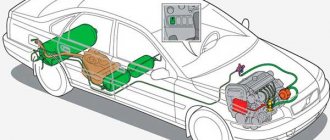

Main components of a car

For normal operation of the engine, it must be constantly cooled, even during the cold winter period.

It is recommended to pay special attention to the serviceability of the pipeline system through which the coolant circulates, as well as to the correct operation of the main part of the liquid cooling system (LCS) - the water pump or, in other words, the water pump of the car.

The engine water pump is the main component of the liquid coolant in any modern car.

Due to their design features, the power units of modern cars are operated at high temperature levels. For example, domestic Gazelle cars are designed for a power unit operating temperature range of 92–99 °C.

Domestic Gazelle cars are fairly common budget options for local cargo transportation.

If the machine is used intensively, the engine begins to heat up beyond normal. But thanks to the timely supply of coolant to the engine elements, the operating temperature of the power unit quickly reaches the required values, and significant loads for the car are no longer dangerous. Antifreeze or antifreeze is used as coolant in the cooling systems of various Gazelle models.

Antifreeze is one of the popular options for high-quality coolant

Thus, the ZhSO performs the task of timely cooling of the engine mechanisms. For the system to operate efficiently, constant coolant circulation is essential. During its movement through the pipelines of the liquid coolant, the antifreeze (antifreeze) is significantly cooled, due to which the performance of the internal combustion engine is maintained.

A cheaper option for non-freezing coolant is antifreeze

The liquid used in the liquid liquid circulation circulates in a forced mode. This circulation is ensured by the car's water pump. Thanks to this component of the motor design, the latter does not overheat and its technical and operational parameters are always within the temperature range required for efficient operation.

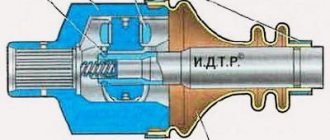

General pump design for Gazelle

A standard water pump includes the following parts:

- pump body;

The pump body is always made of durable alloys - a shaft equipped with an impeller;

The shaft and impeller are the main working element of the pump - bearing;

- sealing gland.

The pump bearing ensures free rotation of the shaft, and the oil seal ensures the tightness of the device

The design of the pump for some modifications of the Gazelle provides a special mechanism for automatically turning on the radiator fan. We are talking about an electric coupling. Replacing the pump in these engine models (for example, in the ZMZ 405) is only possible together with the entire mechanism.

One of the successful options for installing an electric coupling is installation in one unit with a pump

The main disadvantages of this design solution include the following points:

- quite high cost of the unit;

- mandatory replacement of the entire component, even if only one of the elements (electric coupling or pump) breaks down;

- repair of the unit can only be carried out in specialized repair shops with special equipment.

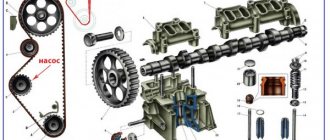

Located on the engine block, the pump operates by connecting through a drive belt from the crankshaft.

The best option for ensuring the functioning of the water pump is connection through the drive belt from the crankshaft

The operating principle of the pump is as follows:

- when the engine and pump operate, a centrifugal force arises in the body of the latter in relation to the coolant entering it;

- due to the movement of the impeller, coolant from the radiator enters the center of the pump;

- then it is tilted to the edges of the internal cavity of the pump;

- Through a special technological hole located in the housing, the coolant then enters the cylinder block, as well as other areas of the power unit that need cooling.

To avoid unwanted coolant leakage, a special sealing gasket is installed between the cylinder block and the pump body. In this case, it is necessary to thoroughly clean the contact surfaces on the engine and pump.

During repairs, it is imperative to replace the gasket under the pump.

The pump shaft outlet is equipped with an oil seal capable of sealing due to its design. It consists of a rubber sleeve and a sealing washer. The seal provides the necessary sealing of the product.

The pump seal should not allow air into the pump, ensuring its complete tightness.

The device has a durable metal alloy body, as well as special hinges that ensure proper attachment to the power unit.

Popular water pump model for Gazelle without electric coupling

Signs of a pump malfunction

The pump is a fairly reliable mechanism, but cases of its sudden failure are not uncommon. To avoid this, you need to know the main signs indicating a possible breakdown of this component.

