The valve system of an internal combustion engine is very complex and precise. To solve a problem in the valve system, it is first necessary to diagnose its cause. Just replacing a damaged valve won't help much if the reason is that the valve guide and valve seat are misaligned. Replacing a valve that has burned out will not solve the situation if its burnout occurred due to a “hot spot” on the cylinder head. As long as the hot spot is present, the valves will continue to burn out.

- How to identify a burnt valve?

- Causes of valve burnout

- Consequences of valve burnout

- How to fix a burnt valve?

Therefore, an important point will be to analyze the causes of the breakdown before attempting repairs. A valve that has burned out or broken, worn guides, or other problems with the valve system are often the end result of a whole chain of events. One problem leads to another, which ultimately leads to valve failure.

How to identify a burnt valve?

There are several ways to check the valve for burnout. The most proven and simplest is the search for a non-working cylinder among all. To do this, you need to start the power unit. While it is idling, it is necessary to remove the caps from the spark plugs. If after this the engine changes speed, then such a power unit is faulty. And if, after removing the cap from the spark plug, you see that the engine is running as before, then the fault has affected the cylinder.

When the engine starts to stall, you should unscrew the spark plugs and swap them, or replace one of them. When you have swapped the spark plugs, start the engine immediately. If after this it starts and works normally, it means that the spark plug turned out to be working and the other cylinder stopped working.

If such a replacement turns out to be ineffective, then insert the spark plug back into the cap and put it on the engine and run it with the starter: if a spark appears, then everything is in order, but if there is no spark, then something is wrong with the slider or distributor or a fist. The very first sign of a burnt-out valve is smoke coming from the breather, which means that the spark plug is left without oil. If the piston breaks, then blue smoke will come out of the breather, and the spark plug will be covered with oil.

Valve burnout is also checked in one old way: to do this, measure the cylinder compression, this is done using a compression meter.

Then fill the cylinder with oil using a syringe and then also check the compression. If after these manipulations the compression does not rise, it means that the valve has burned out. If the compression rises, it means that a breakdown has occurred in the piston. Many motorists do not want to change a burnt-out valve, but this has a detrimental effect on engine power and fuel consumption.

Causes of valve burnout

There are many reasons for valve failure. Less often they talk about already defective factory valves, but this is the second of the main reasons for failure. The main reason is mechanical and thermal overloads.

One of the leading manufacturers of motor valves cited statistics that every fifth valve produced breaks due to manufacturing defects. The results of this study were published ten years ago. The control system has improved significantly since then, although the materials and production processes have not changed. But still, even ultra-modern quality control systems cannot provide a guarantee that the valve you have just purchased is free from any defects.

The defect may be metallurgical heterogeneity included in the alloy, which weakens the valve; forging defects leading to microcracks; pores and heat treatment errors that result in incorrect valve dimensions; poor adhesion of the chrome coating on the valve surface. Therefore, when purchasing a new valve, do the following:

– check that the valve dimensions comply with nominal standards, and that the valve is free of obvious defects;

– purchase valves only from reliable and trusted manufacturers.

All valves wear out over time. But there are those that fail much earlier than expected, and there are two reasons for this - burning and breaking. Exhaust valves often burn out due to the fact that their heating reaches significantly higher values than those of the intake valves.

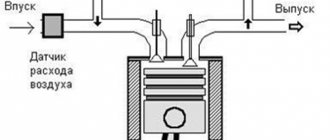

The intake valves are cooled by the incoming air-fuel mixture.

The operating temperature of such valves is approximately 400°C. The exhaust valves do not have such a cooling system and, in addition, they are still heated by the flow of exhaust gases. During operation, these valves heat up to 650°C, which means they are more vulnerable to burnout and destruction. The high-temperature operating environment requires the alloy of which the valve is made to have the proper characteristics. Exhaust valves are usually made of stainless steel, both entirely and just their heads. In powerful gasoline and diesel engines, the operating temperature is even higher, so the exhaust valve is coated with a stellite coating in the form of a cobalt-based alloy, which prevents its rapid wear.

Heat is removed from the intake and exhaust valves through the guide valve and its seat. Three-quarters of the heat is dissipated through the valve seat, so it needs good contact with the seat to prevent burnout. The remaining heat is dissipated through the valve stem and is further exhausted out through the valve guide. If the valve is not regularly cooled, it will overheat and subsequently burn out.

