In what cases is a car “jerking” detected?

Most cases of car “jerking” are associated with problems with wear of spare parts or clogging of one of the car’s systems. While driving, you can detect vehicle twitching at the following stages:

- When starting only at the beginning of the car's movement;

- When driving at low speeds;

- During a sudden increase in speed;

- When driving at high speed;

- When driving in any mode (periodic shocks at different periods of time).

Consider the case of a vehicle malfunction when driving at low speeds.

Inability to gain power

Situations are also possible when the engine makes “heavy” sounds, which is accompanied by the inability to gain full power. And there are reasons for this.

If you purchased Granta new, then the problem may be its newness.

Until a break-in period of 6-7 thousand kilometers is completed, maximum power cannot be gained. Moreover, it is not recommended to increase the crankshaft speed above the 3 thousand mark for the first 2000 thousand kilometers.

Low pressure in the fuel system

If at high speeds it seems to you that the engine:

- does not develop enough power,

- It's like he's hitting a wall

- or when accelerating, “they throw extra weight into tow”

this indicates insufficient pressure in the fuel system. This could be due to a clogged fuel filter. In this case, diagnose and replace the fuel filter.

Bad fuel (gasoline)

The loss of power may be due to low quality fuel, in other words, when you were filled with “badyagu” under the guise of 92 or 95 gasoline. Often, gas stations dilute gasoline with water, or use special “Chinese” cheap additives to increase the octane number of low-grade fuel. In the worst case scenario, you will have to drain all the gasoline from the tank and fill it with new one.

Electronic gas pedal glitches

As in the previous case, the problem may relate to a malfunction of the electronic gas pedal . In addition, there is a chance that the pressure in the ramp is not high enough. The solution to these two problems can be found in the previous section.

The engine will not be able to gain power because the valves are clogged or the spark plugs do not operate stably enough, as a result of which some strokes “skip”.

Insufficient compression

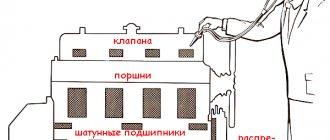

In addition, do not forget about the possibility of low compression in the cylinders, which is less than 1.0 MPa. To find out the reasons for this phenomenon, it is necessary to disassemble the motor. This will make it clear whether the cylinder head gaskets or pistons have burned out, or whether the piston rings have broken or stuck. Among other things, the cause of such compression may be poor adjustment of the timing valves. If the engine has already covered a sufficient mileage, then we are talking about natural wear and tear on the engine components.

On an 8-valve Lada Granta engine, it is necessary to measure compression only after adjusting the valves!

The compression on the Lada Granta should be at least 12-13 atmospheres. If it is more, about 15, then most likely it is necessary to replace the oil scraper rings. If the compression is less, the engine is worn out, it needs to be repaired, it will not develop sufficient traction!

Compression gauge - it is used to measure the compression in the engine

Riding style

Speaking about why the car jerks when starting from a stop, we need to start with the obvious. The very first and most obvious reason is a harsh clutch. If you start, add gas and suddenly release the clutch pedal, the car will definitely jerk. Therefore, first of all, you need to try to change your driving style. At a minimum, when starting off, you need to release the clutch pedal very slowly and add a little more gas. However, you shouldn't press the gas pedal too hard.

However, if with an automatic transmission the car jerks when starting, then you won’t be able to change your driving style here, because there is simply no clutch pedal. But even with a manual transmission, the problem may be different. If the car still jerks even when starting smoothly, the problem is clearly not a sudden grip of the clutch discs.

Unstable engine operation

If the engine runs unstably and stalls when idling, then there are reasons for this. It is quite possible that we are talking about insufficient pressure in the ramp. We also talk about the difficulties in the functioning of the electronic gas pedal.

In the first case, it is worth checking the pressure regulator. Just keep in mind that in new Lada Granta models this regulator may be located in conjunction with the fuel pump. As for the second situation, the check should concern the electronic part of the car, including the power unit adjustment system.

Air supply problems

The problem may also be that there is an air leak in the system. It may be located on the crankcase ventilation hose that connects the inlet pipe to the brake booster. You should carry out additional tightening of the fastening clamps. And, if the need arises, the hoses must be replaced with new ones.