These include:

- rapid overheating of the engine, which occurs due to a malfunction of the water pump itself, its impeller or drive;

- the presence of extraneous noise effects in the pump mounting area that are unusual for the correct operation of the motor;

- insufficient coolant circulation through the cooling system, which is expressed in a rapid increase in fluid temperature;

- excessive wear of bearings, determined by the presence of significant shaft play;

- leakage from the water pump housing, indicating a faulty seal.

Repairing the motor pump is considered impractical by experts. Its design features preclude high-quality independent repairs, so it is recommended to replace this component as an assembly.

A design feature of the water pump used on certain engines of Gazelle cars (ZMZ 405 and other modifications) is that the pump is assembled in a single unit with an electric coupling, which ensures timely activation of the radiator cooling fan. The pump is replaced with a new part complete with an electric coupling.

The modern model of water pump for the ZMZ 405 engine is ideal for Gazelle cars

The marking of individual models of water pumps assembled in a single mechanical unit with an electric coupling is as follows:

- Identification No. 4063–1307007–20 (pump used in Gazelle cars, which are equipped with power units model 40524 E3).

- Identification No. 4063–1307010–10 (pump for Gazelles with a ZMZ 405 engine).

In other cases, with engine modifications (4216, 406, 421, 402), pumps are used whose designs do not include an electric coupling. This component is mounted separately from the water pump.

The pump for engine 4216 is installed on the latest Gazelle-business cars

Video: signs of a faulty Gazelle pump

Location of the water pump on the car

The pump works synchronously with the machine motor. To ensure rotation of the pump shaft with the impeller, the pulley receives the energy of rotational motion through a belt drive from the crankshaft pulley.

The water pump is located in the front upper part of the Gazelle engine

This is the optimal solution for efficient operation of the engine pump.

Where to buy a pump for Gazelle?

You can choose a water pump for Gazelle 405 HERE . Water pumps for other engine models, from different manufacturers, are also presented here.

Mechanism price

For a water pump with an electromagnetic clutch, Gazelle owners will have to pay from 28,000 to 30,000 tenge.

Where can I order a replacement water pump?

Diagnostics, repair and replacement of the pump can be ordered HERE . Auto service specialists provide a wide range of services to owners of trucks and cars.

Owners of the ZMZ 406 engine were faced with a water pump leak. This means it's time to change the part. The process itself is quite simple and only requires the necessary tools and minimal design knowledge of the car.

Procedure for replacing the water pump on a Gazelle car

If the water pump malfunctions, it is recommended to immediately replace it with a new part, since ignoring repairs can lead to more serious consequences and, as a result, to significant financial losses. We are talking about the performance of the engine and, in particular, about the money for its overhaul.

When operating the engine, inevitable wear of the part occurs and the pump must be replaced with a new one. The service life of the water pump may vary. For example, the original pump will last more than 80 thousand km under satisfactory operating conditions. When using a mechanism from an unknown manufacturer or a counterfeit, you should not expect even 20 thousand km. In this case, in addition to purchasing a prematurely failed part, you will have to additionally purchase an expensive coolant.

The main differences between the original design and the fake:

- gray matte color of the product (if there is shine, then it is a fake);

- information about the alloy must be indicated on the body of the original pump;

- there must be a sign from Rosstandart;

- ZMZ product brand icon;

- number marking of the injection mold;

- all information on the case must be cast, but not embossed;

- the part must be processed with high quality, without chips or metal burrs.

The original pump differs from fakes by high-quality cast markings of the body and the dim color tone of the alloy

Preparing tools for replacing the water pump yourself

When dismantling the mechanism, as well as when subsequently installing a new part, the following tools and materials will be needed:

- flat-type screwdriver with a thin tip;

- wrench size No. 12;

- open-end wrench size No. 24;

- wrench size No. 27;

- hex key size No. 6;

- sharp knife;

- a clean container required for draining coolant with a volume of up to 15 liters;

- fine-grain sandpaper;

- rags.

The best solution for carrying out a complete repair is a set of high-quality tools.