We recommend: Motor oil labeling

Anything that prevents the valve from cooling properly or creates excessive heat will cause the valve to burn out. The formation of carbon deposits on the valve and its seat prevents it from properly cooling and leads to inevitable overheating. This is also facilitated by poor contact between the valve and the seat, if it is very narrow and does not have a concentric or elliptical shape.

A spring that is too weak or a decrease in valve clearance worsens the mutual contact between the seat and the valve, which again leads to overheating. This is also facilitated by a worn seat or guide, which prevents heat transfer to the power unit.

When installing the valve, pay attention to its height. Lapped valves are located much deeper in the cylinder head than necessary. This leads to higher protruding rods, the geometry of the rocker arm is disrupted, and when the power unit heats up, the valve clearance disappears. If the required geometry is not restored after grinding down the tips of the rods, the saddles must be replaced. Another option is to install a valve with slightly larger heads that compensate for the ground seat.

Reduced valve clearance is a common cause of valve burnout. If the valve seat is worn, it moves deep into the cylinder head and reduces the clearance. As a result, the gap is completely or partially closed, and the valve does not fit well to the seat, gets very hot and subsequently burns out. This happens mainly on old engines that do not have rigid seats and are installed on heavy trucks, marine, agricultural and industrial vehicles. The way out of this situation is to install more rigid valve seats with stellite coating.

Valves can also burn out due to problems with the cooling system in the power unit itself if its operating temperature becomes extremely high. Lack of coolant, problems with the thermostat, hydraulic pump, clogged radiator, broken fan or fan switch - all this leads to overheating of the power unit. This, in turn, leads to enlargement of the valve stems, reducing the gap between the guide and the stem, which leads to the valve sticking into the guides, and it can jam. If the valve gets stuck in the open position, the piston will hit the valve, which will lead to destruction of the piston, valve and other parts.

Overheating of the valves also occurs due to greatly increased combustion temperatures. Factors such as premature or late ignition, lean fuel mixture, and detonation can play a fundamental role here. Similar reasons leading to valve overheating are exhaust obstruction caused by a clogged catalytic converter or pipe damage.

Consequences of valve burnout

If you do not replace a burnt-out valve for a long time, but continue to drive, then the first negative consequence will be high fuel consumption due to the fact that the engine is not able to produce its normal power, and the valve seat may burn out too much, as a result of which you will have to change the head.

In rare cases, a piece may break off the valve and end up in the cylinder. If this element is too large, it can pierce the head and piston. In special cases, the cylinder may also be punctured, which completely disables the power unit.

If you refuel your car with gas, then the necessary procedure will be periodic adjustment of the valves every ten thousand kilometers.

Gas burns the valves too much, especially in cases where the gas supply is set poorly. In cars that run on gas fuel, the exhaust valves are often slightly tightened. And as soon as you start adjusting the valve, it will clamp and burn out. Cars that “eat” gasoline are less susceptible to valve burnout.

Do not deliberately reduce the gas supply in order to save money. Due to a lean gas mixture, the engine significantly loses power, and excessive gas consumption occurs more significantly, since you have to press the accelerator pedal more, plus the valves and their seats gradually burn out. If the gas mixture is adjusted correctly, the power of the power unit increases so much that the difference between driving on gasoline or gas is smoothed out. But do not forget about frequent valve adjustments when driving on gas. Often, motorists decide to adjust the valves only when noise appears, but this is only suitable for those who drive gasoline. In the case of gas, you should not wait for valve noise to appear. The valve will jam and burn out even without such obvious signs.

How to fix a burnt valve?

When starting this activity, know that the first step is to remove the head from the power unit.

This procedure is performed precisely in cases with a burnt-out valve, when it absolutely does not hold, and the engine begins to stall. Valves of any format are the same, there are differences in size and placement in the head. The lapping is the same everywhere.

You will first need to purchase lapping powder. Dilute its dry composition with machine oil, or the same one you pour into the engine. Pour the powder into a previously prepared container, add oil until you obtain a porridge-like mass of medium thickness. Be sure to prepare a new gasket that you will place under the head, as well as valve seals. Often it is the exhaust valves that burn out. There are many reasons - the valve is jammed, there is a lean mixture (when the unit operates on gas), the guide bushings are significantly worn out, the valve stem is worn out.

We recommend: How to install fog lights: connection diagram

The carburetor does not need to be removed, nor does the manifold from the head. First, desiccate the valve. Place the head on a flat surface, preferably on a table or wooden board. Place a rubber mat under the valve. You will need a tube with an internal diameter of over 13 mm. Place a tube on the valve so that the crackers are inside. Then strike with a hammer. In this case, the valve desiccates, and the crackers remain in the tube. The valve can now be pulled out.