If the problem concerns violation of valve clearances, then the solution requires contacting a service station.

If you own a Granta with an 8-valve engine, it is worth adjusting the timing valves every twenty thousand kilometers.

Or it could be different. If the air filter is clogged, it will be more difficult for air to get through and an overly rich mixture will flow into the injectors. In this case, diagnostics and replacement of the air filter is necessary.

Spark plug

The problem could be the spark plugs.

And, of course, the reason may relate to a malfunction of the ignition system. We are talking about the source of the problem in the form of spark plugs or individual coils. If you have localized the source of the breakdown, then the faulty part must be replaced. On 16-valve engines, AU17D spark plugs are installed from the factory.

More details in the materials:

An indirect factor that may indicate problems with the spark plugs is increased fuel consumption. However, increased consumption may also appear for a number of other reasons; for more details, see the material: reducing the fuel consumption of a Lada Granta car.

Engine and gearbox mounts

If jerks occur when moving the selector from neutral to “reverse” or “drive” on a stationary car, then the first thing you should do is check the health of the engine and gearbox mounts. When they are severely worn, the power unit tilts much more than usual when engaging forward or reverse, which causes a noticeable jolt.

Jerks when engaging forward or reverse gear usually appear due to wear of the rear support of the power unit.

Jerks when engaging forward or reverse gear usually appear due to wear of the rear support of the power unit.

External and internal CV joints

If some suspension parts are poorly secured, then when driving (especially during a sharp start), they can cause the car to jerk. First of all, you need to check the inner and outer CV joints. The inner CV joint transmits rotational energy from the gearbox to the axle shafts and then to the wheels. This element is quite important, and if problems arise with it, it must be changed. This can be done at any service station. Features of failure of the inner CV joint are as follows:

- When destroyed, the inner CV joint becomes loose and can turn when transmitting forces, especially at the start.

- On a straight road without the smallest potholes, the inner CV joint can knock. In this case, it will seem that a dull knock is coming from the wheels.

- Outer CV joints may crunch when turning. If destroyed, they can also cause the car to jerk when starting off.

- Usually, internal CV joints simply wear out and because of this they fail. However, rarely the gearbox can cause a breakdown of this unit. This happens in cases where there is something wrong with the box itself.

- Outer CV joints can break due to impacts or careless driving on a bad road.

If your VAZ car jerks when starting from a stop, then first of all you need to check the CV joints. Often on forums when discussing a similar problem, users point to this particular node. Considering the prevalence of these cars and the cheapness of spare parts, repairing this element is unlikely to be expensive. It is worth noting that a similar problem occurs on the VAZ-2114 car. When starting off, the car jerks, but after replacing the CV joint (“grenade”), the problem disappears.

You will be very lucky if the problem turns out to be in the car's CV joints. These are inexpensive items that are easy to replace. It is much worse if a fault is discovered in the gearbox.

The car jerks at low speed injector

The situation when a car starts to move unevenly is familiar to every motorist. The problem, which manifests itself in jerking and jerking, can be caused by the incorrect operation of various automotive systems. Today we will look at the common symptoms of this “disease” and share recommendations for eliminating them.

So, a violation of the smoothness of the ride and the associated jerks of the car occur:

- when starting off;

- during acceleration;

- at low speeds;

- when the engine is operating at maximum load;

- in transient conditions;

- in all of the above cases.

Determining the culprit of the malfunction

The car can “twitch” while driving for various reasons, so you should adhere to a certain troubleshooting algorithm. If there are no obvious signs of transmission malfunction, then first of all we check the power and ignition system.

Failures in the engine power system

Malfunctions in the system for preparing and supplying the fuel mixture are indicated by jerking of the machine in motion. In this case, the malfunction can manifest itself in different ways:

- The car begins to twitch when the accelerator pedal is pressed sharply. At the same time, instead of gaining speed, the engine runs jerkily, and therefore the car picks up speed very reluctantly. At some stage, the twitching stops and the engine “picks up.” In other cases, the power unit stalls when the throttle is maximally open, or jerking occurs when the gas is released.

- The unevenness of the ride appears unexpectedly - when the car is moving at a constant speed, in a stable speed mode.