Prudent drivers always have tools with them, since for any independent car repair they are simply irreplaceable

The procedure for replacing the pump and the volume of coolant drained

In the event that the pump has exhausted its entire service life, experts recommend draining the maximum possible amount of coolant located in the liquid fluid of the car. In a similar way, the cooling system is cleaned of all kinds of impurities contained in the coolant. This circumstance has a beneficial effect on the performance of the new mechanism being installed.

Coolant is drained, as a rule, from the following components:

- cooling radiator;

The radiator provides coolant cooling during vehicle operation - system expansion tank;

The expansion tank is used to fill coolant, as well as to hold it when heating (increasing volume) - heating system;

The car heater allows you to heat the car interior, as well as the windows during cold weather. - engine cylinder block.

The cylinder block is one of the main parts of the engine

To do this you need:

- Open the lid from the expansion tank of liquid liquid waste.

Engine cooling system pipes provide circulation and supply of coolant to various engine systems and parts - First of all, remove the liquid from the engine cylinder block, which has a special tap.

- It is necessary to pull a hose of the appropriate size onto it (as a rule, a product with a diameter of 12 mm is suitable).

- Next, lead the hose into a drainage container, which is best placed in advance.

The coolant drain valve on the cylinder block allows you to remove most of the coolant when repairing the cooling system or when replacing the coolant, as well as in other necessary cases - Drain as much coolant as possible (about 10 liters in total).

- Similarly, drain the residue from other hoses of the liquid coolant, as well as from the car radiator, in the lower part of which there is a special tap or bolt.

If the coolant is in normal condition (no sedimentary compounds), then it can be reused. It should be taken into account that it will not be possible to completely rid the system of coolant. Residual volume in various components is inevitable, which is taken into account when filling in new coolant. The total volume of coolant in various models can reach up to 11.5–12 liters. When replacing the coolant or during repairs, about 8.5 liters are drained from the system.

Video: self-replacement of coolant in the ZMZ 405 engine of the Gazelle car

Step-by-step steps to independently replace the water pump on various Gazelle engines

After freeing the cooling system from coolant, you can begin dismantling the mechanism:

- De-energize the vehicle's electrical system by disconnecting the battery.

Removing the negative terminal from the battery is necessary when carrying out any type of car repair, as it ensures safety during operation - Unscrew the bolts securing the upper bar above the radiator and, without removing the hood lock cable, move it upward, securing it to the engine elements.

The “TV” in the Gazelle is the front upper part of the car body with a lock and a hood lock cable - Loosen the clamps of the clamps used to secure the hoses leading to the device, as well as to the cooling radiator, and disconnect them.

Underwater hoses to the ZMZ 405 engine pump provide coolant supply/discharge to the cooling system - Loosen the tension roller.

Before removing the drive belt, the roller is brought into a position that allows the belt to be easily removed - Next, remove the pump drive belt first from the roller and then from the generator pulley.

To ensure easy access to the pump, you need to remove the drive belt from the roller and pulleys. - Then remove the coolant radiator.

- Inspect the rubber cushions on which the radiator is installed.

- If necessary, replace them with new ones.

Removing the pump is impossible without dismantling the engine cooling radiator - Remove the cooling fan.

The engine cooling fan is removed during self-repair of the car. - Disconnect the connector from the electrical coupling.

In some cases, the electric coupling of the engine is dismantled along with the pump; the need for this depends on the power unit installed on the car - Remove the thermostat housing (two hexagon bolts).

The engine thermostat housing is removed from the engine to provide access to the pump mounts - Clean its seat with fine-grained sandpaper, first carefully removing the remaining gasket with a screwdriver or knife (during reassembly, the gasket must be replaced with a new one).

To ensure proper sealing, the housing installation site is thoroughly cleaned with sandpaper and treated with lithol before installation - Unscrew the two pump mounting bolts using a hex key.

- Remove the third #12 wrench bolt from the rear of the pump-to-engine mounting.

- Remove the water pump from its seat.

- Remove the old gasket under the pump or its remains.

- Carefully clean the seat with fine-grained sandpaper and wipe with a rag.

Installing a new pump

Reinstallation of the new mechanism is carried out step by step, starting from the end of the step-by-step list for removing the pump.