Mount the new element by gently shaking it. A runout of up to a millimeter is considered normal - the guide sleeve can be left in place. Then try to replace the guide; here you will need a special mandrel. If you decide to knock out a part, work from the inside, towards the camshaft. Here you will need a heavy hammer and a half sledgehammer. The blow should be confident and heavy. If you use a light tool, the bushing will crumble.

Try to drive this valve bushing into the head. The sleeve should easily fit onto the valve - when it hits the head, the element is compressed. First, put on the retaining ring removed from the old bushing and lubricate the assembly with oil. Drive the bushing into the hole in the valve head until it reaches the retaining ring. Proceed carefully, as the structure is quite fragile. Do not strike the valve seal area. You can put the tube on and place it on the sleeve, protecting the parts. Place a piece of tin, a piece of wood on the edge of the bushings, place a bolt and carefully hammer it into the head. After deforming the edge of the bushing hole, make alignment using a drill and a file.

Subscribe to our feeds on social networks such as Facebook, Vkontakte, Instagram, Pinterest, Yandex Zen, Twitter and Telegram: all the most interesting automotive events collected in one place.

Why do valves burn out?

Any rubbing part of a car wears out over time. As for the valves, it is the exhaust valves that burn out more often, since, unlike the intake valves, they are not cooled by the air flow, heat up to 650°C and are more vulnerable to burnout. In them, the main heat removal occurs through the seats and guides, which means that good contact of the part with the seat is very important. The main reasons for valve burnout are the following:

- The appearance of carbon deposits on the valve and seat, creating additional heating.

- Worn valve seat or guide, which prevents complete heat dissipation.

- Violation of the valve seating height after lapping, due to which its rod sticks out higher and disrupts the geometry of the rocker arm, and when heated, the required clearance disappears.

- Underestimation of the permissible valve clearance and wear of the seat, as a result of which, after heating, the valve does not press well against the seat, allows gases to pass through, overheats and burns out.

- Engine overheating due to a breakdown of the cooling system.

- Increased fuel combustion temperature due to late or early ignition, or engine operation on a lean mixture.

- Difficult exhaust due to clogged catalytic converter or damaged exhaust manifold.

Valve burnt out, signs and causes of malfunction

Signs of a burnt valve in a car engine

Due to a violation of the tightness of the seal in the assembly: the valve seat - the working surface of the valve plate, the tightness of the combustion chamber during the compression stroke decreases, the compression decreases, the necessary conditions for ignition of the fuel mixture are absent, the cylinder stops working normally. As a result, the vehicle's performance deteriorates and the engine's service life decreases.

- Unstable engine idle speed (up to stop)

- Strong pops and smoke from the muffler (if the exhaust valve is burnt out)

- Popping sounds in the exhaust manifold (if the intake valve is burnt out)

- Reduced engine power and response (dips and jerks)

- Increased fuel consumption

- Engine overheating

It should be borne in mind that similar symptoms appear not only when a valve burns out, but also when there is a malfunction of the ignition system (broken spark plugs, armored wires, coil, distributor, incorrect ignition timing, etc.) or the power system (nozzles, carburetor needle valve , fuel pump, injector nozzles).

Cause of malfunction: burnt valve

- Constant operation of the car engine with late ignition

- Constantly running the engine on a lean fuel mixture

- Long-term engine operation with small valve clearances

- Operating the engine with low-quality motor oil and (or) low-quality fuel

- Detonation in combustion chambers

- Constant engine overheating

- Use of low quality spare parts during repairs

How can you tell if a valve is burnt out?

Measure compression in cylinders

It is necessary to check the compression in the engine cylinders; in the cylinder where it is reduced, the valve may burn out. To finally verify this and eliminate wear on the piston rings (which also affects the amount of compression), pour 10-15 cubes of engine oil into the cylinder through the spark plug hole and measure the compression again. The compression readings in the suspicious cylinder are leveled off compared to the others - the piston rings are worn out (stuck, burnt, etc.), there is no 99 percent problem with the valves (in rare cases, cracks in the block or head).

Blowing with compressed air

We set the piston in the cylinder to top dead center, corresponding to the compression stroke. We direct a stream of compressed air from the compressor or pump into the spark plug hole of the cylinder. If the exhaust valve is burnt out, the air will go into the muffler, if the intake valve burns out, it will go into the carburetor or receiver on an injection engine.