As you can see, uneven engine operation can appear both when the crankshaft speed changes sharply or smoothly in one direction or another, or when operating at stable speeds. The reason for these phenomena is a simple lack of combustible mixture, due to which the engine simply cannot develop power sufficient to overcome the resistance of the transmission.

To eliminate negative phenomena, we check several main components of the power system:

1. Filter. Even with a working fuel pump and a clean fuel line, the engine will begin to starve if the fuel filter is clogged with dirt. The way out is to replace or clean the filter element - it all depends on where exactly the blockage occurred. The fact is that car engines have several cleaning elements installed along the fuel path. If you are dealing with an injection internal combustion engine, then you should pay attention to the third filter element located after the fuel pump. Designed to separate the smallest particles, it clogs quite often, which is why the gas pump cannot pump the required volume of fuel through it. For carburetor cars, we check both the third filter installed in front of the carburetor, and the second one - it is located between the fuel tank and the fuel pump. If replacing them did not yield anything, then you should check the coarse filter installed on the fuel receiver. In addition, the cause of insufficient fuel supply may be the mesh located in front of the float chamber in the carburetor body.

2. Throttle assembly . Malfunctions in the throttle can be caused by wear and damage to its parts and contamination. And if the first requires serious repairs, then in the second case, simple cleaning of the throttle assembly elements mechanically will help. In the case of carburetor internal combustion engines, the situation is more complicated, because you will have to completely disassemble the carburetor and clean all channels, jets, diffusers, etc.

3. Fuel pump. To troubleshoot the fuel pump, remove the cap, then inspect the diaphragm and valve hole. In most cases, the jerking of the car when driving, associated with a decrease in fuel supply due to the fuel pump, occurs due to the o-ring - it may be located somewhere near the valve or may be completely absent. To restore the pump's functionality, replace the damaged diaphragm and the problematic valve, and then restore the tightness of the system. In addition, it is recommended to clean the mesh, which is located directly in the fuel pump housing. As for injection engines, their fuel pumps are electrically driven and located in the tank. Therefore, check if there are any losses in the fuel line itself.

4. Sensors. Since the power system of a modern car is crammed with electronics, one should not lose sight of malfunctions of the mass air flow sensor (mass air flow sensor), idle speed sensor (regulator) and throttle valve position (TPS). Very often the car jerks just when starting from a stop - at this time the throttle position sensor signals the engine control unit about the need to increase the fuel supply. Naturally, if the operation of the TPS is disrupted in the transient mode, jerks and dips will be observed.

5. Fuel rail. Due to increased (more than 4 atm) or decreased (less than 2 atm) pressure in the fuel rail, the composition of the combustible mixture changes towards depletion or enrichment, since the ECU calculates the fuel supply for normal parameters. In this case, the stable operation of the engine will be disrupted.

6. Air ducts. We check how tight the connection between the air filter and the receiver is.

There is no need to rush into checking the power system if jerking began immediately after refueling the car. Perhaps the reason is bad fuel or gasoline, the octane number of which does not correspond to that for which the car’s power unit is designed. In this case, the low-quality fuel should be drained and gasoline purchased at a trusted gas station should be used.

Jerking and jerking also occur due to malfunctions in the ignition system. At the same time, very often uneven driving is accompanied by an increase in fuel consumption, a problem with starting the internal combustion engine or a loss of power.

Something else useful for you:

Incorrect operation of the ignition system

Interruptions in engine operation and the associated uneven movement of the car most often occur due to untimely ignition of the fuel in the cylinders or an insufficiently powerful spark. First of all, pay attention to the following points:

1. Performance of spark plugs. By the shade of soot on their working part, one can judge both the correct operation of the ignition system and how well the air-fuel mixture ratio corresponds to the norm. For example, black carbon deposits indicate a rich mixture or a faulty ignition. When starting diagnostics, check and adjust the gap between the spark plug contacts as required by the car manufacturer. After this, proceed to check sparking. The spark generated by the spark plug should be powerful (as drivers say, “fat”), with a blue or purple tint. The orange color and filament-like state of the spark may indicate current leakage through insulator cracks, and the ignition coil voltage is not high enough. Don't forget that problems with candles can occur due to using them for too long.

