtained, conclusions can be drawn in accordance with recommendations developed over many years of practice:

- from 13 to 14 Bar - excellent compression, observed on new run-in engines;

- from 12 to 13 Bar - good indicators, the power unit is in normal condition;

- 11-12 Bar - acceptable indicators, the condition of the piston group is within normal limits, but is approaching wear;

- a pressure of 10 bar or lower indicates that it is time to repair the engine.

When carrying out the analysis, it is necessary to take into account an important point - the uniformity of readings in all cylinders.

If over time the pressure gradually and equally decreases in each of them, then there is a natural process of wear of the piston rings, piston walls and cylinders. If 1 or 2 measurements differ sharply from the others, then regarding repairs you need to be guided by the worst indicators.

It wouldn’t hurt to examine the condition of spark plugs that were operating with poor compression. If their electrodes are covered with oil deposits, and the lubricant itself is present in the area of the sealing ring, then the piston rings in these cylinders are at least damaged. If the electrode of the spark plug is covered with a black coating, then the combustible mixture in this chamber was not completely burned, which may be caused by the spark plug itself, and the consequences may be development and carbon deposits on the piston.

You should start to seriously worry in 2 situations:

- when all indicators fell below 11 Bar;

- when the readings in different cylinders differ by more than 1 bar.

- if in one of the cylinders there is a pressure of 0 to 3 bar.

When there is practically no compression in some place, this means that this cylinder does not take part in the operation of the engine, which is why gasoline consumption immediately increases by 25%. Repairs must be made immediately.

Troubleshooting

In most cases, when the rubbing parts of the engine wear out, the pressure decreases, although there is a malfunction in which the compression, on the contrary, increases. It is necessary to consider possible breakdowns in order, starting from the causes of low pressure:

- The piston rings are worn out. Average engine oil consumption is observed (up to 300 g per 1000 km), and compression decreases evenly in all cylinders. To verify this, you can drop 5-7 g of oil inside, crank the crankshaft with the starter and repeat the measurement. If the pressure increases sharply by 2-3 bar, then the problem is in the rings.

- The entire piston group has exhausted its service life. Oil consumption is high - from 300 to 500 g per 1000 km, blue smoke is noticeable from the exhaust pipe, and oil deposits are present on the spark plugs. When the pressure is measured again with the addition of oil, the indicator does not increase, since the gaps between the walls of the rubbing parts of the engine are too large.

- The valves are poorly adjusted, in the jargon they are clamped. If there is no gap between the valve tappet and the camshaft journal when cold, then when heated, the latter expands and opens the channel slightly, it remains constantly open. Because of this, compression may drop to zero and the cylinder will fail.

- The valves may be slightly open due to accumulated carbon deposits on the working part. Then the pressure can also drop significantly. Typically, this situation is the result of oil entering the combustion chamber through worn rings. That is, the malfunction is complex and is detected when the cylinder head is removed.

Sometimes in Niva cars, compression can disappear in cylinder 4 and decrease noticeably in cylinder 3: this is the result of engine overheating.

The fourth piston, being the farthest from the cooling fan, expanded greatly and damaged the cylinder walls (in jargon, it burned out). The same thing happens with piston 3, although to a lesser extent.

The engine runs poorly and smokes, oil consumption is up to 1 liter per 1000 km. Major repairs are urgently needed.

What cars was it used in?

Motor 21214 was used to equip several cars manufactured by AvtoVAZ:

- Lada Niva 4x4 (VAZ-21214) – three-door SUV;

- Lada 4x4 M - modernized version with power steering and ABS;

- Lada 4x4 5D (VAZ-213100) – an extended modification of a five-door SUV;

- “Ambulance” (VAZ-213145) – Euro-2/3 in small series;

- Lada Nadezhda (VAZ-2120) is a seven-seater all-wheel drive minivan.

Niva Lynx 4x4

The management did not consider it necessary to install it on the seven-seater Largus minivan. But in all modifications of the Niva 3- and 5-door (Bronto, Kedr, Pickup, Reka, Bys and armored collection vehicle) it was present.