Notes and additions

In addition to burnout, similar symptoms are possible if other problems arise with the valves: severe carbon deposits on the valve discs, cavities and cavities on the working surface of the valve discs, too large thermal gaps in the valve drive. All of them lead to a loose fit of the valve plate to the seat in the head and, accordingly, disruption of the normal operation of the cylinder.

In any case, the fault can be eliminated only by removing the engine head and checking the valves. There are no other repair options.

Source

How to understand that the valve has burned out

Indirect factors help determine such a nuisance. The driver should be wary of the engine running rough. This is one of the most popular signs of a burnt valve or several. It is worth considering that similar problems occur during ignition failures, so we recommend monitoring this system as well.

When a valve burns out, symptoms may include decreased power and loss of vehicle response. The car has great difficulty gaining momentum and has difficulty overtaking on the highway.

We recommend listening to the exhaust system. Engines with burnt-out valve plates periodically emit popping noises into the manifold. A characteristic sound occurs when driving or accelerating. It is not advisable to postpone repair work in such a situation.

If the gaps are adjusted poorly, this will lead to clamps. As a result, traction will decrease. Signs of pinched valves are complemented by increased fuel consumption. It is advisable to make the gap smaller than permissible rather than leaving it larger, otherwise you will soon have to replace the entire cylinder head.

Now about the signs of valve burnout

Signs of valve burnout vary; it is generally accepted that one of the most obvious and characteristic signs of “dead” valves is unstable engine operation. It starts to triple, the revs fluctuate, in general it will be difficult not to notice. However, do not rush to pass such a terrible sentence on your engine as soon as it starts to stall. It is quite possible that the reason is much simpler and is related to spark plugs, explosive wires, and in general to the ignition system. The engine can also “tune” for a number of other reasons related to fuel and the fuel system...

The second sign that the valve or valves are burnt out is a drop in power. During acceleration, you will notice that the car “does not move”, traction and dynamics will disappear. All this, one way or another, is associated with a loss of compression in the cylinder(s), which is significantly reduced due to a loose valve fit or its partial destruction. Measuring compression in the cylinders will help confirm this assumption.

The appearance of popping noises in the intake manifold is also considered to be the first “sign” that the valve has burned out. In addition, popping noises can appear not only in the manifold, but also in the exhaust system.

Signs that the valve is burnt out

What does a burnt valve look like?

Signs of a burnt-out valve include engine shaking, smoke from the breather (the breather is a valve for venting the crankcase and releasing excess pressure) and, when the engine operates for a long time with a burnt-out valve, increased fuel consumption. Let us explain the popular concept of “motor troit”. This means a malfunction of one cylinder, which manifests itself in a loss of power and throttle response, vibration and shots in the exhaust pipe. But these signs of a burnt out valve are ambiguous.

The engine can also stall due to broken spark plugs or a weak spark.

Smoke from the breather can also occur if the piston is damaged. But there is a distinctive feature here - the color of the smoke should be bluish, and the spark plug should be covered with oil, which is associated with a broken piston. In case of burnout, the spark plug remains dry. Note that a burnt valve in a carburetor engine and in an injector gives the same symptoms, because The only difference is the fuel injection system.

Consequences of valve burnout

At the first signs of burnout, a diagnosis should be made. If during this process it is determined that the valve or valves are burnt out, measures must be taken immediately. Further operation of such a car will be fraught with aggravation of the situation and will lead to even more serious consequences.

An untimely response to such a breakdown or a delay in repairs will lead to increased fuel consumption and a decrease in power, and this, believe me, is the most harmless thing that can happen. In more complex cases, such valve “sores” may result in engine overhaul, replacement of the cylinder head, or complete replacement of the power unit. The fact is that fragments of crumbled valves can get into the cylinders, after which it will be difficult to predict the consequences. Pieces of metal destroy the CPU (cylinder-piston group), forming a lot of scuffs and scratches on the cylinder walls.

Also, sometimes valve burnout also leads to destruction of the valve seat. Such a defect cannot be eliminated and the only solution is to replace the “head” or completely replace the power unit.

Let's summarize...

Such a breakdown is classified as complex and can cause serious damage to the engine and a large loss to the owner. That is why you should constantly monitor the condition of the motor, and also “listen” to any changes in its operation. At the slightest hint of a burnt-out valve, take immediate action; this is the only way you will be able to avoid serious problems with the engine and avoid large financial waste.