2. High voltage wires. A visual inspection should be made for damage and the condition of the conductors should be checked with a megger. Current leakage along the surface of the wire is clearly visible in the dark.

3. Sensors. If checking and replacing spark plugs and wires yields nothing, then the cause of unstable operation is the camshaft position sensor (CPS). You can check it using a conventional multimeter - the moment a metal object approaches the DPRV magnet, the readings of the device should change. Sometimes a breakdown of the knock sensor leads to interruptions, but this rarely happens - most likely, the car simply will not start.

4. Ignition coils. If there is no spark or its power weakens, check for a break in both windings and current leakage to the housing. The latter occurs with external damage, so before starting measurements, the coils are examined visually.

Transmission breakdowns

Jerking when starting off and jerking of the car while moving can appear due to malfunctions:

- clutch;

- mechanical or automatic gearboxes;

- mounting points for the gearbox or power unit (breakage of brackets, wear of supports, etc.);

- wear of parts of internal CV joints.

As you yourself understand, wear or breakdown of gearbox or clutch parts can only be identified after removing the problem unit and disassembling it. As for checking the condition of the power unit supports or diagnosing the CV joint, this can be done on an inspection pit or a lift. The condition of the constant velocity joint is checked by turning the drive shaft in one direction or the other at an angle of 20-40 degrees. If the CV joint remains motionless, this indicates the need to replace it due to excessive wear.

Oil filter

This is another reason why the box may kick. This element traps all dirt and waste products. Over time, this filter becomes clogged, which reduces its throughput. Because of this, the oil pressure in the box drops noticeably.

As a result, the friction discs cannot stop at the right time. With an automatic transmission, when you engage reverse gear, the car jerks. The solution to the problem is quite simple - replace the filter with a new one.

| Dear visitors! The site offers standard solutions to problems, but each case is individual and has its own nuances. |

| If you want to find out how to solve your particular problem, call toll-free ext. 504 (consultation free) |

Please note that the oil strainer is a consumable item. It cannot be cleaned mechanically and cannot be reinstalled in the automatic transmission. The element is subject to replacement only.

Is it due to the fuel filter?

So, it has been determined that the car jerks only under certain conditions. The fuel system pipes are all normal, but it is believed that the cause lies in the fuel system.

This means that the filters need to be checked next. Often it is because of them that this malfunction appears.

The task of any filter element in the fuel system is to clean the fuel from impurities, but at the same time, these impurities do not disappear anywhere, they remain in the filter itself.

Over time, it becomes so clogged with impurities and dirt that its throughput drops, and greatly.

As a result, the fuel pump pumps as expected, but the fuel does not have time to pass through the filter elements and the engine begins to “starve”, accompanied by the car jerking. There is only one way out here - .

If you take into account a carburetor car, then the number of filters it has is 2-3 pieces, but one of them, the usual mesh on the fuel receiver, can be practically discounted.

This mesh is aimed only at catching large particles, so it is practically incapable of becoming clogged to such an extent that it stops the flow of fuel in the required quantity.

But the second filter, usually located in the pipelines leading to the fuel pump, is worth checking.

This filter is designed to capture smaller particles, and it is not difficult for it to become clogged.

The third filter is not available on all carbureted vehicles and is usually located at the fuel inlet to the carburetor. It is also a regular mesh, but only fine.

This filter itself is small, so it often gets clogged.

Older machines had another filter installed - a coarse filter, also known as a sediment filter.

The design of this filter is such that it is not capable of becoming clogged to such an extent that it will not allow fuel to pass through. But this filter will subsequently cause rapid clogging of the fine filter.

If this filter accumulates a large amount of debris and dirt, then eventually it will not begin to clean the fuel from impurities, but, on the contrary, will begin to add them.

Injection car filters.

Most modern injection cars are also equipped with three filters. The first of them is a mesh for catching large particles installed in the neck of the tank. This mesh is clearly not the cause of the twitching.

The second filter is located on the fuel pump installed in the tank. This filter is also often a mesh, only with smaller cells; its task is to prevent large debris from entering the fuel pump.

It is also unlikely that it can cause a fuel shortage.

But the third filter, a fine filter, is located behind the fuel pump and is quite capable of becoming clogged to such an extent that the pump cannot push the required amount of fuel through it.