Features of installing a new pump:

- When installing sealing gaskets under the pump and under the thermostat cover, their seats must first be treated with a thin layer of lithol to obtain a certain protection against corrosion and the necessary sealing.

Litol is used to process pipes and parts where they fit, which are subsequently secured with screws or bolts - The same actions must be performed with the pipes that fit onto the pump, thermostat cover outlet and cooling radiator.

- This is done in order to obtain a better seal after tightening the clamps on the pipes.

- It is recommended to tighten the drive belt using a special mechanism and roller carefully and never overtighten it.

- After installing the new pump, thermostat, radiator, fan, tension pulley, drive belt, all hoses and pipes, electrical connectors, you must visually verify the correct assembly.

- Install the upper metal bar above the radiator with the car hood locking device.

- After connecting all the necessary hoses and pipes, pour coolant into the LSO expansion tank.

- First, it is recommended to fill the expansion tank with liquid up to the MIN mark on it.

- Connect the battery.

- Then start the engine.

- Use a special screw to bleed the system, to do this, loosen this screw and, adding engine speed to 2 thousand, wait until all the air from the system comes out from under it and coolant flows (the screw is located under the panel near the entrance of the pipes to the car heater).

- Tighten this screw.

- Bring the motor to operating temperature (approx. 90 °C).

- Next, assessing the coolant level in the expansion tank, add the required volume to the MAX mark.

- Check all connections again for leaks by external inspection.

Video: step-by-step instructions for replacing the water pump yourself

Dismantling the pump

The next stage involves dismantling the thermostat. This element is held in place with 2 hex bolts (6mm). The pump is held in place using the same fasteners. Most likely, the thermostat gasket will require replacement. The pump is held in place by 2 nuts (8 mm) and bolts (6 mm), plus an additional nut installed on the reverse side. To unscrew it you will need a 12 mm wrench.

Now you can dismantle the pump and install a new one. During the work process, it is imperative to replace the gasket, previously lubricated with lithol. Nuances:

- Before installing a new part, the surface must be thoroughly cleaned;

- It is advisable to replace the pipe that is connected to the pump.

Replacing consumables will avoid additional assembly and disassembly of the unit in question. The assembly of the structure is carried out in the reverse order.

Replacing the pump on other engine models

For almost all engines of modifications UMZ, ZMZ, which are installed on Gazelle vehicles, the main steps for replacing the water pump will be similar. Only minor differences regarding the structural arrangement of the unit are possible.

When performing work on the power units of the Gazelle Business vehicle, model UMZ-4216, there are some differences in the actions and their sequence:

- The water pump is accessible from the lower right side of the car.

- It is not necessary to dismantle the cooling radiator.

- It is necessary to remove the front right wheel of the car, after first raising the body with a jack.

- The further process is similar to the work described above with ZMZ 405 engines.

On Gazelle-Business UMZ-4216 engines, it is not necessary to remove the radiator, since access to the pump is through the lower right part of the car.

In all modifications of Gazelle cars, replacing the water pump involves almost the same steps. In any case, the coolant is removed from the motor fluid supply system, and the drive belt is also dismantled. The procedure is not complicated: it is quite feasible for drivers with basic car maintenance skills.

Malfunctions and procedure for self-replacement of the heater radiator of a Daewoo Nexia car

Features of replacing the Opel Astra pump

How to remove and replace the pump on a Gazelle 405?

First of all, you need to drain the coolant. To do this, you need to open the tap, which is located directly on the block and connect a hose to it.

It will take some time to drain the cooler. Therefore, you can begin to dismantle individual elements:

- the upper part of the TV, held in place by bolts, is removed;

- the tensioner roller becomes loose;

- The belt becomes loose. To do this, you will need a 10mm wrench. It is recommended to use a special wrench;

- The belt is dismantled, first from the roller, and then from the generator.

Now you need to dismantle the upper pipe. You need to install a container under the radiator, after which you can remove the lower pipe. After this, you can carefully dismantle the radiator and drain the remaining coolant from it.

Particular attention should be paid to the radiator cushions, since sometimes car owners lose these elements.

Before removing the pump on the Gazelle 405 , it is necessary to remove the fan.

At the next stage, you need to disconnect all connectors, remembering the operating sequence.