Why do valves burn out?

What does a burnt valve look like?

Experts identify a number of reasons why valves in internal combustion engines burn out. The most common and widespread of them are the following:

- Factory defects of the parts themselves;

- Incorrect adjustment;

- Malfunctions of the cooling system of power units;

- Malfunctions and wear of other parts of the gas distribution system;

- Long-term engine operation on a lean fuel mixture.

We recommend: Which oil is better to fill in for the winter: top 10 best brands

Not long ago, one of the companies specializing in the production of automotive components provided statistics indicating that approximately 20% of failed valves are caused by manufacturing defects. Nowadays, many companies are engaged in the production of these parts, and among them there are those that do not fully comply with the technology of their manufacture. Valves from these manufacturers most often burn out. As for the defects due to which they fail, they are the heterogeneity of the metal; defects that appear during forging and improper heat treatment; microcracks; poor adhesion of the valve surface coating.

A fairly common cause of valve burnout is improper adjustment of their thermal clearances. It leads to overheating of parts with all the ensuing consequences. It should be noted that for this reason, valves burn out both in engines in which they are adjusted manually and in those in which this process is carried out automatically. In the second case, hydraulic compensators are responsible for adjusting the thermal gap, and if for some reason they fail, the valves begin to overheat.

Their temperature can also rise excessively in cases where the engine is poorly cooled. This may occur due to problems with the pump, thermostat, clogged radiator, or a simple lack of coolant.

It often happens that during long-term operation of the engine, the valve guides wear out. This, as well as such a defect as weakening of the elasticity of the clamping spring, often leads to incorrect positioning of the part and, as a consequence, its overheating and burnout. In addition, valves often burn out when engines run on a lean fuel mixture for a long time.

Products for cleaning carbon deposits on valves

Many car owners are interested in the question of how to wash off carbon deposits on valves? Currently, there are a number of chemical products designed directly to remove such deposits. Typically these are additives added to fuel. They are mixed with gasoline, and during the combustion process, together with the air-fuel mixture, they soften this composition, facilitating its combustion along with the fuel. Among these additives, the following are especially popular among car owners:

- Valve cleaner from Liqui Moly Ventil Sauber. The additive is designed to be added to gasoline during the next refueling. Can be used with any type of gasoline. The function of the additive is to remove deposits formed on valves, injectors, carburetor and other elements of the intake tract. It also protects the listed elements from corrosion. Can be used with engines with catalytic converters and turbocharging. Sold in a 250 ml can, which is designed to be dissolved in 75 liters of fuel. The article number for this package is 1989. Its price as of winter 2018/2019 is about 470 rubles.

- Valve and power system cleaner HI-GEAR FUEL SYSTEM & VALVES CLEANER. Another popular product among car enthusiasts. It cleans not only valves very well, but also other elements of the power system. Can be used with any gasoline engines, including those equipped with catalysts and turbochargers. The product is intended for engines up to 2.5 liters. It is recommended to use it as a preventive measure every 3,000 thousand kilometers. Sold in two different jars - 295 ml and 325 ml. The volume of the second can (325 ml) is enough to dilute 40 liters of gasoline. The article numbers for these packages are HG3235 and HG3236. The prices are respectively 440 rubles and 530 rubles.

- Cleaning the engine without disassembling MITSUBISHI SHUMMA ENGINE CONDITIONER. This product was specially created by specialists from the famous Japanese automaker Mitsubishi for cars of this brand equipped with engines with direct fuel injection (GDI). It is recommended to use this product as a preventative every 100 thousand kilometers. However, given that these recommendations are given for Japanese conditions, for domestic roads and gasoline this interval must be significantly reduced. The product is a foam cleaner that is used to treat the internal working surfaces of fuel system elements. Detailed instructions are given on the packaging (in particular, you need to work with a cold engine!). Reviews about the product are very positive. Sold in a 250 ml can. The article number for this package is MZ100139EX. Its price for the above period is about 1300 rubles.