Chevrolet Niva suspension, diagnostics and repair

Repairs or diagnostics can be carried out either at a specialized car dealership or independently. And in order to save money, many prefer the second option. And if you also prefer the second option, this article will help you with this.

An excellent domestic SUV is the Chevrolet Niva; the front suspension, just like on any other car, requires timely maintenance so that it lasts a long time.

- Check that all rubber parts are free of signs of wear, aging and mechanical damage.

- Also check that there are no various cracks or signs of aging on the rubber-metal hinges, or that the rubber has not come off the reinforcement. If you find such elements, they should be urgently replaced with new ones.

- Check the condition of the protective covers of the ball joints and hinges. If they seem worn out, you will have to replace the entire hinge assembly.

- Pay attention to the condition of the bushings of the rubber lower and upper hinges.

- Check the condition of the rubber-metal bushings of the levers at the lower and upper hinges.

- Inspect the rubber bushings on the stabilizer bar, check the condition of the stabilizer brackets, which are attached to the arms and side members.

Also interesting: Niva 4x4 or Chevrolet Niva: which is better, comparison, how it differs from a simple Lada, which one to choose, 2121 or 2231, reviews from car owners

Increased pressure

A paradoxical situation with increasing compression occurs when motor lubricant hits the piston rings from above, from the side of the combustion chamber. It seals the interface and when measured, the pressure jumps to 14-15 bar.

The reason is due to worn valve seals, which leak a lot of lubricant into the Niva’s combustion chamber. The exhaust smokes desperately, the oil consumption is high, but the pistons and rings have nothing to do with it. The problem is detected when the valve cover is opened and the clamps are removed from the valve tappets. Unusable caps have an “oak” feel to the touch or are covered with cracks. Oil seals can be changed without disassembling the power unit.

Source: korchim.ru

Independent Wheel Bearing Clearance Repair

If you feel or feel vibration in the steering column while driving, then most likely the clearance on the front wheels in the bearings of the hub itself has increased, so their service life will be reduced, and the tires will begin to wear unevenly. And if there is no gap at all, then the hub will rotate tightly, which will also lead to a decrease in service life, so its gap should be greater than zero fifteen ml. Adjustment of the front bearings is carried out using a wheelbrace wrench, a twenty-seven wrench and a hammer.

- A wheel that is in a suspended state should be rocked; if there is play, the gap must be adjusted. After this, press the brake pedal and rock the wheel; if there is no play, then there is a gap in the bearings.

- It is necessary to dismantle the decorative cap and unscrew the lock nut from the hub, and hold it with a wrench to prevent it from turning. When repairing the chassis while adjusting the hub, it is advisable to install new hub nuts, since even after adjustment there is a high probability that the old ones will take their original place, which will not allow them to be properly locked. If this is not possible, then you can take the nut from Drugov’s car.

- Then you need to twist the hub nut so that the torque is 19.6 Nm. turning the hub several times, ninety degrees in two directions, will install the bearing itself. After this, loosen the adjusting nut and tighten it to 6.8 Nm. Having done all this, simply unscrew the nut twenty-five degrees.

- After everything is done, change the collar of the nut on the pin of the external drive joint.

- After the adjustment is made, check how the wheels rotate; if they rotate easily, then everything is fine. The final check can be made only after driving several kilometers without braking, assessing how the hub heats up.

Also interesting: Suspension lift in the field yourself

Recommendations

Comments 11

I was present on an interesting occasion when a broken head gasket was being replaced on a shnivy. And after assembly it does not start, there is no compression. It turns out that before assembly it was necessary to remove the oil from the hydraulics and compress them until they stop. Otherwise there will be no compression.

Did you remove the camshaft?

I removed the camshaft, but as it turned out I had simple adjusting bolts and there were no hydraulic compensators. When I changed the oil scraper, it started up without any problems.

I didn't set the labels correctly.

Yes, I bent the valves, how much you can harp on the same thing. Take off the head, install new valves, grind them in. Business day.