On more modern cars, there may be additional filters, which can also cause the car to twitch.

What causes the car to jerk when running at low speeds?

Since the car begins to twitch when reaching even low speeds, it will not be possible to immediately identify one specific problem. Problems may be hidden:

- In the engine fuel mixture supply system;

- In the vehicle ignition system;

- At the checkpoint;

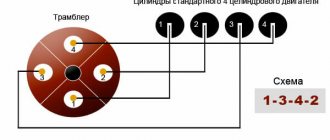

- In the distributor design;

- Includes fuel filters;

- In the sparking system;

- In the control unit of the vehicle's on-board computer.

Let's go through the faults in each of the listed systems in detail.

Tip: When detecting a “jerking” behavior in the vehicle, the brakes may also squeak when braking. These 2 problems can be either interrelated or indicate completely different breakdowns.

Checking the engine fuel mixture supply system

Often the reason that the car jerks at low speeds is due to a malfunction of the power system. When the car starts to move, the cylinders simply cannot receive the required amount of fuel mixture, as a result of which the car is unable to transfer the required amount of power to the chassis for smooth driving and smooth commissioning of the transmission. As a result of increased pressure and transmission resistance, uneven running of the machine appears.

Causes of overclocking failure

You can determine the reason why the car jerks using diagnostics. Possible problems:

- Malfunction of the fuel supply system;

- Damage to engine temperature and mixture enrichment sensors;

- Errors in the ECU;

- Faulty spark plugs;

- Damage to high-voltage wires or ignition coils;

- Clogged or faulty injectors:

On HBO, the problem may arise due to:

- Faulty HBO control unit;

- There is interference in the harness to which the fuel injectors are connected;

- Gas wiring;

- Bad mass.

Why does the VAZ-2112 injector twitch when accelerating: symptoms and treatment

More than once, drivers encounter a problem when a VAZ-2112 begins to stall and twitch when accelerating. What is this connected with? The reason that unites all the factors remains the wrong gasoline mixture or its poor quality.

The video shows symptoms and treatment methods when the car jerks:

A front-wheel drive car of the VAZ family is considered.

Steering gear

If the steering mechanism is faulty, a similar problem can also occur. If the steering rack has any malfunction, it can create jerks when starting. In this case, the worn parts of the rack are simply replaced, and the problem disappears.

Also, the steering rack tips may have strong play. As a result, during a sharp start or braking, or increase in speed, so-called steering wheel wobble may occur. Bent tie rods result in a sharp jerk of the steering wheel to one side when starting off. This problem requires a quick solution.

Other elements of the steering system, including bushings and silent blocks, can cause the car to knock and jerk when driving. All this applies to the steering mechanism - it can be the reason why, for example, a GAZelle car jerks when starting off. But GAZelle is not the only brand where such breakdowns occur.

Note that problems with the steering mechanism are easier to solve than problems with the automatic transmission. However, the steering mechanism requires urgent repair for the safety of the driver and passengers.

Common reasons for all engines

The engine characteristics specified in the vehicle's passport data are provided under certain conditions. This is the normal filling of the cylinders with air, which in an internal combustion engine is the working fluid. This is also an opportunity to heat it to the required temperature in time - to supply a certain amount of fuel of the appropriate quality and ignite it in time (the peak pressure for maximum efficiency should occur at the moment the piston passes the top dead center).

ICE duty cycle

Loss of engine power, regardless of its design, results from a number of common reasons. Let's start with the fuel: its quality remains lottery, but the engine is tuned to a certain grade. That is, the mixture prescribed in the injection maps or set by the carburetor settings may deviate from the ideal one, and the combustion rate of the mixture changes. So, if problems appeared immediately after refueling, you know which way to look.

Filling the cylinders with air is strictly related to the valve timing. It is enough to leave the marks, and the operating cycles of the internal combustion engine will be shifted: already a difference of 1 tooth can significantly reduce the engine power. Moreover, the belt or chain does not have to jump - more and more motors are receiving keyless pulleys, which require rigid fixation of the shafts with special devices during installation. When replacing the timing belt, you will not reach the pulley, and one day it will move from the specified position. And it’s good if the engine simply loses traction, and does not hit the piston on the valves that did not close in time, driving them into the cylinder head.