Wurth valve carbon cleaner. Like the previous one, this product is a foamy detergent composition that is used to wash the contaminated surfaces of the elements of the car’s fuel system. Allows cleaning without disassembling the engine. So, to do this you just need to disconnect a few hoses. Detailed instructions are indicated in the description of the drug

Please note that this product can only be used in combination with a spray wand. One cylinder is enough to treat a four-cylinder engine, and two cylinders are enough to treat six- and eight-cylinder engines

Also, in addition to factory products, carbon deposits from valves can be removed using phosphoric acid. You can use not its pure composition, but a diluted one. It perfectly removes various deposits, so it will also cope well with carbon deposits. Tested by car enthusiasts in practice! Interestingly, the popular drink Coca-Cola also contains phosphoric acid in small quantities, so it can also be used to remove stains.

Replacing burnt out valves

The operation of replacing the valves of different engines is similar, and differs only in the size of the parts and their placement on the cylinder head. Before performing the operation, prepare lapping powder, new valve seals and a new head gasket. After dismantling the cylinder head, operations are performed in the following order:

1. Valve desiccation. To do this, the head is laid out on a flat surface and a rubber mat is placed under the valve. A tube with a diameter of 13 mm is placed on the valve so that the crackers are inside, and blows are applied with a hammer. The valve desiccates, and the crackers remain in the tube. The operation is also easily carried out using a special device that compresses the vein and allows you to pull out the crackers.

- The valve is pulled out, a new one is inserted, and the bushing guide is checked by shaking. If runout is up to 1 mm, the guide is not replaced.

3. If it is necessary to replace the guide, use a special mandrel. The old part is knocked out in the direction of the camshaft using a half-sledge hammer with a heavy blow so that the part does not crumble. Afterwards, a new bushing is driven into the head, having first put a retaining ring on it.

4. The new valve is secured with a retaining ring and the assembly is lubricated with oil.

5. Valve grinding. The seat is initially treated with a special cutter, after which lapping powder is applied to the edge of the valve, inserted into the head, the other end is clamped into the drill chuck, and by pulling it up and down, the valve is provided with a tight fit to the seat. It is advisable to carry out the operation for all valves.

6. Drying of the valve. To do this, press the spring firmly and insert crackers. The cylinder head is attached to the engine cylinder block.

The described method allows you to replace the burnt valves of all models of the VAZ: 2101, 2102, 2103, 2104, 2105, 2106, 2107, 2108, 2109, 21099, 2110, 2111, 2112, 2113, 2114, Niva, Lada Priora, viburnum, Grant, Grant, Grant. Vesta and most foreign cars.

Adjustment of valves

Valve adjustment is carried out on vehicles that require this type of maintenance, after replacing a part and at certain intervals during the vehicle's mileage. To do this, with the engine cooled down, the valve cover and the toothed belt protective cover must be removed, the spark plugs must be unscrewed and the oil must be removed from the tanks in the head. Before the procedure, the surface of the cams is inspected: they should not have holes, burrs or other damage. To control the size of the gap, feelers with a width of 10 mm are used.

The procedure for adjusting the valves is as follows:

1. In the cylinder on which the adjustment will be made, the first piston is installed at TDC by aligning the mark on the pulley and the cylinder block, at this moment all the valves on it are in a closed state. The adjustment procedure is determined by the manufacturer. To adjust the next cylinder, turn the crankshaft clockwise 180°, and the camshaft accordingly turns 90°.

2. Loosen the lock nut on the bolt or screw, insert the feeler gauge under the rocker (rocker arm), and adjust the height by placing a washer or rotating the adjusting bolt (depending on the design of the cylinder head). When the required clearance is established, the locknut is tightened.

3. After tightening, check the gap again. If it does not meet the norm, the procedure is repeated again. With excellent adjustment, the probe should enter with little effort, but not bend.

Valve burnout is a problem that owners of domestic cars most often encounter. But it would be unfair to blame exclusively the products of the Russian automobile industry, since they are also found in foreign cars, even if they are far from new. But any valve malfunction, including burnout, can lead to very serious consequences, so every car owner simply needs to be able to recognize the signs of a burnt-out valve in a timely manner in order to be able to promptly correct what can still be fixed without unpleasant surprises.

What is burnout?

Metal destruction under the influence of high temperatures is typical for both diesel and gasoline engines. Even taking into account the fact that most of the important parts of the gas distribution mechanism are made of special high-strength steel grades, under certain conditions they are destroyed.

The actual combustion of the metal is not carried out in the classical form. Parts are destroyed from different sides.

It is important to know that a burnt-out valve can be identified by cracks formed on the edges or by obvious penetrations in the working surface.

Due to the fact that defects form on some coins, the tightness of the interface between the seat and the plate disappears. As a result, this results in engine problems, and can manifest itself in serious damage to the internal combustion engine.