Doesn't it show in any cylinder? Prehistory - why did you start measuring compression? Not a single sensor affects the compression... By ear - when cranking the engine, if there is a “squeak” sound from the cylinders quite loudly, then there is compression, the compression gauge turns out to be broken. The day before yesterday we picked up a new one at the store, it seems 5.5 maximum, I checked with mine, it seems 12.5 on the 21083 engine, it happens.

There are no sprays, but the air is spitting out. The backstory is scary. I changed the chain, put it on the wrong marks, spun it - it didn’t start. Now I have assembled it according to the marks and am checking to see if the valves are bent. The compression gauge is working, I checked it on 2 cars. Maybe the battery is dead?

Then most likely the valves are bad. Even on the podskvshim there will be compression

There are no sprays, but the air is spitting out. The backstory is scary. I changed the chain, put it on the wrong marks, spun it - it didn’t start. Now I have assembled it according to the marks and am checking to see if the valves are bent. The compression gauge is working, I checked it on 2 cars. Maybe the battery is dead?

You can check the valves like this: put the hose to the cylinder (from where you unscrewed the spark plug) and blow, if it blows easily or hisses from another cylinder, it means the valves...

There are no sprays, but the air is spitting out. The backstory is scary. I changed the chain, put it on the wrong marks, spun it - it didn’t start. Now I have assembled it according to the marks and am checking to see if the valves are bent. The compression gauge is working, I checked it on 2 cars. Maybe the battery is dead?

It will be science. Before you turn the engine with the starter (if you have one in the garage), jack up the wheel and turn the engine smoothly with the wheel for a few revolutions, if not according to the marks, then the valve will rest...

Malfunctions, causes, elimination

Initially, engine 21214 has a characteristic failure - failure of 1 - 2 cylinders due to failure of the ignition module due to overheating. The coils and control switch burn out, and electrical equipment needs to be replaced. Other breakdowns are typical for most VAZ engines:

| At idle, the internal combustion engine is unstable and stalls. | 1) damage to the insulation of high-voltage wires 2) spark plug malfunction 3) valve timing failure 4) compression decreased | 1)replacement of high-voltage beams 2)adjusting the interelectrode gap, cleaning carbon deposits 3) installation according to shaft marks 4) valve grinding, cylinder repair |

| XX speed decreased spontaneously | 1) production of DXX | 1) replacing the idle speed sensor |

| The engine stalls while driving in the heat | 1) check valve stuck 2) the hose or tube is pinched 3) the drain line has failed 4) steam plug in the supply system | 1) valve replacement 2) inspection and correction of geometry 3) purging the line 4) purge and cleaning |

Hydraulic compensators eliminate the need for scheduled adjustment of valve clearances after 5–15 thousand kilometers.

Fuel and drain line

Signs and causes of disappearance

There are actually quite a few signs and reasons why there is no compression in one, two or all cylinders at once. Therefore, for users of our resource, materials have been collected that can help determine a decrease in the pressure level in the system.

Signs

If a gasket burns out in the cylinder head, the tightness of the cylinder itself is immediately compromised. This can be seen if exhaust gases begin to escape through the resulting gap. At this moment, the rings become stuck, which entails increased consumption of motor fluid and gasoline. In addition, in some cases, the engine power may increase, and smoky exhaust will come out of the exhaust pipe.

Cylinder operation diagram

If your car has lost compression in all cylinders at the same time or in just one of them, then the signs may be as follows:

- the engine became much more difficult to start;

- the engine is unstable, both at idle and while driving in gear, at all speeds;

- you noticed that your “iron horse” began to consume much more fuel;

- problems also began with the cylinders;

- if your car is equipped with a diesel internal combustion engine, then while the engine is running you will hear frequent popping noises;

- The pressure in the cooling system pipes increases.