In engines with variable gas distribution, the camshafts (at least one) have the ability to shift so that, with sufficient throttle response at the bottom (small phase overlap), it does not lose at the top (the camshafts move “towards each other”, increasing the overlap phase, which increases power at high speeds ). Possible reasons why the car does not pick up speed are a failure of the VVTi control valve or problems with the phase shifter clutches. We have already discussed this issue when talking about injection system errors.

In addition, the filling of the cylinders is tied to the intake and exhaust resistance. To clog the air filter so much that it loses its flow capacity - this must be done, but oil emissions through the crankcase ventilation system, especially if the piston is already worn out and the oil catcher is primitive, are not uncommon. On a VAZ-2106 it is not difficult to force the engine to “sip oil” through the crankcase ventilation, and even on new front-wheel drive cars (2109, 2110, 2114) such cases are possible. An oily air filter has a sharp increase in resistance, hence the loss of engine thrust.

The exhaust on carburetor cars and old diesel engines is simple, and reducing the flow area sufficiently enough for the engine to start “choking” on exhaust gases can only be done with a powerful blow (when driving over bumps, for example) or with the canonical potato - but at least it’s immediately noticeable.

If the engine with electronic injection does not pull, then the catalyst comes under suspicion in this case. Overheating and ingress of fuel due to malfunctions in the power supply system can cause sintering of its honeycombs. For diesel engines with particulate filters, soot becomes the main enemy: automatic burning of the filter on the go is ineffective, and at a minimum, forced regeneration must be performed.

Problems with the exhaust easily reveal themselves: when the engine is turned off, when you try to start it again, it emits smoke into the intake, the sound of the engine changes, and leaks immediately “crawl” out (the exhaust begins to “cut” to the damaged area).

The engine must not only receive the right amount of air and fuel - it must ignite in time. A gasoline engine requires an appropriate ignition timing; a diesel engine requires an injection timing. Since modern injection engines do not have a separate ignition system, problems with ignition timing are primarily characteristic of carburetor cars and old injection systems with a distributor (the Japanese used such systems right up until the early 2000s). Check the basic advance angle, adjusted by the distributor, and the operation of the advance machines in it (if there is a malfunction, the angle that is normal at idle will begin to “go away” when the speed increases).

A separate case is engines where the distributor is driven by a separate pulley from the timing belt (old Audis and Volkswagens). Here, when replacing the belt, the distributor pulley is placed “as needed” (there are no marks on this pulley!), forgetting that when replacing the belt, the distributor must be oriented with the cam along the risk on the crankcase under it. After such a replacement, the car stops driving because the ignition angles change. For diesel engines with a mechanical injection pump, the initial injection angle is set, in addition, the advance regulator works - they are checked according to the data from the repair and maintenance instructions.

On gasoline engines, we also include spark plugs as suspects: even if the engine operates normally at idle, it is not a fact that the spark plugs will work well under load, when the pressure in the cylinders at the end of the compression stroke increases and the conditions for sparking become worse. It’s worth installing another set for testing: without an oscilloscope that allows you to take voltage curves from a working ignition system, it’s difficult to determine how the spark plug actually behaves under load. In the illustration below, look at the peak voltages corresponding to the moment of spark formation: in the third cylinder the gap is excessively widened, the spark flares up at too high a voltage, and its duration drops (the power accumulated in the ignition coil is not enough for the spark to burn normally).

If we talk about compression, then under normal conditions it decreases with wear so slowly that the decrease in power occurs unnoticed by the driver. The exception is rapidly developing breakdowns (cracks of piston rings, destruction of partitions between the rings, burnout of valves). Simultaneously with the drop in power, the idle stability will sharply drop; the final diagnosis will definitely be made by a compression meter.

As for turbocharged engines, the condition of the turbocharger has a good effect on their dynamics. An ideal centrifugal pump (turbocharger impeller) has a quadratic dependence of performance on rpm: as soon as the rpm drops by half, the boost pressure drops by four. Wedging of the rotor due to destruction or coking of the bearings, burning of the “hot” impeller is the probable reason why a turbocharged car does not pull. Here, as with compression, a pressure gauge will help out.