Causes

What could be the reasons? There are a lot of them, but we will look at them all:

- cracks have appeared in the exhaust valve device, as a rule, this is caused by wear of the motor;

- the exhaust valve fits very poorly, which entails leakage through the place where the valve comes into contact with the “seat”;

- the valve “seat” itself is completely destroyed or has mechanical damage;

- The cylinder head gasket has burnt out. This could happen due to wear and tear. In addition, the cause of gasket wear may be contamination on the contact surfaces of the gasket. It can also burn out as a result of engine overheating, which will subsequently lead to cracks on the block or deformation of the cylinder head or the block itself;

- due to engine overheating, cylinder scuffing may occur;

- the cylinder-piston group in your engine is worn out;

- the inter-ring bridges of the piston have failed, that is, they have collapsed;

- in addition, the reason why there is no compression in one or two cylinders may be a failure of the intake valve;

- a crack has formed in one or more cylinders or on the pistons themselves;

- carbon deposits have appeared on the oil seals and piston rings, which reduces the pressure in the system;

- there are malfunctions or malfunctions in the operation of the gas distribution system;

- broken chain or timing belt. If the timing belt or chain breaks while driving a car, this may well be the reason why the valves are bent;

- the valve has stopped closing or there is a large gap when closing it. If the gap is too large, then the valve most likely does not open enough, which may be caused by incorrect adjustment or wear of the elements. Additionally, if there is not enough air flowing to one or more of the cylinders, you will hear a knocking sound under the valve covers.

Checking compression in Chevrolet Niva cylinders

Checking compression in engine cylinders

Compression gives an idea of the condition of the engine. The test results indicate whether the valves and pistons (piston rings) are OK or worn. In addition, the test results allow you to decide whether to replace the engine, whether it requires a complete overhaul, or whether it is sufficient to replace the cylinder head gasket. To check, a compression meter is required, which for gasoline engines is available in specialized stores at an affordable price.

The engine must be warmed up to operating temperature and the battery must be fully charged. You will also need the help of an assistant.

Remove the fuel pump fuse from the mounting block (refer to the Chapter On-board electrical equipment ). Start the engine and wait until it stops. If the engine does not start, crank the starter for about 10 seconds.

To gain access to the spark plugs, remove the oil filler cap and remove the plastic engine boot. Replace the cover.

Disable the ignition system by disconnecting the connector from the ignition coil. Remove all spark plugs.

Install a compression gauge into the spark plug hole of the first cylinder. It is advisable to use a compression gauge, the tip of which is screwed into the spark plug hole.

Have an assistant keep the accelerator pedal fully depressed and turn on the starter. After several cycles, the compression in the cylinder will reach its maximum value and will not change anymore. Write down your result.

The maximum permissible pressure difference in individual cylinders can be 3.0 bar (for diesel engines 5.0 bar).

Compression in a working engine increases very quickly. A low value shown after the first cycle, increasing with subsequent cycles, indicates piston ring wear. A low value after the first cycle that does not increase after the next cycle indicates that either the valves are leaking or the head gasket is broken (a crack in the head may also be the cause). The presence of carbon deposits on the valve plates can lead to a decrease in compression.

Please note that due to different starter rotation speeds on different models, the measured results may vary. The results obtained from measuring compression should be approximately the same for all cylinders.

If the pressure in any cylinder is at the minimum permissible level or even lower, then follow these steps to determine the cause. Pour a teaspoon of engine oil into the cylinder through the spark plug hole and repeat the compression measurement.

If adding oil temporarily improves compression, the cause of the drop is most likely piston, ring or cylinder wear. If there is no increase in compression, then we can assume that the reason is leaky valves or a broken head gasket.

Low compression in two adjacent cylinders is almost certainly a consequence of a blown head gasket. The presence of coolant in the combustion chambers or in the engine crankcase will confirm this assumption.

If the compression in one of the cylinders is about 20% lower than in the others, and the idle speed is unstable, then the cause may be excessive wear on the camshaft cam.

After completing the check, reinstall the spark plugs, put the high-voltage wire tips on them, and connect the connector to the ignition coil. Reinstall the plastic engine cover and fuel pump fuse.

Compression pressure values for various engines are given in the Specifications .

Check for leaks

During this test, the exit speed of the compressed air pumped into them from the cylinders and the leak locations are determined. This test is an alternative to a compression test. Moreover, from many points of view, it is much more effective, since it is easier to visually identify the source of the leak than to comprehend the results of compression measurements.

The equipment required to check for leaks is not publicly available, so this check will have to be carried out by service center specialists.